Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cuthbert’s Epistles to the Mognoscenti: Door Pillar Reinforcement<br />

Morgan Oasis Garage<br />

Hoodsport, Washington<br />

Cuthbert J. Twillie, Proprietor<br />

Friends,<br />

Years ago Jim Dietz asked the lovely<br />

Flowerbelle to make a tonneau cover and a<br />

boot for his four place Morgan. I drove the<br />

car over here to the shop so she could have<br />

it on hand for the work. While the upholstery<br />

was being done there were a few things that<br />

needed doing and I did them. One thing I<br />

didn't do was repair the door hinge fastenings.<br />

Jim hadn't said anything, but they were<br />

as sloppy as any I've seen. Of course Jim<br />

was aware of that situation, and when the car<br />

was returned he asked if the hinges could be<br />

seen to.<br />

Ken McClinton was the source of a great<br />

deal of knowledge he'd picked up in his decades<br />

of Mogging. Bob Hauge can figure<br />

problems out on the phone, and he is one of<br />

the best, if not the best Wrench in the club.<br />

Bob has decades of Morganeering also.<br />

These are the guys I go to for solutions to a<br />

Morgan's nagging problems.<br />

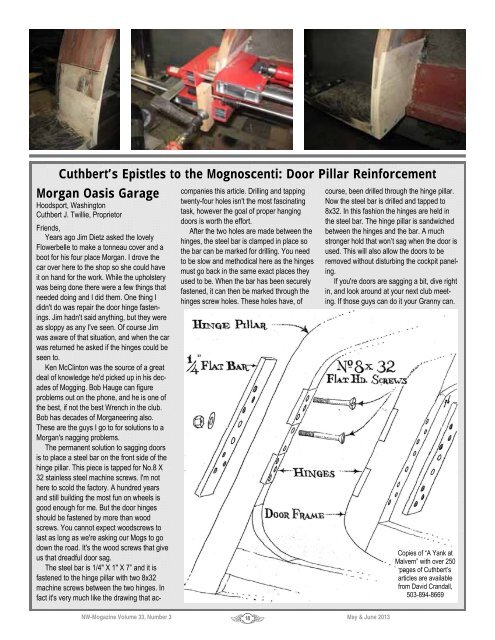

The permanent solution to sagging doors<br />

is to place a steel bar on the front side of the<br />

hinge pillar. This piece is tapped for No.8 X<br />

32 stainless steel machine screws. I'm not<br />

here to scold the factory. A hundred years<br />

and still building the most fun on wheels is<br />

good enough for me. But the door hinges<br />

should be fastened by more than wood<br />

screws. You cannot expect woodscrews to<br />

last as long as we're asking our Mogs to go<br />

down the road. It's the wood screws that give<br />

us that dreadful door sag.<br />

The steel bar is 1/4" X 1" X 7” and it is<br />

fastened to the hinge pillar with two 8x32<br />

machine screws between the two hinges. In<br />

fact it's very much like the drawing that accompanies<br />

this article. Drilling and tapping<br />

twenty-four holes isn't the most fascinating<br />

task, however the goal of proper hanging<br />

doors is worth the effort.<br />

After the two holes are made between the<br />

hinges, the steel bar is clamped in place so<br />

the bar can be marked for drilling. You need<br />

to be slow and methodical here as the hinges<br />

must go back in the same exact places they<br />

used to be. When the bar has been securely<br />

fastened, it can then be marked through the<br />

hinges screw holes. These holes have, of<br />

NW-Mogazine Volume 33, Number 3 <strong>May</strong> & June 2013<br />

18<br />

course, been drilled through the hinge pillar.<br />

Now the steel bar is drilled and tapped to<br />

8x32. In this fashion the hinges are held in<br />

the steel bar. The hinge pillar is sandwiched<br />

between the hinges and the bar. A much<br />

stronger hold that won’t sag when the door is<br />

used. This will also allow the doors to be<br />

removed without disturbing the cockpit paneling.<br />

If you're doors are sagging a bit, dive right<br />

in, and look around at your next club meeting.<br />

If those guys can do it your Granny can.<br />

Copies of “A Yank at<br />

Malvern” with over 250<br />

pages of Cuthbert’s<br />

articles are available<br />

from David Crandall,<br />

503-894-8669