Type AT Signal - Alstom

Type AT Signal - Alstom

Type AT Signal - Alstom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

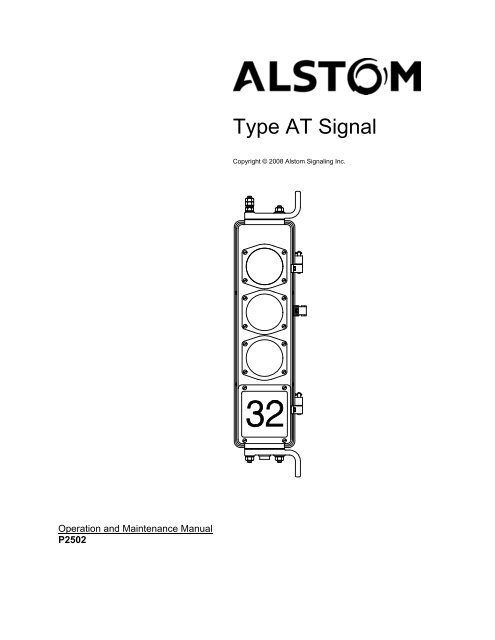

<strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

Copyright © 2008 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.<br />

Operation and Maintenance Manual<br />

P2502

<strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

Copyright © 2008 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.<br />

Operation and Maintenance Manual<br />

<strong>Alstom</strong> <strong>Signal</strong>ing Inc.<br />

P2502, Rev. February 2008, Printed in U.S.A.

LIST OF EFFECTIVE PAGES<br />

P2502, <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Operation and Maintenance Manual<br />

ORIGINAL ISSUE D<strong>AT</strong>E: April 2008<br />

CURRENT REVISION AND D<strong>AT</strong>E: April 2008<br />

PAGE<br />

Cover<br />

Title page<br />

Preface<br />

i thru vi<br />

CHANGE OR REVISION LEVEL<br />

Apr/08<br />

Apr/08<br />

Apr/08<br />

Apr/08<br />

1–1 thru 1–8 Apr/08<br />

2–1 thru 2–8 Apr/08<br />

3–1 thru 3–4 Apr/08<br />

4–1 thru 4–8 Apr/08<br />

5–1 thru 5–4 Apr/08<br />

6–1 thru 6–12 Apr/08<br />

7–1 thru 7–42 Apr/08<br />

A–1 thru A–8 Apr/08<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

PREFACE<br />

NOTICE OF CONFIDENTIAL INFORM<strong>AT</strong>ION<br />

Information contained herein is confidential and is the property of <strong>Alstom</strong><br />

<strong>Signal</strong>ing Incorporated. Where furnished with a proposal, the recipient<br />

shall use it solely to evaluate the proposal. Where furnished to customer, it<br />

shall be used solely for the purposes of inspection, installation or<br />

maintenance. Where furnished to a supplier, it shall be used solely in the<br />

performance of the contract. The information shall not be used or<br />

disclosed by the recipient for any other purposes whatsoever.<br />

FOR QUESTIONS AND INQUIRIES, CONTACT CUSTOMER SERVICE <strong>AT</strong><br />

1–800–717–4477<br />

OR<br />

WWW.ALSTOMSIGNALINGSOLUTIONS.COM<br />

ALSTOM SIGNALING INC.<br />

1025 JOHN STREET<br />

WEST HENRIETTA, NY 14586<br />

REVISION LOG<br />

Revision Date Description By Checked Approved<br />

0 April 2008 Original issue MAS RR NI<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

ABOUT THE MANUAL<br />

This manual is intended to provide the necessary information to maintain and ensure<br />

proper operation of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

The information in this manual is arranged into sections. The title and a brief description<br />

of each section follow:<br />

Section 1 – GENERAL DESCRIPTION: This section gives general information on the<br />

components of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

Section 2 – THEORY OF OPER<strong>AT</strong>ION: This section gives general information on the<br />

operation of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

Section 3 – INSTALL<strong>AT</strong>ION: This section describes the field installation and setup of<br />

the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

Section 4 – PREVENTIVE MAINTENANCE: This section describes the tools,<br />

preventive maintenance procedures, and functional tests used on the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

The frequency and interval, for the performance of the given information, are also<br />

included. Safety precautions are also provided in this section.<br />

Section 5 – TROUBLESHOOTING: This section describes possible failures/symptoms<br />

along with the corrective action for the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

Section 6 – CORRECTIVE MAINTENANCE: This section describes the adjustment<br />

and replacement procedures associated with corrective maintenance of the <strong>Type</strong> <strong>AT</strong><br />

<strong>Signal</strong>. Safety precautions are also provided in this section.<br />

Section 7 – PARTS C<strong>AT</strong>ALOG: This section identifies and lists the spare parts<br />

associated with operations of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

Appendix A – DRAWINGS: This section has representative circuit drawings along with<br />

an installation and space requirement drawing of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

MANUAL SPECIAL NOT<strong>AT</strong>IONS<br />

In the <strong>Alstom</strong> manuals, there are three methods used to convey special informational<br />

notations to the reader. These notations are warnings, cautions, and notes. Both<br />

warnings and cautions are readily noticeable by boldface type two lines beneath the<br />

caption.<br />

Warning<br />

A warning is the most important notation to heed. A warning is used to tell the reader<br />

that special attention needs to be paid to the message because if the instructions or<br />

advice is not followed when working on the equipment then the result could be either<br />

serious harm or death. The sudden, unexpected operation of a switch machine, for<br />

example, or the technician contacting the third rail could lead to personal injury or death.<br />

An example of a typical warning notice follows:<br />

Caution<br />

WARNING<br />

WHENEVER THE GEAR COVER IS REMOVED DISCONNECT THE<br />

MOTOR ENERGY. OTHERWISE, THE SWITCH MACHINE MAY<br />

OPER<strong>AT</strong>E UNEXPECTEDLY AND POSSIBLY CAUSE PERSONAL<br />

INJURY.<br />

A caution statement is used when an operating or maintenance procedure, practice,<br />

condition, or statement, which if not strictly adhered to, could result in damage to or<br />

destruction of equipment. A caution statement is also used when personnel could be<br />

surprised if shocked by a circuit operating at a low current. A typical caution found in a<br />

manual is as follows:<br />

Note<br />

CAUTION<br />

Turn power off before attempting to remove or insert circuit boards into a<br />

module. Boards can be damaged if power is not turned off.<br />

A note is normally used to provide minor additional information to the reader to explain<br />

the reason for a given step in a test procedure or to just provide a background detail. An<br />

example of the use of a note follows:<br />

NOTE<br />

A capacitor may be mounted on the circuit board with a RTV adhesive.<br />

Use the same color RTV.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Topic<br />

TABLE OF CONTENTS<br />

Page<br />

1. SECTION 1 – INTRODUCTION............................................................................. 1–1<br />

1.1. SCOPE OF MANUAL ....................................................................................... 1–1<br />

1.2. GENERAL ........................................................................................................ 1–1<br />

1.3. PHYSICAL CHARACTERISTICS ..................................................................... 1–3<br />

1.3.1. Housing.......................................................................................................... 1–4<br />

1.3.2. Lens Assembly .............................................................................................. 1–5<br />

1.4. INCANDESCENT LIGHT SOURCE ................................................................. 1–6<br />

1.5. LED LIGHT SOURCE....................................................................................... 1–7<br />

2. SECTION 2– THEORY OF OPER<strong>AT</strong>ION.............................................................. 2–1<br />

2.1. GENERAL ........................................................................................................ 2–1<br />

2.2. FUNCTIONAL DESCRIPTION ......................................................................... 2–1<br />

2.3. TYPE <strong>AT</strong> INCANDESCENT SIGNAL FUNCTIONAL DESCRIPTION .............. 2–2<br />

2.3.1. <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Wiring............................................................. 2–3<br />

2.4. LED UNIT FUNCTIONAL DESCRIPTION........................................................ 2–4<br />

2.4.1. LED Lamp Wiring........................................................................................... 2–5<br />

3. SECTION 3 – INSTALL<strong>AT</strong>ION.............................................................................. 3–1<br />

3.1. GENERAL ........................................................................................................ 3–1<br />

3.2. SIGNAL MOUNTING........................................................................................ 3–1<br />

4. SECTION 4 – PREVENTIVE MAINTENANCE...................................................... 4–1<br />

4.1. GENERAL ........................................................................................................ 4–1<br />

4.2. PREVENTIVE MAINTENANCE........................................................................ 4–2<br />

4.2.1. Inspection ...................................................................................................... 4–3<br />

4.2.2. Lens Cleaning................................................................................................ 4–4<br />

4.2.3. Lubrication ..................................................................................................... 4–6<br />

4.2.4. <strong>Signal</strong> Operational Test ................................................................................. 4–7<br />

5. SECTION 5 – TROUBLESHOOTING.................................................................... 5–1<br />

5.1. GENERAL ........................................................................................................ 5–1<br />

5.2. TROUBLESHOOTING GUIDE ......................................................................... 5–1<br />

6. SECTION 6 – CORRECTIVE MAINTENANCE ..................................................... 6–1<br />

6.1. GENERAL ........................................................................................................ 6–1<br />

6.2. INCANDESCENT LAMP REPLACEMENT....................................................... 6–2<br />

6.3. LENS REPLACEMENT .................................................................................... 6–3<br />

6.4. TRANSFORMER REPLACEMENT .................................................................. 6–4<br />

6.5. LAMP RECEPTACLE REPLACEMENT ........................................................... 6–5<br />

6.6. LED MODULE REPLACEMENT ...................................................................... 6–6<br />

6.7. LED BOARD/ILLUMIN<strong>AT</strong>ED NUMBER PL<strong>AT</strong>E REPLACEMENT.................... 6–8<br />

6.8. SIGNAL HEAD REPLACEMENT...................................................................... 6–9<br />

6.9. WAYSIDE SIGNAL SITING............................................................................ 6–11<br />

P2502, Rev. Apr/08 i <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Topic<br />

TABLE OF CONTENTS (CONT.)<br />

Page<br />

7. SECTION 7 – PARTS C<strong>AT</strong>ALOG ......................................................................... 7–1<br />

7.1. GENERAL ........................................................................................................ 7–1<br />

7.2. EXAMPLE SIGNALS ........................................................................................ 7–1<br />

7.3. LENSES ........................................................................................................... 7–3<br />

7.4. SINGLE ASPECT TYPE <strong>AT</strong> INCANDESCENT SIGNAL UNIT WITH<br />

TRANSFORMER.............................................................................................. 7–5<br />

7.5. 3 ASPECT TYPE <strong>AT</strong> INCANDESCENT SIGNAL, CEILING/HORIZONTAL<br />

MOUNT ............................................................................................................ 7–9<br />

7.6. 3 ASPECT TYPE <strong>AT</strong> INCANDESCENT SIGNAL, WALL MOUNT ................. 7–13<br />

7.7. 3 ASPECT TYPE <strong>AT</strong> INCANDESCENT SIGNAL, POLE MOUNT ................. 7–17<br />

7.8. LED UNITS..................................................................................................... 7–21<br />

7.9. 2 ASPECT TYPE <strong>AT</strong> SIGNAL UNIT WITH LED LIGHT SOURCE,<br />

POLE MOUNT................................................................................................ 7–23<br />

7.10. 7 ASPECT TYPE <strong>AT</strong> SIGNAL UNIT WITH LED LIGHT SOURCE,<br />

POLE MOUNT................................................................................................ 7–31<br />

7.11. 3 ASPECT TYPE <strong>AT</strong> SIGNAL UNIT WITH LED LIGHT SOURCE,<br />

CEILING/HORIZONTAL MOUNT ................................................................... 7–39<br />

A. APPENDIX A – DRAWINGS .................................................................................A–1<br />

A.1. GENERAL ........................................................................................................A–1<br />

A.2. TYPE <strong>AT</strong> INCANDESCENT SIGNAL WIRING DIAGRAMS.............................A–1<br />

A.3. TYPE <strong>AT</strong> SIGNAL UNIT WITH LED P/N 20179-0XX-00 WIRING DIAGRAMS A–4<br />

P2502, Rev. Apr/08 ii <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Description<br />

LIST OF FIGURES<br />

Page<br />

Figure 1–1. Typical Three Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> ..................................................... 1–2<br />

Figure 1–2. Typical Three Aspect and Single Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Housings,<br />

Side View .............................................................................................................. 1–4<br />

Figure 1–3. Typical <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Active Light Compartment ................................. 1–5<br />

Figure 1–4. Typical <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> ..................................................... 1–6<br />

Figure 1–5. Typical <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> LED Light Source Unit ....................................... 1–7<br />

Figure 2–1. Typical <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> With Transformers<br />

Circuit Diagram...................................................................................................... 2–2<br />

Figure 2–2. Typical 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> With Transformers and<br />

Illuminated Number Plate Wiring........................................................................... 2–3<br />

Figure 2–3. Typical <strong>Type</strong> <strong>AT</strong> 3 Aspect LED <strong>Signal</strong> Wiring Diagram........................... 2–5<br />

Figure 2–4. Typical <strong>Type</strong> <strong>AT</strong> 3 Aspect LED <strong>Signal</strong> Wiring Diagram (Center Aspect<br />

is Blank) ................................................................................................................ 2–6<br />

Figure 2–5. Typical <strong>Type</strong> <strong>AT</strong> LED Single Aspect <strong>Signal</strong> Wiring Diagram................... 2–7<br />

Figure 3–1. Typical Wall Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> ........................................................ 3–2<br />

Figure 3–2. Typical Ceiling (Horizontal) Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> ................................. 3–3<br />

Figure 3–3. Typical 3 Aspect Pole Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> ......................................... 3–4<br />

Figure 5–1. Incandescent <strong>Signal</strong> Aspect Dim or Not Illuminated................................ 5–2<br />

Figure 5–2. LED <strong>Signal</strong> Aspect Dim or Not Illuminated.............................................. 5–3<br />

Figure 5–3. LED or Illuminated Number Dim or Not Illuminated................................. 5–4<br />

Figure 7–1. Replacement Outer Lenses and Gaskets................................................ 7–3<br />

Figure 7–2. Example Single Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformer, <strong>AT</strong>007-000-00.................................................................................. 7–5<br />

Figure 7–3. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit Without<br />

Transformers, With Illuminated LED Number Plate, Ceiling/Horizontal Mount,<br />

<strong>AT</strong>000-108-00 ....................................................................................................... 7–9<br />

Figure 7–4. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformers, Enameled Number Plate, Door Stop and Side Plate, Wall Mount,<br />

<strong>AT</strong>000-001-00 ..................................................................................................... 7–13<br />

Figure 7–5. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformers, Enameled Number Plate, Door Stop and Side Plate, Pole Mount,<br />

<strong>AT</strong>000-024-00 ..................................................................................................... 7–17<br />

Figure 7–6. LED Unit P/N 20179-0XX-00................................................................. 7–21<br />

Figure 7–7. Example 2 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source,<br />

Pole Mount, <strong>AT</strong>100-001-00 ................................................................................. 7–23<br />

Figure 7–8. Example 7 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source, Pole<br />

Mount, <strong>AT</strong>100-002-00 ......................................................................................... 7–31<br />

Figure 7–9. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source,<br />

Ceiling/Horizontal Mount ..................................................................................... 7–39<br />

P2502, Rev. Apr/08 iii <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Description<br />

LIST OF FIGURES (CONT.)<br />

Page<br />

Figure A–1. Typical Single Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Wiring Diagram ....A–1<br />

Figure A–2. Typical 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With Illuminated<br />

Number plate and Transformers Wiring Diagram..................................................A–2<br />

Figure A–3. Typical 4 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With Enameled<br />

Number Plate and Transformers Wiring Diagram (Single Aspect Plus 3 Aspect) .A–3<br />

Figure A–4. Typical Single Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> With LED Unit P/N 20179-0XX-00<br />

Wiring Diagram......................................................................................................A–4<br />

Figure A–5. Typical 3 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> With LED Unit P/N 20179-0XX-00 Wiring<br />

Diagram.................................................................................................................A–5<br />

Figure A–6. Typical 3 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> With LED Unit P/N 20179-0XX-00 and<br />

Illuminated Number Wiring Diagram......................................................................A–6<br />

Figure A–7. Typical Four Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> With LED Unit P/N 20179-0XX-00<br />

Wiring Diagram (Single Aspect Plus and 3 Aspect)...............................................A–7<br />

P2502, Rev. Apr/08 iv <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Description<br />

LIST OF TABLES<br />

Page<br />

Table 1–1. <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Basic Housing Dimensions .............................................. 1–5<br />

Table 4–1. Preventive Maintenance Index ................................................................. 4–2<br />

Table 4–2. Inspection Procedures.............................................................................. 4–3<br />

Table 4–3. External Lens Cleaning Procedure........................................................... 4–5<br />

Table 4–4. Lubrication Procedure .............................................................................. 4–6<br />

Table 4–5. <strong>Signal</strong> Operational Test Procedure .......................................................... 4–7<br />

Table 5–1. Troubleshooting Symbols......................................................................... 5–1<br />

Table 6–1. Corrective Maintenance Procedures ........................................................ 6–1<br />

Table 6–2. Incandescent Aspect Lamp Replacement Procedure............................... 6–2<br />

Table 6–3. Outer Lens Replacement Procedure ........................................................ 6–3<br />

Table 6–4. <strong>Signal</strong> Transformer Replacement Procedure ........................................... 6–4<br />

Table 6–5. Receptacle Replacement Procedure........................................................ 6–5<br />

Table 6–6. LED P/N 20179-0XX-XX Module Replacement Procedure ...................... 6–6<br />

Table 6–7. LED Board/Illuminated Number Plate Replacement Procedure ............... 6–8<br />

Table 6–8. <strong>Signal</strong> Head Replacement Procedure ...................................................... 6–9<br />

Table 6–9. Wayside <strong>Signal</strong> Siting Procedure ........................................................... 6–11<br />

Table 7–1. Replacement Outer Lenses...................................................................... 7–3<br />

Table 7–2. Example Single Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformer, <strong>AT</strong>007-000-02 Part Numbers........................................................... 7–7<br />

Table 7–3. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit Without<br />

Transformers, With Illuminated LED Number Plate, Ceiling/Horizontal Mount,<br />

<strong>AT</strong>000-108-01 Part Numbers .............................................................................. 7–11<br />

Table 7–4. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformers, Enameled Number Plate, Door Stop and Side Plate, Wall Mount,<br />

<strong>AT</strong>000-001-01 Part Numbers .............................................................................. 7–15<br />

Table 7–5. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Unit With<br />

Transformers, Enameled Number Plate, Door Stop and Side Plate, Pole Mount,<br />

<strong>AT</strong>000-024-01 Part Numbers .............................................................................. 7–19<br />

Table 7–6. LED Unit Part Numbers.......................................................................... 7–21<br />

Table 7–7. Example 2 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source, Pole<br />

Mount, <strong>AT</strong>100-001-01 Part Numbers .................................................................. 7–27<br />

Table 7–8. Example 7 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source, Pole<br />

Mount, <strong>AT</strong>100-002-01 Part Numbers .................................................................. 7–35<br />

Table 7–9. Example 3 Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Unit With LED Light Source,<br />

Ceiling/Horizontal Mount Part Numbers .............................................................. 7–41<br />

P2502, Rev. Apr/08 v <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 vi <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

1. SECTION 1 – INTRODUCTION<br />

1.1. SCOPE OF MANUAL<br />

This manual is intended to provide the necessary information to maintain and ensure<br />

proper operation of the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>. The technical material in this manual assumes<br />

the reader has a basic knowledge of railroad signaling terminology and basic<br />

maintenance principles.<br />

1.2. GENERAL<br />

This section briefly describes the components and physical characteristics of a typical<br />

<strong>Alstom</strong> <strong>Type</strong> <strong>AT</strong> transit signal, available with two types of light fixtures:<br />

• Incandescent Lamp P/N 48088-028-00<br />

• LED Unit P/N 20179-0XX-00<br />

The components and configuration of signals can vary depending on the specific<br />

requirements of their locations. <strong>Signal</strong>s can be stacked to produce a multi Aspect signal.<br />

The signal can be wall, ceiling or pole mounted through the use of mounting brackets<br />

attached to the signal housing. Wall brackets hold a signal securely to a concrete wall or<br />

ceiling through the use of concrete bolts. A wall signal can be mounted in either a left or<br />

right hand configuration. These mounting configurations are produced by changing the<br />

position of the wall mounting bracket attached to the signal housing. Ladders can be<br />

provided where required. The <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> conforms to requirements of the AREMA<br />

<strong>Signal</strong> Manual, Part 7.1.1.<br />

P2502, Rev. Apr/08 1–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

LENS<br />

ASSEMBLIES (3)<br />

HINGED<br />

BACK DOOR<br />

NUMBER PL<strong>AT</strong>E ENAMEL<br />

OR ILLUMIN<strong>AT</strong>ED<br />

3 ASPECT<br />

SIGNAL HOUSING<br />

Figure 1–1. Typical Three Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

P2502, Rev. Apr/08 1–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

1.3. PHYSICAL CHARACTERISTICS<br />

The <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> arrangement as well as the aspects and enamel number plate, vary<br />

depending on the location requirements. The configuration of the signal and use of<br />

illuminated or enamel number plate depends on the requirements of the location. <strong>Signal</strong><br />

configurations are identified by the signal drawing number. Example configurations are<br />

shown and described within this manual.<br />

The <strong>Type</strong> <strong>AT</strong> 3 Aspect <strong>Signal</strong>, as shown in Figure 1–1, consists of a housing with<br />

hinged door, an illuminated or enamel number plate, three Aspect lens assemblies, and<br />

internal electrical components to illuminate the aspects and number plate if so<br />

configured.<br />

The <strong>Type</strong> <strong>AT</strong> Single Aspect <strong>Signal</strong> is often used in a multi Aspect application. The<br />

single aspect signal consists of a housing unit with a hinged door, a single aspect lens<br />

assembly, and internal electrical components to illuminate the aspect.<br />

This signal is available with the following options:<br />

• Mounting:<br />

− Wall Right Hand<br />

− Wall Left Hand<br />

− Column<br />

− Pole<br />

− Horizontal<br />

• Aspect Arrangements:<br />

− Red<br />

− Yellow<br />

− Lunar White<br />

− Timing indication (S)<br />

− Speed indication (15 or 20)<br />

− Blank (metal disk covers lamp compartment)<br />

P2502, Rev. Apr/08 1–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

1.3.1. Housing<br />

The signal housing is of cast-aluminum construction. Access to the internal parts of the<br />

signal is made through a hinged door at the rear of the housing.<br />

The <strong>Type</strong> <strong>AT</strong> 3 Aspect <strong>Signal</strong> is internally divided into four potentially active light<br />

compartments. Three compartments are used for aspect signals and one for the<br />

number display (number plate, illuminated (incandescent) number or LED number). The<br />

door of the three Aspect signal is equipped with two ventilators to prevent moisture and<br />

heat build-up within the housing and a gasket with sealant to prevent water from<br />

entering the housing.<br />

The <strong>Type</strong> <strong>AT</strong> Single Aspect <strong>Signal</strong> is available with or without an enamel number plate.<br />

The single aspect door has one ventilator. A latch is provided to padlock the door and<br />

prevent unauthorized access.<br />

Housings can be stacked to make 4, 5, 6, 7, or 8 aspect configurations.<br />

VENTIL<strong>AT</strong>ORS<br />

4 COMPARTMENTS IN<br />

A 3 ASPECT SIGNAL<br />

NUMBER PL<strong>AT</strong>E<br />

Figure 1-2. Typical Three Aspect and Single Aspect <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Housings,<br />

Side View<br />

P2502, Rev. Apr/08 1–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

`<br />

Introduction<br />

Table 1–1. <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Basic Housing Dimensions<br />

Dimension 3 Aspect Single Aspect<br />

Height 28.75" (73 cm) 9.75" (24.8 cm)<br />

Width 8.60" (21.8 cm) 8.60" (21.08 cm)<br />

Depth 9.69" (24.6 cm) 9.69" (24.6 cm)<br />

Outer Lens Diameter 5.0" (12.7 cm) 5.0" (12.7 cm)<br />

1.3.2. Lens Assembly<br />

The lens assembly of a <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> aspect, whether incandescent or LED, consists<br />

of a colored (Green, Yellow, or Red) lens and a mounting ring that holds the lens to the<br />

signal case. See Figure 1–3 for lens detail.<br />

LENS<br />

GASKETS<br />

LAMPS AND LAMP<br />

RECEPTACLES (2)<br />

LENS<br />

GASKETS<br />

LED LAMP UNIT<br />

TERMINAL POSTS<br />

BEZEL<br />

RING<br />

BEZEL<br />

RING<br />

LED UNIT<br />

OUTER<br />

LENS<br />

SCREW &<br />

WASHER<br />

GASKET<br />

LIGHTING<br />

TRANSFORMERS<br />

TERMINALS<br />

OUTER<br />

LENS<br />

SCREW &<br />

WASHER<br />

TYPE <strong>AT</strong> SINGLE ASPECT INCANDESCENT SIGNAL<br />

GASKET<br />

CENTERLINE OF<br />

OUTER LENS &<br />

LAMP UNIT LENS<br />

LED LAMP UNIT<br />

MOUNTING SCREW<br />

& WASHER<br />

TYPE <strong>AT</strong> SINGLE ASPECT LED SIGNAL<br />

Figure 1–3. Typical <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> Active Light Compartment<br />

P2502, Rev. Apr/08 1–5 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

1.4. INCANDESCENT LIGHT SOURCE<br />

Each active incandescent light source compartment uses two lamps. Each lamp has a<br />

single filament.<br />

An active aspect or illuminated number plate light compartment contains a lighting<br />

transformer, terminals for power connection, and appropriate lamp receptacles as<br />

shown in Figure 1–4.<br />

LIGHTING<br />

TRANSFORMERS (2)<br />

ASPECT<br />

LENS<br />

ASSEMBLY<br />

LAMPS AND<br />

LAMP RECEPTACLES (2)<br />

TERMINALS<br />

LAMPS AND LAMP<br />

RECEPTACLES (2)<br />

TERMINALS<br />

FRONT VIEW<br />

ILLUMIN<strong>AT</strong>ED<br />

NUMBER PL<strong>AT</strong>E<br />

SIDE VIEW<br />

LIGHTING<br />

TRANSFORMERS (2)<br />

Figure 1-4. Typical <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong><br />

P2502, Rev. Apr/08 1–6 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

1.5. LED LIGHT SOURCE<br />

The LED light source unit P/N 20179-0XX-00 measures 2.2” (5.6 cm) in diameter. It is a<br />

self contained unit; the lens and individual LEDs are not replaceable.<br />

Two secured color coded 300V, 125ºC, 16 AWG jacketed wires 12" (30.5 cm) long with<br />

ring terminals compatible with the AAR terminal posts (.242” O.D. [.61 cm]) are<br />

provided. The AAR terminal posts are provided for field electrical connections.<br />

Figure 1-5. Typical <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> LED Light Source Unit<br />

The LED lamp units used on this project have the following physical characteristics:<br />

• Color • Light Angle<br />

− Red<br />

− 20 degree<br />

− Green • Operating Voltage<br />

− Yellow<br />

− 110 VAC (60Hz)<br />

− Lunar White • Brightness<br />

• BackLight − Fixed, Not Adjustable<br />

P2502, Rev. Apr/08 1–7 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Introduction<br />

.<br />

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 1–8 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

2. SECTION 2– THEORY OF OPER<strong>AT</strong>ION<br />

2.1. GENERAL<br />

This section contains operating information on the <strong>Alstom</strong> <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> along with<br />

diagrams showing power distribution and wiring to the signal.<br />

2.2. FUNCTIONAL DESCRIPTION<br />

<strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>s are controlled externally through relay logic circuits or vital processors.<br />

Depending on the distance of the signal from the relay room, power supplied to the<br />

signal may vary.<br />

P2502, Rev. Apr/08 2–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

2.3. TYPE <strong>AT</strong> INCANDESCENT SIGNAL FUNCTIONAL DESCRIPTION<br />

<strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong>s are configured with transformers to operate on fused 60<br />

Hz (ungrounded), 110 VAC power, controlled externally through relay logic circuits.<br />

Depending on the distance of the signal from the power source, the nominal 110 VAC<br />

power supplied to the primary windings of the signal transformers may vary. It must,<br />

however, be between 90 to 130 VAC (60 Hz) for the signal to function properly.<br />

Figure 2–1 is a simplified circuit diagram of a <strong>Type</strong> <strong>AT</strong> 3 Aspect <strong>Signal</strong> with<br />

transformers. One aspect contains two single filament lamps installed in a receptacle<br />

assembly consisting of two non-tapping transformers, two lamp receptacles, and a<br />

terminal block attached to a mounting bracket.<br />

Terminal connection points A, C, and E from terminal blocks within the three signal<br />

aspects, are connected to the signal lighting relay logic circuits. These circuits receive<br />

power through a fused feed, from an energy source in the relay room. The three<br />

aspects, points A, C, and E, are fed from a single fuse. The common 1 and 2 feeds<br />

(points B and F) are not fused. These feeds are connected to the same energy source<br />

but not through the relay logic control circuits. A signal lamp receives the 10 VAC from a<br />

transformer within the signal. Detailed wiring diagrams on specific <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>s are<br />

given in Appendix A.<br />

LAMP<br />

TERMINAL CONNECTION POINTS<br />

TRANSFORMER A TRANSFORMER<br />

LAMP<br />

10<br />

VAC<br />

110<br />

VAC<br />

110<br />

VAC<br />

10<br />

VAC<br />

ASPECT 1<br />

B<br />

C<br />

10<br />

VAC<br />

110<br />

VAC<br />

110<br />

VAC<br />

10<br />

VAC<br />

ASPECT 2<br />

D<br />

E<br />

10<br />

VAC<br />

110<br />

VAC<br />

110<br />

VAC<br />

10<br />

VAC<br />

ASPECT 3<br />

F<br />

Figure 2–1. Typical <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> With Transformers Circuit Diagram<br />

P2502, Rev. Apr/08 2–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

2.3.1. <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> Wiring<br />

Figure 2–2 is a wiring diagram of a typical <strong>Type</strong> <strong>AT</strong> Incandescent 3 Aspect <strong>Signal</strong> with<br />

transformers. The signal wiring shown in dotted lines represents the field wiring of a<br />

seven conductor, number 14 AWG cable. The internal wiring of lamps and transformers<br />

are represented by solid lines.<br />

G<br />

Y<br />

R<br />

ILLUMIN<strong>AT</strong>ED<br />

NO. PL<strong>AT</strong>E<br />

110 VAC<br />

COMMON (BCX OR ACX)<br />

LAMPS<br />

TRANSFORMERS<br />

TERMINAL<br />

BLOCK<br />

BLACK<br />

BCX<br />

ILLUM<br />

NO. PL<strong>AT</strong>E<br />

R Y ACX G<br />

RED<br />

TYPICAL WIRING OF A<br />

LAMP AND TRANSFORMER<br />

Figure 2–2. Typical 3 Aspect <strong>Type</strong> <strong>AT</strong> Incandescent <strong>Signal</strong> With Transformers and<br />

Illuminated Number Plate Wiring<br />

P2502, Rev. Apr/08 2–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

2.4. LED UNIT FUNCTIONAL DESCRIPTION<br />

The LED Unit P/N 20179-0XX-00 is available in 4 colors:<br />

• Green LED 20179-008-00<br />

• Red LED 20179-009-00<br />

• Yellow LED 20179-010-00<br />

• Lunar White LED 20179-011-00<br />

This is a single, self-contained device that does not require any field assembly. The<br />

lamp is wired via ring terminals to AAR terminal posts within the signal unit.<br />

Each unit contains an LED board and a power supply board contained in the signal<br />

housing. These housings are replaceable as a unit and are not serviceable.<br />

The LED unit power boards operate from 90 to 130 VAC (60 Hz.<br />

P2502, Rev. Apr/08 2–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

2.4.1. LED Lamp Wiring<br />

Figure 2–3 is a wiring diagram of a typical three aspect LED Unit P/N 20179-0XX-00<br />

LED signal configured, green, yellow, and red.<br />

The signal wiring shown in dotted lines represents field wiring of multi-conductor<br />

number 14 AWG cable. <strong>Signal</strong> number is represented by xxx in this example. See<br />

Appendix A for additional example wiring diagrams.<br />

G<br />

1<br />

2<br />

Y<br />

1<br />

2<br />

R<br />

1<br />

2<br />

xxxRG<br />

xxxHG<br />

ACX<br />

xxxDG<br />

Figure 2-3. Typical <strong>Type</strong> <strong>AT</strong> 3 Aspect LED <strong>Signal</strong> Wiring Diagram<br />

P2502, Rev. Apr/08 2–5 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

Figure 2–4 is a wiring diagram of a typical three aspect LED signal (one aspect blank)<br />

configured red, blank, red.<br />

The signal wiring shown in dotted lines represent field wiring of four-conductor number<br />

14 AWG cable.<br />

R<br />

1<br />

2<br />

X<br />

R<br />

1<br />

2<br />

ACX<br />

xxxRG<br />

Figure 2-4. Typical <strong>Type</strong> <strong>AT</strong> 3 Aspect LED <strong>Signal</strong> Wiring Diagram<br />

(Center Aspect is Blank)<br />

P2502, Rev. Apr/08 2–6 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

Figure 2–5 is a wiring diagram of a typical one aspect LED signal.<br />

The signal wiring shown in dotted lines represent field wiring of two-conductor number<br />

14 AWG cable.<br />

L<br />

1<br />

2<br />

CX<br />

L<br />

Figure 2-5. Typical <strong>Type</strong> <strong>AT</strong> LED Single Aspect <strong>Signal</strong> Wiring Diagram<br />

P2502, Rev. Apr/08 2–7 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Theory of Operation<br />

.<br />

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 2–8 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Installation<br />

3. SECTION 3 – INSTALL<strong>AT</strong>ION<br />

3.1. GENERAL<br />

This section describes installation of the <strong>Alstom</strong> <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>. If a fault is suspected<br />

upon installation, the maintainer should refer to Section 5 for the proper signal<br />

troubleshooting procedure.<br />

3.2. SIGNAL MOUNTING<br />

The <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> can be mounted on a wall, ceiling (horizontal) or pole. The wall and<br />

ceiling mounted signals are mounted using brackets. The pole mounted signal is<br />

mounted on a 3” (7.62 cm) diameter pole. The pole is inserted in and fastened to a cast<br />

aluminum split base. The split base is bolted to a concrete foundation. Example<br />

mounting configurations are shown in Figures 3-1 through 3-3.<br />

Refer to Section 7 for example parts and signal assembly drawings. To determine the<br />

part number to use when ordering a complete signal for your configuration or to obtain<br />

the parts list for your specific configuration, contact your <strong>Alstom</strong> <strong>Signal</strong>ing Inc.<br />

representative.<br />

P2502, Rev. Apr/08 3–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Installation<br />

Figure 3-1. Typical Wall Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

P2502, Rev. Apr/08 3–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Installation<br />

Figure 3-2. Typical Ceiling (Horizontal) Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

P2502, Rev. Apr/08 3–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Installation<br />

Figure 3–3. Typical 3 Aspect Pole Mount <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong><br />

P2502, Rev. Apr/08 3–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4. SECTION 4 – PREVENTIVE MAINTENANCE<br />

4.1. GENERAL<br />

This section describes preventive maintenance and testing for the <strong>Alstom</strong> <strong>Type</strong> <strong>AT</strong><br />

<strong>Signal</strong>s. If a fault is suspected as a result of this maintenance, the maintainer should<br />

refer to Section 5 for the proper signal troubleshooting procedure.<br />

Preventive maintenance procedures deal with inspection, cleaning, and preventive<br />

maintenance (PM) checks. PM checks are performed to ensure proper equipment<br />

operation based on specific tolerances. These checks identify and isolate possible<br />

malfunctions.<br />

Corrective maintenance, at the field service level, is intended to restore malfunctioning<br />

equipment to its normal operating condition as quickly as possible. Corrective<br />

maintenance procedures including component replacement, voltage adjustments, and<br />

wayside sighting are provided in Section 6.<br />

P2502, Rev. Apr/08 4–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4.2. PREVENTIVE MAINTENANCE<br />

Table 4–1 lists the typical preventive maintenance procedures for the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong>.<br />

The Interval column gives the recommended frequency of procedures. The<br />

Maintenance Action column lists the preventive maintenance procedure to be performed<br />

at the prescribed interval. The Reference column lists the table number containing the<br />

procedure.<br />

Table 4–1. Preventive Maintenance Index<br />

Interval Maintenance Action Reference<br />

Monthly Periodic Inspection Table 4–2<br />

Monthly External Lens Cleaning Table 4–3<br />

Quarterly Door Handle, Hinge and Latch Lubrication Table 4–4<br />

As Needed <strong>Signal</strong> Operational Test Table 4–5<br />

WARNING<br />

ABIDE BY ALL OPER<strong>AT</strong>IONAL AND SAFETY RULES WHEN<br />

ENTERING AND WORKING IN THE RIGHT OF WAY.<br />

P2502, Rev. Apr/08 4–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4.2.1. Inspection<br />

The Inspection Procedure can be performed any time personnel are in close proximity<br />

to the signal. Follow the inspection procedures as outlined in Table 4–2, in the order<br />

given. If required, take the corrective actions described to be sure the signal is properly<br />

serviced.<br />

Table 4–2. Inspection Procedures<br />

Step Procedure Action<br />

1 Inspect cases for scratches, large dents,<br />

cracks, warped doors, or other obvious<br />

mechanical damage.<br />

2 Check for loose hardware or loose<br />

connections.<br />

3 Inspect interior of signal housing for<br />

excessive dirt, dust, or foreign objects.<br />

4 Inspect wiring and cables for broken or brittle<br />

wires or cracked insulation.<br />

5 Verify each lamp illuminates when energized<br />

and check for proper brightness<br />

Paint scratches and replace<br />

excessively damaged parts.<br />

Tighten.<br />

Remove foreign objects. Clean<br />

case with damp lint-free cloth.<br />

Clean lens.<br />

Replace wire or cable.<br />

Refer to Troubleshooting<br />

Section 5.<br />

6 Inspect for excessive dirt or dust on lens Clean external lens; see Table<br />

4–3.<br />

7 Inspect for cracked or broken external lens. Replace lens, as required, see<br />

corrective maintenance, Table<br />

6–3.<br />

8 Inspect vent screen in door for air blockage. Clean screen with brush.<br />

9 Inspect door handle, hinges and latch. Lubricate as required, see Table<br />

4–4.<br />

10 Inspect grounding of signal. (When<br />

Applicable)<br />

Clean and tighten connections.<br />

11 Inspect condition of door gasket(s) (1 per<br />

door).<br />

Replace damaged gasket.<br />

P2502, Rev. Apr/08 4–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4.2.2. Lens Cleaning<br />

Clean lenses any time an inspection reveals the need for cleaning.<br />

CAUTION<br />

Do not look directly into an illuminated lamp at close range.<br />

Tools required for lens cleaning include:<br />

• Cleaners such as Brillianize (The Brillianize Company), Novus Plastic Polish No. 1<br />

(Novus Plastic Polish Ltd.) or equivalent plastic cleaner and polish approved for use<br />

on polycarbonate and Plexiglas® lenses<br />

NOTE<br />

If no other cleaner is available, use a solution of one part mild dishwashing<br />

liquid to 50 parts water. Rinse each lens with clean water and dry<br />

immediately with a damp chamois.<br />

• Pump or spray dispenser<br />

• Damp chamois<br />

CAUTION<br />

Never use an abrasive to clean a lens.<br />

Do not use a dry chamois on a dry lens; this prevents accidental<br />

scratching of the lens. Do not use a cleaner with ammonia; this type of<br />

cleaner may attack the lens material.<br />

P2502, Rev. Apr/08 4–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

Table 4–3. External Lens Cleaning Procedure<br />

Step<br />

Procedure<br />

1 WARNING<br />

Spray lens.<br />

USE A SAFETY BELT WHEN THE CLEANING LENSES OF ANY<br />

POLE MOUNTED UNIT WHILE STANDING ON LADDER STEPS.<br />

WARNING<br />

DO NOT LOOK DIRECTLY INTO AN ILLUMIN<strong>AT</strong>ED LAMP <strong>AT</strong><br />

CLOSE RANGE.<br />

2 Wipe lens with a damp chamois.<br />

P2502, Rev. Apr/08 4–5 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4.2.3. Lubrication<br />

Hinges on doors, door handles, and padlocks are lubricated with lightweight mineral<br />

based oil (Mobil Aero HFA or equivalent).<br />

Table 4–4. Lubrication Procedure<br />

Step<br />

Action<br />

1 Sparingly oil door hinges, locking eyebolt, and any padlocks used.<br />

LUBRIC<strong>AT</strong>E<br />

LUBRIC<strong>AT</strong>E<br />

2 Wipe off excess oil.<br />

P2502, Rev. Apr/08 4–6 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

4.2.4. <strong>Signal</strong> Operational Test<br />

The <strong>Signal</strong> Operational Test verifies the visibility of the signal. If an indication is not met,<br />

proceed to Troubleshooting, Section 5. This operational test that should be performed<br />

when:<br />

• a signal malfunction is suspected<br />

• the signal or one of its components has been repaired<br />

• the signal or one of its components has been replaced<br />

WARNING<br />

DO NOT LOOK DIRECTLY INTO AN ILLUMIN<strong>AT</strong>ED LAMP <strong>AT</strong> CLOSE<br />

RANGE.<br />

Table 4–5. <strong>Signal</strong> Operational Test Procedure<br />

Step<br />

Action<br />

1 Call each signal aspect and verify the correct LED module is lit.<br />

2 From a position 300 feet in approach to the signal and six feet over the top<br />

of the running rail, view signal at stop. Aspect must be clearly visible.<br />

3 If any viewed signal aspect is dim or not illuminated refer to Section 5 for<br />

<strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> troubleshooting.<br />

P2502, Rev. Apr/08 4–7 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Preventive Maintenance<br />

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P2502, Rev. Apr/08 4–8 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Troubleshooting<br />

5. SECTION 5 – TROUBLESHOOTING<br />

5.1. GENERAL<br />

Troubleshooting information is given in the form of a fault isolation flowchart provided in<br />

Figure 5–1. The chart begins with the malfunction symptoms and, based on<br />

observations and tests by the maintainer, the chart branches out to isolate probable<br />

causes of the malfunction.<br />

Troubleshooting flowchart symbols are explained in Table 5–1.<br />

5.2. TROUBLESHOOTING GUIDE<br />

The guide gives instructions on how to sequentially do a series of checks or tests,<br />

resulting in a practical repair solution. It is important to follow the instructions in the<br />

sequence given.<br />

Table 5–1. Troubleshooting Symbols<br />

Symbol<br />

Explanation<br />

Malfunction statement as derived from operator's report.<br />

Basic instruction for preparation of a test, procedure, or<br />

observation. The action taken results in a diagnostic<br />

decision.<br />

Result from previous action, which is answered yes or no. If<br />

result is within tolerance, answer yes. If not, answer no. Do<br />

not consider any gray areas between yes and no.<br />

Final step of instructions involving corrective measures.<br />

Reference publication indicates suspected problem area.<br />

P2502, Rev. Apr/08 5–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Troubleshooting<br />

SIGNAL ASPECT<br />

DIM OR NOT ILLUMIN<strong>AT</strong>ED<br />

CHECK CONDITION OF<br />

LAMPS AND LAMP<br />

RECEPTACLES<br />

(SEE NOTE 1)<br />

YES<br />

OK?<br />

NO<br />

CHECK FOR 110 VAC<br />

<strong>AT</strong> SIGNAL LIGHTING<br />

TRANSFORMER<br />

PRIMARY<br />

(SEE NOTE 2)<br />

REPLACE<br />

LAMPS AND/OR<br />

RECEPTACLES<br />

YES<br />

OK?<br />

NO<br />

CHECK FOR 10 VAC<br />

<strong>AT</strong> SIGNAL LIGHTING<br />

TRANSFORMER<br />

SECONDARY<br />

(SEE NOTE 3)<br />

CHECK<br />

CONDITION<br />

OF POWER<br />

FEED FUSES<br />

YES<br />

OK?<br />

NO<br />

YES<br />

OK?<br />

NO<br />

CHECK FOR 10 VAC<br />

<strong>AT</strong> ASPECT<br />

RECEPTACLES AND<br />

TERMINAL BLOCK<br />

(SEE NOTE 3)<br />

REPLACE<br />

TRANSFORMER<br />

TROUBLESHOOT<br />

110 VAC POWER<br />

SUPPLY AND<br />

FIELD WIRING<br />

REPLACE<br />

FUSES<br />

YES<br />

OK?<br />

NO<br />

NOTES:<br />

1. FOR A THREE ASPECT SIGNAL, DETERMINE<br />

WHETHER SIGNAL IS CONDITIONED TO CLEAR OR TO<br />

STOP BEFORE CHECKING LAMP CONDITION.<br />

REPLACE<br />

LAMP AND<br />

CLEAN LENS<br />

REPLACE/REPAIR<br />

LAMP WIRING AS<br />

REQUIRED<br />

2. FOR A THREE ASPECT SIGNAL WITHOUT AN<br />

INTERNAL SIGNAL LIGHTING TRANSFORMER, CHECK<br />

SIGNAL LIGHTING TRANSFORMER IN CASE.<br />

3. FOR SIGNALS WITHOUT AN INTERNAL<br />

TRANSFORMER, THE OUTPUT VOLTAGE <strong>AT</strong> SIGNAL<br />

LIGHTING TRANSFORMER SECONDARY MAY BE<br />

HIGHER THAN 10 VAC TO COMPENS<strong>AT</strong>E FOR<br />

DISTANCE BETWEEN SIGNAL AND TRANSFORMER.<br />

Figure 5–1. Incandescent <strong>Signal</strong> Aspect Dim or Not Illuminated<br />

P2502, Rev. Apr/08 5–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Troubleshooting<br />

SIGNAL ASPECT<br />

DIM OR NOT ILLUMIN<strong>AT</strong>ED<br />

CHECK CONDITION OF LED<br />

LAMP UNIT RING TERMINAL<br />

CONNECTION TO THE<br />

LED SIGNAL TERMINAL<br />

NOTE:<br />

1. DETERMINE THE SIGNAL<br />

CONTROL CONDITION BEFORE<br />

CHECKING LED INTEGRITY.<br />

YES<br />

OK?<br />

NO<br />

CHECK FOR CORRECT<br />

VOLTAGE <strong>AT</strong> LED<br />

TERMINAL POSTS<br />

TIGHTEN<br />

CONNECTION OR<br />

REPLACE TERMINALS<br />

AS NEEDED<br />

YES<br />

OK?<br />

NO<br />

REPLACE<br />

LED MODULE<br />

CHECK<br />

CONDITION<br />

OF POWER<br />

FEED FUSES<br />

YES<br />

OK?<br />

NO<br />

REPLACE<br />

FUSES<br />

CHECK FOR<br />

CORRECT VOLTAGE <strong>AT</strong><br />

SIGNAL LIGHTING<br />

POWER SUPPLY<br />

IN RELAY ROOM<br />

YES<br />

OK?<br />

NO<br />

TROUBLESHOOT<br />

AND REPAIR<br />

FIELD WIRING<br />

TROUBLESHOOT<br />

POWER<br />

DISTRIBUTION<br />

Figure 5-2. LED <strong>Signal</strong> Aspect Dim or Not Illuminated<br />

P2502, Rev. Apr/08 5–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Troubleshooting<br />

SIGNAL ASPECT<br />

DIM OR NOT ILLUMIN<strong>AT</strong>ED<br />

CHECK CONDITION OF LED<br />

LAMP UNIT RING TERMINAL<br />

CONNECTION TO THE<br />

LED SIGNAL TERMINAL<br />

NOTE:<br />

1. DETERMINE THE SIGNAL<br />

CONTROL CONDITION BEFORE<br />

CHECKING LED INTEGRITY.<br />

YES<br />

OK?<br />

NO<br />

CHECK FOR CORRECT<br />

VOLTAGE <strong>AT</strong> LED<br />

TERMINAL POSTS<br />

TIGHTEN<br />

CONNECTION OR<br />

REPLACE<br />

TERMINALS AS<br />

NEEDED<br />

YES<br />

OK?<br />

NO<br />

REPLACE LED<br />

BOARD/<br />

ILLUMIN<strong>AT</strong>ED<br />

NUMBER PL<strong>AT</strong>E<br />

CHECK<br />

CONDITION<br />

OF POWER<br />

FEED FUSES<br />

YES<br />

OK?<br />

NO<br />

REPLACE<br />

FUSES<br />

CHECK FOR<br />

CORRECT VOLTAGE<br />

<strong>AT</strong> SIGNAL LIGHTING<br />

POWER SUPPLY<br />

IN RELAY ROOM<br />

YES<br />

OK?<br />

NO<br />

TROUBLESHOOT<br />

AND REPAIR<br />

FIELD WIRING<br />

TROUBLESHOOT<br />

POWER<br />

DISTRIBUTION<br />

Figure 5–3. LED or Illuminated Number Dim or Not Illuminated<br />

P2502, Rev. Apr/08 5–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6. SECTION 6 – CORRECTIVE MAINTENANCE<br />

6.1. GENERAL<br />

Corrective maintenance, at the field level, is intended to restore proper operation to<br />

malfunctioning equipment by replacing components found to be faulty through the<br />

troubleshooting procedures described in Section 5 and the preventive maintenance<br />

procedures described in Section 4.<br />

This section contains procedures for replacing the <strong>Type</strong> <strong>AT</strong> <strong>Signal</strong> lamps, transformers,<br />

receptacles, LED modules and lenses used in the various light source versions of the<br />

signals as well as signal head replacement and wayside signal siting procedures, as<br />

listed in Table 6–1.<br />

Table 6–1. Corrective Maintenance Procedures<br />

Interval Maintenance Action Reference<br />

Periodically, as<br />

determined by local<br />

authorities<br />

Incandescent Lamp Replacement Table 6–2<br />

As Needed Outer Lens Replacement Table 6–3<br />

As Needed Transformer Replacement (If used) Table 6–4<br />

As Needed<br />

As Needed or every<br />

43,800 hours<br />

Lamp Receptacle Replacement<br />

(For Incandescent Versions of the <strong>AT</strong> <strong>Signal</strong> Only)<br />

Table 6–5<br />

LED Unit P/N 20179-0XX-XX Replacement Table 6–6<br />

As Needed LED Board/Illuminated Number Plate Replacement Table 6–7<br />

As Needed <strong>Signal</strong> Head Replacement Table 6–8<br />

As Needed Wayside <strong>Signal</strong> Siting Table 6–9<br />

WARNING<br />

VERIFY TH<strong>AT</strong> POWER IS REMOVED FROM THE SIGNAL UNIT PRIOR<br />

TO PERFORMING ANY CORRECTIVE MAINTENANCE PROCEDURE.<br />

WARNING<br />

ABIDE BY ALL OPER<strong>AT</strong>IONAL AND SAFETY RULES WHEN<br />

ENTERING AND WORKING IN THE RIGHT OF WAY.<br />

P2502, Rev. Apr/08 6–1 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

CAUTION<br />

Do not look directly into an illuminated light source at close range.<br />

CAUTION<br />

Allow incandescent lamps to cool before touching them.<br />

6.2. INCANDESCENT LAMP REPLACEMENT<br />

Incandescent lamps should not be allowed to burn themselves out. Replace aspect<br />

lamps according to the Authority's schedule, using the procedure listed in Table 6–2.<br />

Table 6–2. Incandescent Aspect Lamp Replacement Procedure<br />

Step<br />

Procedure<br />

1 Remove power to signal by removing power feed fuses. (Refer to circuit<br />

drawings for location and identity of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Press lamp into socket and turn counter-clockwise. Remove lamp from socket<br />

and discard. Repeat for second lamp.<br />

4 Align bayonet pins on replacement lamp with slots in socket. Push lamp into<br />

socket. Turn lamp 1/4 turn clockwise. Release lamp. Repeat for second lamp.<br />

5 Repeat steps 3 and 4 for additional light compartments.<br />

6 Reapply power to the signal by reinstalling the power feed fuses.<br />

7 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

8 Close rear door. Re-install and lock padlock.<br />

P2502, Rev. Apr/08 6–2 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

`<br />

Corrective Maintenance<br />

6.3. LENS REPLACEMENT<br />

Replace an aspect light lens using the procedure listed in Table 6–3 in the sequence<br />

given. There is no need to re-focus the signal after a lens is replaced. Refer to the<br />

exploded view of a lens assembly shown in Section 6.<br />

There is no need to refocus the signal after a lens is replaced.<br />

Table 6–3. Outer Lens Replacement Procedure<br />

Step<br />

Procedure<br />

1 Remove power to signal by removing power feed fuses. (Refer to circuit<br />

drawings for location and identity of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Remove four screws securing lens assembly to signal case. Lens and lens ring<br />

are released.<br />

LENS<br />

GASKETS<br />

LAMPS AND LAMP<br />

RECEPTACLES (2)<br />

LENS<br />

GASKETS<br />

LED LAMP UNIT<br />

TERMINAL POSTS<br />

BEZEL<br />

RING<br />

BEZEL<br />

RING<br />

LED UNIT<br />

OUTER<br />

LENS<br />

SCREW &<br />

WASHER<br />

GASKET<br />

LIGHTING<br />

TRANSFORMERS<br />

TERMINALS<br />

OUTER<br />

LENS<br />

SCREW &<br />

WASHER<br />

TYPE <strong>AT</strong> SINGLE ASPECT INCANDESCENT SIGNAL<br />

GASKET<br />

CENTERLINE OF<br />

OUTER LENS &<br />

LAMP UNIT LENS<br />

LED LAMP UNIT<br />

MOUNTING SCREW<br />

& WASHER<br />

TYPE <strong>AT</strong> SINGLE ASPECT LED SIGNAL<br />

P2502, Rev. Apr/08 6–3 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

Table 6–3. Outer Lens Replacement Procedure (Cont.)<br />

Step<br />

Procedure<br />

4 Remove the bezel ring, gaskets and outer lens from the housing.<br />

5 Remove the outer lens and replace outer lens gasket.<br />

6 Replace outer lens, verifying that the outer lens gasket is uniformly in place<br />

against the signal case. Replace gaskets if they are not in good condition.<br />

7 Reinstall the bezel ring, gaskets and outer lens from the housing.<br />

8 Tighten the 4 screws holding bezel ring, gaskets and outer lens to the housing.<br />

9 Reapply power to the signal by reinstalling the power feed fuses.<br />

10 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

11 Close rear door. Reinstall and lock padlock.<br />

6.4. TRANSFORMER REPLACEMENT<br />

Replace signal transformer using the procedure listed in Table 6–4 in the sequence<br />

given.<br />

Table 6–4. <strong>Signal</strong> Transformer Replacement Procedure<br />

Step<br />

Procedure<br />

1 Remove power to signal head by removing power feed fuses. (Refer to circuit<br />

drawings for location and identity of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Identify, tag, and disconnect wires of transformer.<br />

4 Remove the two screws securing transformer to receptacle bracket and remove<br />

transformer.<br />

5 Install new transformer and reconnect wires as tagged.<br />

6 Reapply power to the signal by reinstalling the power feed fuses.<br />

7 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

8 Close rear door. Reinstall and lock padlock.<br />

P2502, Rev. Apr/08 6–4 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6.5. LAMP RECEPTACLE REPLACEMENT<br />

A lamp receptacle can be replaced using the procedure listed in Table 6–5, as long as<br />

the mounting bracket is not moved or replaced. Moving or replacing the mounting<br />

bracket effects the horizontal and vertical position of the lamp, as well as lamp distance<br />

from the lens. The lamp position controls the illuminating quality of an aspect.<br />

Should an aspect lamp receptacle be defective and warrant replacement, then the<br />

entire receptacle unit should be removed and replaced. Since the horizontal and vertical<br />

position of the lamp receptacle, as well as the distance of the lamp receptacle distance<br />

from the lens, controls the illuminating quality of an aspect, care should be taken to<br />

position the new receptacle unit in the same position as the replaced unit.<br />

The illuminating quality of an aspect is changed through horizontal and vertical position<br />

adjustments made to the signal head lamp receptacle unit while viewing the aspect<br />

approach from a distance of up to 300 feet and about 6 feet above the running rail. A<br />

formal test specification (<strong>Alstom</strong> specification number <strong>AT</strong>S-10Q-28) exists for shop use.<br />

This specification may be used in field locations.<br />

Table 6–5. Receptacle Replacement Procedure<br />

Step<br />

Procedure<br />

1 Remove power to signal head by removing power feed fuses. (Refer to circuit<br />

drawings for location and identity of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Identify, tag, and disconnect wires from the lamp receptacle.<br />

4 Remove lamp from receptacle and screws securing receptacle to the receptacle<br />

bracket.<br />

5 Remove receptacle and install new receptacle.<br />

6 Reconnect wires as tagged on new lamp receptacle.<br />

7 Reapply power to the signal by reinstalling the power feed fuses.<br />

8 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

9 Close rear door. Reinstall and lock padlock.<br />

P2502, Rev. Apr/08 6–5 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6.6. LED MODULE REPLACEMENT<br />

LED P/N 20179-0XX-XX modules should be replaced before the end of their life<br />

expectancy. Replace LED modules as determined by the local authorities. LED module<br />

life is approximately 43,800 hours. Use the procedure provided in Table 6–6 to replace<br />

the LED module.<br />

Table 6–6. LED P/N 20179-0XX-XX Module Replacement Procedure<br />

Step<br />

Action<br />

1 Remove power to the signal by removing its power feed fuses. (Refer to circuit<br />

drawings for location of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Verify that field wires connected to the signal head are tagged or tag, as<br />

necessary.<br />

4 Disconnect the field wiring from the LED <strong>Signal</strong> Terminal Posts.<br />

LED LAMP UNIT<br />

AAR TERMINAL POSTS<br />

LENS<br />

GASKETS<br />

BEZEL<br />

RING<br />

LED<br />

LAMP<br />

UNIT<br />

C L<br />

OUTER<br />

LENS<br />

SCREW &<br />

WASHER<br />

GASKET<br />

CENTERLINE OF<br />

OUTER LENS &<br />

LAMP UNIT LENS<br />

LED LAMP UNIT<br />

MOUNTING SCREW<br />

& WASHER<br />

P2502, Rev. Apr/08 6–6 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

Table 6–6. <strong>AT</strong> LED Unit P/N 20179-0XX-XX Replacement Procedure (Cont.)<br />

Step<br />

Action<br />

5 Remove the fasteners holding the LED lamp unit to the housing mounting<br />

brackets.<br />

6 Remove the LED lamp unit.<br />

7 Remove retaining fasteners and standoffs from old LED lamp unit mounting<br />

bracket.<br />

8 Install retaining fasteners and standoffs onto new LED lamp unit mounting<br />

bracket.<br />

NOTE<br />

Use the same mounting holes in the new LED lamp unit mounting<br />

bracket as were used in the old unit to ensure the unit can be<br />

mounted and aligned properly.<br />

9 Place the new LED lamp unit into position.<br />

10 Tighten the fasteners holding the LED lamp unit to the housing brackets.<br />

11 Reconnect the field wires to the LED lamp unit AAR terminal posts.<br />

12 Repeat steps 3 through 11 for any additional LED lamp units requiring<br />

replacement.<br />

13 Reapply power to the signal by reinstalling the power feed fuses.<br />

14 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

15 Close rear door. Reinstall and lock padlock.<br />

P2502, Rev. Apr/08 6–7 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6.7. LED BOARD/ILLUMIN<strong>AT</strong>ED NUMBER PL<strong>AT</strong>E REPLACEMENT<br />

Replace the LED board/illuminated number plate unit using the procedure listed in<br />

Table 6–7 in the sequence given.<br />

Table 6–7. LED Board/Illuminated Number Plate Replacement Procedure<br />

Step<br />

Action<br />

1 Remove power to the signal by removing its power feed fuses. (Refer to circuit<br />

drawings for location of power feed fuses.)<br />

2 Remove padlock and open rear door.<br />

3 Identify and disconnect LED board wires from terminal in signal head housing.<br />

4 Remove the four screws securing the LED board/illuminated number plate to the<br />

signal housing.<br />

5 Install the new LED board/illuminated number plate to the signal housing.<br />

6 Reconnect LED board wires to terminal in signal head housing.<br />

7 Apply power to signal by replacing power feed fuses.<br />

8 Perform <strong>Signal</strong> Operational Test, Table 4–5.<br />

9 Close rear door. Reinstall and lock padlock.<br />

P2502, Rev. Apr/08 6–8 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6.8. SIGNAL HEAD REPLACEMENT<br />

The signal head replacement procedure provided in Table 6–8 applies to the pole, wall,<br />

and ceiling mounted signal examples provided in this manual. Your installation may<br />

vary.<br />

CAUTION<br />

<strong>Signal</strong> heads are heavy. Stand clear of falling signal heads or obtain help<br />

to hold the signal head during removal so that it does not fall on you. The<br />

use of a rope and pulley or a come-along is recommended to raise and<br />

lower the signal.<br />

Table 6–8. <strong>Signal</strong> Head Replacement Procedure<br />

Step<br />

Procedure<br />

1 Remove the power to the signal head by removing the power feed fuses. (Refer<br />

to the circuit drawings for location and identity of the power feed fuses in the<br />

relay room.)<br />

2 Remove the padlock and open rear door.<br />

3A Pole mounted signal head removal:<br />

Identify, tag, and disconnect the wires contained in the signal head that connect<br />

to wires in the pole. Loosen the bolts on the signal head mounting socket and lift<br />

the signal head off.<br />

P2502, Rev. Apr/08 6–9 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

Table 6–8. <strong>Signal</strong> Head Replacement Procedure (Cont.)<br />

Step<br />

3B<br />

Procedure<br />

Wall or ceiling mounted signal head removal:<br />

Disconnect the conduit; verify that wires connected to the signal head are<br />

tagged or tag, as necessary. Disconnect wires.<br />

Remove the bottom two bolts that secure the signal head to the wall; then<br />

remove the top two bolts, and lower the signal head to the ground, using caution<br />

to remain clear of the lowered equipment. Let the cable come out of the signal<br />

head.<br />

4 If signal is equipped with an enamel number plate, detach plate from the<br />

removed signal head and secure it to the replacement signal head. Replace<br />

number plate gaskets as needed.<br />

5 Secure the replacement signal head to the mounting by reversing the procedure<br />

used to remove the replaced signal head, as follows:<br />

Pole mounted: Feed the cable through the replacement signal head. Lower the<br />

signal head onto the pole and tighten the bolts on the signal head mounting<br />

socket. Reconnect the wires tagged in Step 3A.<br />

Wall mounted: Feed the cable through the replacement signal head. Raise the<br />

signal head into position and secure to the wall using the four bolts removed in<br />

Step 3. Replace the conduit. Reconnect the wires tagged in Step 3B.<br />

6 Reapply power to the signal by reinstalling the power feed fuses.<br />

7 Verify lamp operation per <strong>Signal</strong> Operational Test, Table 4–5.<br />

8 Complete the Wayside <strong>Signal</strong> Siting provided in Table 6–9.<br />

9 Close rear door. Reinstall and lock padlock.<br />

P2502, Rev. Apr/08 6–10 <strong>Alstom</strong> <strong>Signal</strong>ing Inc.

Corrective Maintenance<br />

6.9. WAYSIDE SIGNAL SITING<br />

After installing a new signal head, the procedure in Table 6–9 is to be performed to<br />

ensure that the oncoming train operator properly sees the signal.<br />

Table 6–9. Wayside <strong>Signal</strong> Siting Procedure<br />

Step<br />

Procedure<br />

1 Sight the signal head starting from a position 300 ft (91.44 m) in approach to the<br />

signal and 6 ft (1.83 m) over the top of the running rail (use the running rail<br />

located beneath the train operator). Sight the signal at 30 ft (9.14 m) intervals<br />

moving towards the signal.<br />

Where the track in approach to the signal is not tangent, sight the signal<br />

throughout a 150 ft (45.72 m) approach distance.<br />

Record the sighting distance used on the data sheet for future reference.<br />

2 Verify that the signal is properly aligned for optimum visibility of the illuminated<br />

signal aspect throughout the 300 ft (91.44 m) approach distance.<br />

3 Verify that the illuminated signal aspect is continuously readily readable<br />