PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 33<br />

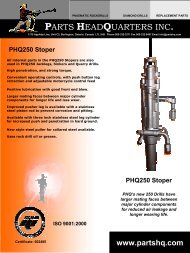

PICTURE SHOWS A STOPER DRILLDURING RUN-IN PROCEDURE<br />

Water Testing Procedure.<br />

Testing of water connections <strong>and</strong> the flow of water through the drill can be accomplished while<br />

the drill is “running in” on the test bench.<br />

The air connection to the drill is already in place, leave the air valve turned on.<br />

Shut the hammering of the drill down temporarily using the throttle h<strong>and</strong>le.<br />

Connect the water hose to the proper connection on the drill <strong>and</strong> turn on the water valve.<br />

Connect the banjo fitting on the spring loaded shank assembly to a drain hose (into a bucket)<br />

Advance the throttle h<strong>and</strong>le forward to engage the valve to the second notch. Water should be<br />

exiting from the water tube at the front of the drill <strong>and</strong> coming out of the drain hose.<br />

Return the throttle lever to the “off” position <strong>and</strong> the water should stop running in the drain.<br />

With the water pressure still on check for leaks around the water inlet <strong>and</strong> automatic water valve.<br />

NOTE: The water regulation control valve will not work if the water pressure supplied to<br />

the drill is equal to or greater than the air pressure supplied to the drill. The ideal air<br />

pressure for PHQ drills is 7 bar (100psi). The ideal water pressure is 3 bar (45 psi).<br />

Version 200711