Surgical Manual - Dental-Depot

Surgical Manual - Dental-Depot

Surgical Manual - Dental-Depot

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

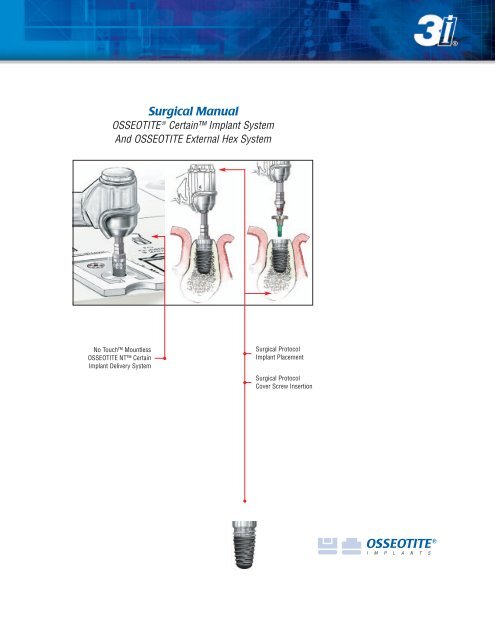

<strong>Surgical</strong> <strong>Manual</strong><br />

OSSEOTITE ® Certain Implant System<br />

And OSSEOTITE External Hex System<br />

No Touch Mountless<br />

OSSEOTITE NT Certain<br />

Implant Delivery System<br />

<strong>Surgical</strong> Protocol<br />

Implant Placement<br />

<strong>Surgical</strong> Protocol<br />

Cover Screw Insertion

Table Of Contents<br />

Introduction And Treatment Planning ..........................................................................................2<br />

Preoperative Planning ..................................................................................................................3<br />

Radiographic Marking Balls ..........................................................................................................3<br />

Top-Down Treatment Planning ......................................................................................................4<br />

<strong>Surgical</strong> Precautions ....................................................................................................................5<br />

Cleaning And Sterilization ............................................................................................................6<br />

3i Depth Gauge And Drill Marking System....................................................................................7<br />

OSSEOTITE NT Certain And OSSEOTITE NT Implant Placement Protocol Guide....................8<br />

OSSEOTITE NT Implant Taps ........................................................................................................8<br />

OSSEOTITE ® Certain Implant Placement Protocol ........................................................................9<br />

Implant Placement Protocol Quick Reference<br />

OSSEOTITE NT ..........................................................................................................12<br />

MicroMiniplant (3.25)..............................................................................................13<br />

OSSEOTITE XP ® 3/4....................................................................................................13<br />

Standard Diameter (3.75) ..........................................................................................13<br />

Standard Diameter (4.00) ..........................................................................................14<br />

OSSEOTITE XP 4/5 ....................................................................................................15<br />

OSSEOTITE XP 5/6 ....................................................................................................15<br />

Wide Diameter (5.0) ..................................................................................................16<br />

Wide Diameter (6.0) ..................................................................................................17<br />

OSSEOTITE NT <strong>Surgical</strong> Tray ......................................................................................................18<br />

OSSEOTITE NT Certain And OSSEOTITE NT Implant Crestal Placement Protocol ......................19<br />

OSSEOTITE Parallel Wall Implant <strong>Surgical</strong> Tray ..........................................................................24<br />

OSSEOTITE Certain And OSSEOTITE Implant Crestal Placement Protocol ................................25<br />

Single-Stage Treatment With A Two-Stage Implant System ......................................................30<br />

<strong>Surgical</strong> Indexing For 3i External Hex Implants ..........................................................................31<br />

How To Use The Icon Key:<br />

The icons represent the connection type<br />

of the implant system and both internal<br />

and external connection types are represented<br />

in this manual. In the fully illustrated protocols,<br />

each icon is present by each step. When a dark<br />

blue icon and a light blue icon are present<br />

together, the dark blue indicates which system<br />

is illustrated. When both icons are dark blue,<br />

then both systems are illustrated together.<br />

Icon Key<br />

OSSEOTITE Certain Internal<br />

Connection Implant System:<br />

OSSEOTITE External Hex<br />

Connection Implant System:<br />

OSSEOTITE Certain Internal<br />

and OSSEOTITE External Hex<br />

Connection Implant System:<br />

1

Introduction And<br />

Treatment Planning<br />

This manual was designed to serve as a<br />

reference guide for the dental practitioner to<br />

utilize 3i implants and surgical instruments to<br />

their maximum potential. 3i’s implant system<br />

was developed to meet the diverse needs of the<br />

patient and to offer the practitioner a choice of<br />

surgical techniques customized to meet each<br />

patient’s individual requirements.<br />

3i’s unique designs enable the practitioner to place<br />

implants in edentulous mandibles or maxillae<br />

to serve as support abutments for fixed and<br />

removable bridgework or single tooth crowns<br />

and to provide the stabilization needed for securing<br />

overdentures. 3i’s system uses proven surgical<br />

procedures to properly secure the implant in the<br />

osseous tissue, thus achieving the physiological<br />

phenomenon referred to as osseointegration.<br />

General Information:<br />

This manual will instruct practitioners in the use<br />

of 3i’s implant systems. The success of any dental<br />

implant system depends upon proper use of the<br />

components and instrumentation. This manual<br />

is not intended for use as a substitute for<br />

professional training and experience.<br />

TREATMENT PLANNING<br />

Patient Evaluation And Selection:<br />

Several important factors must be considered when<br />

evaluating a patient prior to implant surgery. The<br />

presurgical evaluation must include a cautious and<br />

detailed assessment of the patient’s general health,<br />

current medical status, medical history, oral hygiene,<br />

motivation and expectations. Factors such as<br />

heavy tobacco use, chewing patterns and alcohol<br />

consumption should also be considered. In addition,<br />

the clinician should determine if the case presents<br />

an acceptable anatomical basis conducive to implant<br />

placement. An extensive intraoral examination should<br />

be undertaken to evaluate the oral cavity for any<br />

potential bone or soft-tissue pathology. The examiner<br />

should also determine the periodontal status of the<br />

remaining teeth, the health of the soft tissue or the<br />

presence of occlusal abnormalities, such as bruxism<br />

or crossbite. The presence of other conditions that<br />

could adversely affect any existing, natural dentition<br />

or healthy tissue surrounding the implant should also<br />

be evaluated.<br />

Diseases of the mucous membrane and connective<br />

tissues, pathologic bone disease and severe<br />

malocclusion could affect the determination of<br />

whether the patient is a suitable implant candidate.<br />

The use of anticoagulants and the existence of<br />

metabolic diseases, such as diabetes, allergies,<br />

chronic renal or cardiac disease and blood dyscrasia<br />

could significantly influence the patient’s ability to<br />

successfully undergo implant procedures.<br />

If the patient’s medical history reveals an existing<br />

condition or signals a potential problem that may<br />

compromise treatment and/or the patient’s wellbeing,<br />

consultation with a physician is recommended.<br />

2

Preoperative Planning<br />

Preoperative Planning:<br />

Proper treatment planning, as well as the selection of<br />

the proper implant length and diameter, are crucial to<br />

the long-term success of the implant and restoration.<br />

Before an implant can be selected, the anatomical<br />

foundation available to receive the implant must be<br />

carefully assessed. Several steps should be taken to<br />

complete the evaluation:<br />

1. Clinical examination of the oral cavity can provide<br />

important information about the health of the soft<br />

tissue at the proposed implant site. Tissue tone<br />

and the state of the superficial tissues should<br />

be evaluated. In addition, the patient should<br />

demonstrate an adequate dimension of attached<br />

mucosa or keratinized tissue at the site selected<br />

for implantation. In partially edentulous cases,<br />

the periodontal status of the remaining dentition<br />

should be assessed and interaction between<br />

the implant restoration and the adjacent<br />

natural dentition should be considered.<br />

2. The bony foundation and ridge need to be clinically<br />

analyzed to ensure the presence of proper<br />

dimensions and the amount of bone for implant<br />

placement. At least one millimeter of bone should<br />

be present at the buccal and lingual aspects<br />

of the implant following placement. During the<br />

planning state, it is useful to measure the existing<br />

bone foundation.<br />

Radiographic Marking Balls (RMB30)<br />

The vertical height of the bone is best determined<br />

radiographically. Accurate measurement of the vertical<br />

dimension on the radiograph facilitates the selection<br />

of the appropriate implant length. This helps avoid<br />

implant placement into the maxillary sinus, the floor<br />

of the nose or the mandibular canal and prevents<br />

perforation of the inferior aspect of the mandible.<br />

Measurements can be made directly on panographic<br />

film using a millimeter ruler. Corrections should be<br />

made for the degree of enlargement produced by the<br />

particular radiographic equipment.<br />

Radiographic marking balls of a known dimension can<br />

be embedded in a plastic template prior to radiographic<br />

examination. Once the radiograph is taken and the metal<br />

marking balls are visible on the image, measurements<br />

can be taken to determine the amount of bone available<br />

for implant placement.<br />

To calculate the distortion factor, a simple<br />

formula can be utilized:<br />

(5 ÷ A) x B = amount of actual bone available.<br />

Formula Key=<br />

• Radiographic marking ball = 5mm in diameter<br />

• A = Size of marking ball image on radiograph<br />

• B = Length in millimeters on the radiograph of<br />

available bone between the crest of the ridge and<br />

the inferior alveolar nerve canal<br />

Example:<br />

A = 6.5mm<br />

B = 14mm<br />

Therefore: (5 ÷ 6.5) x 14 = 10.76mm actual bone available<br />

NOTE: A 2mm margin of safety, from the apical end<br />

of the implant to the adjacent vital structure,<br />

should be considered.<br />

Marking Ball Image<br />

(6.5mm on this radiograph)<br />

Inferior Alveolar<br />

Nerve Canal<br />

A<br />

B<br />

3

Top-Down<br />

Treatment Planning<br />

In its simplest form, top-down treatment planning<br />

refers to a protocol whereby the desired restorative<br />

result is considered first, leading to consideration<br />

of the ideal prosthetic platform and subsequent<br />

implant selection based on bony anatomy.<br />

A top-down treatment planning methodology will<br />

provide maximum biomechanical stability and allow<br />

for soft tissue flaring by utilizing an implant with a<br />

prosthetic platform slightly smaller in diameter than<br />

the emergence diameter of the tooth being replaced.<br />

3i’s wide selection of implants allows clinicians to<br />

match the size of the prosthetic platform to the<br />

restoration it will eventually support, while allowing<br />

for different bone volumes and anatomical features<br />

at the implant site.<br />

Implant and healing abutment selections are based<br />

upon the relationship of several key measurements:<br />

• The emerging dimension of the crown in relation to<br />

the diameter of the prosthetic platform of the implant<br />

• The height and diameter of the intended restoration<br />

at the tissue exit point<br />

• The bone volume at the implant site in relation<br />

to the diameter of the implant body<br />

The Emergence Profile (EP ® ) Healing Abutment<br />

System consists of healing abutments of various<br />

diameters and heights for shaping the soft tissue<br />

to replicate the geometry and gingival contours<br />

of natural dentition.<br />

5/6mm 6mm 4mm 4mm 5mm 3.25mm<br />

5mm<br />

Implant<br />

Prosthetic<br />

Platform<br />

8 8 5 5 5.5 5 7.5<br />

Crown<br />

Diameter<br />

8 9 5 5 5.5<br />

4<br />

3.5<br />

5/6mm 6mm 4mm 4mm 4/5mm<br />

4mm<br />

3.25mm<br />

4

<strong>Surgical</strong> Precautions<br />

Clinical Considerations<br />

True bone contours can only be evaluated after<br />

tissue flaps have been reflected at the time of<br />

surgery. Even if bone dimensions are painstakingly<br />

measured prior to surgery, the doctor and patient<br />

must accept the possibility that inadequate bone<br />

anatomy might be discovered during surgery and<br />

preclude implant placement.<br />

During the presurgical planning phase, it is<br />

important to determine the vertical dimension - the<br />

actual space available between the alveolar crest and<br />

the opposing dentition - to confirm that the available<br />

space will accommodate the proposed abutment and<br />

the final crown restoration. The height required by<br />

the abutment may vary with the type of abutment;<br />

therefore, the surgeon and restorative dentist should<br />

carefully evaluate the abutment size. The final<br />

prosthesis should be designed prior to the<br />

placement of the implant.<br />

Study models should be used preoperatively to<br />

evaluate the residual ridge and to determine the<br />

position and angulation of all implants. These models<br />

allow the clinician to evaluate the opposing dentition<br />

and its effect on the implant position. A surgical<br />

guide stent, which is critical for determining the<br />

precise position and angulation of the implant, can<br />

be constructed on the study model.<br />

NT Shaping Drill out of the osteotomy, whereupon the<br />

bone particles can be collected.<br />

Bone surgery utilizes a high-torque electric drilling<br />

unit that can be operated in forward and reverse<br />

modes at speeds ranging from 0 to 1,500 rpm,<br />

depending on the surgical requirements. Sharp<br />

instruments of the highest quality should be utilized<br />

during implant site preparation to reduce possible<br />

overheating and trauma of the bone. Minimizing<br />

trauma enhances the potential for successful<br />

osseointegration.<br />

The time elapsed between surgical placement of the<br />

implant and final abutment placement is referred to<br />

as the healing period. Healing periods can vary or be<br />

modified, depending on the quality of the bone at the<br />

implantation site, bony response to the implant surface<br />

and other implanted materials and the surgeon’s<br />

assessment of the patient’s bone density at the time<br />

of the surgical procedure. Extreme care must be<br />

taken to avoid excessive force being applied to the<br />

implant during the healing period.<br />

To prevent damage to the bone tissue and to prevent<br />

compromising osseointegration, abundant and<br />

continuous irrigation with a cool, sterile irrigating<br />

solution is mandatory during all drilling procedures.<br />

The application of excessive pressure during preparation<br />

of the bone site must be avoided.<br />

If the surgeon wishes to collect bone from the site<br />

for bone augmentation while placing an NT Implant,<br />

it is recommended that, once the NT Shaping Drill is<br />

fully advanced into the osteotomy site, stop the drill,<br />

discontinue all irrigation and suction and pull the<br />

5

Cleaning And Sterilization<br />

Single use drills/burs are supplied sterile and<br />

should be properly disposed of after each procedure.<br />

Reusable drills/burs and instrumentation are<br />

supplied nonsterile and must be sterilized prior to<br />

use. Nonsterile items must be removed from the<br />

packaging before sterilization.<br />

Multiple sterilizations may affect the flow of fluid<br />

through internally irrigated drills. The drills should be<br />

checked following each sterilization cycle to determine<br />

if fluid flows through them. Although the surgical<br />

drills are constructed of stainless steel, they should<br />

be adequately dried prior to packaging for sterilization<br />

and again after the sterilization cycle.<br />

To extend the useful life of 3i’s instrumentations,<br />

certain procedures should always be followed:<br />

Cleaning:<br />

1. After use, place drills into a beaker of plain water,<br />

mild soap or specialized cleaning solution.<br />

2. Rinse with tap water for a minimum of two<br />

minutes while brushing with a soft bristled<br />

brush to remove visible debris. Clean the<br />

interior lumen with a thin wire to remove any<br />

remaining debris.<br />

3. Place instruments in an ultrasonic bath containing<br />

enzymatic detergent for five minutes*. Scrub<br />

the instruments again with a soft bristled brush<br />

and ream interior lumen to remove any<br />

remaining debris.<br />

4. Rinse and flush the instruments for one minute<br />

using tap water.<br />

5. Inspect visually for any remaining bone<br />

fragments or debris and scrub as necessary.<br />

Sterilization:<br />

6. Remove the bur block from the surgical tray.<br />

Scrub the surgical tray and block with a soft<br />

bristled brush and mild soap. Rinse thoroughly.<br />

7. Place the components into the surgical tray and<br />

pour ethyl alcohol (do not use rubbing alcohol)<br />

over the burs and tray to remove soap residue<br />

and minerals from the water. This step is<br />

important to help prevent corrosion and<br />

spotting.<br />

8. Wrap the surgical tray in paper or autoclaveapproved<br />

bags twice to prevent a tear of the<br />

outer packaging from contaminated instruments.<br />

9. Steam gravity sterilize for forty minutes at a<br />

temperature of 270˚ - 275˚F (132˚ - 135˚C).<br />

Notes:<br />

1. Multiple sterilizations may affect the flow of fluid<br />

through internally irrigated burs. After each use,<br />

ream the burs individually with wire to remove<br />

any bone fragments or debris that will prevent<br />

the flow of water. This is done prior to the<br />

sterilization cycle.<br />

2. Do not remove drills, instrumentation or surgical<br />

tray from the autoclave until the “dry cycle” is<br />

complete. Very Important!<br />

3. These guidelines DO NOT apply to the cleaning<br />

and sterilization of your powered instrumentation.<br />

Please follow your powered instrumentation<br />

manufacturer’s instructions.<br />

Please refer to ART630 for complete instructions on<br />

the sterilization and care of stainless steel.<br />

*ENZOL enzymatic detergent was used to validate this process, per the<br />

manufacturer’s dilution recommendation.<br />

6

3i Depth Gauge And<br />

Drill Marking System<br />

The 3i depth measurement system provides a mark<br />

on the drill that corresponds to the placement of the<br />

implant within a historical procedure. 3i’s original<br />

protocol follows the principles of protecting the<br />

implant from premature loading by placing the<br />

implant Sub-Crestally.<br />

The drill depth markings do not indicate implant<br />

lengths. Rather, the markings represent the length<br />

of the implant with the cover screw in place.<br />

As a result, to place an implant and cover screw<br />

Sub-Crestally requires drilling to the middle of the<br />

matching drill line. For Crestal placement, drill half<br />

way before the corresponding mark for the implant<br />

length. For Supra-Crestal placement, the drill mark<br />

should remain above the bone by approximately<br />

1.5mm. Please refer to the following chart for<br />

further information.<br />

Crest<br />

of Bone<br />

Tip Dimensions<br />

Drill Diameter<br />

Drill Tip<br />

2.00mm<br />

.6mm<br />

2.30mm<br />

.7mm<br />

2.75mm<br />

.9mm<br />

3.00mm<br />

.9mm<br />

3.15mm<br />

1.0mm<br />

3.25mm<br />

1.0mm<br />

4.25mm<br />

.4mm<br />

5.25mm<br />

.5mm<br />

Note: A drill extension for areas of limited access is available.<br />

2.00mm<br />

TWIST DRILL<br />

DEPTH<br />

GAUGE<br />

IMPLANT W/<br />

COVER SCREW<br />

OSSEOTITE NT<br />

Implant Length<br />

(Label)<br />

Actual<br />

OSSEOTITE NT<br />

Length<br />

Parallel Sided<br />

Implant Length<br />

(Label)<br />

Actual Parallel<br />

Sided Implant<br />

Length<br />

Cover Screw Height<br />

Actual Drill Length<br />

to Mark*<br />

7.0mm 6.6mm 1.0mm 7.6mm<br />

8.5mm 8.1mm 8.5mm 8.1mm 1.0mm 9.1mm<br />

10.0mm 9.6mm 10.0mm 9.6mm 1.0mm 10.6mm<br />

11.5mm 11.1mm 11.5mm 11.1mm 1.0mm 12.1mm<br />

13.0mm 12.6mm 13.0mm 12.6mm 1.0mm 13.6mm<br />

15.0mm 14.6mm 15.0mm 14.6mm 1.0mm 15.6mm<br />

18.0mm 17.6mm 1.0mm 18.6mm<br />

20.0mm 19.6mm 1.0mm 20.6mm<br />

* From point on drill at which maximum diameter starts. (Drill mark is .5mm wide) Drill length listed in chart does not include drill tip.<br />

Important Information Concerning Countersink Drills<br />

CD500 and CD600<br />

A second depth line has been added to the 5mm and<br />

6mm diameter Countersink Drills (CD500 & CD600).<br />

The bottom line (closest to the apex) is positioned<br />

where the original, single line has traditionally been.<br />

The top line (closest to the shank) has been added to<br />

accommodate the new OSSEOTITE ® Certain Implant.<br />

Sub-Crestal<br />

Implant Placement<br />

Crestal<br />

Implant Placement<br />

3i External<br />

Hex Implant<br />

3i OSSEOTITE<br />

Certain Implant<br />

3i External<br />

Hex Implant<br />

3i OSSEOTITE<br />

Certain Implant

OSSEOTITE NT Certain And<br />

OSSEOTITE NT Implant<br />

Placement Protocol<br />

SUB-CRESTAL Placement:<br />

Drill to the second line on the appropriate shaping<br />

drill (indicated as a solid line in the illustration). Place<br />

the implant to the groove on the implant mount to<br />

properly locate the top of the cover screw at the<br />

crest of the bone.<br />

CRESTAL Placement:<br />

Drill to the first line on the appropriate shaping drill<br />

(indicated as a green line in the illustration). Place the<br />

implant to the juncture of the implant mount and the<br />

implant platform to properly locate the implant at the<br />

crest of the bone.<br />

SUPRA-CRESTAL Placement:<br />

Drill to the first notch on the appropriate shaping<br />

drill (indicated as the dotted line in the illustration).<br />

This will position the seating surface of the implant<br />

1.25mm above the bone.<br />

When placing the OSSEOTITE NT Implant, it is<br />

typical for the implant to advance into the osteotomy<br />

approximately 40 to 50 percent, depending on the<br />

length of the implant being placed, before coming into<br />

contact with the prepared osteotomy. This is a<br />

normal feature of the tapered implant and does not<br />

prevent it from obtaining ideal primary stability<br />

when fully seated.<br />

OSSEOTITE NT Implant Taps:<br />

When placing an OSSEOTITE NT Implant into dense<br />

bone, it may be necessary to tap the osteotomy prior<br />

to implant placement.<br />

The OSSEOTITE NT Implant Taps are all 8.5mm in<br />

length and are designed to tap the coronal aspect of<br />

the osteotomy. For both crestal and sub-crestal<br />

OSSEOTITE NT Implant placement, the tap is<br />

advanced into the osteotomy until the junction of<br />

the colored mount and the tap body is level with the<br />

crest of the bone. The recommended speed for<br />

tapping is 15-20 rpm.<br />

8.5mm<br />

Osteotomy<br />

OSSEOTITE NT Certain<br />

OSSEOTITE NT<br />

11mm<br />

Osteotomy<br />

13mm<br />

Osteotomy<br />

Sub-Crestal<br />

Crestal<br />

Supra-Crestal<br />

Sub-Crestal<br />

Crestal<br />

Supra-Crestal<br />

8

OSSEOTITE ® Certain Implant<br />

Placement Protocol<br />

Sub-Crestal Placement Of The 4mm<br />

OSSEOTITE Certain Implant:<br />

Two-Stage Surgery<br />

When placing the 4mm OSSEOTITE Certain Implant<br />

sub-crestally, the flare created by the countersink<br />

determines where the cover screw will ultimately seat.<br />

For sub-crestal placement, drill the countersink to the<br />

top of the laser line.<br />

Place the OSSEOTITE Certain Implant so that the top<br />

of the cover screw replica on the Certain Implant<br />

Driver is even with the crest.<br />

Note: If the implant is placed too deeply, the cover<br />

screw may not seat completely, leaving a gap.<br />

To correct the gap between the cover screw and the<br />

implant, first remove the cover screw and try one or<br />

all of the following:<br />

• Back out the implant to the proper height<br />

• Remove the interfering crestal bone using either:<br />

- The bone profiling pin (IBPGP) with the<br />

4.0 – 5.0mm bone profiler (BP450)<br />

or<br />

- The round drill (RD100) (Avoid contact with<br />

the implant.)<br />

Sub-crestal OSSEOTITE Certain<br />

implant placement<br />

Certain cover<br />

screw seated<br />

Anatomy Of The Certain Implant<br />

Placement Driver, IIPDTL Or IIPTDTS<br />

The unique design of the Certain Implant Placement<br />

Driver allows it to function as both an implant driver<br />

and a cover screw inserter.<br />

Implant placed too deeply<br />

Depth indicators:<br />

4mm<br />

3mm<br />

2mm<br />

1mm<br />

0mm<br />

Gap between cover screw<br />

and implant<br />

Implant hex<br />

orientation<br />

Cover screw<br />

replica<br />

Implant pick up and insertion hex<br />

O-ring<br />

Cover screw pick up and insertion tip<br />

IIPDTS/L<br />

9

OSSEOTITE ® Certain Implant<br />

Placement Protocol (Continued)<br />

Pick Up And Delivery Of The OSSEOTITE<br />

Certain Implant<br />

Care must be taken when inserting the Implant<br />

Placement Driver tip into the implant. A very low<br />

RPM must be used as you approach the internal<br />

connection of the implant with the driver tip to<br />

properly align the internal hex of the implant with<br />

the external hex of the driver. Press down firmly<br />

to engage the implant securely.<br />

Hex<br />

Implant and driver hex design<br />

Pick Up And Delivery Of The Certain Implant Cover<br />

Screw Or Healing Abutment<br />

The .048 inch tip of the Certain Implant Placement<br />

Driver can be used to pick up and place the cover<br />

screw or the healing abutment. When placing the<br />

cover screw, lower the torque on the drill unit<br />

to 10Ncm.<br />

Implant pick up<br />

The cover screw replica portion of the driver<br />

allows for visual verification of the cover screw<br />

position, making sub-crestal and<br />

crestal placement of the implant predictable.<br />

Cover screw pick up<br />

Sub-Crestal Placement<br />

Crestal Placement<br />

10

OSSEOTITE ® Certain Implant<br />

Placement Protocol (Continued)<br />

Two-Piece Bone Profiling Pin (IBPGP)<br />

The OSSEOTITE Certain Implant<br />

requires a dedicated Bone Profiling<br />

Pin, which is used with the existing<br />

EP ® Bone Profilers. This new<br />

two-piece design allows the pin<br />

to engage the internal hex of the<br />

implant. The hex engagement<br />

prevents the pin from tightening<br />

into the implant during profiling,<br />

making it easy to remove.<br />

Lubricating the top of the pin with an<br />

Two-Piece<br />

Bone Profiler Pin<br />

appropriate lubricant, such as tetracycline ointment,<br />

is recommended. Do not exceed 50 RPM<br />

when using the Bone Profilers.<br />

EP Healing Abutments<br />

A two-piece Bone Profiling Pin (IBPGP) and<br />

corresponding EP Bone Profilers are available to<br />

contour the bone that is to receive the EP Healing<br />

Abutment. These tools are especially helpful in a<br />

single-stage surgical protocol when the implant is<br />

placed sub-crestally.<br />

If the implant is placed sub-crestally and use of an EP<br />

Healing Abutment is indicated, the coronal aspect of<br />

the osteotomy must be prepared to receive the flare<br />

of the EP Healing Abutment.<br />

Bone Profiling Technique:<br />

• EP Bone Profiler slides over<br />

the two-Piece Bone Profiler<br />

Pin.<br />

• EP Bone Profiler creates a<br />

flare in the crest of bone.<br />

• Flare of EP Abutment matches<br />

the flare of the corresponding<br />

EP Bone Profiler.<br />

EP Bone Profilers correspond to sizes of EP Healing Abutments<br />

• EP Healing Abutment seated<br />

properly onto the implant in<br />

sub-crestal placement.<br />

Note:<br />

Non-EP, straight healing abutments and impression<br />

copings are available if bone profiling is not<br />

preferred at either stage 1 or stage 2 surgery.<br />

11

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE NT Certain Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

PD100<br />

(OPTIONAL)<br />

3.25<br />

NTSD32XX<br />

4.0<br />

NTSD4XX<br />

5.0<br />

NTSD5XX<br />

6.0<br />

NTSD6XX<br />

Round Drill<br />

RD100<br />

Internal<br />

Connection<br />

OSSEOTITE NT Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

PD100<br />

(OPTIONAL)<br />

INT32XX INT4XX INT5XX INT6XX<br />

3.25<br />

NTSD32XX<br />

4.0<br />

NTSD4XX<br />

5.0<br />

NTSD5XX<br />

6.0<br />

NTSD6XX<br />

Note:<br />

Sequential NT shaping<br />

drills are recommended<br />

up to the final diameter<br />

of the OSSEOTITE NT<br />

implant to be placed.<br />

Note:<br />

When placing a 3.25mm<br />

OSSEOTITE NT Implant,<br />

an Initial Twist Drill<br />

with a maximum<br />

diameter of 2.0mm<br />

is recommended.<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

NT32XX NT4XX NT5XX NT6XX<br />

12

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE ® MicroMiniplant Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

Round Drill<br />

RD100<br />

Internal<br />

Connection<br />

External Hex<br />

Connection<br />

3.25mm<br />

OSSEOTITE XP ® 3/4 Or ST 3.75mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

C’sink Drill<br />

CD100<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

XP 3/4mm<br />

ST 3.75mm<br />

13

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE ® Certain 4mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0 or 3.25mm<br />

Twist Drill<br />

C’sink Drill<br />

ICD100<br />

Round Drill<br />

RD100<br />

Internal<br />

Connection<br />

4.0mm<br />

OSSEOTITE 4mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0 or 3.25mm<br />

Twist Drill<br />

C’sink Drill<br />

CD100<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

4.0mm<br />

14

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE XP ® 4/5mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0 or 3.25mm<br />

Twist Drill<br />

4/5 C’sink Drill<br />

CD4500<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

XP 4/5<br />

OSSEOTITE XP 5/6mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

5mm Pilot/C’sink<br />

CD500<br />

4.25mm<br />

Twist Drill<br />

5/6mm Pilot/C’sink<br />

CD5600<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

XP 5/6mm<br />

15

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE ® Certain 5mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

5mm Pilot/C’sink<br />

CD500<br />

4.25mm<br />

Twist Drill<br />

Round Drill<br />

RD100<br />

Internal<br />

Connection<br />

Wide 5.0mm<br />

OSSEOTITE 5mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

5mm Pilot/C’sink<br />

CD500<br />

4.25mm<br />

Twist Drill<br />

Round Drill<br />

RD00<br />

External Hex<br />

Connection<br />

Wide 5.0mm<br />

16

Implant Placement Protocol<br />

Quick Reference<br />

OSSEOTITE ® Certain 6mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

5mm Pilot/C’sink<br />

CD500<br />

4.25mm<br />

Twist Drill<br />

6mm Pilot/C’sink<br />

CD600<br />

5.25mm<br />

Twist Drill<br />

Round Drill<br />

RD100<br />

Internal<br />

Connection<br />

Wide 6.0mm<br />

OSSEOTITE 6mm Implant<br />

Crestal Placement<br />

2.0 or 2.3mm<br />

Twist Drill<br />

Pilot Drill<br />

PD100<br />

3.0mm<br />

Twist Drill<br />

5mm Pilot/C’sink<br />

CD500<br />

4.25mm<br />

Twist Drill<br />

6mm Pilot/C’sink<br />

CD600<br />

5.25mm<br />

Twist Drill<br />

Round Drill<br />

RD100<br />

External Hex<br />

Connection<br />

Wide 6.0mm<br />

17

OSSEOTITE NT <br />

<strong>Surgical</strong> Tray<br />

Coordinating the use of the <strong>Surgical</strong> Tray with the<br />

<strong>Surgical</strong> <strong>Manual</strong> illustrations:<br />

The OSSEOTITE NT <strong>Surgical</strong> Tray is numbered to indicate<br />

the appropriate steps of the implant placement protocol.<br />

The following illustrated implant placement protocol uses<br />

the same numbering sequence.<br />

Close-up view of <strong>Surgical</strong> Tray illustrating numbering sequence<br />

18

OSSEOTITE NT Certain<br />

And OSSEOTITE NT Implant<br />

Crestal Placement Protocol<br />

1. Once the implant site has been determined, mark<br />

the site with a Round Drill and penetrate the cortical bone.<br />

Set the drill speed at approximately 1,500 rpm.<br />

• Instruments needed:<br />

Round Drill (RD100)<br />

2a. Proceed with the Initial Twist Drill. Penetrate the<br />

bone at the marked site to the desired depth.<br />

• Instruments needed:<br />

2 or 2.3mm Twist Drill<br />

(ITD215, DT215 or DTN215)<br />

2b. Verify the direction and position of the preparation<br />

by inserting the thin portion of the Direction Indicator into<br />

the osteotomy.<br />

• Instruments needed:<br />

Direction Indicator (DI100 or DI2310)<br />

3. OPTIONAL STEP<br />

Use the Pilot Drill to shape the coronal aspect of<br />

the implant site. Drill to the laser etched depth marking for<br />

placement of an OSSEOTITE NT Implant.<br />

• Instruments needed:<br />

Pilot Drill (PD100)<br />

19

OSSEOTITE NT Certain<br />

And OSSEOTITE NT Implant<br />

Crestal Placement Protocol<br />

4. Final Drilling Step for 3.25mm OSSEOTITE NT Implant<br />

Proceed with the 3.25mm NT Shaping Drill that<br />

is the same length as the OSSEOTITE NT Implant to be<br />

placed (300 rpm is the recommended speed when<br />

using the shaping drill. In dense bone, the speed may<br />

need to be increased to 500 rpm).<br />

• Instruments needed:<br />

3.25mm NT Shaping Drill (NTSD32xx)<br />

• Proceed to step 8a for 3.25mm OSSEOTITE NT<br />

Implant placement<br />

5. Final Drilling Step for 4.0mm OSSEOTITE NT Implant<br />

Continue preparing the osteotomy with the<br />

4mm NT Shaping Drill that is the same length as the<br />

OSSEOTITE NT Implant to be placed (300 rpm is the<br />

recommended speed when using the shaping drill. In<br />

dense bone, the speed may need to be increased to<br />

500 rpm).<br />

• Instruments needed:<br />

4mm NT Shaping Drill (NTSD4xx)<br />

• Proceed to step 8a for 4.0mm OSSEOTITE NT<br />

Implant placement<br />

6. Final Drilling Step for 5.0mm OSSEOTITE NT Implant<br />

Resume preparing the osteotomy with the 5mm<br />

NT Shaping Drill that is the same length as the<br />

OSSEOTITE NT Implant to be placed (300 rpm is the<br />

recommended speed when using the shaping drill. In<br />

dense bone, the speed may need to be increased to<br />

500 rpm).<br />

• Instruments needed:<br />

5mm NT Shaping Drill (NTSD5xx)<br />

• Proceed to step 8a for 5.0mm OSSEOTITE NT<br />

Implant placement<br />

7. Final Drilling Step for 6.0mm OSSEOTITE NT Implant<br />

Finish preparing the osteotomy with the 6mm<br />

NT Shaping Drill that is the same length as the<br />

OSSEOTITE NT Implant to be placed (300 rpm is the<br />

recommended speed when using the shaping drill. In<br />

dense bone, the speed may need to be increased to<br />

500 rpm).<br />

• Instruments needed:<br />

6mm NT Shaping Drill (NTSD6xx)<br />

• Proceed to step 8a for 6.0mm OSSEOTITE NT<br />

Implant placement<br />

20

OSSEOTITE NT Certain<br />

And OSSEOTITE NT Implant<br />

Crestal Placement Protocol<br />

8a. No-Touch Delivery System<br />

Remove contents from the implant box.<br />

8b. Nonsterile assistant should peel back the tray<br />

lid and drop the No-Touch Implant Tray onto the<br />

sterile drape.<br />

8c. Place the No-Touch Implant Tray into the appropriate<br />

location on the surgical tray.<br />

8d. Peel back the tray lid to expose the implant and<br />

cover screw.<br />

21

OSSEOTITE NT Certain<br />

And OSSEOTITE NT Implant<br />

Crestal Placement Protocol<br />

9. Pick up the implant from the surgical tray using<br />

the Certain Implant Placement Driver Tip<br />

(IIPDTS or IIPDTL).<br />

or<br />

Pick up the implant from the surgical tray using<br />

the Handpiece Connector (MDR10).<br />

Carry the implant to the mouth facing upward to<br />

prevent accidental dislodging.<br />

10. Place the implant in the prepared site at about<br />

15 to 20 RPM. The Spiral ICE design will allow smooth<br />

and precise implant placement without tapping in all but<br />

the most dense bone.<br />

• Instruments needed:<br />

Certain Implant Placement Driver Tip<br />

(IIPDTS or IIPDTL)<br />

or<br />

Handpiece Connector (MDR10)<br />

11. To remove the Certain Implant Placement Driver<br />

Tip (IIPDTS or IIPDTL) from the implant, pull straight up<br />

and out.<br />

or<br />

To remove the implant mount, place the Open-<br />

End Wrench onto the mount. Loosen the screw at the<br />

top of the mount with a Large Hex Driver or the Large<br />

Hex Driver Tip inserted into the Right-Angle Driver and<br />

rotate counter-clockwise. After the screw is loosened,<br />

rotate the Open-End Wrench counterclockwise slightly<br />

before removing the mount. The mount may be carried<br />

from the mouth with the Open-End Wrench.<br />

• Instruments needed:<br />

Open-End Wrench (CW100),<br />

Large Hex Driver Tip (RASH3),<br />

Right-Angle Driver (CATDB with CADD1),<br />

or Large Hex Driver (PHD02N)<br />

22

OSSEOTITE NT Certain<br />

And OSSEOTITE NT Implant<br />

Crestal Placement Protocol<br />

12. Pick up the cover screw from the No-Touch<br />

Implant Tray with:<br />

the internal connection implant driver (IIPDTS or<br />

IIPDTL) and place onto the implant.<br />

or<br />

the Small Hex Driver (PHD00N) or the Cover<br />

Screw Inserter (CSI10) and place onto the implant. The<br />

Cover Screw Inserter is used for Cover Screws 4.5mm in<br />

diameter only, while the Small Hex Driver may be used for the<br />

3.5mm, 4.5mm, 5mm and 6mm Cover Screws. Final hand<br />

tightening of the cover screw should be done with the<br />

Small Hex Driver.<br />

13. Close tissue and suture.<br />

23

OSSEOTITE ® Parallel Wall Implant<br />

<strong>Surgical</strong> Tray<br />

Coordinating the use of the <strong>Surgical</strong> Tray<br />

with the <strong>Surgical</strong> <strong>Manual</strong> illustrations:<br />

The OSSEOTITE Parallel Wall Implant <strong>Surgical</strong><br />

Tray is numbered to indicate the appropriate<br />

steps of the implant placement protocol. The<br />

following illustrated implant placement protocol<br />

uses the same numbering sequence.<br />

24<br />

Close-up view of <strong>Surgical</strong> Tray illustrating numbering sequence

OSSEOTITE ® Certain<br />

And OSSEOTITE Implant<br />

Crestal Placement Protocol<br />

For A 6mm Diameter Implant<br />

The drilling protocol for the Crestal Placement of the 6mm<br />

OSSEOTITE Certain and OSSEOTITE Implant was chosen<br />

as a representative protocol to provide a detailed implant<br />

placement synopsis. For the drilling protocol specific to<br />

implant diameter and design, please refer to the Implant<br />

Placement Protocol Quick Reference section of this manual.<br />

1. Once the implant site has been determined, mark<br />

the site with a Round Drill and penetrate the cortical bone.<br />

Set the drill speed at approximately 1,500 RPM.<br />

• Instruments needed:<br />

Round Drill (RD100)<br />

2a. Proceed with the Initial Twist Drill. Penetrate the<br />

bone at the marked site to the desired depth.<br />

• Instruments needed:<br />

2 or 2.3mm Twist Drill<br />

(ITD215, DT215 or DTN215)<br />

2b. Verify the direction and position of the preparation<br />

by inserting the thin portion of the Direction Indicator into<br />

the osteotomy.<br />

• Instruments needed:<br />

Direction Indicator (DI100 or DI2310)<br />

25

OSSEOTITE ® Certain<br />

And OSSEOTITE Implant<br />

Crestal Placement Protocol<br />

For A 6mm Diameter Implant<br />

3. Use the Pilot Drill to shape the coronal aspect<br />

of the implant site. Drill to the laser etched depth<br />

marking for placement of an OSSEOTITE Implant.<br />

• Instruments needed:<br />

Pilot Drill (PD100)<br />

4. Once proper alignment is verified using the<br />

Direction Indicator, proceed with the 3.00mm Twist Drill<br />

to the desired depth.<br />

• Instruments needed:<br />

3.00mm Twist Drill (ITD315)<br />

5. Use the first cutting groove on the 5.00mm<br />

Pilot Countersink Drill to widen the coronal aspect of<br />

the osteotomy to allow the 4.25mm Twist Drill to enter<br />

the osteotomy.<br />

• Instruments needed:<br />

5mm Pilot Countersink Drill (CD500)<br />

6. Once the coronal aspect of the osteotomy has<br />

been piloted, proceed with the 4.25mm Twist Drill to the<br />

desired depth.<br />

• Instruments needed:<br />

4.25mm Twist Drill (ITD423)<br />

26

OSSEOTITE ® Certain<br />

And OSSEOTITE Implant<br />

Crestal Placement Protocol<br />

For A 6mm Diameter Implant<br />

7. Advance the 6.00mm Pilot Countersink drill all<br />

the way to the laser marking. This will countersink the<br />

implant and allow for crestal placement of the OSSEOTITE<br />

Certain implant.<br />

or<br />

Advance the 6.00mm Pilot Countersink drill to the<br />

first cutting groove. This will countersink the External Hex<br />

OSSEOTITE implant and allow for crestal placement.<br />

• Instrument needed:<br />

6.00mm Pilot Countersink Drill (CD600)<br />

8. Once the coronal aspect of the osteotomy has<br />

been piloted, proceed with the 5.25mm Twist Drill to the<br />

desired depth. The recommended speed for a 5.25mm<br />

Twist Drill is 900 RPM.<br />

• Instrument needed:<br />

5.25mm Twist Drill (ITD523)<br />

9a. No-Touch Delivery System<br />

Remove contents from the implant box.<br />

9b. A nonsterile assistant should peel back the tray lid<br />

and drop the No-Touch Implant Tray onto the sterile<br />

drape.<br />

27

OSSEOTITE ® Certain<br />

And OSSEOTITE Implant<br />

Crestal Placement Protocol<br />

For A 6mm Diameter Implant<br />

9c. Place the No-Touch Implant Tray into the<br />

appropriate location on the surgical tray.<br />

9d. Peel back the tray lid to expose the implant and<br />

cover screw.<br />

10. Pick up the implant from the surgical tray using<br />

the Certain Implant Placement Driver Tip<br />

(IIPDTS or IIPDTL) .<br />

or<br />

Pick up the implant from the surgical tray using<br />

the Handpiece Connector (MDR10).<br />

Carry the implant to the mouth facing upward to<br />

prevent accidental dislodging.<br />

11. Place the implant in the prepared site at about<br />

15 to 20 RPM. The ICE ® design will allow smooth and<br />

precise implant placement without tapping in all but the<br />

most dense bone.<br />

28

OSSEOTITE ® Certain<br />

And OSSEOTITE Implant<br />

Crestal Placement Protocol<br />

For A 6mm Diameter Implant<br />

12. To remove the Certain Implant Placement Driver<br />

Tip (IIPDTS or IIPDTL) from the implant, pull straight up<br />

and out.<br />

or<br />

To remove the implant mount, place the Open-End<br />

Wrench onto the mount. Loosen the screw at the top of the<br />

mount with a Large Hex Driver or the Large Hex Driver Tip<br />

inserted into the Right-Angle Driver and rotate counterclockwise.<br />

After the screw is loosened, rotate the Open-End<br />

Wrench counterclockwise slightly before removing the<br />

mount. The mount may be carried from the mouth with the<br />

Open-End Wrench.<br />

• Instruments needed:<br />

Open-End Wrench (CW100), Large Hex Driver Tip<br />

and Right-Angle Driver (RASH3 and CATDB with CADD1),<br />

or a Large Hex Driver (PHD02N)<br />

13. Pick up the cover screw from the No-Touch<br />

Implant Tray with:<br />

the internal connection implant driver (IIPDTS or<br />

IIPDTL) and place onto the implant.<br />

or<br />

the Small Hex Driver (PHD00N) or the Cover<br />

Screw Inserter (CSI10) and place onto the implant. The<br />

Cover Screw Inserter is used for Cover Screws 4.5mm in<br />

diameter only, while the Small Hex Driver may be used for the<br />

3.5mm, 4.5mm, 5mm and 6mm Cover Screws. Final hand<br />

tightening of the cover screw should be done with the<br />

Small Hex Driver.<br />

14. Close tissue and suture.<br />

29

Single-Stage Treatment With<br />

A Two-Stage Implant System<br />

Several advantages can be realized by utilizing a two-stage<br />

implant system in a single-stage treatment protocol.<br />

Attaching a one-piece or two-piece healing abutment<br />

immediately following implant placement eliminates the need<br />

for a second-stage surgery. Eliminating the second surgical<br />

procedure reduces trauma and decreases treatment time, while<br />

the two-stage implant design maintains restorative flexibility.<br />

1. After the implant is fully seated in the osteotomy,<br />

remove the implant mount from the external hex implant.<br />

2. Select the appropriate one-piece healing<br />

abutment depending upon the implant seating surface,<br />

tissue depth and desired EP ® dimension.<br />

or<br />

Select the appropriate one or two-piece healing<br />

abutment depending upon the implant seating surface,<br />

tissue depth and desired EP dimension.<br />

Bone profiling of the osteotomy may be<br />

necessary to fully seat the healing abutment onto<br />

the implant.<br />

3. Tighten the one or two-piece healing abutment<br />

Screw to 20Ncm and suture the soft tissue around the<br />

healing abutment.<br />

30

<strong>Surgical</strong> Indexing For<br />

3i External Hex Implants<br />

By indexing the external hex implant after placement using<br />

a <strong>Surgical</strong> Index Coping, a provisional restoration can be<br />

fabricated in the laboratory while the bone and soft tissues are<br />

healing. The <strong>Surgical</strong> Index Coping screws into the implant and<br />

registers the orientation of the implant hex.<br />

The Index Coping is then transferred to the guide stent. The<br />

implant analog is mated to the Index Coping and secured in the<br />

preoperative stone model.<br />

1. Align and attach the index coping with the<br />

implant hex and attach the coping to the guide stent with<br />

cold-cure acrylic resin.<br />

2. Unscrew the index coping from the implant<br />

and remove the guide stent and index coping assembly.<br />

3. Mate the implant analog with the index coping and<br />

attached guide stent.<br />

31

<strong>Surgical</strong> Indexing For<br />

3i External Hex Implants<br />

4. Prepare the stone model using a large round<br />

bur to allow space for insertion of implant analog.<br />

5. Secure implant analog in the stone model<br />

using a cold-cure acrylic resin or dental stone and then<br />

remove the guide stent and index coping.<br />

• Instruments needed:<br />

<strong>Surgical</strong> Index Coping (IC100)<br />

32

Implant Innovations, Inc.<br />

Global Headquarters<br />

4555 Riverside Drive<br />

Palm Beach Gardens, FL 33410<br />

1.800.342.5454<br />

Outside U.S.: + 561.776.6700<br />

Fax: + 561.776.1272<br />

www.3i-online.com<br />

3i and design, OSSEOTITE, OSSEOTITE XP, EP and ICE are registered trademarks and<br />

OSSEOTITE NT, Microminiplant, No Touch, Spiral Ice and Certain are trademarks of<br />

Implant Innovations, Inc. © 2003 Implant Innovations, Inc. All rights reserved.<br />

CATSM<br />

REV C 11/03<br />

SUBSIDIARIES<br />

BRAZIL<br />

Phone: +55-11-5081-4405<br />

Fax: +55-11-5081-7484<br />

SPAIN<br />

Phone: +34-93-470-59-50<br />

Fax: +34-93-372-11-25<br />

AUSTRIA<br />

Wieladent<br />

Phone: +43-7672-93901<br />

Fax: +43-7672-93903<br />

EL SALVADOR<br />

Dentimerc SA de CV<br />

Phone: +503-263-6350<br />

Fax: +503-263-6676<br />

KOREA<br />

Jungsan Biomed Corp.<br />

Phone: +82-2-516-1808<br />

Fax: +82-2-514-9434<br />

SINGAPORE<br />

Asia Implant Support & Services<br />

Phone: +65-6223-3229<br />

Fax: +65-6220-3538<br />

CANADA<br />

Phone: +514-956-9843<br />

Fax: +514-956-9844<br />

FRANCE<br />

Phone: +33-1-41054343<br />

Fax: +33-1-41054340<br />

GERMANY<br />

Phone: +49-721-6314-220<br />

Fax: +49-721-6314-233<br />

MEXICO<br />

Phone: +52-55-5679-1619<br />

Fax: +52-55-5684-8098<br />

SWITZERLAND<br />

Phone: +41-1-3804646<br />

Fax: +41-1-3834655<br />

U.K.<br />

Phone: +44-1628-829314<br />

Fax: +44-1628-820182<br />

DISTRIBUTORS<br />

ARGENTINA<br />

<strong>Dental</strong>max, SA<br />

Phone: +541-1482-71001<br />

Fax: +541-1482-67373<br />

BENELUX<br />

Titamed, NV<br />

Phone: +32-2-5410290<br />

Fax: +32-2-5410291<br />

CHILE<br />

Cybel, SA<br />

Phone: +56-2-2321883<br />

Fax: +56-2-2330176<br />

COLOMBIA<br />

Implantes y Componentes<br />

Phone: +571-612-9362<br />

Fax: +571-620-5450<br />

GREECE<br />

Kostas Kornisorlis and Co.<br />

Phone: +302310-269-079<br />

Fax: +302310-555-573<br />

ISRAEL<br />

H.A. Systems<br />

Phone: +972-3-6138777<br />

Fax: +972-3-6138778<br />

ITALY<br />

Biomax, srl.<br />

Phone: +39-0444-913410<br />

Fax: +39-0444-913695<br />

LEBANON<br />

Tamer Freres s.a.l.<br />

Phone: +961-1-485690<br />

Fax: +961-1-510233<br />

PANAMA<br />

Odontomedica, S.A.<br />

Phone: +507-2-239622<br />

Fax: +507-2-239621<br />

PARAGUAY<br />

Andres H. Arce y Cia SRL<br />

Phone: +595-21-208185<br />

Fax: +595-21-496291<br />

TAIWAN<br />

Kuo Hwa <strong>Dental</strong> Suppliers Co., Ltd.<br />

Phone: +886-2-2226-1770<br />

Fax: +886-2-2226-8747<br />

THAILAND<br />

PT Endeavour Co., Ltd.<br />

Phone: +662-264-2574<br />

Fax: +662-264-2573<br />

UKRAINE<br />

Porcelain Ltd.<br />

Phone: +380-44-246-9679<br />

Fax: +380-44-246-8468<br />

NORDIC REGION<br />

Phone: +46-40-17-6090<br />

Fax: +46-40-17-6099<br />

AUSTRALIA<br />

Rudolf Gunz & Co. Pty., Ltd.<br />

Phone: +61-2-9935-6655<br />

Fax: +61-2-9935-6650<br />

COSTA RICA<br />

Implantec S.A.<br />

Phone: +506-2-256411<br />

Fax: +506-2-247620<br />

JAPAN<br />

Implant Innovations Japan<br />

Phone: +81-66-868-3012<br />

Fax: +81-66-868-2444<br />

POLAND<br />

<strong>Dental</strong> <strong>Depot</strong><br />

Phone: +48-71-341-3091<br />

Fax: +48-71-343-6560<br />

URUGUAY<br />

Jelenko Distribution SRL<br />

Phone: +598-408-3003<br />

Fax: +598-2-7-12-5399