You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

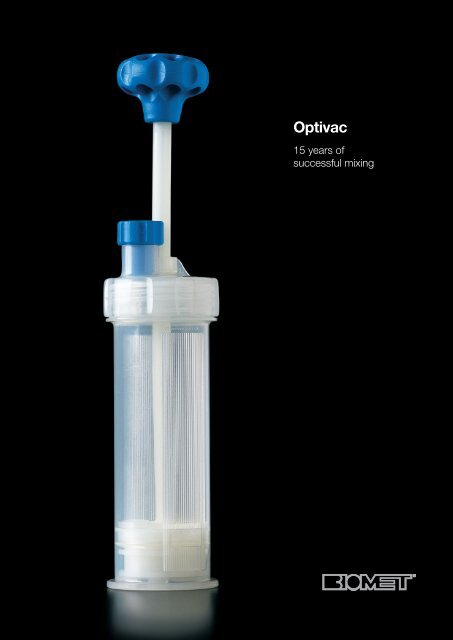

<strong>Optivac</strong><br />

15 years of<br />

successful mixing

Congratulations <strong>Optivac</strong>!<br />

Aseptic loosening due to porosity in bone<br />

cement has been a major problem since the<br />

start of cemented hip arthroplasty. The first<br />

experiments to reduce porosity in bone cement<br />

took place almost 25 years ago. This later led to<br />

the patented invention of bone cement collection<br />

under vacuum, which has been proven to<br />

eliminate macropores. In 1993, <strong>Optivac</strong> was<br />

introduced on the market and now celebrates<br />

15 years of successful mixing.<br />

<strong>Optivac</strong> is the world-leading vacuum mixing<br />

system and is a result of many years of<br />

continuous improvement.<br />

<strong>Optivac</strong> is unmatched in documentation<br />

among vacuum mixing systems. 1,2,3,4,5<br />

2 | O P T I V A C

The <strong>Optivac</strong> system is used in<br />

more than 45 countries worldwide<br />

Cement mixed under vacuum 7 Cement mixed at atmospheric pressure 7<br />

Improvement of bone cement quality<br />

Minimized porosity and improved<br />

mechanical strength<br />

Cement porosity directly affects the fatigue<br />

behavior of the bone cement. Reducing the<br />

number of pores can lead to remarkable<br />

improvements in cement strength and fatigue life.<br />

Several methods have been introduced in the<br />

interest of reducing cement porosity, the most<br />

efficient of which is applying vacuum throughout<br />

the mixing and collection of the cement. The<br />

fatigue life improves 10 times with vacuum mixing<br />

at 4º C compared to hand mixing. 6<br />

Improvement of bone cement quality by using a<br />

vacuum mixing system is one of the key pillars in<br />

Modern Cementing Technique.<br />

O P T I V A C | 3

Improvement of bone cement quality<br />

Mixing and collection under<br />

vacuum minimizes both<br />

macropores and micropores<br />

Comparison of vacuum mixing with<br />

or without collection 7<br />

Two types of pores are classified in fully<br />

polymerized bone cement:<br />

1) macropores, with a pore diameter of more<br />

than 1.0 mm.<br />

2) micropores, with a pore diameter of<br />

0.1–1 mm. 1,8<br />

Mixing under vacuum reduces the cement’s<br />

microporosity, but has less effect on macroporosity.<br />

Continuous vacuum – from mixing to<br />

collection – prevents macropore entrapment in<br />

high viscosity cement.<br />

With its patented design for collection<br />

under vacuum, <strong>Optivac</strong> reduces both<br />

microporosity and macroporosity. 1,5,4,2,9<br />

By dramatically reducing macroporosity,<br />

<strong>Optivac</strong> helps to prolong cement fatigue life.<br />

4 | O P T I V A C ®<br />

Bone cement<br />

mixed with a<br />

vacuum mixing<br />

system without<br />

collection under<br />

vacuum. High<br />

occurrence of<br />

macropores.<br />

Bone cement<br />

mixed with a<br />

vacuum mixing<br />

system with<br />

collection under<br />

vacuum.

Safe working environment<br />

<strong>Optivac</strong> meets modern safety standards and the<br />

high demands on mixing bone cement. Bone<br />

cement in <strong>Optivac</strong> is mixed and delivered in the<br />

same cartridge, precluding direct contact with the<br />

bone cement.<br />

The packing is PVC free and the blister pack<br />

also serves as a working tray, which minimizes<br />

the waste.<br />

<strong>Optivac</strong> contains no latex.<br />

By drawing monomer fumes through special<br />

filters, <strong>Optivac</strong> minimizes MMA exposures in<br />

the OR to barely detectable levels.<br />

Retrograde filling<br />

Optigun and Optigun Ratchet are used to deliver<br />

bone cement from the <strong>Optivac</strong> vacuum mixing<br />

system in a retrograde fashion. The guns are<br />

identical except for the feeding mechanism and<br />

rod. With the Optigun and Optigun Ratchet<br />

you will get adequate cement filling and the<br />

application under pressure will increase the<br />

cement’s interface strength and prevent air and<br />

blood inclusions in the cement mantle. 3,11<br />

The Swedish Arthroplasty Register has shown<br />

that retrograde cement filling of the femur<br />

reduces risk of revision and is an important step<br />

in Modern Cementing Technique. 10<br />

O P T I V A C | 5

Standardized procedure and a flexible system<br />

The <strong>Optivac</strong> standardized mixing procedure<br />

produces homogeneous cement with the lowest<br />

possible porosity.<br />

All types of bone cements can be mixed with the<br />

<strong>Optivac</strong> system. <strong>Optivac</strong> is adaptable to various<br />

application areas, such as hip, knee or shoulder<br />

arthroplasty. Suitable nozzles can be found in<br />

our assortment to be used for different types of<br />

application areas.<br />

Depending on the amount of the bone cement<br />

required, choose the suitable <strong>Optivac</strong> cartridge.<br />

Three sizes of <strong>Optivac</strong> cartridges are available,<br />

small, medium and large.<br />

Mixing is easy, requiring only a few simple steps.<br />

Illustrated step-by step instructions can be found<br />

on every product.<br />

<strong>Optivac</strong> was introduced in<br />

1993 and celebrates 15 years<br />

of successful mixing<br />

All sets include cartridge, nozzle, a vacuum line with sterile<br />

charcoal filter, a funnel, ampoule breakers and a working<br />

tray. The <strong>Optivac</strong> Hip and <strong>Optivac</strong> M sets also include<br />

a femoral pressurizer for optimal pressurization of the<br />

femoral canal.<br />

6 | O P T I V A C

Ordering information<br />

<strong>Optivac</strong> sets<br />

REF<br />

For low volume cements<br />

<strong>Optivac</strong> Hip Set ...................................... 4150<br />

<strong>Optivac</strong> S ............................................... 4161<br />

<strong>Optivac</strong> M .............................................. 4160<br />

<strong>Optivac</strong> L ............................................... 4152<br />

For high volume cements<br />

<strong>Optivac</strong> + Hip Set ................................... 4250<br />

Instrumentation<br />

REF<br />

Optigun .................................... 4193<br />

Optigun Ratchet...................................... 4195<br />

Vacuum pump ........................................ 4232<br />

Accessories<br />

REF<br />

Nozzle angled......................................... 4149<br />

<strong>Optivac</strong> Nozzle Knee............................... 4146<br />

Nozzle slim ............................................. 4154<br />

Nozzle revision ....................................... 4155<br />

Knee cementation nozzle ........................... 4312<br />

Nozzle cutter .......................................... 4159<br />

O P T I V A C | 7

References<br />

1 Wang J-S, Franzén H, Jonsson E, Lidgren L. Porosity of bone<br />

cement reduced by mixing and collecting under vacuum. Acta<br />

Orthop Scand 1993, 64 (2): 143-146.<br />

2 Wang J-S, Kjellson F. Bone Cement Porosity in Vacuum Mixing<br />

Systems, Bone Cements and Cementing Technique 2001,<br />

Walenkamp, Murray (Eds). Springer Verlag.<br />

3 Malchau H, Herberts P, Garellick G, Söderman P, Eisler T.<br />

Prognosis of Total Hip Replacement. Scientific Exhibition<br />

presented at the 69 the Annual meeting of the American Academy<br />

of Orthopaedic Surgeons. February 13-17, 2002, Dallas.<br />

4 Dunne N-J, Orr J.F. Influence of the mixing techniques on the<br />

physical properties of acrylic bone cement. Biomaterials 2001; 22:<br />

1819-1826.<br />

5 Wilkinson J.M., Stockely I, et al. Effect of mixing techniques on the<br />

Properties of Acrylic Bone-Cement, The Journal of Arthroplasty,<br />

2000; 15:663-667.<br />

6 Wang J-S, Toksvig-Larsen S, Muller-Wille P, Franzen H. Is there<br />

any difference between vacuum mixing systems in reducing bone<br />

cement porosity? Journal of Biomedical Materials Research. 1996;<br />

33: (2):115-8.<br />

7 Lidgren L, Bodelind B, Möller J. Bone cement improved by vacuum<br />

mixing and chilling, Acta Orthop Scand 1987; 57: 27-32.<br />

8 Lewis G. Properties of Acrylic Bone Cement: State of Art Review, J<br />

Biomed Mater Res. 1997; 38 (2): 155-82<br />

9 Breusch S, Cementing Techniques in Total Hip Replacement:<br />

Factors Influencing Survival of Femoral Components, In Bone<br />

cements and Cementing technique ed by Walenkamp G, Murray<br />

D, Springer Verlag 2001.<br />

10 Oates KM; Barrera DL; Tucker WN; Chau CC, Bugbee WK,<br />

Convery FR In vivo effect or pressurization of polymethyl<br />

methacrylate bone cement. Biomechanical and histologic analyis.<br />

J Arthroplasty 1995; 10(3), pp. 373-381<br />

11 McCaskie AW, Barnes MR, Lin E, Harper WM, Gregg PJ. Cement<br />

pressurisation during hip replacement. J Bone Joint Surg Br. 1997;<br />

May:79(3):379-84.<br />

<strong>Optivac</strong> is a trademark of <strong>Biomet</strong> Cementing Technologies AB.<br />

©2011 <strong>Biomet</strong>. All rights reserved.<br />

Patents U.S. 5 328 262, U.S. 5 501 520.<br />

For further inquires please contact: <strong>Biomet</strong> Cementing Technologies<br />

Box 306, 201 23 Malmö, Sweden · Phone + 46 40 669 7000<br />

www.bonecement.com · se.bonecement@biomet.com<br />

Responsible manufacturer: <strong>Biomet</strong> France Sarl<br />

58 Avenue de LAUTAGNE, BP75, 26903 Valence Cedex 9, FRANCE<br />

Ref: BR4150-02 · CO 10-0223