best available technologies for manure treatment - Baltic Green Belt

best available technologies for manure treatment - Baltic Green Belt

best available technologies for manure treatment - Baltic Green Belt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Best Available Technologies <strong>for</strong> <strong>manure</strong> <strong>treatment</strong> baltic sea 2020<br />

Best Available Technologies <strong>for</strong> <strong>manure</strong> <strong>treatment</strong> baltic sea 2020<br />

ANNEX E: TABLES WITH SHORT DESPRIPTION OF LIVESTOCK MANURE TREATMENT TECHNOLOGIES<br />

Best Available Techniques <strong>for</strong> <strong>manure</strong> <strong>treatment</strong> - <strong>for</strong> intensive rearing of pigs in <strong>Baltic</strong> Sea Region EU Member States Technical Report "Best Practice Manure Handling, Phase 2"<br />

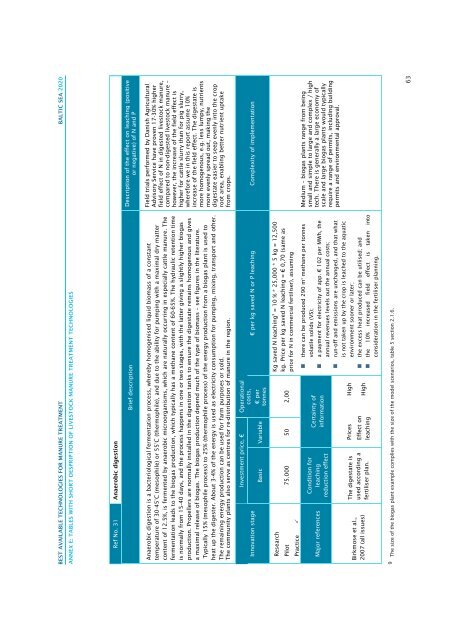

Ref No. 31 Anaerobic digestion<br />

Brief description<br />

Description of the effect on leaching (positive<br />

or negative) of N and P<br />

Anaerobic digestion is a bacteriological fermentation process, whereby homogenised liquid biomass of a constant<br />

temperature of 30-45°C (mesophile) or 55°C (thermophile), and due to the ability <strong>for</strong> pumping with a maximal dry matter<br />

content of 12.5%, is fermented by anaerobic microorganisms, which are naturally occurring in especially cattle <strong>manure</strong>. The<br />

fermentation leads to the biogas production, which typically has a methane content of 60-65%. The hydraulic retention time<br />

is normally from 15-40 days, and the process happens in one or two stages, with the latter giving a slightly higher biogas<br />

production. Propellers are normally installed in the digestion tanks to ensure the digestate remains homogenous and gives<br />

a maximal release of biogas. The biogas production depend much of the type of biomass – see figures in the literature.<br />

Typically 15% (mesophile process) to 25% (thermophile process) of the energy production from a biogas plant is used to<br />

heat up the digester. About 3-4% of the energy is used as electricity consumption <strong>for</strong> pumping, mixing, transport and other.<br />

The remaining energy production can be used <strong>for</strong> farm purposes or sold.<br />

The community plants also serve as centres <strong>for</strong> re-distribution of <strong>manure</strong> in the region.<br />

Field trials per<strong>for</strong>med by Danish Agricultural<br />

Advisory Service have proven 17-30% higher<br />

field effect of N in digested livestock <strong>manure</strong>,<br />

compared to non-digested livestock <strong>manure</strong> –<br />

however, the increase of the field effect is<br />

higher <strong>for</strong> cattle slurry than <strong>for</strong> pig slurry,<br />

where<strong>for</strong>e we in this report assume 10%<br />

increase of the field effect. The digestate is<br />

more homogenous, e.g. less lumpy, nutrients<br />

more evenly spread out, making the<br />

digestate easier to seep evenly into the crop<br />

root area, enabling better nutrient uptake<br />

from crops.<br />

Innovation stage<br />

Investment price, <br />

Basic Variable<br />

Operational<br />

costs,<br />

per<br />

tonnes<br />

per kg saved N or P leaching Complexity of implementation<br />

Research<br />

Pilot<br />

Practice <br />

Major references<br />

Birkmose et al.,<br />

2007 (all issues)<br />

75.000 50 2,00<br />

Condition <strong>for</strong><br />

leaching<br />

reduction effect<br />

The digestate is<br />

used according a<br />

fertiliser plan.<br />

Certainty of<br />

in<strong>for</strong>mation<br />

Prices High<br />

Effect on<br />

leaching<br />

High<br />

Kg saved N leaching 9 = 10 % * 25,000 * 5 kg = 12,500<br />

kg. Price per kg saved N leaching = 0,70 (same as<br />

price <strong>for</strong> N in commercial fertiliser), assuming<br />

there can be produced 290 m 3 methane per tonnes<br />

volatile solids (VS);<br />

a payment <strong>for</strong> electricity of app. 102 per MWh, the<br />

annual revenues levels out the annual costs;<br />

run-off and emissions are unchanged, and that what<br />

is not taken up by the crop is leached to the aquatic<br />

environment sooner or later;<br />

the excess heat produced can be utilised; and<br />

the 10% increased field effect is taken into<br />

consideration in the fertiliser planning.<br />

Medium – biogas plants range from being<br />

small and simple to large and complex / high<br />

tech. There is generally a large economy of<br />

scale and large biogas plants would typically<br />

require a range of permits, including building<br />

permits and environmental approval.<br />

9 The size of the biogas plant example complies with the size of the model scenarios, table 5 section 2.1.6.<br />

9 The size of the biogas plant example complies with the size of the model scenarios, table 5 section 2.1.6.<br />

63<br />

Side 64<br />

63