MANmagazine Bus edition 1/2015

Stockholm revs up. By the end of 2015 the bus fleet of Keolis Sverige AG, Stockholm´s largest bus line operator for regional public transport, will operate without any fossil fuels. MAN supplies with a lot of urban coaches powered by gas and hybrid drives. In the new edition of the MANmagazine, you can get an impression about the most important milestones of 100 years commercial vehicles at MAN and also read about the team coach for the FC Bayern Munich soccer team that was built in Turkey´s Ankara.

Stockholm revs up. By the end of 2015 the bus fleet of Keolis Sverige AG, Stockholm´s largest bus line operator for regional public transport, will operate without any fossil fuels. MAN supplies with a lot of urban coaches powered by gas and hybrid drives. In the new edition of the MANmagazine, you can get an impression about the most important milestones of 100 years commercial vehicles at MAN and also read about the team coach for the FC Bayern Munich soccer team that was built in Turkey´s Ankara.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1/<strong>2015</strong><br />

International<br />

On the road with green public transport<br />

Clean commute<br />

in Stockholm

MAN MAGAZINE<br />

1/<strong>2015</strong><br />

Explore much<br />

more of<br />

on your tablet.<br />

digitally<br />

04<br />

12<br />

CONTENT<br />

International<br />

04 Ecological envoys<br />

In Spain, Alberto Gómez and José Luis Soria<br />

drive clean hybrid buses.<br />

FOR ANDROID<br />

Simply<br />

download the<br />

app for free:<br />

FOR iOS<br />

The best of MAN’s world<br />

WHAT ARE THE HIGHLIGHTS of MAN’s century-old<br />

experience in commercial vehicle<br />

design and manufacturing? Why is Stockholm<br />

a pioneer in green public transport? And why<br />

was the MAN Lion’s City GL CNG named “<strong>Bus</strong><br />

of the Year <strong>2015</strong>”? This third issue of <strong>MANmagazine</strong><br />

offers answers to these and other interesting<br />

questions. It reflects the world of MAN:<br />

a world shaped by technology, with fascinating<br />

topics drawn from the realm of trucks and<br />

buses all the way to the turbines and engines<br />

that are deployed in ships or power plants.<br />

We hope you enjoy this <strong>edition</strong> of <strong>MANmagazine</strong>.<br />

You can also download the digital<br />

tablet version for free, which is available on<br />

iOS and Android.<br />

MASTHEAD<br />

MAN MAGAZINE is published twice a year<br />

in 16 languages.<br />

PUBLISHED BY MAN Corporate Communications<br />

Andreas Lampersbach (V.i.S.d.P.),<br />

Ungererstraße 69, 80805 Munich, Germany<br />

RESPONSIBLE EDITOR & PROJECT MANAGER<br />

Joachim Kelz, Tel.: +49. 89. 1580-1175,<br />

magazin@man.eu, www.man.eu<br />

PUBLISHER C3 Creative Code and Content GmbH,<br />

Heiligegeistkirchplatz 1, 10178 Berlin, Germany<br />

Tel.: +49. 30. 44032-0, www.c3.co,<br />

Shareholders of C3 Creative Code and Content GmbH<br />

are the Burda Gesellschaft mit beschränkter Haftung<br />

(limited liability company), Offenburg, and the KB Holding<br />

GmbH, Berlin, with 50% each. Sole shareholder of<br />

the Burda Gesellschaft mit beschränkter Haftung is the<br />

Hubert Burda Media Holding Kommanditgesellschaft<br />

(limited partnership), Offenburg. Shareholders of<br />

KB Holding GmbH are Mr. Lukas Kircher (managing<br />

director, Berlin) and Mr. Rainer Burkhardt (managing<br />

director, Berlin) with 50% each.<br />

EDITORS & AUTHORS Klaus-Peter Hilger (resp.),<br />

Yasmine Sailer (dep.). Freelance authors: Tobias Birzer,<br />

Alexandra Grossmann, Dr. Wolfgang Hörner,<br />

Martin Kaluza, Sarah Paulus, Marcus Schick,<br />

André Schmidt-Carré, Miryam Torrecilla<br />

INTERNATIONAL EDITORS Patricia Preston<br />

(resp., freelance editor), Asa. C. Tomash<br />

MANAGING EDITOR Sara Austen<br />

CONCEPT Stefan Lemle, A New Kind<br />

(freelance contributor)<br />

GRAPHICS Micheline Pollach, Andrea Hüls, Christian<br />

Kühn, Anna-Sophie Werner (freelance contributor)<br />

GRAPHICS EDITOR Elke Latinovic,<br />

André Kirsch (freelance contributor)<br />

COVER IMAGE Daniel Blom<br />

PRODUCTION C3 Creative Code and Content GmbH<br />

PRINTING Gotteswinter und Aumaier GmbH,<br />

Joseph-Dollinger-Bogen 22, 80807 Munich, Germany<br />

REPRODUCTION permitted with reference.<br />

Any changes must be coordinated with the editors.<br />

SUBSCRIPTION SERVICE Thomas Mahler GmbH,<br />

Postfach 50 04 65, 80974 Munich, Germany<br />

Tel.: +49. 89. 1580-3724,<br />

Thomas.Mahler-ext@man.eu<br />

ADVERTISING SERVICE Zeitzeichen Vertriebs GmbH,<br />

Radka Neumann, Tel.: +49. 8323. 9984630,<br />

radkaneumann@zeitzeichen.de<br />

COPYRIGHT ©<strong>2015</strong> MAN and C3 Creative Code and<br />

Content GmbH<br />

Photos: APPLE INC. Pr<br />

22<br />

34<br />

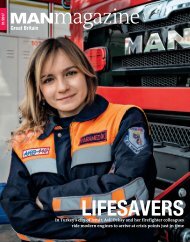

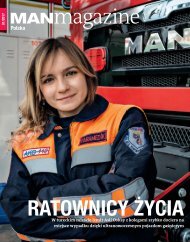

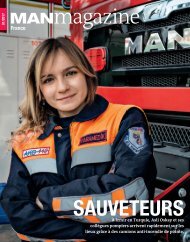

COVER STORY<br />

Stockholm is a trendsetter in terms of clean public transport,<br />

with MAN supplying the innovative bus technologies.<br />

40<br />

06 Prize-winning design<br />

The NEOPLAN Jetliner coach won the<br />

German Design Award <strong>2015</strong>.<br />

08 Rocking the desert<br />

MAN racing vehicles and service trucks<br />

successfully mastered the Dakar Rally.<br />

10 Current cruising<br />

Engines by MAN Diesel & Turbo drive the<br />

luxury vessels of Norwegian Cruise Lines.<br />

12 Ready for the future<br />

The key milestones of MAN’s century-old<br />

tradition in commercial vehicle production<br />

18 News<br />

Current news in MAN’s world<br />

22 Välkommen ombord!<br />

Stockholm revs up<br />

Hybrid and biogas buses serve the capital of<br />

Sweden.<br />

28 In a league of its own<br />

The team coach for the FC Bayern Munich<br />

soccer team is built in Turkey’s Ankara.<br />

32 Addition to the coach family<br />

Augmenting MAN’s portfolio is the standard<br />

regional coach Lion’s Intercity.<br />

34 Closer to the clouds<br />

Comfort, efficiency, design and safety: the<br />

NEOPLAN Skyliner’s valued features<br />

38 The sandman<br />

Peter Meyer shuttles tourists around<br />

Fraser Island in a converted MAN truck.<br />

40 Clean winner<br />

The MAN Lion’s City GL CNG was named<br />

“<strong>Bus</strong> of the Year <strong>2015</strong>”.<br />

44 Under ground<br />

Reporting for mine duty, an MAN truck<br />

travels underground in pieces.<br />

48 Systematic safety<br />

A wide range of MAN assistance systems<br />

improves the safety of bus traffic.<br />

02 03

man magazine<br />

1/<strong>2015</strong><br />

Quiet and comfortable: driver José<br />

Luis Soria appreciates the comfort<br />

and low noise level of the hybrid bus.<br />

What routes do the buses cover? José<br />

Luis Soria: The buses operate in the city centres<br />

of Valdemoro and Aranjuez, not far from<br />

Madrid. It’s a low average speed, with a lot of<br />

stops and large numbers of passengers. On<br />

routes like this, the hybrid technology is particularly<br />

beneficial.<br />

How do passengers react to the buses?<br />

José Luis Soria: They’re very happy, especially<br />

the pensioners, because of the easy access.<br />

The bus can be quickly lowered quite a way at<br />

stops, to make it easier for people to board.<br />

Also, the broad seats with arm rests have been<br />

very well received.<br />

Is special training needed to be operating<br />

the MAN Lion’s City Hybrid? Alberto<br />

Gómez: We did have special training. First we<br />

took a course on hybrid technology and safety<br />

precautions. After that we received a few<br />

driving lessons.<br />

How much fuel does the bus save in<br />

comparison with a standard diesel bus?<br />

José Luis Soria: On average it comes to 25%<br />

fuel savings, which also means lower CO 2<br />

emissions. It is our goal to get the maximum<br />

savings out of the hybrid technology. We<br />

manage this by operating the vehicles for<br />

long shifts.<br />

What does the environment mean to<br />

you personally? Alberto Gómez : For me personally,<br />

the environment is a very important<br />

issue and I am happy to be making a contribution<br />

to climate protection by driving an environmentally<br />

friendly vehicle.<br />

25 %<br />

fuel savings<br />

With their hybrid technology, Aisa’s MAN<br />

Lion’s City buses cut diesel consumption<br />

by as much as 25%.<br />

my man<br />

Ecological<br />

The Spanish transport company Aisa uses<br />

two environmentally friendly Lion’s City Hybrid<br />

buses for municipal transport in Valdemoro<br />

and Aranjuez. The drivers José Luis Soria and<br />

Alberto Gómez talk about their daily working<br />

life with the new buses.<br />

envoys<br />

What do you think of the new hybrid<br />

buses? Alberto Gómez: The bus is great to<br />

drive. The driver’s cabin is extremely comfortable,<br />

especially the seat. This makes my<br />

work even more enjoyable.<br />

So what makes these vehicles special?<br />

José Luis Soria: I think it remarkable how very<br />

quiet the bus is, while handling so smoothly.<br />

Photos: Juan Caraballo<br />

For the benefit of the environment:<br />

Alberto Gómez is proud to be driving<br />

a clean bus and thereby contributing to<br />

environmental conservation.<br />

04<br />

05

man magazine<br />

1/<strong>2015</strong><br />

Prize-winning<br />

Design<br />

Characteristic for NEOPLAN: The<br />

Jetliner is dynamic, well proportioned<br />

and powerful, as well as elegant.<br />

Illustrations: MAN<br />

Powerful, dynamic, elegant. Descriptions<br />

often used to define sports cars actually<br />

also apply to the NEOPLAN Jetliner. This<br />

coach, part of the mid-decker segment, is<br />

groundbreaking in terms of both technology<br />

and design. That judgement was shared by<br />

the jury of the German Design Award <strong>2015</strong>,<br />

which gave an award to the NEOPLAN Jetliner<br />

for its exceptional design quality in the<br />

“Excellent Product Design – Transportation<br />

and Public Design” category. Based i n Frankfurt<br />

am Main, the German Design Council has<br />

honoured outstanding design achievements<br />

with the annual German Design Award for the<br />

past 60 years.<br />

Among the distinguishing features of<br />

MAN’s Jetliner are powerful proportions with<br />

forward-thrusting dynamics. “Because of its<br />

dynamic design and especially the streamlined<br />

sides, the coach has a really fluid and<br />

forward-moving appearance. It looks as<br />

though it’s already in motion while it’s still<br />

stationary,” says Stephan Schönherr, Vice<br />

President Design <strong>Bus</strong> at MAN. The smooth<br />

surface, drag coefficient-optimised silhouette<br />

and clearly defined lines are all typical of the<br />

NEOPLAN image. The premium design standards<br />

are also reflected by the vehicle’s interior,<br />

offering both driver and passengers a pleasant<br />

atmosphere with maximum functionality.<br />

According to Stephan Schönherr and his<br />

successful design team, the coach is shaped<br />

by a comprehensive approach that incorporates<br />

holistic elements and the harmony<br />

between interior and exterior characteristics.<br />

“The NEOPLAN Jetliner definitely deserved<br />

this award. We reinterpreted an already established<br />

concept, thus significantly modernising<br />

the vehicle as the youngest representative<br />

of the NEOPLAN brand.”<br />

Since 2002, MAN and NEOPLAN brand<br />

coaches have received a total of 12 accolades<br />

for design, including the prestigious Red Dot<br />

Design Award and the iF DESIGN AWARD.<br />

An image gallery of design prizes and an<br />

interview with Stephan Schönherr are available<br />

at > www.man.eu/discovermanbusdesign<br />

06<br />

07

man magazine<br />

1/<strong>2015</strong><br />

Rocking<br />

the<br />

desert<br />

Three countries, 9,000 kilometres,<br />

43° Celsius maximum temperature, 4,500 metres<br />

altitude: In this year’s Dakar Rally through<br />

Argentina, Bolivia and Chile, the trucks were<br />

once again pushed to the limits of endurance.<br />

The 15 participating MAN vehicles withstood<br />

the extreme conditions especially well: In the<br />

overall rankings, two MAN prototypes crewed<br />

by the VEKA racing team made it into the top<br />

10, coming in fourth and eighth. In the category<br />

of vehicles close to production, MAN even<br />

finished in first and second place, and also<br />

managed a decisive lead in the three-axle<br />

class. This result not only made MAN the second-best<br />

manufacturer in the top 10 after<br />

Kamaz, but also delivered yet another success<br />

story: Out of MAN’s 15 racing trucks, only one<br />

vehicle malfunctioned due to a technical defect.<br />

This serves to prove the outstanding robustness<br />

of MAN racers, as well as the sterling<br />

work of the MAN service team. With thousands<br />

of replacement parts and in-depth competence<br />

in case of complicated repairs, the official<br />

MAN service truck lent much support,<br />

while 50 additional MAN brand trucks carried<br />

parts and equipment needed en route by the<br />

participating teams.<br />

The MAN works team led by Hans Echter,<br />

Hans-Werner Nell and Josef Kreppold also celebrated<br />

a special anniversary at this year’s<br />

Dakar Rally. The three mechanics have been<br />

starting in the now South American desert<br />

event for a full decade. “It is quite normal that<br />

teams will stay together for three or four<br />

years,” says Josef Kreppold. “Yet to find the<br />

same team starting with the same vehicle for<br />

10 years in a row is absolutely exceptional and<br />

totally unique as a combination.”<br />

Photo: Leon Jansen/ Dakarpress.com<br />

One of the front runners: Carrying<br />

the number 503, the MAN prototype<br />

starting for the VEKA racing team<br />

took fourth place in the overall ranking.<br />

08<br />

09

man magazine<br />

1/<strong>2015</strong><br />

Current<br />

cruising<br />

Modern machinery: Four-stroke MAN engines with<br />

common rail injection power the Breakaway class.<br />

Home port New York: Norwegian<br />

Cruise Line operates vessels for<br />

luxury cruises in the Caribbean.<br />

Photos: gettyimages, Ingrid Fieback<br />

certainly not a common sight, the anchored<br />

vessel rising up against the skyline of<br />

Manhattan. It is decidedly not one of the<br />

small ferries shuttling to and from the Statue<br />

of Liberty and Staten Island, but rather one of<br />

the world’s largest and most modern cruise<br />

ships. The US-based shipping company Norwegian<br />

Cruise Line (NCL) sails the eastern waters<br />

of the Caribbean with its ships Norwegian<br />

Breakaway and Norwegian Getaway. Both vessels<br />

are part of NCL’s Breakaway class, each<br />

with room for 4,028 guests and a crew of 1,640,<br />

and designed to fundamentally improve the<br />

cruising experience.<br />

With the new ships built by the Meyer<br />

Werft in Papenburg, Germany, the shipyard<br />

relied on the know-how and experience of<br />

MAN Diesel & Turbo to supply state-of-the-art<br />

engines for the luxury vessels. Thus, MAN<br />

equipped both the Norwegian Breakaway and<br />

Norwegian Getaway with two 12V and two 14V<br />

48/60CR four-stroke medium-speed diesel<br />

engines, each with with common rail injection.<br />

Together, the four engines per ship<br />

deliver a performance of 84,840 hp. “Our<br />

common rail injection system offers a much<br />

better performance than conventional engines,”<br />

explains Benjamin Andres, Head of<br />

Order Management Cruise & Ferry at MAN<br />

Diesel & Turbo. “We are rather proud to contribute<br />

to the NCL fleet, thus helping to shape<br />

the future of modern cruising.”<br />

Among the unusual characteristics of<br />

ships in the Breakaway class is the Freestyle<br />

Cruising concept, with no set meal times or<br />

formal dress code, but rather a brand-new<br />

deck design with easier passenger access to<br />

shops, restaurants and bars. Another four<br />

ships will be added by 2019 as part of the new<br />

Breakaway Plus line: The maiden voyage for<br />

the Norwegian Escape is scheduled for fall of<br />

<strong>2015</strong>, with the Norwegian Bliss set to follow in<br />

2016. Another two vessels are planned for<br />

2018 and 2019.<br />

10<br />

11

man magazine<br />

1/<strong>2015</strong><br />

Ready for<br />

the future<br />

1915<br />

Looking back on a history<br />

of more than 250 years,<br />

the MAN Group celebrates<br />

yet another significant<br />

anniversary in <strong>2015</strong>: The<br />

history of commercial<br />

vehicle construction at<br />

MAN began a century ago.<br />

An overview of the most<br />

important milestones.<br />

E<br />

ntered into the trade register of<br />

the City of Nuremberg on 21 June<br />

1915 was a new company, namely<br />

“Lastwagenwerke M.A.N.-Saurer”. The company<br />

had been established as a joint venture<br />

between Maschinenfabrik Augsburg-Nürnberg<br />

AG and Saurer, a Swiss producer of commercial<br />

vehicles. Soon thereafter, the first MAN-<br />

Saurer three-tonne truck left the joint factory<br />

in Lindau, Germany, on Lake Constance, followed<br />

by the first buses used as long-distance<br />

coaches by the Imperial Post Office, and transporting<br />

passengers as well as letters and<br />

parcels. This was the beginning of commercial<br />

vehicle construction at MAN, a success story<br />

that has not only decisively shaped the history<br />

of the company itself. With its advanced and<br />

often revolutionary innovations, MAN has significantly<br />

influenced the development of<br />

trucks and buses for the last 100 years – an endeavour<br />

that continues to this very day.<br />

Production shifted to the MAN plant in<br />

Nuremberg in 1916 and the company traded<br />

as “M.A.N. Lastwagenwerke” following the departure<br />

of Sauer two years later. In 1924, MAN<br />

presented the first truck with a direct dieselinjection<br />

engine – which formed the basis for<br />

the triumphant deployment of diesel engines<br />

in truck construction. It saved up to 75% of<br />

operating costs compared with the gasoline<br />

engines common at the time. Back then,<br />

economy and efficiency were already two<br />

1924<br />

In cooperation with the Saurer company, MAN<br />

builds the first trucks and buses in Lindau in<br />

southern Germany. One year later, production<br />

moves to MAN’s plant in Nuremberg. MAN develops the first vehicle<br />

engine with direct diesel<br />

injection. This launches the<br />

triumphant success story of<br />

diesel engines in trucks –<br />

which continues until today.<br />

1951<br />

The first German truck<br />

engine with exhaust turbocharging<br />

achieves a 35%<br />

performance improvement<br />

over conventional truck<br />

engines: the six-cylinder<br />

engine MAN 1546 GT with<br />

175 hp instead of 130 hp.<br />

1961<br />

With the 750 HO, MAN introduces the first bus with<br />

a modular chassis for city and regional buses as<br />

well as travel coaches to the market.<br />

1897<br />

Together with MAN<br />

engineers, Rudolf<br />

Diesel develops the<br />

first diesel engine.<br />

1932<br />

With 140 hp, the MAN<br />

S1H6 is the world’s most<br />

powerful diesel truck.<br />

A year later, MAN even<br />

markets a truck model<br />

with 150 hp.<br />

Photos: Historical Archive MAN Truck & <strong>Bus</strong><br />

1951<br />

The MAN truck F8 with its V8<br />

180-hp engine becomes a flagship<br />

of Germany’s emerging “economic<br />

miracle” period.<br />

1955<br />

The production of trucks, buses and<br />

tractors moves from Nuremberg to<br />

the new plant in Munich. The first<br />

truck coming off the production line<br />

is an MAN 515 L1. Engine production<br />

remains in Nuremberg.<br />

12<br />

13

man magazine<br />

1/<strong>2015</strong><br />

essential development targets of MAN, objectives<br />

that still apply today. That same year,<br />

MAN produced the first low-floor bus with a<br />

specially designed low-frame chassis. Until<br />

then, buses previously built by MAN had been<br />

based on a truck chassis.<br />

In 1928, MAN presented its first threeaxle<br />

truck, which became the precursor of all<br />

subsequent heavy-duty trucks made by MAN.<br />

In 1932, the S1H6 truck was equipped with a<br />

D4086 diesel engine that delivered 140 hp –<br />

then considered the most powerful diesel<br />

truck in the world. The next technical milestone<br />

was reached in 1937 with the development<br />

of an extremely fuel-efficient directinjection<br />

diesel engine and the introduction<br />

of the all-wheel drive.<br />

Trucks were much in demand during reconstruction<br />

work after World War II. In the<br />

1950s, the MAN F8 with its 180-hp V8 motor<br />

advanced to the flagship of the economic<br />

miracle period experienced by a still-young<br />

Federal Republic of Germany. As early as 1951,<br />

MAN was already demonstrating its level<br />

of innovation when it introduced the first<br />

German truck engine with exhaust gas turbocharging.<br />

The six-cylinder engine achieved<br />

175 hp with an 8.72-litre displacement, a<br />

remarkable performance increase of 35%. In<br />

1955, MAN moved truck and bus production<br />

to its new site in Munich. The Nuremberg<br />

plant evolved into the centre of competence<br />

for engine production.<br />

MAN also repeatedly proved its innovative<br />

powers in bus construction. In 1961,<br />

the company introduced the market to the<br />

750 HO, the first bus in modular design.<br />

Different structure variants were mounted<br />

on a standardised chassis for regular line<br />

service and regional buses, as well as longdistance<br />

travel coaches.<br />

140<br />

horsepower<br />

In 1932, MAN’s S1H6 with its 140-hp<br />

engine was the world’s strongest diesel<br />

truck. Issued one year later was an even<br />

more powerful version with 150 hp.<br />

Photos: Historical Archive MAN Truck & <strong>Bus</strong><br />

When acquiring Büssing Automobilwerke<br />

and the company’s plant in Salzgitter in 1971,<br />

MAN adopted Büssing’s specialised underfloor<br />

engine technology as well as the specific<br />

Büssing logo for its own corporate identity.<br />

The stylised Brunswick Lion has since decorated<br />

the radiator grille of all commercial<br />

vehicles made by MAN. In the late 1970s, MAN<br />

began a collaboration with VW in the lighttruck<br />

segment, with the G-series’ six- and<br />

eight-tonne trucks jointly produced until<br />

1993. Today, MAN is part of the VW Group.<br />

the show horses of MAN have always<br />

remained the short-hooded trucks for<br />

construction work and heavy-duty forwardcontrolled<br />

trucks for long-distance transport<br />

– including the 19.280 type that was the first<br />

MAN truck to receive the “Truck of the Year”<br />

award in 1978. Numerous awards followed,<br />

such as for the MAN F90 introduced in 1986<br />

and recognised as “Truck of the Year” the following<br />

year. Especially the generous driver’s<br />

cab of the F90 left a lasting impression. Then<br />

as today, driver ergonomics and comfort have<br />

always been of major concern for MAN designers.<br />

The most successful truck model of<br />

the 1990s was the F2000. The heavy-duty series<br />

already featured standard engines with<br />

electronic injection control back in 1994.<br />

MAN buses also had their milestones. In<br />

1992, MAN presented the Lion’s Star, a travel<br />

coach that would shape the names of all MAN<br />

bus generations to come. With drag coefficient<br />

value of 0.41, the long-distance highdecker<br />

was especially aerodynamic and therefore<br />

fuel-efficient.<br />

New innovations marked the entry into a<br />

new millennium. In 2000, the “Trucknology<br />

Generation Type A”, or TGA series, set new<br />

standards in terms of comfort and ergonomics,<br />

as well as new technologies such as the<br />

“The past and<br />

present success of<br />

MAN is defined by<br />

industry expertise,<br />

customer focus and<br />

innovative drive.”<br />

Henning Stibbe, Head of the Historical Archive,<br />

MAN Truck & <strong>Bus</strong><br />

1977<br />

Start of a collaboration with Volkswagen<br />

Nutzfahrzeuge to develop a light vehicle<br />

range from 6 to 10 tonnes gross weight.<br />

Production of the so-called VW-MAN joint<br />

series begins in 1979.<br />

1986<br />

MAN introduces the F90 series, with a<br />

completely new driver’s cab, to the market.<br />

1992<br />

The travel coach MAN Lion’s Star<br />

enters the market and is named<br />

“Coach of the Year”.<br />

2000<br />

The presentation of the Trucknology Generation TGA<br />

is the starting point of a major product campaign.<br />

1971<br />

MAN acquires the ÖAF and<br />

Büssing Automobilwerke.<br />

The Büssing lion is adopted<br />

in MAN’s logo.<br />

1978<br />

MAN receives the “Truck of the<br />

Year” award for the first time,<br />

with the 19.280 model.<br />

2001<br />

MAN acquires the brands<br />

NEOPLAN, ERF and Star.<br />

14<br />

15

man magazine<br />

1/<strong>2015</strong><br />

MAN TipMatic or MAN Comfort-Shift for optimised<br />

gear changing. Acquiring the NEOPLAN<br />

brand in 2001 strengthened MAN’s position in<br />

the premium travel-coach segment.<br />

Introducing the D20 engines with common<br />

rail injection in 2004 was a real milestone<br />

in engine technology. MAN was the<br />

first commercial vehicle manufacturer to<br />

convert all its engines to this economical and<br />

environmentally friendly, electronically controlled<br />

injection method. MAN also modernised<br />

the light and medium series by introducing<br />

the TGL and the TGM in 2005. Meeting<br />

Euro 4, the exhaust gas standard at the time,<br />

could be achieved through a combination of<br />

exhaust gas recycling and particle filters<br />

without any additives such as AdBlue. Two<br />

years later, two models were to succeed the<br />

TGA in the heavy-duty series: While the TGX<br />

is designed for long-distance transport, the<br />

TGS operates in the areas of traction and<br />

heavy-duty distribution. Both MAN models<br />

received the “Truck of the Year” award for the<br />

seventh time – an industry record.<br />

In 2010, MAN began serial production of a<br />

city bus with a hybrid drive, the Lion’s City<br />

Hybrid. Due to its innovative hybrid drive,<br />

this vehicle saves up to 30% in fuel. The model<br />

quickly became a huge success and received<br />

the ÖkoGlobe Award in 2011 and the Green <strong>Bus</strong><br />

Award in 2012 for its sustainable concept.<br />

The development of resource-saving and<br />

environmentally friendly vehicles has<br />

always been one of the main objectives of<br />

MAN Truck & <strong>Bus</strong>. Meeting the latest exhaust<br />

gas standard Euro 6 was a challenge met by<br />

MAN in 2012 with its latest generation of TG<br />

vehicles. These fulfil the strictest requirements<br />

with maximum fuel efficiency. In the<br />

autumn of 2014, MAN introduced the latest<br />

engine generation D38, representing the<br />

“This century-old<br />

success story<br />

wrote the basis<br />

for a future filled<br />

with ideas and an<br />

innovative spirit.”<br />

Dr. Georg Pachta-Reyhofen,<br />

Chief Executive Officer, MAN SE<br />

current culmination of 100 years of engine<br />

development for commercial vehicles. Utilising<br />

a two-stage turbocharger, the frugal Euro<br />

6 diesel engines reach up to 640 hp.<br />

driving factors in today’s product development<br />

include sustainability and corporate<br />

climate goals, as well as policy frameworks<br />

and the limited availability of fossil fuels.<br />

MAN is therefore investigating the advanced<br />

development of various alternative drive concepts.<br />

In future, hybrid drives in commercial<br />

vehicles will be part of the drive concept in all<br />

application areas. Urban buses already use a<br />

serial diesel/electric hybrid drive. As for the<br />

commercial vehicles sector, MAN introduced<br />

the TGX Hybrid at the 2014 IAA exhibit as a<br />

concept vehicle for a TCO-optimised truck hybrid<br />

drive in long-distance transport. An allelectrically-operated<br />

heavy truck with Range<br />

Extender for operating in urban environs, the<br />

Metropolis research vehicle conceptualised<br />

by MAN is currently in its test phase.<br />

Compressed natural gas (CNG) and biogas<br />

are already available as alternatives. Engines<br />

suitable for CNG can also run on biogas in an<br />

almost CO 2 -neutral manner, as exemplified<br />

by the new Lion’s City GL CNG natural gas articulated<br />

vehicle that won the “<strong>Bus</strong> of the Year<br />

<strong>2015</strong>” award. The established range of natural<br />

gas city buses will be supplemented by trucks<br />

with a CNG drive in 2016.<br />

Future-forecast analysts investigate global<br />

megatrends and define the direction for developing<br />

future vehicle generations. In its predevelopment,<br />

MAN is working on vehicles that<br />

no longer require a driver for certain activities,<br />

such as safety vehicles securing motorway<br />

construction sites. These and other entirely<br />

new ideas will serve MAN Truck & <strong>Bus</strong> in<br />

continuously driving the advancement of<br />

state-of-the-art commercial vehicles in future.<br />

250 years of<br />

MAN history<br />

While MAN has built commercial vehicles for<br />

a century, the historical roots of today’s MAN<br />

Group can be traced back to three starting<br />

points: the founding of the St. Antony ironworks<br />

in Oberhausen in 1758 as well as the<br />

Sandersche Maschinenfabrik in 1840 and<br />

the establishment of the Eisengießerei und<br />

Maschinenfabrik Klett & Comp in Nuremberg<br />

in 1841. In 1878, the St. Antony ironworks<br />

merged with two other ironworks in the Ruhr<br />

area to form the “Gutehoffnungshütte” (GHH),<br />

while the two southern German predecessor<br />

companies merged to form Maschinenfabrik<br />

Augsburg-Nürnberg AG in 1898 – abbreviated<br />

to the name MAN. From 1893 to 1897, Rudolf<br />

Diesel developed the first diesel engine in this<br />

Augsburg factory, which provided the basis<br />

for later engine generations in MAN’s<br />

commercial vehicle construction. In 1921,<br />

MAN and GHH merged to form the company<br />

still existing today, which has been part of<br />

the VW Group since 2011.<br />

2005<br />

2010<br />

The market launch of the TGL<br />

and TGM models in the light- and<br />

medium-weight class from<br />

7.5 to 26 tonnes completes the<br />

MAN Trucknology Generation.<br />

The MAN Hybrid<br />

city bus enters<br />

series production.<br />

2014<br />

The new D38 Euro 6 engines are<br />

offered for the MAN TGX series with<br />

520 hp to 640 hp.<br />

2004<br />

Introduction of the D20 Common Rail<br />

engine series offers an entirely new,<br />

electronically controlled injection<br />

technology.<br />

2007<br />

In the heavy-duty truck series, the TGA<br />

develops into the MAN TGS and TGX models.<br />

Both are awarded the “Truck of the Year<br />

2008” title by trade journalists.<br />

Photos: Historical Archive MAN Truck & <strong>Bus</strong><br />

2011<br />

Return of a<br />

legend: The<br />

double-decker<br />

NEOPLAN<br />

Skyliner re-enters<br />

the market.<br />

2012<br />

Premiere: Euro-6 compliant MAN TG vehicles<br />

in the TGL, TGM, TGS and TGX series<br />

<strong>2015</strong><br />

The articulated natural gas Lion’s City<br />

GL CNG is named “<strong>Bus</strong> of the Year”.<br />

16<br />

17

man magazine<br />

1/<strong>2015</strong><br />

For a green future: MAN intends<br />

to cut CO 2 emission levels<br />

of 2008 by 25% until 2020.<br />

Imperial Cargo keeps<br />

counting on MAN<br />

Climate goal in sight<br />

The photovoltaic system renders the MAN plant in<br />

Pinetown, South Africa, a climate-neutral site.<br />

In 2014, the MAN Group saved more than<br />

105,000 tonnes of CO 2 as compared with the<br />

reference year 2008, which amounts to more<br />

than 19% less harmful climate gas. Accordingly,<br />

the company succeeded in reducing its CO 2<br />

emissions by another 5% compared with the<br />

previous year. As MAN takes its corporate responsibility<br />

for climate protection seriously,<br />

the company developed a climate strategy in<br />

2011. The target: a reduction of annual CO 2<br />

emissions at all production sites by 25% until<br />

2020 in comparison with the base year 2008.<br />

That amounts to 135,000 tonnes less CO 2 each<br />

year, roughly the equivalent of emissions<br />

produced by a small German town of 15,000<br />

residents. With the results for 2014, MAN has<br />

taken another step towards reaching this<br />

target. The successful outcome has resulted<br />

from a multitude of measures to effectively<br />

reduce CO 2 emissions. These include not only<br />

more efficient technologies in the production<br />

process, but also optimised heating and<br />

ventilation systems or the use of renewable<br />

energy sources.<br />

One outstanding measure contributing to<br />

climate targets at MAN Truck & <strong>Bus</strong> was the<br />

installation of a photovoltaic system at its<br />

Pinetown site in South Africa. Since December<br />

2014, the system has supplied the truck and<br />

bus chassis production plant with clean energy.<br />

This makes Pinetown a climate-neutral site<br />

as of <strong>2015</strong>, while the solar system also renders<br />

it independent of energy price fluctuations.<br />

Thus, the investment will be amortised in just<br />

a few years. Another example of environmental<br />

protection initiatives is MAN Diesel &<br />

Turbo’s site in Frederikshavn, Denmark, where<br />

a system recovering the exhaust heat from<br />

an engine testing centre supplies about 250<br />

households with district heating.<br />

Photos: Shutterstock, MAN<br />

Futuristic design: Presented at the 2014 IAA trade show,<br />

the MAN TGX Hybrid demonstrates the advantages of a<br />

hybrid drive with lower CO 2 emissions and fuel usage.<br />

Hybrid truck concept<br />

Hybrid drives are likely to play an important<br />

role in powering the commercial vehicles<br />

of the future. With its TGX Hybrid, MAN has<br />

for the first time introduced a hybrid vehicle<br />

concept for long-distance transport. The<br />

truck is powered by a parallel hybrid system,<br />

combining a 440-hp diesel engine and an<br />

electric engine with an output of 130 kilowatts.<br />

While the diesel engine serves as the<br />

main drive, the electrical motor operates in<br />

overrun mode and as a generator when braking.<br />

Thereby regained energy is stored in a<br />

battery and utilised in uphill road conditions<br />

to support the diesel engine torque. With its<br />

fuel savings, the TGX Hybrid reduces its CO 2<br />

emissions by approximately 8%.<br />

300<br />

TGS for Egypt<br />

Petroleum Arrows, Egypt’s national<br />

company for fuel logistics, is modernising<br />

its fleet with the addition of 300 MAN<br />

tractor-trailer units. The company has<br />

maintained MAN trucks in its fleet for<br />

decades. The associated tanker<br />

semitrailers will be delivered by Egyptian<br />

MAN importer Gorica.<br />

based in South Africa and Namibia,<br />

the logistics expert Imperial Cargo has<br />

just expanded its fleet by adding 60 MAN<br />

TGS trucks for long-haul transport. The<br />

60 new vehicles will cover on average<br />

16,000 kilometres per month, or practically<br />

200,000 kilometres in a year. They<br />

supplement the 44 TGS vehicles already<br />

owned by the company.<br />

Christo Theron, Managing Director of<br />

the Imperial Cargo Group, trusts his positive<br />

experience with MAN’s TGS model in<br />

the past: “We subject every new truck that<br />

we add to our fleet to strenuous tests,<br />

especially with regard to fuel consumption.<br />

The MAN TGS vehicles in our longhaul<br />

fleet score impressively with a 10%<br />

lower consumption rate compared with<br />

other brands.” The trucks are typically<br />

operated with two trailers attached, explains<br />

Theron. “Each truck transports a<br />

payload of around 36 tonnes. The TGS<br />

offers the perfect balance between<br />

performance, payload and efficient fuel<br />

consumption, so the overall operating<br />

costs achieved will set new standards.<br />

Our drivers are delighted with the MAN<br />

vehicles, as they are very comfortable and<br />

easy to handle. Another important factor<br />

for us is the customer service we receive<br />

from MAN’s branch in Cape Town. Response<br />

times are short, and we are in regular<br />

contact with them for planning our<br />

scheduled servicing.” Imperial Cargo<br />

serves long-distance routes in South Africa<br />

and Namibia, as well as in the neighbouring<br />

countries of Zimbabwe, Zambia,<br />

Angola, Botswana and Mozambique.<br />

MAN TGS power for Africa: The trucks of the South African logistics company Imperial Cargo<br />

operate in South Africa, Namibia, Zimbabwe, Zambia, Angola, Botswana and Mozambique.<br />

18<br />

19

man magazine<br />

1/<strong>2015</strong><br />

815<br />

buses for german rail<br />

DB Regio <strong>Bus</strong>, Germany’s largest bus<br />

travel provider, placed an order with<br />

MAN Truck & <strong>Bus</strong> for up to 435<br />

municipal and regional buses for <strong>2015</strong><br />

and 2016, amounting to a value of<br />

around €100 million. The subsidiary of<br />

Deutsche Bahn (German Rail) retains the<br />

option of ordering an additional 380<br />

municipal and regional buses for the<br />

years 2017 and 2018. The framework<br />

agreement with MAN specifies modern<br />

municipal and regional buses of models<br />

MAN Lion’s City, MAN Lion’s City Ü and<br />

MAN Lion’s City G/GÜ.<br />

Controlling costs with MAN’s TCO tool<br />

When purchasing a new truck, overall<br />

cost calculation ought to place a strong emphasis<br />

on the total cost of ownership (TCO) –<br />

namely the total operating costs for the vehicle<br />

from procurement through retirement. To<br />

enable customers to work out the TCO of their<br />

future MAN truck or bus in a fast and reliable<br />

fashion, MAN Truck & <strong>Bus</strong> now offers a TCO<br />

Optimizer tool. Available on the MAN website,<br />

this online calculator allows for listing all the<br />

important factors, such as fuel consumption<br />

and the cost of repairs and servicing. In addition,<br />

it shows how intelligent MAN solutions<br />

provide the basis for cutting costs and proficiently<br />

maximise potential. The TCO calculator<br />

can be found at > www.man.eu/tco-optimizer<br />

Market leader for the 12th time<br />

The world’s<br />

largest engine<br />

Alongside the MAN B&W 12S90ME-C Mark 9.2,<br />

an adult human being looks positively tiny. It is, after<br />

all, the largest engine ever built. Measuring<br />

more than 15 metres in height, the two-stroke diesel<br />

engine provides the drive power for yet another<br />

record-breaking ship: The CSCL Globe, which is currently<br />

the largest seafaring vessel in the world.<br />

Owned by China Shipping Container Lines Co. Ltd.<br />

(CSCL), the container ship is just under 400 metres<br />

long and 58.60 metres wide, and can hold 19,000<br />

standard containers. It set off on its maiden voyage<br />

in early <strong>2015</strong>.<br />

The MAN B&W diesel engine has a maximum<br />

performance of 69,709 kilowatts, with 84 revolutions<br />

per minute. For its deployment on the CSCL<br />

Globe, however, it had been scaled down to 56,900<br />

kilowatts. The engine was built at HHI-EMD, a subsidiary<br />

of the South Korean company Hyundai<br />

Heavy Industries Ltd.<br />

Based in Shanghai, China Shipping Container<br />

Lines Co. Ltd. is one of the largest container shipping<br />

companies in the world. CSCL belongs to the<br />

China Shipping Group, which has ordered engines<br />

for other container ships from MAN Diesel & Turbo<br />

in the past.<br />

David and Goliath: The MAN B&W<br />

12S90ME-C Mark 9.2 is about<br />

eight times as tall as a grown man.<br />

anfavea, brazil’s Association of Automotive Manufacturers,<br />

has confirmed MAN Latin America’s market leadership position for<br />

trucks in Brazil for the twelfth year in succession. The company<br />

finished the year 2014 with 36,157 licensed vehicles on the roads.<br />

On the list of the top ten truck sellers in Brazil, MAN Latin<br />

America is also represented by three truck models. With 7,673<br />

registered units, the “VW Constellation 24.280 6x2” model maintained<br />

its first place. The truck comes equipped with an efficient<br />

275-hp engine as well as cost-cutting EGR emission technology,<br />

and is suitable for short-, medium- or long-haul transport operations.<br />

The light VW Delivery 8.160 truck came in second place with<br />

5,742 units, while the VW Delivery 10.160 finished in ninth place.<br />

The company also scored rather well in the category of buses,<br />

taking second position with 6,480 licenced vehicles.<br />

MAN Latin America is the largest truck manufacturer in South<br />

America and operates one of the world’s most advanced production<br />

sites for trucks and buses with its plant in Resende.<br />

Ahead of the pack again: With its top model VW Constellation 24.280,<br />

MAN Latin America is market leader for trucks in Brazil for the 12th time.<br />

Photos: Deutsche Bahn AG, shotshop, MAN<br />

In MAN we trust: 700 MAN TGX trucks in the company’s typical red and white colours<br />

were ordered by the major Belgian freight forwarding company H.Essers.<br />

Big order from Belgium<br />

The major transport company H.Essers, based in Genk,<br />

Belgium, has asked MAN to supply 700 TGX vehicles. The logistics<br />

specialist known for its characteristic red and white truck designs<br />

thereby continues its long standing partnership with MAN. In<br />

making its purchasing decision, H.Essers company relied on a<br />

comparison of all shortlisted vehicles based on straightforward<br />

TCO (total cost of ownership) criteria. The TGX with Euro 6 compliance<br />

emerged as the clear winner. The H.Essers fleet consists of<br />

1,250 trucks, with 95% supplied by MAN. Other than the quality of<br />

the vehicles, H.Essers also values MAN’s comprehensive customer<br />

service. H.Essers has some 3,900 employees working at 37 offices<br />

in 11 European countries.<br />

20<br />

21

man magazine<br />

1/<strong>2015</strong><br />

Pioneer: Stockholm’s municipal<br />

transport relies on renewable fuels,<br />

with numerous urban coaches<br />

powered by gas and hybrid drives.<br />

Välkommen<br />

ombord!<br />

Stockholm<br />

revs up<br />

Stockholm is a metropolis that unites environmental<br />

conservation, economic growth and quality of life.<br />

Sweden’s capital is especially progressive with regard to<br />

clean local transport, with MAN supplying the needed<br />

innovative bus technology.<br />

Photo: ALIMDI.NET / Erich Fend<br />

22<br />

23

man magazine<br />

1/<strong>2015</strong><br />

All aboard, please! Eva Svensson<br />

drives her MAN gas bus on Line 2,<br />

transporting passengers through the<br />

centre of Stockholm.<br />

“I like MAN buses.<br />

They are good for<br />

the environment<br />

and good for us<br />

drivers.”<br />

Eva Svensson, Stockholm bus driver<br />

Stockholm<br />

94%<br />

of MAN buses<br />

Nearly all the buses operated by Keolis<br />

in Stockholm are supplied by MAN – in<br />

the hybrid and gas category, that ratio<br />

reaches 98%.<br />

S<br />

tockholm may be built close to<br />

and around the water, yet the<br />

Swedish capital is by no means a<br />

diluted kind of town. Not even in the dark season<br />

of the year, when the sun performs merely<br />

part time. Winter hibernation in the “Venice of<br />

the North”? Not likely. Stockholm is multifaceted<br />

whatever the season – at once modern,<br />

historic, cool and laid-back. This metropolis<br />

succeeds in merging environmental conservation,<br />

economic growth and quality of life. In<br />

2010, the European Commission named it the<br />

environmental capital of Europe, the first city<br />

to receive this accolade – and for good reason.<br />

In the utilisation of renewable fuels,<br />

Stockholm’s local transport authorities have<br />

long been a pioneer. The first ethanol vehicles<br />

were in service as early as the 1990s, with<br />

biogas and biodiesel fuel platforms following<br />

in 2004 and 2010, respectively. Finally, the<br />

first hybrid-drive vehicles were introduced in<br />

2014. Visitors and locals can rely on a network<br />

of numerous bus lines to negotiate the 14 urban<br />

districts, in addition to underground and<br />

metropolitan railway lines. <strong>Bus</strong>es in red or<br />

blue, identified by two- or three-digit numbers,<br />

serve the municipal area and surrounding<br />

region. The central “Blåbusslinjer” are<br />

numbered 1 to 4, using articulated vehicles<br />

that are 18 metres long and painted blue. Carrying<br />

about 65,000 passengers per workday,<br />

Line 4 is the most heavily used in the city. The<br />

interesting aspect about Stockholm’s approach:<br />

The entire gas bus fleet is powered exclusively<br />

by biogas made from municipal<br />

wastewater. It sounds like a fairy tale from the<br />

German storytellers Brothers Grimm – as if<br />

gold could be spun from more than just straw<br />

up here in Europe’s north.<br />

“Stockholm operates the largest fleet of<br />

biogas and hybrid buses in the world,” says<br />

Magnus Åkerhielm, Chairman of the Executive<br />

Board of Keolis Sverige. The company is<br />

Sweden’s second-largest as well as Stockholm’s<br />

largest bus line operator for regional<br />

public transport. “By late <strong>2015</strong>, our entire bus<br />

fleet will operate without any fossil fuels entirely,”<br />

adds his executive board colleague<br />

Karl Orton, who oversees technical operations.<br />

Already the market leader in Sweden’s<br />

municipal bus sector with a share of 44%,<br />

MAN supplied the lion’s share of this fleet.<br />

“An impressive 94% of all buses operated by<br />

Keolis in the city of Stockholm come from<br />

MAN,” explains Orton. When considering gas<br />

and hybrid buses, that ratio actually climbs<br />

to 98%. This means that MAN’s lion is more<br />

of a presence in Stockholm public transport<br />

than practically any other brand. This close<br />

partnership, says Åkerhielm, is rooted in the<br />

fact that since 2004, MAN has not only supplied<br />

reliable vehicles that are much appreciated<br />

by drivers, but has also delivered a comprehensive<br />

package of attractive terms and<br />

services.<br />

MAN received its latest order from<br />

Keolis in December 2013, for 52 hybrids, 72<br />

biodiesel and 71 gas buses of the Lion’s City<br />

class. And these buses are equipped to the<br />

hilt: “The hybrid variant comes with a serial<br />

system that is ideal for heavy-duty urban buses,”<br />

reports Robert Staimer, an MAN expert in<br />

alternative drives. It includes a high-performance<br />

capacitor – called “Ultracap” – for energy<br />

storage and a six-cylinder 250-hp diesel<br />

engine as a generator drive. While MAN’s<br />

Lion’s City Hybrid bus received its market<br />

introduction in 2010, MAN can look back on<br />

decades worth of tradition in the gas bus sector.<br />

The first MAN bus running on municipal<br />

gas made its appearance as early as 1943, followed<br />

in 1992 by the SL 202, which uses compressed<br />

natural gas (CNG). The current CNG<br />

engine is based on a high-end natural gas injector<br />

that sets new standards in terms of dosing<br />

precision and gas density. Both drive variants<br />

are compliant with Euro 6 standards.<br />

On the trail of an MAN Lion’s City on its<br />

daily tour of the Swedish metropolis: It sets<br />

Photos: Daniel Blom<br />

off from a bus depot in the Södermalm district<br />

– one of three bus depots run by Keolis in<br />

Stockholm’s centre. This is where a partial<br />

fleet of the gas-driven MAN vehicles is<br />

parked, fuelled, washed and serviced. At the<br />

same time, this facility is a central point of<br />

call for drivers who operate the buses stationed<br />

here. Keolis employs more than 1,250<br />

drivers in urban Stockholm, with about 13%<br />

of the workforce being women. One female<br />

driver, who is absolutely familiar with<br />

manoeuvring 18-metre juggernauts, is Eva<br />

Svensson. “My father was a bus driver. And I<br />

always liked driving cars – and especially the<br />

big ones,” says the dark-blonde native of<br />

Stockholm, when recalling her career choice<br />

29 years ago. While a young girl, she had<br />

wished to change the world and make it a better<br />

place. And until this very day, she still<br />

views herself not just as a bus driver, but rather<br />

a kind of “environmental worker”, she says.<br />

Blue giant – the buses numbered 1 to 4 operate in<br />

Stockholm’s urban centre.<br />

Keolis not only entrusted Svensson with the<br />

job of test-driving the MAN hybrid variant,<br />

she was also selected to leave the Södermalm<br />

depot with the first of the new MAN gas buses<br />

for regular line service. She talks enthusiastically<br />

about the new technology, including the<br />

totally smooth gear changes and the smart<br />

braking process. “And the quiet, those soundless<br />

doors. Just like heaven.”<br />

It’s 2.46 pm at the Spårvägsmuseet stop,<br />

not far from the depot. Svensson pulls up<br />

punctually with her blue, gas-powered bus,<br />

serving Line 2 that connects Barnängen and<br />

Norrtull – one of her favourite routes. “There<br />

are plenty of passengers – but not quite the<br />

same squeeze as on line 4.” This afternoon,<br />

among those boarding is Matilda Johansson,<br />

from Karlskrona and studying in Stockholm.<br />

She takes the bus every day “because it’s<br />

better for the environment when we all<br />

24<br />

25

man magazine<br />

Clean fleet: The gas buses (left)<br />

and hybrid buses supplied by<br />

MAN support Stockholm in its<br />

environmental conservation efforts.<br />

“By the end of <strong>2015</strong>,<br />

our bus fleet will<br />

operate without any<br />

fossil fuels.”<br />

Karl Orton, Technology Manager of Keolis Sverige AG<br />

CO 2 -neutral: The Stockholm buses use processed<br />

biogas for the drive.<br />

share transport, rather than travelling separately”.<br />

The journey progresses through the<br />

historic Gamla Stan district, then continues<br />

to Östermalm, Norralm and finally Vasastan.<br />

The bus has filled up – almost all the seats are<br />

taken. Most passengers use the bus for rather<br />

short trips of five stops at most. For commuting<br />

to and from work, like Daniel Öström. Or<br />

– like Emily Andy, from China, who moved to<br />

Stockholm for love – to pick up the children.<br />

Both appreciate being able to travel in an environmentally<br />

friendly, modern vehicle. “Although<br />

it’s even more important,” they both<br />

add, “that the buses arrive on time.” Fredrik<br />

Åkesson, who is taking the bus today because<br />

his car broke down, considers it important<br />

that buses should be able to run on biogas or<br />

with hybrid drives. Even though he regards<br />

the cost of tickets as far too high.<br />

Regardless, is it still sensible to invest<br />

in environmentally friendly buses? After all,<br />

the acquisition of gas and hybrid vehicles<br />

runs between 15% to 30% higher than purchasing<br />

standard diesel buses. Whether the<br />

investment pays off in the long term depends<br />

not least on maintenance, local taxes on fuels<br />

and the costs of toxic emissions and noise<br />

pollution. Gaining an overview is quite a<br />

challenge. Once again, Robert Staimer shares<br />

his experience: “With hybrid buses, the reduction<br />

in diesel consumption and CO 2 emissions<br />

amounts to about 25% on annual average.”<br />

Maintenance requirements are only<br />

moderately higher than those for standard<br />

diesel buses – especially considering that the<br />

Ultracaps’ service life is designed to coincide<br />

with the service life of the vehicle itself, thus<br />

not necessitating replacement, as do competitors’<br />

models. In the case of gas buses, calculations<br />

are a little more complicated, as vehicle<br />

profitability is tied to the type and cost of<br />

utilised gas. Just in terms of CO 2 emissions<br />

there are vast differences: Fuels derived from<br />

fossil natural gas already save 20% over fossil<br />

diesel, yet with biogas, savings amount to<br />

more than 95%– a value reached only by<br />

purely electric vehicles charged with power<br />

from renewable sources. The Keolis executives<br />

Åkerhielm and Orton put it in a nutshell:<br />

“Both the idea of recycling and energy<br />

production without any fossil fuels represent<br />

an actual mantra in Sweden.” Thus, their<br />

decision to invest in the MAN Lion’s bus is a<br />

long-term one, based on a durable and sustainable<br />

partnership.<br />

Photos: Daniel Blom<br />

You‘re responsible for your passengers.<br />

We help keep them safe.<br />

If you‘re in the business of transporting<br />

the most valuable cargo of all, then<br />

your top priorities are safety and comfort.<br />

Just as they are for the people portfolio from<br />

Continental, our latest Generation 3 tires,<br />

which have been specifically designed for coaches.<br />

Our innovative tire technologies mean<br />

better performance for you, your passengers<br />

and your business.<br />

For more information visit<br />

www.continental-truck-tires.com<br />

Conti Coach HA3<br />

Conti CityPlus HA3<br />

26

man magazine<br />

1/<strong>2015</strong><br />

In a league of its own<br />

Surpassing all expectations,<br />

the team coach of<br />

FC Bayern Munich carries<br />

goalie Neuer & co. safely<br />

and comfortably to their<br />

matches. The luxury coach<br />

was built at MAN’s ultramodern<br />

plant in Ankara.<br />

S<br />

wathes of mist drift across the<br />

empty stage, with the outline of a<br />

coach eventually appearing on a<br />

curtain in the background. Amidst flying<br />

sparks, the stage is ablaze with light. Quick as a<br />

flash, the illusionist Julius Frack pulls back the<br />

curtain, and all of a sudden it appears: an MAN<br />

Lion’s Coach L Supreme in fiery red – the new<br />

team coach of the FC Bayern Munich football<br />

club. With this spectacular show, MAN handed<br />

over the luxury vehicle in August 2014 to the<br />

record-breaking champions. Some 300 invited<br />

guests, including Bayern legend Paul Breitner,<br />

double winner Thiago Alcántara, as well as executive<br />

board member and sports manager<br />

Matthias Sammer, witnessed the presentation<br />

on the esplanade of the Allianz Arena. “The<br />

coach is an important entity for the team and<br />

we are very happy to be starting into our<br />

new season with this new vehicle,” observed<br />

Sammer. Until this point in time, however,<br />

the team coach had literally come a long way,<br />

Photo: MAN<br />

Showcase plant: MAN’s coach<br />

works in Ankara is renowned for<br />

its excellent work – as FC Bayern<br />

Munich is also aware.<br />

28<br />

29

man magazine<br />

1/<strong>2015</strong><br />

“The bus offers all<br />

that a football team<br />

could wish for.”<br />

Paul Breitner, Brand Ambassador of FC Bayern Munich<br />

Proud of their product: Some MAN<br />

employees in Ankara wore their<br />

FC Bayern jerseys during the bus<br />

production process.<br />

The app contains a<br />

film about the<br />

vehicle construction<br />

in Ankara.<br />

having been built almost 2,000 kilometres<br />

away from Munich, at MAN’s plant near Turkey’s<br />

capital of Ankara.<br />

man’s production of commercial vehicles<br />

in Turkey dates back to 1966, when the<br />

truck plant in Istanbul became the company’s<br />

first production site outside of Germany. With<br />

more than 1,600 employees, the Ankara plant<br />

is MAN’s largest and most modern coach production<br />

facility today. The assembly of urban,<br />

long-distance and touring coaches for the<br />

MAN and NEOPLAN brands spreads over an<br />

area of around 320,000 square metres. The<br />

Lion’s Coach L Supreme of FC Bayern also<br />

joined the line here on 21 March 2014. For<br />

about two years, all coach models – ranging<br />

from the Bayern footballers’ flagship to the<br />

unassuming municipal bus – have been manufactured<br />

on a single production line. This<br />

renders production highly flexible and efficient.<br />

Vehicle completion takes only 22 days.<br />

Overall, the site has a technical capacity of<br />

3,400 vehicles per year.<br />

In order to build the FC Bayern team<br />

coach, MAN specifically set up a special nine-<br />

person project team in Ankara, which followed<br />

the coach through every construction<br />

phase. Production begins with structural<br />

work, when the skeleton of what eventually<br />

becomes the team coach is first welded<br />

together and later serves as the base on which<br />

to mount the inner and outer sheet metal<br />

plates. For measurement control purposes,<br />

one randomly chosen vehicle is analysed precisely<br />

each day at the plant’s 3D Centre: A laser<br />

tracker compares some 700 measurement<br />

points all over the coach, with accuracy down<br />

to a tenth of a millimetre. The cathode dip<br />

painting facility, which is one of the most advanced<br />

in all of Europe, first provided the<br />

Bayern team coach with a chemical coating<br />

for corrosion protection, followed by a paint<br />

job in the team’s characteristic colours. This<br />

special shade proved a real challenge for the<br />

paint professionals: Several coats were necessary<br />

to achieve a perfect match. The next stop<br />

was the pre-assembly station, where the<br />

coach was fitted with tinted windows, an airconditioning<br />

system, axles and its Euro 6<br />

engine, a 480-hp power pack from the plant in<br />

Nuremberg. Prior to its installation, the elaborate<br />

cabling for the exclusive interior was addressed,<br />

followed by interior panelling, the<br />

dashboard and the premium leather seats.<br />

After receiving its final touches, the Lion’s<br />

Coach L Supreme was thoroughly checked<br />

once more during various tests and finally<br />

handed over to sales for the last inspection<br />

round. Until delivery, the vehicle had to undergo<br />

a total of seven quality checks.<br />

A vision in red: At the Allianz Arena,<br />

MAN officially handed over the new<br />

luxury coach to FC Bayern Munich.<br />

the new fc bayern team coach was<br />

ready for shipment to Germany in early May<br />

2014, with about 1,000 MAN employees in<br />

Ankara involved in building the coach. And<br />

naturally, they are proud to think that a top<br />

team like Bayern Munich will be on the road<br />

in their creation. “As I spent two years living<br />

in Munich, the ‘Bavarian’ coach was very special<br />

for me,” says Kartal Erköy, production<br />

manager in the fittings department. “We<br />

sometimes need to work night and day<br />

to build such a complex vehicle, but we do<br />

it gladly and with so much motivation,” he<br />

Photo: MAN<br />

explains. “The high-tech standard of this<br />

coach is no less fabulous than the football expertise<br />

of the FC Bayern team itself.”<br />

Before the lavish unveiling ceremony at<br />

the Allianz Arena, the Lion's Coach L Supreme<br />

still needed to receive its exclusive interior<br />

features, including a full service entertainment<br />

centre, 19-inch LCD screens, WLAN, a<br />

sound system, retractable tables, leg rests and<br />

a fully equipped kitchen. Finally, the decor for<br />

the current season was applied by hand<br />

through a foil, with the sides adorned by the<br />

team’s logo and an oversized FC Bayern shirt.<br />

The luxury vehicle was received with<br />

enormous enthusiasm by FC Bayern players<br />

and managers alike. “There’s no comparison<br />

to previous models. This new coach offers all<br />

that a football team could wish for or need,”<br />

commented Paul Breitner. Absolutely the top<br />

coach for a top team. And not least due to the<br />

commitment and passion of the employees at<br />

MAN’s plant in Ankara.<br />

Find a video on the assembly of the<br />

FC Bayern coach at MAN’s Ankara plant under<br />

the link > www.man.eu/discovermanfcbayernbus<br />

3 400<br />

vehicles<br />

MAN’s production site in Ankara builds<br />

3,400 coaches every year – ranging from<br />

simpler municipal types to a unique<br />

model for FC Bayern Munich.<br />

30<br />

31

man magazine<br />

1/<strong>2015</strong><br />

Addition to the<br />

coach family<br />

Amidst high demand for standard long-distance buses, operating<br />

conditions remain a challenge. The new MAN Lion’s Intercity was<br />

tailored to specifically meet the requirements of this segment.<br />

Photo: MAN<br />

The new MAN Lion’s Intercity is<br />

customised for long-distance and<br />

connecting services, as well as<br />

school commutes.<br />

O<br />

ffering its customers tailormade<br />

solutions has always been<br />

part of MAN’s business philosophy.<br />

The segment of standardised long-distance<br />

coaches is currently experiencing rapid<br />

growth figures throughout Europe, yet customers<br />

have very specific requirements that<br />

are not easily reconciled. Demands might encompass<br />

features typical for long-distance<br />

coaches, such as generous stowage room or an<br />

aerodynamic design, while the purchasing<br />

price of vehicles ought to remain rather low.<br />

MAN therefore developed a specific product<br />

to exactly meet these expectations: the MAN<br />

Lion’s Intercity.<br />

“During the development process for the<br />

MAN Lion’s Intercity, we focused on the overall<br />

operating costs, namely the Total Cost of<br />

Ownership, or TCO,” explains Florian Rott,<br />

Product Marketing <strong>Bus</strong>es & Coaches at MAN<br />

Truck & <strong>Bus</strong>. “Our customers value a lightweight<br />

design, maintenance and repair<br />

friendliness, and economical fuel consumption.”<br />

One of the many features significantly<br />

contributing to achieve this target is the new<br />

MAN D08 Common Rail engine, a smaller and<br />

therefore lighter unit with a cubic capacity of<br />

just 6.9 litres. This variation alone resulted in<br />

weight savings of at least 450 kilos. The new<br />

and especially efficient air-conditioning system<br />

also reduces vehicle weight by a further<br />

65 kilos. As air drag and associated fuel consumption<br />

play an important role in long-distance<br />

transport – as opposed to urban traffic<br />

– MAN engineers paid particular attention to<br />

aerodynamic considerations. Among other<br />

characteristics, the Lion’s Intercity features<br />

an arched, slightly slanted panoramic front<br />

window and a sharp tear-off edge in the rear.<br />

Robustness and reliability are not just<br />

values generally associated with MAN, but<br />

play a larger than average role in this coach<br />

segment. “The MAN Lion’s Intercity is built<br />

for strenuous daily use,” explains Florian<br />

Rott. The coach not only scores well in terms<br />

of reliability, but also because of its user-<br />

290<br />

horsepower<br />

A highly efficient D08 common rail<br />

engine powers the two-axle coach<br />

manufactured by MAN.<br />

friendly furnishings: Materials and designs<br />

used inside are resistant to dirt, while the<br />

smooth surfaces used in the interior –<br />

including the floor – make for easy cleaning<br />

and therefore an improved TCO ratio. Both<br />

the passenger area and the driver’s cab are designed<br />

for comfort and practicality. In the<br />

MAN Lion’s Intercity segment, customers do<br />

not expect to find an on-board WC or a kitchen<br />

– a distinguishing difference to the new<br />

MAN Lion’s Regio coach. On the other hand,<br />

the option of a removable landing allows for<br />

the accommodation of wheelchairs or prams.<br />

Considering the fact that the MAN Lion’s<br />

Intercity is typically deployed as a school bus,<br />

there are absolutely no compromises made in<br />

terms of safety. The vehicle has a very comprehensive<br />

set of standard safety features, including<br />

an electronic braking system, an<br />

emergency braking assistant, an electronic<br />

stability programme and a fire warning system.<br />

“On request, all of MAN’s available safety<br />

systems can be applied to the MAN Lion’s Intercity,”<br />

emphasises Florian Rott. In addition,<br />

the elaborate ring-spar construction shape of<br />

the MAN Lion’s Intercity already conforms to<br />

the ECE R66.02 mandatory standard, which<br />

comes into effect as of 2017. It offers improved<br />

safety in case of a rollover – the first coach in<br />

its segment to do so..<br />

Discover more details about the distinctive<br />

design, numerous applications and outstanding<br />

security features of the MAN Lion’s<br />

Intercity in our interactive web special at<br />

> www.man.eu/lionsintercity<br />

32<br />

33

man magazine<br />

1/<strong>2015</strong><br />

Closer to<br />

the clouds<br />

Night drive: En route to Milan,<br />

the Giosy Tours’ NEOPLAN<br />

Skyliner passes Lake Lugano.<br />

34<br />

Coach with a view: The generous panoramic<br />

windows of the NEOPLAN Skyliner offer<br />

passengers an almost 360-degree perspective.<br />

Photos: Claudio Bader<br />

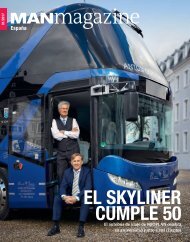

A legend returns: Now in its fifth generation, the NEOPLAN Skyliner coach<br />

debuts once again in <strong>2015</strong>. Coach operators, drivers and passengers alike<br />

are impressed by its outstanding features of economy, safety, design and<br />

comfort – and not least the spectacular views.<br />

Tinny loudspeaker announcements<br />

in Italian waft from platform<br />

2. In the bustling parking<br />

zone of the Lugano railway station,<br />

they sonorously announce<br />

the departure of long-distance<br />

trains destined for Chiasso or “Milano Centrale”.<br />

Since 1874, trains have been departing<br />

from Lugano, tucked away in Switzerland’s<br />

southernmost Italian-speaking corner, heading<br />

further south to Italy or due north via the<br />

Gotthard Tunnel. As there are no rail connections<br />

to Milan’s Malpensa airport, however,<br />

flight passengers are lined up at the Giosy<br />

Tours bus stop on Piazzale Besso, just behind<br />

the station. Based not far away in Cadenazzo,<br />

the Ticino bus company offers several regular<br />

services daily to Malpensa. When the coach<br />

pulls up, travellers are dazzled: As the flagship<br />

of Giosy Tours, this NEOPLAN Skyliner is a<br />

bright red double-decker touring coach, four<br />

metres high, 15 metres long and 2.55 metres<br />

wide. The three-dimensional convexity of the<br />

windshield, the seamlessly smooth bodywork,<br />

as well as flush-mounted doors and hatches,<br />

lend the 505-hp vehicle a spectacularly dynamic<br />

silhouette.<br />

“It’s always a special moment when the<br />

Skyliner drives up,” comments Corrado<br />

Bernasconi. The driver enjoys how people<br />

on the street turn their heads to look at his<br />

505<br />

horsepower<br />

The NEOPLAN Skyliner is powerful and<br />

efficient. The MAN TipMatic transmission<br />

and a drag coefficient value of 0.41 result<br />

in economical fuel consumption.<br />

In the app: Ride along<br />

with Corrado Bernasconi<br />

and his passengers on the<br />

NEOPLAN Skyliner.<br />

35

man magazine<br />

1/<strong>2015</strong><br />

Streamlined: Compared with other double-deckers without an<br />

aerodynamically optimised design, the Skyliner reduces fuel<br />

consumption by up to 5%.<br />

coach. “I appreciate the design, and the many<br />

functional details at my workstation,” enthuses<br />

the driver. The 50-year-old especially values<br />

the high safety standards, which are also<br />

a major priority for passengers, he says. Today,<br />

travellers on board are joined by both the<br />

founder as well as the managing director of<br />

Giosy Tours. Lino Bassi greets travellers with<br />

a classic “Salve” and wholeheartedly participates<br />

in stowing away the luggage. Now 83, he<br />

founded the company 35 years ago and handed<br />

over management to his son Matthias just<br />

two years ago. A trained automotive mechanic,<br />

44-year-old Matthias has built up a modern<br />

fleet, comprising 15 vehicles with capacities<br />

ranging from nine to 79 seats. “We have<br />

the right fit for all purposes and all kinds of<br />

travel,” he states. Matthias Bassi first saw the<br />

Skyliner "live" at an exhibition in Rimini,<br />