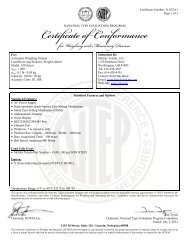

Certificate Number: 96-092A5 Page 1 of 3 1135 M ... - Mettler Toledo

Certificate Number: 96-092A5 Page 1 of 3 1135 M ... - Mettler Toledo

Certificate Number: 96-092A5 Page 1 of 3 1135 M ... - Mettler Toledo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Certificate</strong> <strong>Number</strong>: <strong>96</strong>-<strong>092A5</strong><br />

<strong>Page</strong> 1 <strong>of</strong> 3<br />

For:<br />

Weighing/Load Receiving Element<br />

Vehicle Scale, Modular design, Load Cell Electronic<br />

Model: 7563, VTS311<br />

n max : 10 000<br />

e min : 20 lb<br />

Capacity: 120 000 to 400 000<br />

CLC: Up to 100 000 lb<br />

Accuracy Class: III L<br />

Submitted By:<br />

<strong>Mettler</strong>-<strong>Toledo</strong>, LLC<br />

1150 Dearborn Drive<br />

Worthington, OH 43085<br />

Tel: 614-438-4393<br />

Fax: 614-438-4355<br />

Contact: Scott Davidson<br />

Email: scott.davidson@mt.com<br />

Web site: www.mt.com<br />

Standard Features and Options<br />

Installations must satisfy the relationship <strong>of</strong> v min d/N (d = division size and N= number <strong>of</strong> load cells) and nominal capacity<br />

CLC x (N - 0.5), where N is the number <strong>of</strong> sections in the scale.<br />

The relationship <strong>of</strong> the value for the load cell verification interval (v min ) to the scale division (e) for a specific scale<br />

installation shall be: v min e N (where N is the number <strong>of</strong> load cells in the scale)<br />

Note: On a side-by-side installation such as this, where the two weighing elements that make up the system are not mechanically<br />

connected together, the number <strong>of</strong> sections is the total number <strong>of</strong> sections on both weighing elements.<br />

Increased platform areas and lengths for scales with two or more modules are not restricted as long as the width complies with the<br />

parameters below and the load cells meet the v min formula.<br />

Additional modules to increase length must be <strong>of</strong> the same type as those used in the device submitted for evaluation.<br />

Range <strong>of</strong> Module Lengths: 8.5 feet to 24 feet<br />

Scale Deck Type: Steel or Concrete<br />

Range <strong>of</strong> Module Widths: 7 feet to 12 feet<br />

Scale Pit Type: Pit or Above Ground Installation<br />

Maximum capacity for single width scales is 200 000 lb<br />

Maximum capacity for double width scales is 400 000 lb. These will consist <strong>of</strong> 2 independent platforms installed side by side and<br />

will function as a complete scale for weighing large <strong>of</strong>f road vehicles.<br />

Load Cells Used:<br />

<strong>Mettler</strong>-<strong>Toledo</strong> Model 760 (NTEP CC No. 88-091), Model SLC820 (NTEP CC No. 08-090) or other NTEP certified metrologically<br />

equivalent.<br />

Temperature Range: -10 ºC to 40 ºC (14 ºF to 104 ºF)<br />

This device was evaluated under the National Type Evaluation Program and was found to comply with the applicable technical requirements <strong>of</strong> "NIST Handbook 44:<br />

Specifications, Tolerances and Other Technical Requirements for Weighing and Measuring Devices." Evaluation results and device characteristics necessary for<br />

inspection and use in commerce are on the following pages.<br />

Stephen Benjamin<br />

Chairman, NCWM, Inc.<br />

Kurt Floren<br />

Chairman, National Type Evaluation Program Committee<br />

Issued: February 8, 2013<br />

<strong>1135</strong> M Street, Suite 110 / Lincoln, Nebraska 68508<br />

The National Conference on Weights and Measures (NCWM) does not approve, recommend or endorse any proprietary product or material, either as a single item or as<br />

a class or group. Results shall not be used in advertising or sales promotion to indicate explicit or implicit endorsement <strong>of</strong> the product or material by the NCWM.

<strong>Certificate</strong> <strong>Number</strong>: <strong>96</strong>-<strong>092A5</strong><br />

<strong>Page</strong> 2 <strong>of</strong> 3<br />

<strong>Mettler</strong>-<strong>Toledo</strong>, LLC<br />

Weighing/Load Receiving Element / 7563, VTS311<br />

Application: For use in general purpose weighing <strong>of</strong> vehicles.<br />

Identification: The required information is located on a metal identification badge that is riveted to the side <strong>of</strong> the gap cover support<br />

bar located at section two (2) <strong>of</strong> scale deck.<br />

Sealing: The load cell junction box contains no adjustments for sections or cells. All metrological functions are done through the<br />

indicator.<br />

Test Conditions: This certificate supersedes <strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-092A4 and is issued to add model name<br />

VTS311. The model VTS311 is metrological equivalent to the existing model listed on the certificate. Also added the load cell model<br />

SLC820 (NTEP CC No. 08-090) in the Standard Features and Option Box. No additional testing was deemed necessary. Previous test<br />

conditions are listed below for reference.<br />

<strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-092A4: This <strong>Certificate</strong> is issued without testing to include the CLC in the "For" box,<br />

which was inadvertently omitted from revision <strong>96</strong>-092A3. Wording was also changed in the test conditions section under CC <strong>96</strong>-<br />

092A2 to clarify the determination <strong>of</strong> the number <strong>of</strong> sections for this type <strong>of</strong> side-by-side configuration vehicle scales. An example<br />

picture <strong>of</strong> the device has also been added to the certificate.<br />

<strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-092A3: This certificate supersedes <strong>Certificate</strong> <strong>of</strong> Conformance number <strong>96</strong>-092A2 and is<br />

issued to increase the CLC from 80 000 lb to 100 000 lb and to extend module length to 24 feet. The system capacity was 200 000 lb,<br />

90' x 11' concrete deck. The scale was initially tested using 104 000 lb <strong>of</strong> known test weights. 90 000 lb was used to conduct the CLC<br />

shift test, and a strain load test was conducted to 1<strong>96</strong> 740 lb, using 104 000 lb <strong>of</strong> known test weights. Increasing/decreasing load tests<br />

and shift tests were conducted using the 104 000 lb known test weights. The scale was used for over 90 days, with the minimum use<br />

criteria required by NTEP, then tested again. The increasing/decreasing load, and mid span tests were repeated using 50 000 lb known<br />

test weights. Strain load tests were again conducted to a load <strong>of</strong> 143 000 lb.<br />

<strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-092A2: This <strong>Certificate</strong> is issued without testing to correct the CLC covered for the model<br />

7563 Vehicle Scale. The reference to a 160 000 lb CLC for side-by-side installations was determined to be inappropriate and removed.<br />

An explanatory note to explain determination <strong>of</strong> the number <strong>of</strong> sections when the scale is side-by-side and not mechanically connected<br />

together was added in the "Standard Features and Options" box.<br />

<strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-092A1: This certificate supersedes and replaces <strong>Certificate</strong> <strong>of</strong> Conformance number <strong>96</strong>-092<br />

and is issued to include a double wide scale configuration. The emphasis <strong>of</strong> the evaluation was on the design and performance <strong>of</strong> the<br />

double wide weighing element. Two four module (17.5' per module), 200 000 lb, 70' x 7' (steel deck and above ground installation),<br />

80 000 lb CLC scales, installed side by side with a 2' concrete divider between the platforms were interfaced with a <strong>Mettler</strong>-<strong>Toledo</strong><br />

Model 8530 Indicator (<strong>Certificate</strong> <strong>of</strong> Conformance number 88-259) for the evaluation. The system capacity was 400 000 lb and the<br />

CLC was 160 000 lb. The scale was initially tested using 146 500 lb <strong>of</strong> known test weights. Increasing/decreasing load tests and shift<br />

tests were conducted using the 146 500 lb known test weights. The 146 500 lb was also used to conduct mid span tests. Strain load<br />

tests were conducted using 146 000 lb <strong>of</strong> known test weights to a maximum load <strong>of</strong> 321 600 lb. Several tests were conducted using a<br />

large <strong>of</strong>f road vehicle loaded to 170 650 lb to establish repeatability. The field permanence test was waived due to the prior testing<br />

performed on the individual components <strong>of</strong> the scale system.<br />

<strong>Certificate</strong> <strong>of</strong> Conformance <strong>Number</strong> <strong>96</strong>-0<strong>96</strong>: The emphasis <strong>of</strong> the evaluation was on the design, marking, and performance <strong>of</strong> the<br />

weighing element. A four module (17.5' per module), 200 000 lb x 20 lb, 70' x 10' (steel deck and pit installation), 80 000 lb CLC<br />

scale was interfaced with a <strong>Mettler</strong>-<strong>Toledo</strong> Model 8530 Indicator (<strong>Certificate</strong> <strong>of</strong> Conformance number 88-259) for the evaluation. The<br />

scale was initially tested using 74 000 lb <strong>of</strong> known test weights. Increasing/decreasing load tests and shift tests were conducted using<br />

the 74 000 lb known test weights. The 74 000 lb was also used to conduct mid span tests. Strain load tests were conducted using 74<br />

000 lb known test weights to a maximum load <strong>of</strong> 164 280 lb. The scale was used for over 40 days, with the minimum use criteria<br />

required by NTEP, then tested again. The increasing/decreasing load, shift, and mid span tests were repeated using 43 000 lb known<br />

test weights. Strain load tests were again conducted to a maximum load <strong>of</strong> 129 240 lb.<br />

Evaluated By: A. McCoy (OH) <strong>96</strong>-092; W.West, M.Kelley, P. O’Connor, P. Cawood (OH) <strong>96</strong>-092A1; T. Davis (KS) <strong>96</strong>-092A3

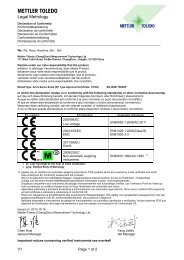

<strong>Certificate</strong> <strong>Number</strong>: <strong>96</strong>-<strong>092A5</strong><br />

<strong>Page</strong> 3 <strong>of</strong> 3<br />

<strong>Mettler</strong>-<strong>Toledo</strong>, LLC<br />

Weighing/Load Receiving Element / 7563, VTS311<br />

Type Evaluation Criteria Used: NIST, Handbook 44: Specifications, Tolerances and Other Technical Requirements for Weighing<br />

and Measuring Devices, 2004. NCWM, Publication 14: Weighing Devices, 2004.<br />

Conclusion: The results <strong>of</strong> the evaluation and information provided by the manufacturer indicate the device complies with applicable<br />

requirements.<br />

Information Reviewed By: W. West (OH), <strong>96</strong>-092A2, S. Patoray (NCWM) <strong>96</strong>-092A2, <strong>96</strong>-092A3; J. Truex (NCWM) <strong>96</strong>-092A4, <strong>96</strong>-<br />

<strong>092A5</strong><br />

Example <strong>of</strong> Device: