Advanced Multiplexed Subsea Production Control System - cedip

Advanced Multiplexed Subsea Production Control System - cedip

Advanced Multiplexed Subsea Production Control System - cedip

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CONTROL<br />

TM<br />

Certified <strong>System</strong> Components<br />

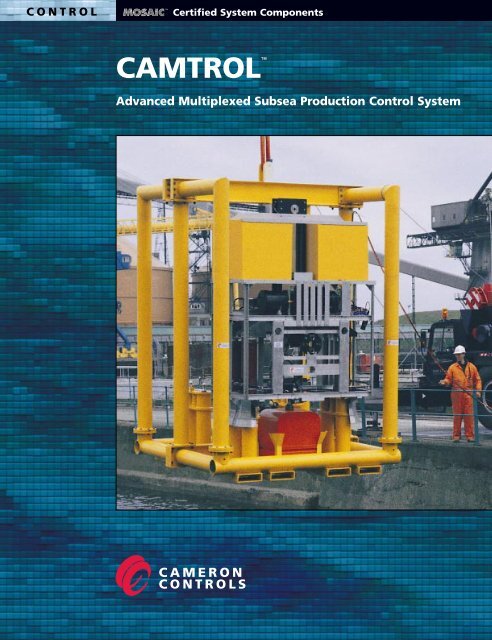

CAMTROL<br />

<strong>Advanced</strong> <strong>Multiplexed</strong> <strong>Subsea</strong> <strong>Production</strong> <strong>Control</strong> <strong>System</strong>

CAMTROL <br />

<strong>Advanced</strong> <strong>Multiplexed</strong> <strong>Subsea</strong> <strong>Production</strong> <strong>Control</strong> <strong>System</strong><br />

One Source for<br />

Dependable <strong>Subsea</strong><br />

<strong>Production</strong> <strong>System</strong>s<br />

The CAMTROL <strong>Advanced</strong><br />

<strong>Multiplexed</strong> <strong>Subsea</strong><br />

Multi-Purpose Intervention Tool<br />

<strong>Production</strong> <strong>Control</strong> <strong>System</strong><br />

from Cameron <strong>Control</strong>s is<br />

part of the MOSAIC system<br />

and offers a modular<br />

approach to controlling<br />

subsea systems. Like<br />

other MOSAIC components<br />

Multi-Mode<br />

Running Tool<br />

<strong>Control</strong><br />

Module<br />

Transportation<br />

Cage<br />

Jumper<br />

Deployment<br />

Basket<br />

(wellheads, Christmas<br />

trees, chokes, and manifolds)<br />

this system offers<br />

the MOSAIC advantage ...<br />

a pre-engineered system<br />

that delivers the time and<br />

money-saving advantages<br />

of modular components -<br />

but with the flexibility of<br />

custom-made.<br />

The CAMTROL <strong>Advanced</strong> <strong>Multiplexed</strong> <strong>Subsea</strong> <strong>Production</strong> <strong>Control</strong> <strong>System</strong> from Cameron<br />

<strong>Control</strong>s combines years of experience in the design, development and employment of subsea<br />

production systems with the industry’s most sophisticated control technology. The result is an<br />

advanced system engineered to meet the worldwide demand for cost-effective control of deepwater<br />

systems. Key considerations in the development of the system include:<br />

• <strong>System</strong>s Approach<br />

A systemic design approach enables the Cameron system to operate and monitor an entire field<br />

development and to be adaptable from field development to field development, eliminating the<br />

need for custom-designed systems every time field parameters change.<br />

• Modular Design<br />

As part of Cameron’s MOSAIC (Modular <strong>Subsea</strong> And Integrated Completions) product line,<br />

the CAMTROL <strong>System</strong> offers maximum flexibility and modular design. The control system<br />

is applicable to many field conditions and can be easily adapted for use in deepwater or shallow<br />

water; with trees or manifolds; or with virtually any production scenario.<br />

• Intervention Flexibility<br />

The CAMTROL <strong>System</strong> uses common intervention methods for the installation and retrieval<br />

of the <strong>Subsea</strong> <strong>Control</strong> Module, Cameron Willis Retrievable <strong>Subsea</strong> Choke, accumulator module<br />

and compact multi-phase flow meter. Methods may include diver-assist, diverless, guideline,<br />

guidelineless, ROV-assisted and totally autonomous.<br />

The development of this revolutionary new control system called for the reconfiguration of several<br />

new key pieces of technology. Each one was engineered based on Cameron’s extensive knowledge<br />

of production systems and experience with highly sophisticated multiplexed electro-hydraulic<br />

controls systems. Such newly packaged technology includes:<br />

• <strong>Subsea</strong> <strong>Control</strong> Module<br />

Weighing only 500 kg (1100 lbs), this pod is smaller, lighter in weight and incorporates more<br />

functionality than any other pod on the market today.<br />

2

The Standard Cameron <strong>Control</strong> <strong>System</strong> Meets All <strong>Subsea</strong> <strong>Production</strong> Options<br />

<strong>Subsea</strong><br />

<strong>Control</strong> Module<br />

<strong>Subsea</strong> <strong>Control</strong> Module<br />

(SCM)<br />

Compact and lightweight,<br />

the SCM includes the<br />

distributed electronics<br />

required for full system<br />

functionality and deepwater<br />

control of up to 32<br />

functions.<br />

<strong>Subsea</strong> Distribution Unit<br />

Provides central connection<br />

source for all SCMs to main<br />

control umbilical.<br />

Electro-Hydraulic<br />

Jumper<br />

SD016986<br />

<strong>Subsea</strong> Accumulator Module<br />

<strong>Subsea</strong><br />

Distribution<br />

Unit<br />

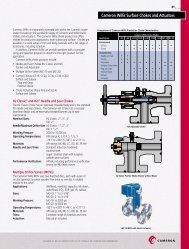

• Directional <strong>Control</strong> Valve<br />

The Directional <strong>Control</strong> Valve is a modular element of the <strong>Subsea</strong> <strong>Control</strong> Module (SCM). Each<br />

valve controls four functions within a miniaturized valve body. By adding as many as eight of<br />

these valves to the control module, each SCM can control up to 32 functions.<br />

• HydraQuad Coupler<br />

Cameron’s exclusive HydraQuad Coupler makes up four hydraulic connections at a time.<br />

It is used to link the Directional <strong>Control</strong> Valve to the external hydraulic connection.<br />

• Multi-Mode Running Tool<br />

The Multi-Mode Running Tool (MMRT) provides the functionality to install and retrieve<br />

system elements. Depending upon field requirements, any of the following methods can be<br />

used with standard SCM and choke designs:<br />

• Diver-assist with a simple mechanical lockdown tool<br />

• Guidelineless with a simple hydraulic lockdown tool<br />

• MMRT on conventional guidelines<br />

• MMRT on lift wire with ROV assistance<br />

• MMRT on ROV<br />

• Autonomous MMRT using thrusters and cameras<br />

• <strong>Subsea</strong> Retrievable Chokes<br />

Cameron Willis <strong>Subsea</strong> Retrievable Chokes are designed with a retrievable insert. The choke<br />

body is mounted on the Christmas tree or manifold. The insert, a unitized trim cartridge and<br />

actuator assembly, is retrieved to the surface, leaving the body subsea.<br />

<strong>Subsea</strong> Accumulator<br />

Module<br />

Provides local source of<br />

hydraulic fluid when<br />

required. Modules can be<br />

replaced using MMRT.<br />

Electro-Hydraulic Jumper<br />

Interconnects several SCMs<br />

to the <strong>Subsea</strong> Distribution<br />

Unit.<br />

Multi-Mode Running Tool<br />

(MMRT)<br />

Capable of change-out of<br />

SCM, subsea retrievable<br />

choke, accumulator module<br />

and multi-phase flow<br />

meter. Suitable for all<br />

common intervention<br />

methods to 3000 m<br />

(10,000 ft) water depth.<br />

<strong>Control</strong> Module<br />

Transportation Cage<br />

Used to lower the SCM to<br />

the seabed for installation<br />

and retrieval.<br />

Multi-Purpose Intervention<br />

Tool (MPIT)<br />

Capable of jumper connection,<br />

choke intervention,<br />

needle valve operation as<br />

well as other intervention<br />

tasks.<br />

Jumper Deployment Basket<br />

Provides a central source<br />

for materials needed to<br />

perform connections<br />

subsea.<br />

3

Intervention Flexibility Key to Modularity and Cost Savings<br />

Standard Components -<br />

Maximum Flexibility<br />

Using a standard <strong>Subsea</strong><br />

<strong>Control</strong> Module and<br />

standard Cameron Willis<br />

<strong>Subsea</strong> Retrievable Choke,<br />

the CAMTROL <strong>Advanced</strong><br />

<strong>Multiplexed</strong> <strong>Subsea</strong><br />

<strong>Production</strong> <strong>Control</strong> <strong>System</strong><br />

can be used in shallow as<br />

well as deepwater applications.<br />

Multi-purpose<br />

intervention tooling<br />

makes this system the<br />

most flexible, cost-effective<br />

system on the market<br />

today.<br />

The CAMTROL <strong>Advanced</strong> <strong>Multiplexed</strong> <strong>Subsea</strong> <strong>Production</strong> <strong>Control</strong> <strong>System</strong> provides maximum<br />

flexibility via various intervention methods depending on water depth and field development<br />

requirements. These methods can be used on either satellite trees or manifolds and offer a range<br />

of choices not available on conventional systems.<br />

The CAMTROL <strong>System</strong> includes two multi-functional intervention tools which provide flexibility<br />

and economy:<br />

Multi-Mode Running Tool<br />

The Multi-Mode Running Tool (MMRT) is used to perform the following functions:<br />

• Installation and change-out of the <strong>Subsea</strong> <strong>Control</strong> Module (SCM)<br />

• Installation and change-out of inserts in the Cameron Willis <strong>Subsea</strong> Retrievable Choke<br />

• Change-out of accumulator module<br />

• Change-out of multi-phase flow meter<br />

The standard design of the MMRT provides functionality for performing these functions via all<br />

common intervention methods for water depths to 3000 m (10,000 ft).<br />

In shallow water applications, the CAMTROL <strong>System</strong> provides a simple manual lift and lock<br />

tool which allows a diver to perform the required functions. For deeper water, a simple hydraulic<br />

lift and lock tool is available which can be run on guidelines or guidelineless.<br />

When use of the MMRT is required, it may be used on conventional guidelines or on lift wire<br />

with ROV assistance. For still deeper water, the MMRT can be used in conjunction with an ROV<br />

using “on bottom” techniques. The MMRT can also be used autonomously with thrusters and<br />

cameras.<br />

The MMRT is designed for efficient operation with<br />

all large work class ROVs and is interface compliant<br />

with API 17H using weight transfer systems for neutral<br />

buoyancy.<br />

Multi-Purpose Intervention Tool<br />

The Multi-Purpose Intervention Tool (MPIT) is used<br />

to perform jumper connections, choke interventions,<br />

valve operations and other intervention tasks.<br />

Like the MMRT, the MPIT is designed for efficient<br />

operation with all large work class ROVs and is<br />

interface compliant with API 17H using weight<br />

transfer systems for neutral buoyancy.<br />

MPIT with ROV making Jumper Connection<br />

SD016998<br />

CAMTROL <strong>System</strong> Intervention Flexibility<br />

0 3000 m (10,000 ft)<br />

Diver<br />

Guideline<br />

Guidelineless<br />

ROV<br />

4

Change-Out of <strong>Subsea</strong> <strong>Control</strong> Module<br />

Change-Out of <strong>Subsea</strong> <strong>Control</strong> Module - <strong>Subsea</strong> Christmas Tree<br />

Opto-electrical<br />

Lift Cable<br />

Lift Cable<br />

Electronics<br />

Module<br />

Hydraulic<br />

Pump<br />

MMRT<br />

SCM<br />

Manual Lift and<br />

Lock Tool<br />

SCM<br />

Christmas<br />

Tree<br />

Diver-Assist using Manual Lift and Lock Tool<br />

MMRT on Guidelines<br />

Buoyancy<br />

Module<br />

Opto-electrical<br />

Lift Cable<br />

MMRT<br />

Transfer<br />

Weights<br />

ROV<br />

MMRT<br />

Thruster<br />

Choke<br />

Location<br />

Interface Frame<br />

SCM<br />

Choke<br />

Location<br />

SCM<br />

Christmas<br />

Tree<br />

MMRT with ROV<br />

Autonomous MMRT with Thrusters and Cameras<br />

Change-Out of <strong>Subsea</strong> <strong>Control</strong> Module - <strong>Subsea</strong> Manifold<br />

Umbilical/<br />

Lift Wire<br />

Hydraulic<br />

Lift and Lock Tool<br />

Interface<br />

Frame<br />

Interface Frame<br />

Manifold<br />

Structure<br />

SCM<br />

SCM<br />

Location<br />

Buoyancy Module<br />

MMRT<br />

ROV<br />

Transfer Weights<br />

SCM<br />

Location<br />

Orientation<br />

Helix<br />

Manifold<br />

Structure<br />

SD24542<br />

Guidelineless using Hydraulic Latch and Lock Tool<br />

MMRT with ROV<br />

5

<strong>Subsea</strong> <strong>Control</strong> Module Provides Functionality in Compact Design<br />

Lightweight, Modular<br />

SCM <strong>Control</strong>s up to<br />

32 Functions<br />

The <strong>Subsea</strong> <strong>Control</strong><br />

Module (SCM) for the<br />

CAMTROL <strong>Advanced</strong><br />

<strong>Multiplexed</strong> <strong>Subsea</strong><br />

<strong>Production</strong> <strong>Control</strong><br />

<strong>System</strong> is lighter in<br />

weight, more compact<br />

and incorporates more<br />

functionality than any<br />

other subsea pod in the<br />

industry.<br />

The CAMTROL <strong>System</strong> <strong>Subsea</strong> <strong>Control</strong> Module (SCM) provides multiplexed electro-hydraulic<br />

monitoring and control of a wide variety of field functions including the traditional tree<br />

functions, manifold valve control, choke adjustment, position indication/feedback, header<br />

pressure/temperature monitoring, downhole monitoring and pressure drops across chokes.<br />

Features of the SCM include:<br />

• Small, compact design<br />

• 650 mm x 690 mm (25 in. x 27 in.) footprint<br />

• 785 mm (31 in.) in height to top of cover<br />

• Lightweight - only 500 kg (1100 lbs)<br />

• Can be used in water depths to 3000 m (10,000 ft)<br />

• Can be installed and retrieved using all common intervention<br />

methods<br />

• HydraQuad Couplers are pressure-balanced<br />

• Four-way directional valve design allows control of up to<br />

32 functions<br />

• Field-proven electrical connectors<br />

• Electrical interfaces accommodate all subsea instrumentation<br />

• Dual input supplies and dual electronics<br />

• Central lockdown with secondary release capability<br />

<strong>Subsea</strong> <strong>Control</strong> Module<br />

Key to the functionality and modularity of the SCM are the Directional <strong>Control</strong> Valve and<br />

HydraQuad Coupler.<br />

Directional <strong>Control</strong> Valve<br />

The Directional <strong>Control</strong> Valve is a repackaged version of Cameron’s highly successful metal-tometal<br />

shear seal valves. For this purpose, the design has been miniaturized and modularized for<br />

maximum functionality and minimum size and weight. The result is a single valve block capable<br />

of controlling four functions. By using eight Directional <strong>Control</strong> Valves, a single SCM can control<br />

up to 32 functions.<br />

HydraQuad Coupler<br />

The hydraulic HydraQuad Coupler uses a rugged 90° gate and seal/seat design which intrinsically<br />

provides pressure-balanced simplicity not inherent in conventional coaxial stab coupler<br />

configurations. By making up to four hydraulic circuits at a time, each connection has a smaller<br />

footprint than available connection systems. This in turn requires less mounting structure and<br />

reduces weight.<br />

SD24617<br />

Operational Requirement<br />

Single Pipeline Valve Block<br />

Two Pipeline Valve Blocks<br />

One <strong>Subsea</strong> Christmas Tree<br />

Up to 32 hydraulic functions can be controlled by a single <strong>Subsea</strong> <strong>Control</strong> Module<br />

Number of Pod Functions<br />

0 4 8 12 16 20 24 28 32<br />

One <strong>Subsea</strong> Christmas Tree and Pipeline Valve Block<br />

Two <strong>Subsea</strong> Christmas Trees<br />

Two <strong>Subsea</strong> Christmas Trees and Related Manifold Functions<br />

6

Modular Components Increase Field Development Options<br />

The CAMTROL <strong>System</strong><br />

<strong>Subsea</strong> <strong>Control</strong> Module (SCM)<br />

Lift Mandrel<br />

Pressure Compensator<br />

<strong>Subsea</strong><br />

Electronics<br />

Module<br />

Directional <strong>Control</strong><br />

Valve Block<br />

High Pressure<br />

Supply Module<br />

HydraQuad Coupler<br />

SD24619<br />

Lockdown<br />

Mechanism<br />

Remote I/O Block<br />

Dump Valve<br />

Filters<br />

Pressure<br />

Transmitter<br />

Filter Block<br />

Connector<br />

Receptacle<br />

Electrical Connector<br />

SD24616<br />

7

Sales, Service and Manufacturing<br />

Cameron <strong>Control</strong>s<br />

10810 Northwest Freeway<br />

Houston, Texas 77092<br />

Tel 713 683 4600<br />

Fax 713 683 4729<br />

http://www.camerondiv.com<br />

Sales and Service<br />

Cooper Cameron (U.K.) Ltd.<br />

5 Mondial Way<br />

Harlington<br />

Hayes UB3 5AR<br />

Tel 44 181 9901800<br />

Fax 44 181 9901888<br />

http://www.camerondiv.com<br />

About the Cover:<br />

Dock Trials for the CAMTROL <strong>Subsea</strong><br />

<strong>Production</strong> <strong>Control</strong> <strong>System</strong> were held<br />

before customer witnesses in Blythe,<br />

England. The trials focused on several<br />

key functions of the system including<br />

pod change-out and umbilical installation.<br />

The trials were very successful and<br />

demonstrated the unique functionality<br />

of the CAMTROL system.<br />

Cameron <strong>Control</strong>s<br />

Units 1 & 2<br />

Boundary Road<br />

Harfrey’s Industrial Estate<br />

Great Yarmouth, Norfolk NR31 OLY<br />

Tel 44 1493 440438<br />

Fax 44 1493 655405<br />

http://www.camerondiv.com<br />

Manufacturing<br />

Cameron <strong>Control</strong>s<br />

Lueckenweg 1<br />

29227 Celle, Germany<br />

Tel 49 5141 8060<br />

Fax 49 5141 806333<br />

CAMTROL, MOSAIC and HydraQuad are trademarks of the Cooper Cameron Corporation, Cameron Division.<br />

© Cooper Cameron Corporation, Cameron Division, Printed in USA, 8/98, TG/5M, WR6589/TC1276