Oberflex Product Range - Abet LTD

Oberflex Product Range - Abet LTD Oberflex Product Range - Abet LTD

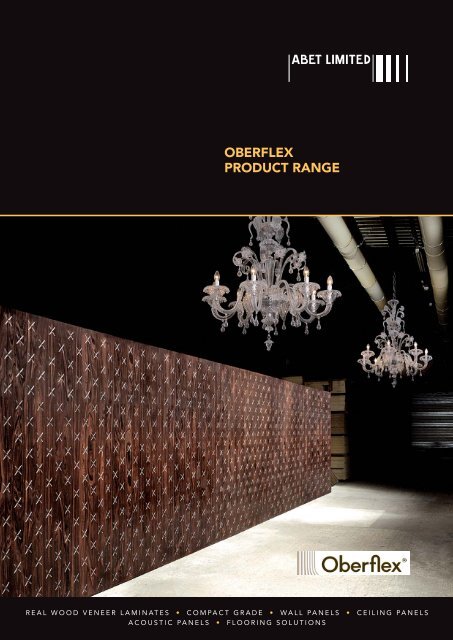

OBERFLEX PRODUCT RANGE REAL WOOD VENEER LAMINATES • COMPACT GRADE • WALL PANELS • CEILING PANELS ACOUSTIC PANELS • FLOORING SOLUTIONS

- Page 2 and 3: OBERFLEX PRODUCT RANGE Oberflex Obe

- Page 4: ABOUT OBERFLEX: The Oberflex Compan

OBERFLEX<br />

PRODUCT RANGE<br />

REAL WOOD VENEER LAMINATES • COMPACT GRADE • WALL PANELS • CEILING PANELS<br />

ACOUSTIC PANELS • FLOORING SOLUTIONS

OBERFLEX PRODUCT RANGE<br />

<strong>Oberflex</strong><br />

<strong>Oberflex</strong> is a high pressure laminate with a unique difference<br />

– it features a real wood veneer finish.<br />

<strong>Oberflex</strong> is a popular material for architects and designers<br />

because it combines the aesthetic beauty of real wood with<br />

the performance and durability of high pressure laminate.<br />

This means a tough surface which is abrasion, impact and<br />

scratch resistant and also resistant to UV light and cigarette<br />

burns.<br />

<strong>Oberflex</strong> is available in over 100 different wood species<br />

ranging from dark woods such as Mahogany and Wenge<br />

through to lighter Sycamore, Ash and Birch. There are<br />

several tints available and the veneer slicing method used in<br />

its manufacture gives specifiers the choice of straight-grain<br />

or flowered veneer, as well as bookmatched or randommatched<br />

finishes. It can be bonded onto most substrates to<br />

provide a visually appealing and low maintenance backdrop<br />

with long life cycle performance.<br />

The range comprises several collections and included in the<br />

UK offering are:<br />

OBERFLEX AND PRESTIGE OBERFLEX –<br />

Comprehensive standard range of pre-finished wood veneer<br />

laminates, available in a vast selection of veneer species,<br />

with matt, satin, brushed or relief textures and various tint<br />

options.<br />

CHIC AND POP – The new Chic & Pop Collection inspired<br />

from current trends, combines two radically opposed styles.<br />

The Chic Collection introduces new whitened, grey, natural<br />

and chocolate tints applied on walnut and zebrano wood<br />

veneers, together with a new Astrakhan finish. A classical,<br />

timeless, elegant and chic collection. The Pop Collection<br />

reveals the natural structure of the wood under new and<br />

unexpected tints. These vibrant fluorescent tints, never seen<br />

on natural wood veneers, are offering offbeat and daring<br />

answers to modern, coloured and pop ideas.<br />

TEXTURED WOODS – A highly effective collection of<br />

nuances of white, black and grey combined with textured<br />

veneers. There are various finishes available including a<br />

tremendous pearlescent finish. This blend of silky and metal<br />

effect adds more than ever an amazing lightness to the<br />

gouged, clawed, sea, hammered, gator and sables wood<br />

textures.<br />

NATURAL SHADES – In addition to the already impressive<br />

selection of Textured Woods, the Natural Shades collection<br />

has been produced using a unique process adapted from the<br />

gouged, sea-wood and gator patterns and combined with<br />

veneer species. The end result is a striking shadow and<br />

colour contrast with very natural nuances.<br />

SPICED WOOD – A collection created using various<br />

coloured tints on contrasting veneers which are then<br />

processed to create a highly attractive striped two-tone<br />

effect. The pepper, nutmeg, star anise, cumin, liquorice and<br />

sesame finishes are complemented by a brushed texture<br />

throughout the range.

OBERFLEX PRODUCT RANGE<br />

Obersound<br />

Obersound are ready-for-use panels consisting of a<br />

substrate bonded on one side with an <strong>Oberflex</strong> real wood<br />

veneer laminate, and counterbalanced on the other side. The<br />

custom-made panels can be supplied entirely machined,<br />

either plain or perforated, depending on acoustic and<br />

aesthetic requirements. They are suitable for both wall and<br />

ceiling installations and offer a particularly efficient surface<br />

treatment which is resistant to scratches, abrasion, UV lights,<br />

chemical products and fire.<br />

Obersound 5.5<br />

<strong>Oberflex</strong> appointed design agency ‘5.5 Designers’ to review<br />

the Obersound panels and propose a new collection of<br />

panels offering an entirely new response to architects and<br />

specifiers calling for a range of acoustic panels manufactured<br />

from <strong>Oberflex</strong>.<br />

Acoustic products generally have standardised perforations,<br />

with the patterns resulting from tools and production<br />

constraints. They are often thought out for the sole purpose<br />

of optimising costs and performances to the detriment of<br />

aesthetic quality.<br />

The development of new production tools in<br />

collaboration with 5.5 Designers meant that new and<br />

original perforation patterns could be created. Far and<br />

above just a catalogue of acoustic performances, they<br />

introduced a collection concept as done in the fashion<br />

world. These proposals now offer an exciting real<br />

potential for architects and specifiers, who are increasingly<br />

sensitive to the details of their constructions.<br />

Deck d’Ober<br />

The Deck d’Ober Collection is a range of boat deck jointed<br />

solid wooden strips. Deck d’Ober panels can be used to<br />

achieve curved surfaces, such as a bathtub apron, or column<br />

wrapping. It is available in four wood species, Teak, Wenge,<br />

Bubinga and Doussie, and is generally supplied unfinished.<br />

The strips are joined together on installation with a choice<br />

of black or white mastic, according to the aesthetic<br />

preference of the specifier. The Teak finish is also suitable<br />

for external applications and for use in very humid<br />

environments such as swimming pools or shower rooms.

ABOUT OBERFLEX:<br />

The <strong>Oberflex</strong> Company concentrates its interests and skills<br />

into the service of transforming a living material chosen for its<br />

environmental qualities: wood.<br />

Laminating wood veneer is at the heart of <strong>Oberflex</strong> knowhow.<br />

As an industrial specialist in wood for more than 80<br />

years, <strong>Oberflex</strong> offers a range of panels with technical highquality<br />

and great aesthetic diversity.<br />

<strong>Oberflex</strong> is now a solidly placed player in the field of interior<br />

decoration. With the strength of its long experience, this<br />

company offers the widest range of wood in the world, with<br />

more than 500 references, for solutions suited for the various<br />

sectors of construction (offices, public buildings, hotels,<br />

restaurants, shop fitting, etc) and also for industry (doors,<br />

furniture, kitchens, bathrooms etc).<br />

OBERFLEX ® KNOW-HOW<br />

The aesthetical qualities of <strong>Oberflex</strong> panels result from a<br />

meticulous selection of the most beautiful species of wood<br />

coming from suppliers from all other the world. <strong>Oberflex</strong><br />

panels fit with all kinds of interior layouts thanks to the<br />

surface finishing obtained by the pressing of hot resin onto<br />

the veneer. The panels are resistant to abrasion, impacts,<br />

scratches, UV lights, cigarette burns and staining. The<br />

<strong>Oberflex</strong> finishing guarantees a high technical quality range<br />

of products, which are fire-resistant (type M1), can be<br />

cleaned with soapy water and don’t require any surface<br />

treatment.<br />

THE TRADITION OF INNOVATION<br />

<strong>Oberflex</strong> makes innovation a daily priority, a determination<br />

expressed in permanent investment in research and<br />

development. The company thus stands out each year by its<br />

ability to modernise and enrich its offer with the twice-yearly<br />

launch of new collections.<br />

ENVIRONMENTAL CONSERVATION<br />

For <strong>Oberflex</strong>, it is essential to<br />

integrate environmental questions<br />

into its industrial approach. The<br />

company deliberately committed<br />

itself to a citizen’s approach,<br />

expressed over several years in a<br />

policy that has radically turned to<br />

ecology and Research &<br />

Development work under the<br />

influence of eco-design. For <strong>Oberflex</strong>, being supplied with<br />

components and timber products from durably managed<br />

forests – under controlled and monitored exploitation – is a<br />

daily commitment expressed in the PEFC certification of its<br />

products. <strong>Oberflex</strong> products also correspond to targets<br />

frequently chosen on the occasion of HEQ (High<br />

Environmental Qualities) projects.<br />

<strong>Oberflex</strong> is exclusively distributed in the UK by <strong>Abet</strong> Ltd.<br />

For further information on the following, please go to our<br />

websites at www.abetuk.com<br />

• Technical / Environmental / Cleaning<br />

• <strong>Product</strong> ranges<br />

• Case studies / projects<br />

• Contact details<br />

Samples and technical information is available from our<br />

sample line on 020 7473 6915<br />

70 Roding Road, London Industrial Park, London E6 6LS<br />

Telephone: +44 (0)20 7473 6910 Fax: +44 (0)20 7476 6935<br />

Email: sales@abet.ltd.uk sales@abet.ie<br />

www.abetuk.com www.abet.ie<br />

OBERFLEX/REV13.4