Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSTRUCTIONS FOR USE<br />

CIRCUIT - BREAKER<br />

<strong>ARION</strong> <strong>WL</strong><br />

OEZ servicing department ensures circuit breaker retrofit and completion of accessories.<br />

Installation, service and maintenance of the electrical equipment may be carried out by<br />

an authorized person only.<br />

Non-observance of this condition may result in loss of warranty!<br />

<strong>991061a</strong> Z00

LIFTING BY CRANE<br />

Caution<br />

Do not place beaker<br />

on its rear side!<br />

!<br />

1 m<br />

><br />

Breaker Guide frame Breaker<br />

+<br />

guide frame<br />

max 12 mm<br />

1 m<br />

><br />

max 12 mm<br />

1)<br />

1 m<br />

><br />

max 12 mm<br />

1)<br />

Frame size/No. of poles<br />

Weight<br />

I / 3<br />

I / 4<br />

II / 3<br />

II / 4<br />

III / 3<br />

III / 4<br />

43 kg<br />

50 kg<br />

max. 64 kg<br />

max. 77 kg<br />

max. 90 kg<br />

max. 108 kg<br />

25 kg<br />

30 kg<br />

max. 45 kg<br />

max. 54 kg<br />

max. 70 kg<br />

max. 119 kg<br />

70 kg<br />

84 kg<br />

max. 113 kg<br />

max. 136 kg<br />

max. 166 kg<br />

max. 227 kg<br />

1)<br />

Hook cable above the label<br />

- 2 - <strong>991061a</strong> Z00

DESIGN<br />

Circuit - breaker<br />

28<br />

27<br />

26<br />

25<br />

24<br />

23<br />

22<br />

21<br />

20<br />

19<br />

18<br />

17<br />

16<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

1 Arc chute<br />

2 Carrying handle<br />

3 Identification tags<br />

4 Motor disconnect switch (option) or "Electrical ON" (option)<br />

5 Type label circuit - breaker<br />

6 Stored - energy indicator<br />

7 "Mechanical ON" button<br />

8 Ampere rating<br />

9 Racking pictogram<br />

10 Make-break operations counter (option)<br />

11 Spring charging lever<br />

12 Racking handle<br />

13 Draw - out unit transport shaft<br />

14 Options label<br />

15 Earthing terminal<br />

16 Position indicator<br />

17 Table for earth-fault protection<br />

18 Safety lock for racking handle (option)<br />

19 Mechanical release of racking hadndle<br />

20 Overcurrent release<br />

21 Rating plug<br />

22 "Mechanical OFF" button or<br />

"EMERG<strong>EN</strong>CY OFF" mushroom button (option)<br />

23 Ready-to-close indicator<br />

24 Breaker ON/OFF indicator<br />

25 Tripped indicator (Reset button)<br />

26 Locking device "Safe OFF" (option)<br />

27 Front panel<br />

28 Receptacle for auxiliary contacts<br />

Guide frame<br />

1<br />

2<br />

1 Arc chute cover (option)<br />

2 Arcing openings<br />

18<br />

17<br />

16<br />

15<br />

14<br />

13<br />

12<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

3 Hole for crane hook<br />

4 Shutter (option)<br />

5 Locking device shutter (option)<br />

6 Type label guide frame<br />

7 Disconnecting contacts<br />

8 Eartihng terminal 14<br />

9 Locking device guide rail<br />

10 Locking device to prevent racking with cubicle door open<br />

(option)<br />

11 Door interlocking guide frame (option)<br />

12 Guide rail<br />

13 Ampere rating cording by factory<br />

14 Sliding contact for circuit-breaker earthing (option)<br />

15 Option-related coding (option)<br />

16 Shutter operating device (option)<br />

17 Position signalling switch (option)<br />

18 Auxiliary disconnects (quantily according to equipment)<br />

11<br />

10<br />

9<br />

- 3 - <strong>991061a</strong> Z00

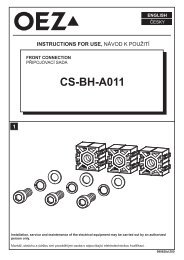

CONNECTING BARS<br />

Fixed-mounted breaker<br />

Horizontal connection<br />

(standard version)<br />

Front connection<br />

single hole double hole raw<br />

Vertical<br />

connection<br />

Guide frame<br />

Horizontal connection<br />

(standard version)<br />

Front connection<br />

single hole double hole raw<br />

Vertical<br />

connection<br />

Flange<br />

connection<br />

AUXILIARY CONDUCTORS<br />

Hand plug SIGUT<br />

(standard)<br />

Hand plug screwless terminal system<br />

(option)<br />

Auxiliary<br />

disconnects<br />

Receptacle<br />

Coding set<br />

For connection of auxiliary circuits, the circuit breakers of fixed version are equipped with manually plug-in<br />

terminal boards with coding pins, which eliminate misuse of the terminal boards in their connecting with<br />

the block of the citcuit breaker blade contacts.The contacts of auxiliary circuits of circuit breakers of<br />

withdrawable version are inserted automatically in circuit breaker moving into the frame.<br />

Conductors of auxiliary circuits are connected to terminal boards in two ways (see the figure).<br />

- 4 - <strong>991061a</strong> Z00

MINIMAL CROSS-SECTIONS OF MAIN LEADS<br />

Frame<br />

size<br />

Breaker<br />

type<br />

to<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1110<br />

I II III<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1112<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1116<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1208<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1210<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1212<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1216<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1220<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1225<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1232<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1340<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1350<br />

<strong>ARION</strong><br />

<strong>WL</strong> 1363<br />

Cu busbars<br />

bare<br />

[mm]<br />

Cu busbars<br />

black<br />

coated<br />

[mm]<br />

1 x<br />

60 x 10<br />

1 x<br />

60 x 10<br />

2 x<br />

40 x 10<br />

2 x<br />

40 x 10<br />

2 x<br />

50 x 10<br />

2 x<br />

50 x 10<br />

1 x<br />

50 x 10<br />

1 x<br />

50 x 10<br />

1 x<br />

60 x 10<br />

1 x<br />

60 x 10<br />

2 x<br />

40 x 10<br />

2 x<br />

40 x 10<br />

2 x<br />

50 x 10<br />

2 x<br />

50 x 10<br />

3 x<br />

50 x 10<br />

3 x<br />

50 x 10<br />

2 x<br />

100 x 10<br />

2 x<br />

100 x 10<br />

3 x<br />

100 x 10<br />

3 x<br />

100 x 10<br />

4 x<br />

100 x 10<br />

4 x<br />

100 x 10<br />

6 x<br />

100 x 10<br />

6 x<br />

100 x 10<br />

6 x<br />

100 x 10<br />

6 x<br />

100 x 10<br />

- 5 - <strong>991061a</strong> Z00

INSTALLATION<br />

MOUNTING DIM<strong>EN</strong>SIONS<br />

Fixed-mounted version:<br />

(standard version)<br />

d<br />

b<br />

a<br />

d<br />

e<br />

210<br />

230<br />

c<br />

127<br />

150<br />

Mounting area to remove the arc chutes<br />

Arcing space<br />

Cubicle door<br />

541,5<br />

461,5<br />

275<br />

150<br />

76 327,5<br />

106<br />

Frame size<br />

<strong>ARION</strong> <strong>WL</strong> I<br />

3 - pole<br />

a [mm] b [mm] c [mm] d [mm] e [mm]<br />

300 320 8 90 60<br />

4 - pole<br />

a [mm] b [mm] c [mm] d [mm] e [mm]<br />

390 410 8 90 60<br />

<strong>ARION</strong> <strong>WL</strong> II<br />

440 460<br />

8<br />

130<br />

90<br />

570 590<br />

8<br />

130<br />

90<br />

<strong>ARION</strong> <strong>WL</strong> III<br />

680 704<br />

10<br />

210<br />

130<br />

890 914<br />

10<br />

210<br />

130<br />

- 6 - <strong>991061a</strong> Z00

Withdrawable:<br />

(standard version)<br />

320<br />

d d e<br />

∅13,5<br />

b<br />

a<br />

f<br />

220<br />

367,5<br />

382,5<br />

c<br />

Test position<br />

Disconnected position<br />

76<br />

150<br />

275<br />

460<br />

327,5<br />

45<br />

45<br />

88,5<br />

121,5<br />

140,5<br />

Frame size<br />

<strong>ARION</strong> <strong>WL</strong> I<br />

3 - pole 4 - pole<br />

a [mm] b [mm] c [mm] d [mm] e [mm] f [mm] a [mm] b [mm] c [mm] d [mm] e [mm] f [mm]<br />

210 320 10 90 70 55 300 410 10 90 70 55<br />

<strong>ARION</strong> <strong>WL</strong> II<br />

350 460<br />

10<br />

130<br />

100<br />

55<br />

480 590<br />

10<br />

130<br />

100<br />

55<br />

<strong>ARION</strong> <strong>WL</strong> III<br />

590 704<br />

10<br />

210<br />

142<br />

57<br />

800 914<br />

10<br />

210<br />

142<br />

57<br />

- 7 - <strong>991061a</strong> Z00

MOUNTING POSITION<br />

Fixing points<br />

Mounting on horizontal surface<br />

Non-removable nut<br />

4 bolts M8-8.8<br />

4 bolts M8-8.8+nuts+strain washers<br />

If several draw-out circuit-breakers are arranged<br />

one above the other in cubicles without compartment<br />

bases we recommend to use arc chute covers.<br />

!<br />

On<br />

CONNECTING THE MAIN CONDUCTORS<br />

4-pole circuit-breakers, the neutral conductor must always be connected<br />

all on the left. Otherwise this can cause malfunctions of the electronic<br />

overcurrent release.<br />

Cleaning the main conductor<br />

connection<br />

- 8 - <strong>991061a</strong> Z00

Cleaning the copper bars<br />

Steel-wire<br />

brush<br />

Remove swarf<br />

Bolt tight line-side bars<br />

BRACING THE MAIN CONDUCTORS<br />

Rear connection<br />

Front connection<br />

support<br />

!When using front leads (withdrawable<br />

version), it is necessary to use supports.<br />

- 9 - <strong>991061a</strong> Z00

MANIPULATION WITH CIRCUIT-BREAKER<br />

Preparation of draw-out circuit breaker<br />

1. Unblocking racking handle / Withdrawing racking handle<br />

(see racking pictogram)<br />

1<br />

4<br />

Hold!<br />

2<br />

3<br />

2. Cranking the breaker into maintenance position<br />

5<br />

Stop<br />

Position<br />

indicator<br />

red<br />

blue<br />

green<br />

3. Inserting racking handle<br />

4. Removing the circuit-breaker<br />

from the guide frame<br />

1<br />

2<br />

3<br />

!Do not turn the crank handle beyond the stop! Otherwise the racking<br />

mechanism will be damaged.<br />

- 10 - <strong>991061a</strong> Z00

5. Mounting the guide frame into the cubicle<br />

see previous chapters<br />

6. Inserting the circuit-breaker in the guide frame<br />

1<br />

2<br />

click<br />

green<br />

1 Check breaker position indicator Ensure it shows DISCON.<br />

Otherwise the circuit-breaker cannot be inserted.<br />

2 Draw out guide rails.<br />

3<br />

4<br />

3 Place the circuit-breaker in the guide frame.<br />

4 Push it into disconnected position.<br />

7. Unblocking racking handle / Withdrawing racking handle<br />

1<br />

4<br />

Hold!<br />

2<br />

3<br />

5<br />

- 11 - <strong>991061a</strong> Z00

8. Racking circuit-breaker into connected position<br />

Stop<br />

Position indicator<br />

red<br />

blue<br />

green<br />

9. Inserting racking handle<br />

2<br />

1<br />

3<br />

4<br />

10. Close cubicle door<br />

!<br />

mechanism<br />

Do not turn the crank handle beyond the stop! Otherwise the racking<br />

will be damaged.<br />

- 12 - <strong>991061a</strong> Z00

11. Position of the breaker in the guide frame<br />

Diagram<br />

Position<br />

indicator<br />

Power<br />

circuit<br />

Auxiliary<br />

circuit<br />

Cubicle<br />

door Shutter *<br />

Maintenance<br />

position<br />

(1)<br />

(2)<br />

(4)<br />

green<br />

disconnected disconnected<br />

open<br />

closed<br />

Disconnected<br />

position<br />

(3)<br />

disconnected disconnected<br />

closed<br />

closed<br />

green<br />

Test<br />

position<br />

blue<br />

disconnected<br />

connected<br />

closed<br />

closed<br />

Connected<br />

position<br />

red<br />

connected<br />

connected<br />

closed<br />

open<br />

(1) Auxiliary circuit (2) Power circuit (3) Cubicle door (4) Shutter<br />

* only if it is installed<br />

- 13 - <strong>991061a</strong> Z00

COMMISSIONING<br />

CHECKLIST FOR COMMISSIONING<br />

Action required:<br />

Switch OFF circuit-breaker.<br />

Rack circuit-breaker into connected poition (only withdrawable version).<br />

Insert rating plug.<br />

Press red pin to reset (mechanical reclosing lockout).<br />

Set the overcurrent release to appropriate values.<br />

Apply auxiliary and control voltages.<br />

Insert racking handle (only withdrawable version).<br />

Charge storage spring.<br />

Close the cubicle door.<br />

Please ensure following:<br />

Under-voltage release.................................................................................... energized<br />

Shunt trip........................................................................................................ not energized<br />

Electrical closing lockout................................................................................ not energized<br />

Electrical interlocking of closing coil in the switch board control wiring.......... disabled<br />

Mutual mechanical interlock........................................................................... not effective<br />

Locking devices.............................................................................................. not activated<br />

Indications:<br />

CLOSING<br />

ON button<br />

Electrical ON<br />

or<br />

Indications:<br />

Without motor<br />

operating mechanism<br />

With motor operating<br />

mechanism after 10s<br />

The storage spring will be recharged by the motor operating<br />

!mechanism immediately after the breaker has closed.<br />

- 14 - <strong>991061a</strong> Z00

SWITCHING OFF<br />

ON button<br />

Indications:<br />

Without motor operating<br />

mechanism<br />

With motor operating<br />

mechanism after 10s<br />

TRIPPING BY OVERCURR<strong>EN</strong>T RELEASE<br />

Overcurrent trip:<br />

Tripped indicator<br />

Indications:<br />

Without motor operating<br />

mechanism<br />

With motor operating<br />

mechanism after 10s<br />

- 15 - <strong>991061a</strong> Z00

OVERCURR<strong>EN</strong>T RELEASE ETU25B<br />

Mechanical RESET<br />

for reclosing lockout<br />

Options:Safety lock,<br />

prevents accidentat<br />

reseting of the lock-out<br />

mechanism after a trip<br />

Indicator overcurrent<br />

release activated<br />

Indicator overload alarm<br />

Trip unit error indicator<br />

Rating plug<br />

Rotary coding switch<br />

long time delay<br />

pickup setting<br />

Rotary coding<br />

switch short time<br />

delay pickup setting<br />

Fixed<br />

instantaneous<br />

pickup<br />

Query button<br />

Test button<br />

Trip cause indicator *<br />

Rotary coding switch<br />

short time delay setting<br />

Sealing eyelet<br />

Clear button<br />

Test connector<br />

* The trip cause is stored internally for at least two days, if the overcurrent release had been activated<br />

for at least 10 min before tripping.<br />

- 16 - <strong>991061a</strong> Z00

Overcurrent protection settings<br />

Adjust parameters only when the circuit-breaker is switched off. If the<br />

parameters are modified with the circuit-breaker switched on, this can<br />

!trip the circuit-breaker unintentionally.<br />

All parameters are adjusted with rotary coding switches.<br />

3 x 0,5<br />

The value 0,1 is set<br />

if the rotary switch is<br />

positioned in this zone.<br />

Protective functions<br />

- overload protection (L-tripping)<br />

- short-time-delay short-circuit tripping (S-tripping)<br />

- instantaneous short-circuit tripping (I-tripping)<br />

Operating characteristic<br />

L-tripping<br />

S-tripping<br />

I-tripping<br />

- 17 - <strong>991061a</strong> Z00

RE-STARTING A TRIPPED BREAKER<br />

1. Find trip cause<br />

2. Remedy causes<br />

indicators:<br />

check downstream load<br />

check overcurrent release settings<br />

overload in main<br />

conductor<br />

overload in neutral<br />

conductor<br />

short circuit:<br />

short-time-delay trip<br />

short circuit:<br />

instantaneous trip<br />

inspect panel<br />

check downstream load<br />

Earth-fault trip<br />

inspect panel<br />

check downstream load<br />

3. Inspect circuit-breaker<br />

check visually the circuit breaker for damage<br />

4. Clear trip cause<br />

5. Reset reclosing lock-out and tripped indicator<br />

manually<br />

or<br />

automatic<br />

- 18 - <strong>991061a</strong> Z00

click<br />

6. Indications<br />

Without motor operating<br />

mechanism<br />

With motor operating<br />

mechanism after 10s<br />

7. Charging the storage spring<br />

a) manually:<br />

9 x<br />

For charging the spring mechanism pull the handle and return the handle<br />

!completly up to the stop.<br />

b) by motor operating mechanism:<br />

Motor operating mechanism starts automatically after applying control voltage.<br />

The motor is automatically de-energized at the end of the charging operation.<br />

8. Closing<br />

see chapter Commissioning<br />

- 19 - <strong>991061a</strong> Z00

CIRCUIT DIAGRAMS<br />

TERMINAL ASSIGNM<strong>EN</strong>T ACCESSORY<br />

(Auxiliary switch S1, S2 = Standard)<br />

Internal wiring Terminals External wiring L / L+<br />

N / L-<br />

U c<br />

Remote reset bell alarm&<br />

tripped indicator F7<br />

G transformer S2<br />

G transformer S1<br />

N sensor S2<br />

N sensor S1<br />

ext. voltage transformer COM<br />

ext. voltage transformer L3<br />

ext. voltage transformer L2<br />

ext. voltage transformer L1<br />

0 V DC<br />

24 V DC<br />

CubicleBUS +<br />

CubicleBUS -<br />

e.g. transformer in the star point of<br />

the summation current transformer<br />

1200 A/1 A<br />

Short terminals if no N-sensor<br />

L1<br />

L2<br />

L3<br />

24 V DC input<br />

Termination resistor, if not external<br />

CubicleBus-module<br />

Not<br />

available<br />

with<br />

communication<br />

connection<br />

"F02".<br />

COM 15<br />

module<br />

is at position<br />

"-X7"<br />

trip signalling switch S24<br />

"Spring charged" signal S21<br />

Local electric close S10<br />

Signaling contact at the<br />

1st auxiliary release S22<br />

COM 15<br />

(Option F02)<br />

L / L+<br />

U s / U c<br />

Signaling contact at the<br />

2nd auxiliary release S23<br />

L / L+ Uc<br />

U c<br />

1st auxiliary release F1 "ST"<br />

N / L-<br />

S1 "NO"<br />

S1 "NC"<br />

Closing solenoid Y1<br />

"Ready to close" signal S20<br />

N / L-<br />

L / L+<br />

S2 "NO"<br />

S2 "NC"<br />

F4 only "quick OFF"<br />

2nd auxiliary release: F2 "ST". F3 "UVR"<br />

F4 "UVR td"<br />

S3 "NO" or S7 "NO"<br />

EMERG<strong>EN</strong>CY OFF or short terminals<br />

L / L+<br />

N / L-<br />

U c<br />

S3 "NC" or S7 "NO"<br />

S4 "NO" or S8 "NO"<br />

S4 "NC" or S8 "NO"<br />

Charging motor<br />

opt. motor main switch S12<br />

L / L+<br />

N / L-<br />

U c<br />

- 20 - <strong>991061a</strong> Z00

MAINT<strong>EN</strong>ANCE<br />

Contact assemblies need to be changed according their condition, but at least after:<br />

-10 000 Operations in FSI and FSII;<br />

-5 000 Operations in FSIII;<br />

-1 000 Operations in FSII and FSIII when used in 1000 V appliances<br />

The switchgear operator has to be determine inspection intervals depending on the breaker<br />

applications:<br />

-min. 1x per annum<br />

-after interruption of heavy loads<br />

-after trips by the overcurrent release (trip unit)<br />

-down stream connected non-automatic circuit breakers have to be inspected also<br />

During the inspection and/or after 1000 switching operations, the following items must be examined<br />

(max. operations see catalog):<br />

-arc chutes and contact systems<br />

-electrical and mechanical functionaliy of the breaker<br />

-mechanical on- / off-functionality<br />

-main and auxiliary circuits, function and connecting quality<br />

-plausibility control of trip unit settings and correction, if necessary<br />

If the breaker endurance is exhausted, then the breaker and old spare parts are to be disposed of,<br />

according to the effective legal regulations.<br />

Draw-Out guide frames with arc-chute covers installed, have to be replaced after no more than three<br />

schort-circuit interruptions of the circuit-breaker.<br />

The arc chutes and the contact system must be replaced depending upon their condition, but latest after<br />

10,000 switching operations.<br />

Depending on the circuit-breaker stress it may also be necessary to replace the operating system after<br />

10,000 switching operations.<br />

The attached CD contains more detailed operating instructions.<br />

Only materials which have low adverse environmental impact and which do not contain dangerous<br />

substances as specified in ROHS directive have been used in the product.<br />

- 21 - <strong>991061a</strong> Z00