Food Safety Magazine - June/July 2013

Food Safety Magazine - June/July 2013

Food Safety Magazine - June/July 2013

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCE<br />

the Harmonized Standards finalized and published, and the<br />

operating policies and continuous improvement established,<br />

members of the Steering Committee were asked, “Will you<br />

endorse audits using the Harmonized Standards?” Many had<br />

no conditions, but some did: Some buyers required the audits<br />

to be done by specific organizations, for example, a government<br />

auditor; some buyers required the audit to be performed<br />

under a Global <strong>Food</strong> <strong>Safety</strong> Initiative (GFSI)-benchmarked<br />

scheme and some had riders. All of these were audit process<br />

conditions, and all of the produce-buying companies on the<br />

Steering Committee agreed that they would accept audits<br />

using the Harmonized Standards under their conditions. According<br />

to Bill Pool, Wegmans manager for produce safety,<br />

“Wegmans <strong>Food</strong> Markets has actively encouraged our suppliers<br />

to use this standard for their audits. We have found that<br />

it works quite well for most farming operations, and I’ve got<br />

folks ranging from a 1-acre organic heirloom tomato grower<br />

to a 500-acre conventional multicrop vegetable grower using<br />

the Harmonized Standard. And I’ve got some greenhouse<br />

growers using it as well. Of all the audits done last year for our<br />

local growers, about 75 percent of them used the Harmonized<br />

Standards.” Charlie Cook, president of Country Fare Consulting<br />

LLC (CFC), retained by Subway to manage its produce<br />

supply chain vendor auditing program, says, “CFC has been<br />

using the Harmonized Standards for the past 2 years, and we<br />

wholeheartedly support the use of this standard by produce<br />

suppliers. The Harmonized Standard incorporates FDA guidance<br />

and best industry practice into one understandable document<br />

supporting the production and supply of safe produce<br />

nationally, thereby reducing the number of audits.” Other<br />

major produce buyers, not on the original Steering Committee,<br />

were also asked whether they would accept audits using<br />

the Harmonized Standards. Invariably, upon being informed<br />

of how the standards were created and tested, and seeing them<br />

for themselves, every produce-buying company approached<br />

has said yes. Again, some have conditions to their acceptance,<br />

the same as mentioned above, so operations are encouraged<br />

to talk with their buyers before scheduling an audit. But the<br />

extent of acceptance among buyers means that an operation<br />

should already be able to reduce its audit burden to only a few<br />

and, in some cases, one per year (Figure 1).<br />

Our technical and customer service<br />

staff averages over 20 years of<br />

experience, ensuring you:<br />

The right testing protocol,<br />

for your food and feed analysis<br />

The most cost-effective solution<br />

(only the tests you need)<br />

A personal commitment to work<br />

in partnership with you<br />

Trusted Testing Solutions Since 1916<br />

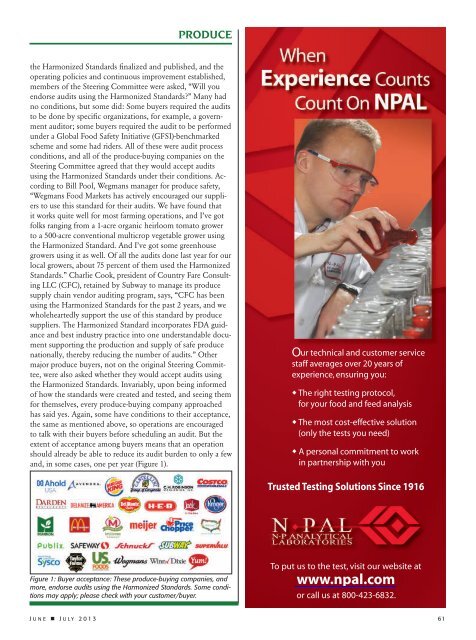

Figure 1: Buyer acceptance: These produce-buying companies, and<br />

more, endorse audits using the Harmonized Standards. Some conditions<br />

may apply; please check with your customer/buyer.<br />

To put us to the test, visit our website at<br />

www.npal.com<br />

or call us at 800-423-6832.<br />

J u n e • J u l y 2 0 1 3 61

![Otomatik indirilmez ise tıklayınız [Download]](https://img.yumpu.com/44170525/1/190x190/otomatik-indirilmez-ise-taklayanaz-download.jpg?quality=85)