PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

PHQ250JHMAVL Jackleg MK 1 Parts and Repair Manual PDF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 21<br />

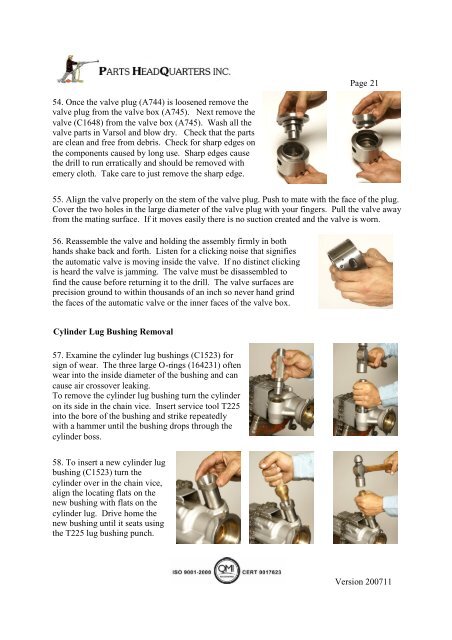

54. Once the valve plug (A744) is loosened remove the<br />

valve plug from the valve box (A745). Next remove the<br />

valve (C1648) from the valve box (A745). Wash all the<br />

valve parts in Varsol <strong>and</strong> blow dry. Check that the parts<br />

are clean <strong>and</strong> free from debris. Check for sharp edges on<br />

the components caused by long use. Sharp edges cause<br />

the drill to run erratically <strong>and</strong> should be removed with<br />

emery cloth. Take care to just remove the sharp edge.<br />

55. Align the valve properly on the stem of the valve plug. Push to mate with the face of the plug.<br />

Cover the two holes in the large diameter of the valve plug with your fingers. Pull the valve away<br />

from the mating surface. If it moves easily there is no suction created <strong>and</strong> the valve is worn.<br />

56. Reassemble the valve <strong>and</strong> holding the assembly firmly in both<br />

h<strong>and</strong>s shake back <strong>and</strong> forth. Listen for a clicking noise that signifies<br />

the automatic valve is moving inside the valve. If no distinct clicking<br />

is heard the valve is jamming. The valve must be disassembled to<br />

find the cause before returning it to the drill. The valve surfaces are<br />

precision ground to within thous<strong>and</strong>s of an inch so never h<strong>and</strong> grind<br />

the faces of the automatic valve or the inner faces of the valve box.<br />

Cylinder Lug Bushing Removal<br />

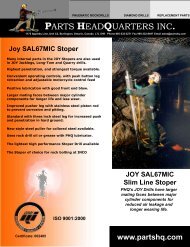

57. Examine the cylinder lug bushings (C1523) for<br />

sign of wear. The three large O-rings (164231) often<br />

wear into the inside diameter of the bushing <strong>and</strong> can<br />

cause air crossover leaking.<br />

To remove the cylinder lug bushing turn the cylinder<br />

on its side in the chain vice. Insert service tool T225<br />

into the bore of the bushing <strong>and</strong> strike repeatedly<br />

with a hammer until the bushing drops through the<br />

cylinder boss.<br />

58. To insert a new cylinder lug<br />

bushing (C1523) turn the<br />

cylinder over in the chain vice,<br />

align the locating flats on the<br />

new bushing with flats on the<br />

cylinder lug. Drive home the<br />

new bushing until it seats using<br />

the T225 lug bushing punch.<br />

Version 200711