Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For Models: JGH:E:K:T Section 2 - Instrumentation<br />

Resistance Temperature Devices (RTD’s)<br />

An RTD is a resistor sensor in which electrical resistance accurately varies with temperature.<br />

Appropriate electronic devices can interpret the resistance as temperature. Main bearing RTD’s are<br />

dual-element RTD instrument assemblies, consisting of two RTD’s in each instrument for each main<br />

bearing. Each element is a three-wire, 100 ohms (at 0°C), Alpha = 0.00385 ohms/ohm/°C, platinum<br />

thin film sensor.<br />

Wire: Use standard 24 AWG (American Wire Gage) instrumentation wire<br />

from the junction box on the side of the compressor frame to sensor<br />

wiring. Wire an RTD three-wire set using a 2, 3 or 4 wire lead system.<br />

More wires increases system accuracy. <strong>Ariel</strong> recommends standard foil<br />

shielded instrumentation cable runs from the compressor frame to control<br />

panel. Ground shields in the control panel.<br />

Sensor Accuracy: 100 + 0.12 ohms at 0°C = 1.1°F (0.6°C) or 0.6%.<br />

Terminals: Use any standard terminals.<br />

For each instrument, one RTD three-wire set connects to the monitoring<br />

circuit. Insulate unused wire ends from each other and conduit ground.<br />

Dual element RTDs allow for rewiring instead of replacing the instrument<br />

if an element fails.<br />

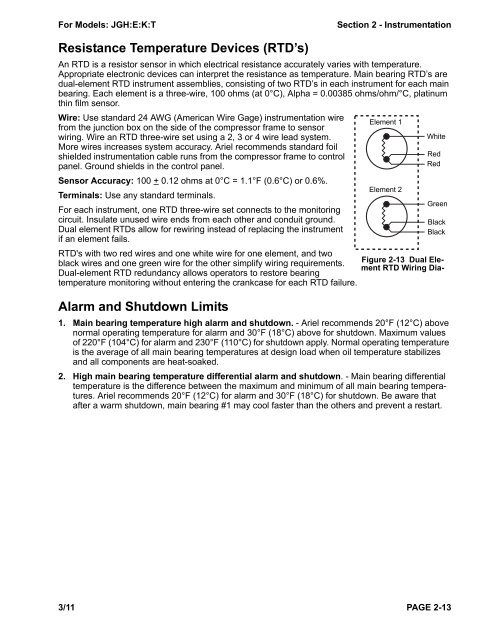

RTD's with two red wires and one white wire for one element, and two<br />

black wires and one green wire for the other simplify wiring requirements.<br />

Dual-element RTD redundancy allows operators to restore bearing<br />

temperature monitoring without entering the crankcase for each RTD failure.<br />

Alarm and Shutdown Limits<br />

Element 1<br />

Element 2<br />

3/11 PAGE 2-13<br />

White<br />

Red<br />

Red<br />

Green<br />

Black<br />

Black<br />

Figure 2-13 Dual Element<br />

RTD Wiring Dia-<br />

1. Main bearing temperature high alarm and shutdown. - <strong>Ariel</strong> recommends 20°F (12°C) above<br />

normal operating temperature for alarm and 30°F (18°C) above for shutdown. Maximum values<br />

of 220°F (104°C) for alarm and 230°F (110°C) for shutdown apply. Normal operating temperature<br />

is the average of all main bearing temperatures at design load when oil temperature stabilizes<br />

and all components are heat-soaked.<br />

2. High main bearing temperature differential alarm and shutdown. - Main bearing differential<br />

temperature is the difference between the maximum and minimum of all main bearing temperatures.<br />

<strong>Ariel</strong> recommends 20°F (12°C) for alarm and 30°F (18°C) for shutdown. Be aware that<br />

after a warm shutdown, main bearing #1 may cool faster than the others and prevent a restart.