Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 4.<br />

Experimental Procedures and Protocols for Analyses<br />

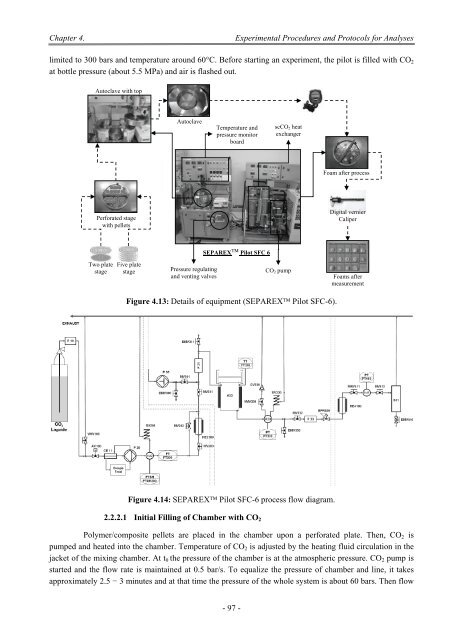

limited to 300 bars and temperature around 60°C. Before starting an experiment, <str<strong>on</strong>g>the</str<strong>on</strong>g> pilot is filled with CO 2<br />

at bottle pressure (about 5.5 MPa) and air is flashed out.<br />

Autoclave with top<br />

Autoclave<br />

Temperature and<br />

pressure m<strong>on</strong>itor<br />

board<br />

scCO 2 heat<br />

exchanger<br />

Foam after process<br />

Perforated stage<br />

with pellets<br />

Digital vernier<br />

Caliper<br />

SEPAREX Pilot SFC 6<br />

Two plate<br />

stage<br />

Five plate<br />

stage<br />

Pressure regulating<br />

and venting valves<br />

CO 2 pump<br />

Foams after<br />

measurement<br />

Figure 4.13: Details <str<strong>on</strong>g>of</str<strong>on</strong>g> equipment (SEPAREX Pilot SFC-6).<br />

Figure 4.14: SEPAREX Pilot SFC-6 process flow diagram.<br />

2.2.2.1 Initial Filling <str<strong>on</strong>g>of</str<strong>on</strong>g> Chamber with CO 2<br />

Polymer/composite pellets are placed in <str<strong>on</strong>g>the</str<strong>on</strong>g> chamber up<strong>on</strong> a perforated plate. <strong>The</strong>n, CO 2 is<br />

pumped and heated into <str<strong>on</strong>g>the</str<strong>on</strong>g> chamber. Temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> CO 2 is adjusted by <str<strong>on</strong>g>the</str<strong>on</strong>g> heating fluid circulati<strong>on</strong> in <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

jacket <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> mixing chamber. At t 0 <str<strong>on</strong>g>the</str<strong>on</strong>g> pressure <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> chamber is at <str<strong>on</strong>g>the</str<strong>on</strong>g> atmospheric pressure. CO 2 pump is<br />

started and <str<strong>on</strong>g>the</str<strong>on</strong>g> flow rate is maintained at 0.5 bar/s. To equalize <str<strong>on</strong>g>the</str<strong>on</strong>g> pressure <str<strong>on</strong>g>of</str<strong>on</strong>g> chamber and line, it takes<br />

approximately 2.5 − 3 minutes and at that time <str<strong>on</strong>g>the</str<strong>on</strong>g> pressure <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> whole system is about 60 bars. <strong>The</strong>n flow<br />

- 97 -