Elastaseal Fibretex RC104 Product Data Sheet - Promain

Elastaseal Fibretex RC104 Product Data Sheet - Promain

Elastaseal Fibretex RC104 Product Data Sheet - Promain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

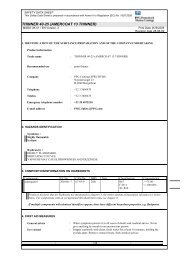

<strong>Elastaseal</strong> fibretex<br />

<strong>RC104</strong><br />

intended uses<br />

product description<br />

Waterproofing membrane coating for protection of sound (small) flat and pitched roofs,<br />

etc. One or two coat system (either stand alone or with <strong>Elastaseal</strong> Top Coat RC101)<br />

depending on substrate conditions, required degree of protection, etc. Also used as<br />

bridging stripe coat on firm lap joints, bolt heads, during refurbishment of profiled metal<br />

sheeted roofs. This product is also used as the elastomeric buildcoat in the Tordeck<br />

PB System.<br />

Cold applied single pack, ultra high solids, moisture activated, elastomeric urethane<br />

containing inert reinforcement fibres. High elasticity allows membrane to “move”<br />

without cracking or splitting. Internal reinforcement often avoids the need to use dry<br />

reinforcement scrims, matting etc, on tight lap joints, bolt heads etc.<br />

product information <strong>Product</strong> reference <strong>RC104</strong><br />

Volume solids 76%<br />

Typical thickness<br />

Theoretical coverage<br />

Practical coverage<br />

Appearance/Colour range<br />

0.6-0.75mm dft per coat<br />

1.0-1.25 m 2 /litre/coat<br />

Dependent on surface profile and condition, reduce by<br />

20% upwards<br />

Fibrous, low sheen/Dove Grey, Slate Grey<br />

VOC content EU Limit value for this product (Cat A/I ):600g/l (2007)<br />

500g/l (2010) . This <strong>Product</strong> contains a maximum of<br />

283g/l<br />

application details Mix ratio N/A (single pack material)<br />

Method of application<br />

Brush or short/medium pile roller. Work material well<br />

into substrate and build up to required thickness. Apply<br />

generous quantities to joints etc, stripe coating if<br />

necessary prior to application of main coat.<br />

Thinner<br />

Cleaner<br />

Pot Life<br />

Drying time<br />

Substrate<br />

Temperature<br />

DO NOT THIN<br />

TH99<br />

N/A<br />

(0.8mm wet film)<br />

Touch Dry Hard Dry Overcoating Interval<br />

Minimum Maximum<br />

20 o C 4 hours 16 hours 8 hours 7 days<br />

Note: Drying/curing times will be shortened by higher temperatures and lengthened by<br />

lower temperatures<br />

storage and handling Storage Store in a safe dry place out of the reach of children.<br />

Pack Size<br />

5 litres<br />

Flash point<br />

<strong>Product</strong> weight<br />

Shelf life<br />

43 o C (approx)<br />

1.4 kilos/litre (approx)<br />

6 months form manufacturing date in unopened<br />

containers at moderate temperatures.<br />

Tor Coatings Limited • Portobello Industrial Estate • Birtley • Chester-le-Street • County Durham • DH3 2RE<br />

Tel: +44 (0)191 4106611 • Fax: +44 (0)191 4920125 • E-mail: enquiries@tor-coatings.com<br />

Revision No: 1 Revision Date:11/12/2007 Page 1 of 2

surface preparation<br />

limitations<br />

safety precautions<br />

Inspect all surfaces to assess soundness of existing substrates or coatings. Where<br />

necessary prepare test areas.<br />

Roof surfaces must be clean, visibly dry and free from all loose debris and roof<br />

contaminants. Repairs to cracks, holes, blisters etc, should be carried out before<br />

application of the coating. All areas of fungal growth, moss, etc should be treated with<br />

Torkill W Anti Fungal Wash, and neutralised residues removed.<br />

Priming, where necessary, should be carried out using suitable compatible materials.<br />

Contact Tor Coatings Technical Department for further advice.<br />

Do not apply if rain is imminent.<br />

Overcoating must be carried out within the timescale overleaf otherwise further<br />

preparation will be necessary.<br />

Take out a working quantity from the tin and re-seal immediately to minimise wastage.<br />

A copy of the appropriate Health & Safety <strong>Data</strong> <strong>Sheet</strong> should be consulted prior to<br />

using the product. This can be faxed if urgently required.<br />

Minimum precautions for all paints:<br />

1. Avoid skin and eye contact i.e. wear gloves, goggles, etc<br />

2. Ensure good ventilation, mechanical if necessary.<br />

3. Store and use away from heat and flame.<br />

4. Do not eat or smoke in the vicinity of work.<br />

5. Wash hands before eating.<br />

6. Refer to supply container for additional warning labels.<br />

definitions Tolerances All information quoted in this data sheet is subject to<br />

normal manufacturing tolerances.<br />

Practical coverage<br />

Pot Life<br />

Practical coverage can vary considerably depending<br />

on method of application, surface roughness, weather<br />

conditions and complexity of the structure.<br />

Applies only to two component products and refers to<br />

the time the mixture remains usable.<br />

disclaimer<br />

The information contained herein is to the best of our knowledge true and accurate<br />

and is given in good faith but without warranty. The user will be deemed to have<br />

satisfied him/herself independently as to the suitability of our products for his/her own<br />

particular purpose. In no event shall Tor Coatings be liable for consequential or<br />

incidental damages.<br />

Tor Coatings Limited • Portobello Industrial Estate • Birtley • Chester-le-Street • County Durham • DH3 2RE<br />

Tel: +44 (0)191 4106611 • Fax: +44 (0)191 4920125 • E-mail: enquiries@tor-coatings.com<br />

Revision No: 1 Revision Date:11/12/2007 Page 2 of 2