reprap-granule-extruder-tudelft1

reprap-granule-extruder-tudelft1

reprap-granule-extruder-tudelft1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

Ṫhe RepRap project<br />

In the beginning of this project, a literature review<br />

was carried out. The goal of this review was to gain<br />

some insight in the RepRap project and to determine<br />

a goal for the project. After the review, the subject of<br />

creating a recycling add-on for the printer was<br />

determined. An extract of the review, with a focus on<br />

the parts about the RepRap project, can be found in<br />

this chapter.<br />

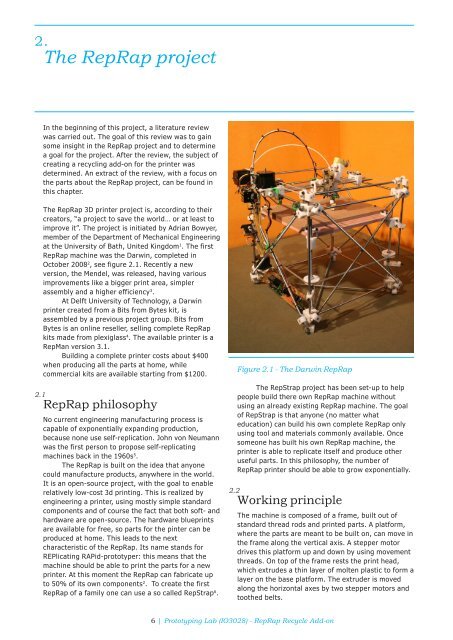

The RepRap 3D printer project is, according to their<br />

creators, “a project to save the world… or at least to<br />

improve it”. The project is initiated by Adrian Bowyer,<br />

member of the Department of Mechanical Engineering<br />

at the University of Bath, United Kingdom 1 . The first<br />

RepRap machine was the Darwin, completed in<br />

October 2008 2 , see figure 2.1. Recently a new<br />

version, the Mendel, was released, having various<br />

improvements like a bigger print area, simpler<br />

assembly and a higher efficiency 3 .<br />

At Delft University of Technology, a Darwin<br />

printer created from a Bits from Bytes kit, is<br />

assembled by a previous project group. Bits from<br />

Bytes is an online reseller, selling complete RepRap<br />

kits made from plexiglass 4 . The available printer is a<br />

RepMan version 3.1.<br />

Building a complete printer costs about $400<br />

when producing all the parts at home, while<br />

commercial kits are available starting from $1200.<br />

2.1<br />

RepRap philosophy<br />

No current engineering manufacturing process is<br />

capable of exponentially expanding production,<br />

because none use self-replication. John von Neumann<br />

was the first person to propose self-replicating<br />

machines back in the 1960s 5 .<br />

The RepRap is built on the idea that anyone<br />

could manufacture products, anywhere in the world.<br />

It is an open-source project, with the goal to enable<br />

relatively low-cost 3d printing. This is realized by<br />

engineering a printer, using mostly simple standard<br />

components and of course the fact that both soft- and<br />

hardware are open-source. The hardware blueprints<br />

are available for free, so parts for the pinter can be<br />

produced at home. This leads to the next<br />

characteristic of the RepRap. Its name stands for<br />

REPlicating RAPid-prototyper: this means that the<br />

machine should be able to print the parts for a new<br />

printer. At this moment the RepRap can fabricate up<br />

to 50% of its own components 2 . To create the first<br />

RepRap of a family one can use a so called RepStrap 6 .<br />

Figure 2.1 - The Darwin RepRap<br />

The RepStrap project has been set-up to help<br />

people build there own RepRap machine without<br />

using an already existing RepRap machine. The goal<br />

of RepStrap is that anyone (no matter what<br />

education) can build his own complete RepRap only<br />

using tool and materials commonly available. Once<br />

someone has built his own RepRap machine, the<br />

printer is able to replicate itself and produce other<br />

useful parts. In this philosophy, the number of<br />

RepRap printer should be able to grow exponentially.<br />

2.2<br />

Working principle<br />

The machine is composed of a frame, built out of<br />

standard thread rods and printed parts. A platform,<br />

where the parts are meant to be built on, can move in<br />

the frame along the vertical axis. A stepper motor<br />

drives this platform up and down by using movement<br />

threads. On top of the frame rests the print head,<br />

which extrudes a thin layer of molten plastic to form a<br />

layer on the base platform. The <strong>extruder</strong> is moved<br />

along the horizontal axes by two stepper motors and<br />

toothed belts.<br />

6 | Prototyping Lab (IO3028) - RepRap Recycle Add-on