Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

For Models: JGH:E:K:T Section 4 Part Replacement<br />

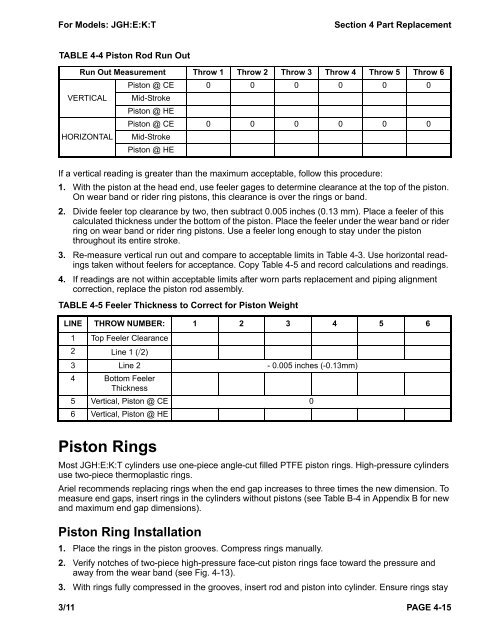

TABLE 4-4 Piston Rod Run Out<br />

Run Out Measurement Throw 1 Throw 2 Throw 3 Throw 4 Throw 5 Throw 6<br />

VERTICAL<br />

HORIZONTAL<br />

If a vertical reading is greater than the maximum acceptable, follow this procedure:<br />

1. With the piston at the head end, use feeler gages to determine clearance at the top of the piston.<br />

On wear band or rider ring pistons, this clearance is over the rings or band.<br />

2. Divide feeler top clearance by two, then subtract 0.005 inches (0.13 mm). Place a feeler of this<br />

calculated thickness under the bottom of the piston. Place the feeler under the wear band or rider<br />

ring on wear band or rider ring pistons. Use a feeler long enough to stay under the piston<br />

throughout its entire stroke.<br />

3. Re-measure vertical run out and compare to acceptable limits in Table 4-3. Use horizontal readings<br />

taken without feelers for acceptance. Copy Table 4-5 and record calculations and readings.<br />

4. If readings are not within acceptable limits after worn parts replacement and piping alignment<br />

correction, replace the piston rod assembly.<br />

Piston Rings<br />

Piston @ CE<br />

Mid-Stroke<br />

Piston @ HE<br />

0 0 0 0 0 0<br />

Piston @ CE<br />

Mid-Stroke<br />

Piston @ HE<br />

0 0 0 0 0 0<br />

TABLE 4-5 Feeler Thickness to Correct for Piston Weight<br />

LINE THROW NUMBER: 1 2 3 4 5 6<br />

1 Top Feeler Clearance<br />

2 Line 1 (/2)<br />

3 Line 2 - 0.005 inches (-0.13mm)<br />

4 Bottom Feeler<br />

Thickness<br />

5 Vertical, Piston @ CE 0<br />

6 Vertical, Piston @ HE<br />

Most JGH:E:K:T cylinders use one-piece angle-cut filled PTFE piston rings. High-pressure cylinders<br />

use two-piece thermoplastic rings.<br />

<strong>Ariel</strong> recommends replacing rings when the end gap increases to three times the new dimension. To<br />

measure end gaps, insert rings in the cylinders without pistons (see Table B-4 in Appendix B for new<br />

and maximum end gap dimensions).<br />

Piston Ring Installation<br />

1. Place the rings in the piston grooves. Compress rings manually.<br />

2. Verify notches of two-piece high-pressure face-cut piston rings face toward the pressure and<br />

away from the wear band (see Fig. 4-13).<br />

3. With rings fully compressed in the grooves, insert rod and piston into cylinder. Ensure rings stay<br />

3/11 PAGE 4-15