Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For Models: JGH:E:K:T Section 4 Part Replacement<br />

an assembly.<br />

5. Pull entire pressure packing out into the crosshead guide, then through the large side opening of<br />

the guide. Take pressure packing to a clean place for disassembly.<br />

6. Set pressure packing on a clean surface on its nose cup or cylinder end. Match mark the outside<br />

diameter of the cups for proper reassembly. Three long tie studs hold the pressure packing<br />

together. The stud holes are unequally spaced to prevent misalignment of the stack of parts.<br />

Remove the stud nuts and unstack the pressure packing. Replace these nuts each time the pressure<br />

packing is serviced.<br />

7. To check ring wear, place assembled rings (note match-marks) on the piston rod. Check end gap<br />

clearance. If the ends butt, or nearly butt, replace the rings. See “Types of Piston Rod Packing<br />

Rings” on page 4-19 for correct ring orientation.<br />

8. Carefully file any fins or wire edges on the rings to square all matching edges.<br />

9. Pry loose the metal gasket on the end cup with a sharp awl. Do not scratch the sides of the gasket<br />

groove.<br />

10. Before reassembly, clean all parts thoroughly.<br />

Piston Rod Packing Reassembly<br />

1. Refer to the pressure packing assembly in your parts book. <strong>Ariel</strong> supplies parts books with each<br />

unit. Contact your distributor to obtain a parts book. Each pressure packing re-build kit includes a<br />

pressure packing assembly drawing.<br />

2. Take care not to scratch mating surfaces of the cups. Cup surfaces must be clean and dry for reassembly.<br />

3. To install a new set of rod rings in an existing packing case, inspect case parts for wear. Cups<br />

should be smooth and flat on the back side where the rod rings must seal. If cups or grooves are<br />

concave or tapered, regrind or relap them. Contact <strong>Ariel</strong> for appropriate rework thickness dimensions.<br />

It is rarely necessary to alter the crosshead side of cups, but if necessary, take care not to<br />

destroy the correct side clearance for the renewal rings.<br />

NOTE: If premature wear is suspected, see <strong>Ariel</strong> “Cylinder and Packing Lubrication<br />

Requirements”.<br />

4. Before a packing case installation, disassemble and thoroughly clean it in an appropriate solvent<br />

for the intended service.<br />

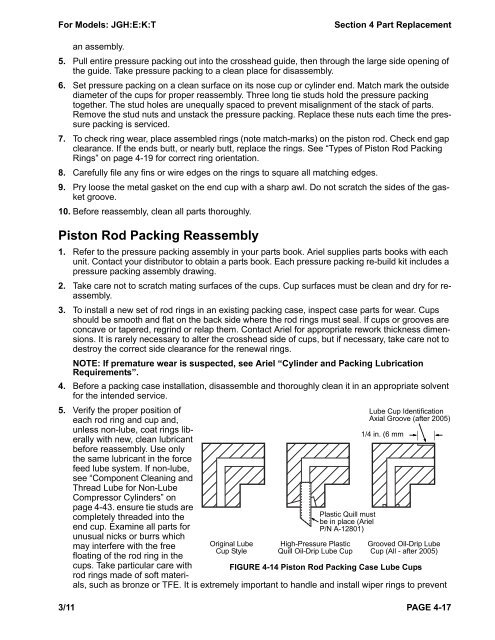

5. Verify the proper position of<br />

each rod ring and cup and,<br />

unless non-lube, coat rings liberally<br />

with new, clean lubricant<br />

before reassembly. Use only<br />

the same lubricant in the force<br />

feed lube system. If non-lube,<br />

see “Component Cleaning and<br />

Thread Lube for Non-Lube<br />

Compressor Cylinders” on<br />

page 4-43. ensure tie studs are<br />

completely threaded into the<br />

end cup. Examine all parts for<br />

unusual nicks or burrs which<br />

may interfere with the free<br />

floating of the rod ring in the<br />

cups. Take particular care with<br />

rod rings made of soft materi-<br />

Original Lube<br />

Cup Style<br />

Plastic Quill must<br />

be in place (<strong>Ariel</strong><br />

P/N A-12801)<br />

High-Pressure Plastic<br />

Quill Oil-Drip Lube Cup<br />

Lube Cup Identification<br />

Axial Groove (after 2005)<br />

1/4 in. (6 mm<br />

Grooved Oil-Drip Lube<br />

Cup (All - after 2005)<br />

FIGURE 4-14 Piston Rod Packing Case Lube Cups<br />

als, such as bronze or TFE. It is extremely important to handle and install wiper rings to prevent<br />

3/11 PAGE 4-17