Passive versus Active Packaging

Passive versus Active Packaging

Passive versus Active Packaging

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

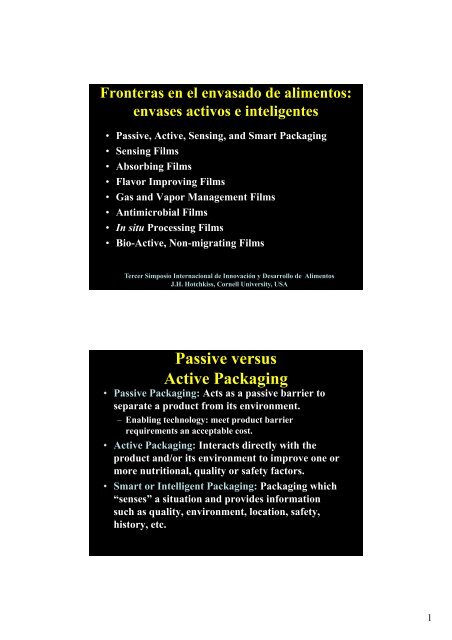

Fronteras en el envasado de alimentos:<br />

envases activos e inteligentes<br />

• <strong>Passive</strong>, <strong>Active</strong>, Sensing, and Smart <strong>Packaging</strong><br />

• Sensing Films<br />

• Absorbing Films<br />

• Flavor Improving Films<br />

• Gas and Vapor Management Films<br />

• Antimicrobial Films<br />

• In situ Processing Films<br />

• Bio-<strong>Active</strong>, Non-migrating Films<br />

Tercer Simposio Internacional de Innovación y Desarrollo de Alimentos<br />

J.H. Hotchkiss, Cornell University, USA<br />

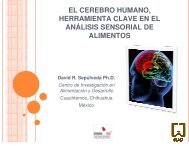

<strong>Passive</strong> <strong>versus</strong><br />

<strong>Active</strong> <strong>Packaging</strong><br />

• <strong>Passive</strong> <strong>Packaging</strong>: Acts as a passive barrier to<br />

separate a product from its environment.<br />

– Enabling technology: meet product barrier<br />

requirements an acceptable cost.<br />

• <strong>Active</strong> <strong>Packaging</strong>: Interacts directly with the<br />

product and/or its environment to improve one or<br />

more nutritional, quality or safety factors.<br />

• Smart or Intelligent <strong>Packaging</strong>: <strong>Packaging</strong> which<br />

“senses” a situation and provides information<br />

such as quality, environment, location, safety,<br />

history, etc.<br />

1

Microbial Sensing “Smart” Films<br />

LASER<br />

DIFFRACTION<br />

PATTERN<br />

ANTIBODY GRID<br />

Removal of Unwanted Food<br />

Components<br />

• Removal of aldehydes and amines from<br />

headspace<br />

• Immobilized Chelating Agents<br />

2

Example: <strong>Active</strong> Control of<br />

Lipid Oxidation in Foods<br />

Conventional control of lipid oxidation in foods:<br />

Additives<br />

Antioxidant<br />

Chelating agents<br />

Barrier packaging/Nitrogen flushing<br />

<strong>Active</strong> control<br />

Absorb products of oxidation<br />

Irreversible Removal of Amines<br />

and/or Aldehydes<br />

• Incorporation of activated sites onto films<br />

• Formation of Schiff’s bases (imines)<br />

• R-NH 2 + R’-C=O R-N=CH-R’<br />

3

Removal of Metals<br />

from Beverages<br />

Fe 2+<br />

Chelating agent<br />

Example: In situ Processing for<br />

Improved Flavor<br />

• Nature makes foods such as citrus bitter to<br />

as a df defense mechanism<br />

• Enzymes exist which degrade the bitter<br />

compounds<br />

4

Immobilization of Flavorenhancing<br />

Enzymes into<br />

Cellulose Ester Films<br />

• Debittering of citrus with naringinase<br />

5

Loss of naringin from grapefruit juice after exposure to CA<br />

film containing naringinase at 7°C<br />

Gas & Vapor Management<br />

• CO 2 ,O 2 , water vapor<br />

• Ethylene<br />

• 1-MCP as an inhibitor of ethylene<br />

receptors<br />

6

Equations for optimal<br />

permeability & atmosphere<br />

Al-Ati & Hotchkiss, 2004<br />

7

Permeabilities and Permselectivity for Selected<br />

Produce to Give Opt Atmosphere<br />

(1 mil, 4°C, mL·mil/cm 2 .hr.atm)<br />

P O2 P CO2 CO 2 /O 2<br />

Strberry 0.245 0.26 1.1<br />

Lettuce 0.049 0.47 9.5<br />

Broccoli 0.032 0.07 2.2<br />

Carrot 0.017 0.06 3.7<br />

Apple 0.017 0.10 6.3<br />

Celery 0.014 0.04 3.2<br />

Cabbage 0.008 0.03 3.0<br />

Grn Peppr 0.007 0.04 6.0<br />

Release of MCP from <strong>Packaging</strong><br />

Materials<br />

CH 2<br />

HC = C – CH 3<br />

8

Release of MCP from LDPE film<br />

containing sliced apples<br />

Antimicrobial Polymers:<br />

Potential Uses<br />

• <strong>Packaging</strong> (food contact films)<br />

• Non-packaging food contact tsurfaces<br />

– tables, filler nozzles, conveyer belts<br />

• Personal hygiene equipment<br />

– gloves, aprons, utensils<br />

• Machinery surfaces<br />

• Non-contact surfaces<br />

– refrigeration systems, walls, floors, drains<br />

9

Antimicrobial Polymers<br />

Migrating: Incorporation and generation<br />

of volatile & nonvolatile antimicrobials in<br />

films<br />

Non-migrating: Immobilization of<br />

antimicrobial agents to food packaging<br />

materials.<br />

Example: Antimicrobial<br />

Enzymes in Films<br />

• Immobilization of lysozyme in cellulosic<br />

ester films.<br />

10

Films Containing Antibiotics<br />

or Antimycotics: Hydrolysis of<br />

benzoic anhydride to benzoic acid<br />

11

Inhibition of Penicillium spp. on cheese by<br />

LDPE containing benzoic anhydride<br />

Nisin Impregnated Antimicrobial<br />

Film/Paper<br />

Hu et al 2000<br />

Scanell et al 2000<br />

12

Non-migrating “food additives”<br />

When is a food additive<br />

not a “food additive?”<br />

Potential Non-migrating<br />

Functional “Additives”<br />

• Anti-microbial<br />

• Enzymes<br />

• Chelating agents<br />

• Anti-oxidants<br />

• Selective aroma sorbents/reactants<br />

• Colors<br />

• Surface energy modifiers<br />

• Sanitizers<br />

• Indicators (chemical & biological)<br />

• Film physical and chemical modifiers<br />

13

Immobilized Functional Food<br />

Ingredients (Bio-active <strong>Packaging</strong>)<br />

Enzyme<br />

Antioxidant<br />

Antimicrobial<br />

Bulk<br />

Solution or<br />

Food<br />

Surface<br />

Bulk Polymer<br />

w modified<br />

surface<br />

Spacer<br />

Anchor<br />

<strong>Active</strong><br />

Agent<br />

Covalent attachment of Bioactive<br />

Molecules to Polymers<br />

Polymer surface<br />

Functionalized<br />

Polymer surface<br />

Functionalized<br />

Polymer surface<br />

Biofunctionalized<br />

Polymer surface<br />

Goddard et al 2006<br />

14

Surface Protein Content of PE Film Before<br />

and After Lactase Attachment<br />

8.00<br />

Avera age μg protein/ /cm 2<br />

7.00<br />

6.00<br />

5.00<br />

4.00<br />

3.00<br />

2.00<br />

1.00<br />

0.00<br />

a<br />

a<br />

a<br />

PE PE-COOH PE-NH2 PE-GL PE-LAC PE-LAC<br />

(SDS)<br />

a<br />

Film Sample<br />

b<br />

c<br />

Relative Activity of Free and Film-Attached Lactase<br />

Re elative Activ vity (%)<br />

100%<br />

90%<br />

80%<br />

70%<br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

0%<br />

4 5 6 7 8 9 10<br />

pH Value<br />

Free Lactase<br />

Film-Attached Lactase<br />

15

AFM view of modified<br />

surface of LDPE<br />

Antimicrobial Peptides<br />

• Occur widely in nature.<br />

• Typically 23 to 34 aa to 35-70 kDa proteins.<br />

• Amphipathic and highly basic (+ charge).<br />

• Helical structure.<br />

• Act at cell surface.<br />

• Permeabilize cell membrane.<br />

16

Synthetic antimicrobial peptide<br />

• 6K8L, leucine and lysine<br />

• low hemolytic activity, strong antimicrobial<br />

activity<br />

17

Changes in OD 600nm of E. coli 0157:H7 in TSB with ()<br />

or without () 50 μg/ml peptide 6K8L at 25°C<br />

(b)<br />

1.2<br />

1<br />

0.8<br />

OD 600nm<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0 20 40 60 80 100 120 140 160<br />

Time (min)<br />

18

Effect of peptide 6K8L on P. fluor., S. liquefac., S. typhy., E.<br />

coli survival in buffer at 25°C for 10 min.<br />

A.<br />

lo og 10<br />

CFU/ml<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

P.f luorescens<br />

S. liquef sciens<br />

S. t yphymurium<br />

E. coli O157:H7<br />

0 20 40 60<br />

Peptide (ug/ml)<br />

Effect of peptide 6K8L on S. aureus, L. mono., and B.<br />

subtilis, K. marxianus in buffer at 25°C for 10 min.<br />

B.<br />

log<br />

10<br />

CFU/ml<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

S. aureus<br />

L. monocytogenes<br />

B. subtilis<br />

K. marxianus<br />

0 20 40 60<br />

Peptide (ug/ml)<br />

19

Peptide Immobilization<br />

• PS resin bead---spacer molecule---peptide<br />

• 345 mg (0.2 mmol) peptide/g resin<br />

• Surface modified polystyrene (SMPS)<br />

Immobilization on PS Beads<br />

Peptide<br />

Spacer<br />

Molecule<br />

Polymer<br />

Bead<br />

20

Effect of 0, 6, 10, 20, 40 mg/ml of SMPS on E. coli 0157:H7<br />

growth in TBS at 25°C. () PS control<br />

12<br />

10<br />

Log10 CFU/ml<br />

L<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 5 10 15 20<br />

Time (h)<br />

21

Concentration (mg/ml) of SMPS required to give a 3 log<br />

reduction in counts in buffer in 10, 30, or 60 min at 25°C<br />

• ORGANISM 10 MIN 30 MIN 60 MIN.<br />

• E. coli 0157:H7 8 5 4<br />

• S. typhimurium 18 17 8<br />

• S. liquefasciens 8 5 ND<br />

• P. fluorescens 7 5 3<br />

• B. subtltis 3 3 2<br />

• L.monocytogenes 12 5 3<br />

• S. aureus >60 57 50<br />

• K. marxiamus 16 9 8<br />

Conclusions<br />

• Surfaces can be reasonably made bioactive<br />

with commercial chemistry.<br />

• Bioactive materials can be covalently<br />

attached to surfaces with acceptable loss of<br />

activity.<br />

• <strong>Active</strong>/smart packaging materials may be<br />

useful in foods and biomedicine.<br />

22

"Discovery is seeing what<br />

everyone has seen and<br />

thinking what<br />

nobody has thought"<br />

-- Albert Szent-Gyogyi<br />

23