SL55 AMG - Sympatico Personal Webspace

SL55 AMG - Sympatico Personal Webspace

SL55 AMG - Sympatico Personal Webspace

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mercedes-Benz <strong>SL55</strong> <strong>AMG</strong> - DIY & Parts Cross-References, etc.<br />

Disclaimer : This collection of info, links, etc., does not imply any endorsement or guarantee of fitness of a given<br />

product or service producer, and also may be subject to errors or omissions. If I have made any mistakes, or if<br />

you wish to contribute related info, please contact me.<br />

Overview<br />

Mercedes seem to have created the perfect car. Superb(ish) quality, gorgeous<br />

looks, super car performance and at the touch of a button it becomes a convertible!<br />

The V8 engine from the SL500 has been heavily modified by <strong>AMG</strong> resulting in a<br />

near 50% increase in power. This is enough to propel the <strong>SL55</strong> to over 200mph<br />

with speed restrictor removed.<br />

Braking is excellent thanks to 8-pot vented discs and ESP brake by wire<br />

technology, while the <strong>SL55</strong> becomes the first Mercedes to feature pushbutton<br />

sequential gear shift. Handling is assisted by state of the art active body control,<br />

however it still struggles to cope with the car's enormous 2 ton mass.<br />

With the <strong>SL55</strong> <strong>AMG</strong>, Mercedes has taken its legendary roadster and injected it with<br />

a major dose of horsepower that elevates it to near super car status. With nearly 500 horsepower emanating<br />

from its supercharged V8, this drop top can outdo most sports cars in a straight line, yet it's still docile enough to<br />

go for a top-down Sunday drive. The ridiculously powerful SL65 <strong>AMG</strong> might overshadow the <strong>SL55</strong> in the minds<br />

of some buyers, but unless you have regular access to roads resembling the German autobahn, the real-world<br />

performance difference will go unnoticed 95 percent of the time. If you're looking for the ultimate combination of<br />

open-air fun and unparalleled performance, the <strong>SL55</strong> satisfies in ways few other cars can.

Details<br />

Construction<br />

• Bonnet/hood! aluminium<br />

• Boot/trunk lid! aluminium<br />

• Front wings/fenders! aluminium<br />

• Doors! ! aluminium<br />

• Inner door shells! magnesium!<br />

Engine<br />

Engine Handcrafted by! ! Florim Avdija, <strong>AMG</strong> Affalterbach, Germany<br />

Bore x Stroke! ! ! 97.00 mm x 92.00 mm<br />

Power! ! ! ! 494 bhp @ 6,100 rpm<br />

Torque! ! ! ! 516 lb/ft @ 2,750 to 4,000 rpm<br />

Maximum RPM!! ! 6,500 rpm<br />

Firing Order! ! ! 1-5-4-2-6-3-7-8<br />

Compression Ratio! ! 9.5:1<br />

Supercharger Max. Boost! 0.8 bar (12 psi)<br />

Air Filter Element! ! K&N 33-2181 (2 required) +15hp<br />

Oil Filter<br />

Oil! ! ! ! Mobil 1 10W30 Fully Synthetic (9.0 US qt (8.5 litres)<br />

Spark Plugs! ! ! NGK PFR 5 R-11 (these are Platinum)<br />

Spark Plug Gap ! ! 0.039 in (1.0 mm)<br />

Spark Plug Torque! ! 15 – 22 lb/ft (20 – 30 Nm)<br />

In-Line Fuel Filter<br />

Poly-V-Belts! ! ! 2 belts (Length 8ft 1 in (2462 mm) and 4 ft 3 in (1289 mm))<br />

Cooling System!Anti-Freeze! MB 320.0 anticorrosion/antifreeze with water 50:50

Transmission<br />

Gearbox! ! ! 5-speed Auto<br />

Ratios! ! ! ! 1st-3.59; 2nd-2.19; 3rd-1.41; 4th-1.00; 5th-0.83<br />

Gear Oil! ! ! MB Automatic Transmission Fluid (9.1 US qt (8.1 litres))<br />

Final Drive! ! ! ! !<br />

Ratio! ! ! ! 2.82 : 1<br />

Oil! ! ! ! Hypoid Gear Oil SAE 85 W 90 (1.5 US qt (1.4 litres))<br />

Suspension<br />

Front! ! ! ! Double Wishbones and Coil Springs with ABC (Active Body Control)<br />

Rear! ! ! ! Five-link with ABC (Active Body Control)<br />

Steering<br />

Type! ! ! ! Power assisted, rack and pinion<br />

Ratio<br />

Turn Lock to Lock<br />

Turning Circle! ! ! 36.2 ft<br />

Power Fluid! ! ! MB Power Steering Fluid (Pentosin CHF 11S)<br />

Braking System<br />

Front! ! ! ! Brembo Ventilated 14.2” Discs with 8 piston fixed-type callipers<br />

Rear! ! ! ! Brembo Ventilated 13.0 in Discs with 4 piston fixed-type callipers<br />

Master Cylinder!! ! Servo-assisted master cylinder<br />

Fluid! ! ! ! Mercedes-Benz DOT 4+

Described! ! ! Electronically controlled 4-circuit with 4-wheel discs.<br />

Sensotronic Brake Control! Electronic braking system transmits brake pressure individually to<br />

! ! ! ! each wheel based on driver input and various vehicle parameters.<br />

! ! ! ! Sensotronic optimises brake pressure at each wheel in normal<br />

! ! ! ! braking, emergency stopping and during ESP activity. “Soft Stop”<br />

! ! ! ! feature precisely modulates brake pressure as the car approaches a<br />

! ! ! ! stop during normal braking. Automatic brake drying applies the<br />

! ! ! ! brakes lightly and briefly based on windscreen wiper use and driver<br />

! ! ! ! braking intervals, to reduce moisture on the brake surfaces.<br />

! ! ! ! Predictive brake priming sets the brake pads nearer the discs when<br />

! ! ! ! the driver quickly releases the accelerator, for faster braking<br />

! ! ! ! response.<br />

Brake Assist! ! ! System senses emergency barking via the speed at which the driver<br />

! ! ! ! presses the brake pedal and immediately applies maximum available<br />

! ! ! ! braking force, potentially reducing the overall stopping distance by<br />

! ! ! ! eliminating the delay caused by a common human tendency, not to<br />

! ! ! ! brake hard enough, soon enough. Letting up on the brake pedal<br />

! ! ! ! releases “Brake Assist”.<br />

Antilock Braking System! ABS senses impending wheel lockup under heavy braking and<br />

! ! ! ! pumps the front brakes individually or the rear brakes together (to<br />

! ! ! ! help to maintain stability) as needed, up to 30 times per second, to<br />

! ! ! ! prevent lockup and maintain steering ability. Sensotronic eliminates<br />

! ! ! ! the pedal pulsation commonly associated with conventional brake<br />

! ! ! ! systems and ABS.<br />

Electrical<br />

Alternator! ! ! ! 14 V / 180 A<br />

Starter Motor! ! ! ! 12 V / 1.7 kW<br />

Starter Battery! ! ! ! 12 V / 35Ah<br />

Consumer/Accessory Battery! ! 12 V / 70Ah<br />

Wheels<br />

PCD! ! ! ! ! 5 x 112 mm<br />

Centre Bore! ! ! ! 66.6 mm<br />

Std. M.B. Wheel Bolts! ! ! M14 x 1.5” thread pitch, Ball Seat, Thread Length - 25 - 28mm<br />

Standard Original<br />

<strong>AMG</strong> ultra-thin-spoke, light alloy, wheels (Style V)<br />

Front ! ! 8.5" x 18" ! ET 30 mm! 255/40 R 18<br />

Rear ! ! 9.5" x 18" ! ET 33 mm! 285/35 R 18<br />

Note :<br />

• Mercedes-Benz wheel bolts have a “Ball Seat”, while most aftermarket wheels require bolts with a “ 60<br />

degree Taper Seat”<br />

• Higher positive ET/offset = more”set-in”. (i.e. if original has ET 38, and new has ET 28, then new wheel<br />

will sit further out by 10 mm, and will be more flush with fender).<br />

• Minimum wheel bolt engagement inside hub is about 1 1/2 times the bolt diameter i.e. 14mm diameter<br />

bolt will require at least 21mm engagement inside hub (or another way, 21mm outside inner edge of<br />

wheel).<br />

Currently Fitted<br />

Mandus Manheim Painted/Gun Metal<br />

Front! ! 8.5" x 19" ! ET 25 mm! 255/35 R 19! ! SKU: W-1985MAH255112B66

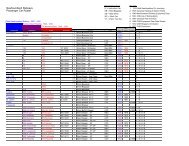

DIY Maintenance, Part Cross-References & Modifications<br />

What Can Go Wrong? - General Problem Areas and Common Faults<br />

The <strong>SL55</strong> is fairly reliable, but... when it goes down it goes down hard.<br />

The things that are weak on the car and will break (at around 100,000 km) are (in no particular order) :<br />

• front ABC strut/shocks $1,200 ea - ($1,500 - $2,000 ea dealer installed)<br />

• rear ABC strut/shocks $1,000 ea - ($1,300 - $1,700 ea dealer installed)<br />

• ABC valve blocks $1,100 ea - ($2,700 each including installation)<br />

• ABC tandem pump - power steering pump and ABC pump combined $1,200 - ($3,500 dealer installed). As<br />

a space-saving measure the tandem pump was engineered as one unit.<br />

• Intercooler pump ($500 dealer installed)<br />

• Engine mounts ($2,500 for all three, dealer installed)

• Lower ball joints ($700 dealer installed)<br />

• Supercharger bearing<br />

An independent may be cheaper, except for ABC work (as components and fluid are expensive).<br />

Brakes<br />

This vehicle has sensotronic brake control (SBC). If the SBC light on the dash illuminates, have the brakes<br />

checked. If the SBC is not working, limited brake pressure is delivered to the front brakes, increasing the<br />

distance it takes to stop. The SBC hydraulic unit has a specific service life programmed into the control module;<br />

follow the manufacturer's recommended service procedure for proper maintenance of the SBC. Follow the twoyear<br />

service interval for brake fluid flush.<br />

Engine<br />

Oil leaks from the PCV vent housings on the valve covers and inspection plates on the front of the engine are<br />

common. The rubber bond in the harmonic balancer can decay, which causes the balancer to move and work its<br />

way into the timing chain cover. If the balancer comes into contact with the timing cover while the engine is<br />

running, it will fracture and damage the timing case and potentially other surrounding parts. The harmonic<br />

balancer should be inspected at every service. Oil leaks from the oil level sensor are common. The crankshaft<br />

position sensors tend to fail.<br />

Suspension & Steering<br />

Front thrust arm and control arm bushings can crack and sometimes tear completely. If this is not repaired<br />

quickly, damage to the front subframe unit will occur, which is very expensive to repair. Updated control arms<br />

(that prevent damage to the subframe when the bushings wear out) are available. The active body control<br />

system can leak fluid from numerous areas, including the tandem pump, hydraulic lines, struts, and/or seals. If it<br />

is not repaired, the vehicle ride height could drop too low and cause damage to the undercarriage.<br />

Drive Train<br />

A vibration felt through the centre floor of the vehicle can be caused by driveshaft flex discs, which crack and<br />

shred, causing excessive driveshaft movement. Not repairing these can cause damage to the driveshaft centre<br />

support bearing, or, in the worst case scenario, damage to the transmission or differential. High mileage or older<br />

vehicles develop leaks at the differential seals and cover; the whole unit needs to be resealed to repair the leaks.<br />

The wire connector on the transmission leaks fluid into the wiring harness. If not repaired, the oil will migrate<br />

through the wiring harness and damage the transmission control module. A new harness and control module are<br />

required to fix the problem.<br />

Electrical & Lights<br />

Brake light switch failure can cause the ESP and BAS warnings to illuminate. The early versions of the central<br />

gateway module (which allows different systems to communicate with each other) have software problems.<br />

Heating & Air Conditioning<br />

The evaporator temperature sensor can fail, causing the AC compressor not to cycle. If the AC compressor does<br />

not cycle on, the AC system will not blow cold air. If the AC compressor is stuck on, the air will be very cold at<br />

first, before warming up.<br />

Repository of R230 Info<br />

R230FuseMap.PDF<br />

Vario Roof Diagnostic Aid.pdf<br />

Manually Closing the Vario Roof.pdf<br />

Dual Battery.pdf<br />

FSS operating instructions.pdf

FSS reset.pdf<br />

Instrument Cluster.pdf<br />

Wiring diagrams - reading.pdf<br />

remove shifter lever[1].pdf<br />

remove center console cover[1].pdf<br />

change front pads.pdf<br />

change rear pads.pdf<br />

The brake thread to go along with the brake pdf's.<br />

http://www.benzworld.org/forums/r230...83-brakes.html<br />

2004 SL500 MANUAL R230 SBC Tool info.pdf<br />

2004 SL500 MANUAL R230 SBC Safety Sheet Involves BRAKES.pdf<br />

2004 SL500 MANUAL R230 SBC Disable wo STAR_DIAGNOSIS.pdf<br />

2004 SL500 MANUAL R230 SBC disable on other MB.pdf<br />

2004 SL500 MANUAL R230 SBC ABS info.pdf<br />

removal front bumper.pdf<br />

removal rear bumper.pdf<br />

replace fuel filter.pdf<br />

headlight removal.pdf<br />

headlight replace.pdf<br />

Remove rocker panels, aprons, etc.<br />

http___127.0.0.1_38562_repairandmaintenance_AZ_AZ88.pdf<br />

http___127.0.0.1_38562_repairandmaintenance_AR_AR88.80-P-6000R.pdf<br />

Steering wheel/Airbag<br />

AR46.pdf<br />

AR46.10-P-0100I.pdf<br />

AR46.10-P-0200I.pdf<br />

AR46.10-P-0300I.pdf<br />

AR54.25-P-2802I.pdf

AR91.60-P-0660R.pdf<br />

Servicing & Intervals<br />

For all, their performance and luxury, the new <strong>SL55</strong> is designed to be remarkably easy to live with, offering<br />

flexible service intervals, dependant on way you drive car.<br />

A full service history is absolutely essential, and itʼs equally important that the car has been looked after by a<br />

qualified specialist. Gaps in the history should sound warning bells, particularly if they occur at the same time as<br />

a change in ownership, and make sure bills for parts match the recommended schedule – itʼs easy to fill the<br />

service book with oil changes but never do the more expensive maintenance jobs.<br />

Service Parts<br />

Servicing Costs (Labour + Parts)<br />

• Prices vary significantly; these are rough estimates for costs at an independent shop.<br />

• Minor service (every ?): c$?<br />

• Major service (every ? miles): c$?<br />

• Clutch replacement: c$0<br />

• Brakes (pads plus rotor resurfacing): c$?-?<br />

Parts Costs<br />

• Front brake pads - c$?<br />

• Rear brake pads - c$?<br />

• New alternator - c$?<br />

• New starter motor - c$?<br />

• Replacement headlamp - c$?<br />

• New exhaust - c$? (including catalysts but excluding manifolds)<br />

Recalls<br />

Jacking Points<br />

For a floor/trolley jack, the 4 lift points are :<br />

• front - protruding pins behind front wheels<br />

• rear - protruding pins in front of rear wheels

A Service<br />

B Service

Additional Work<br />

Diagnostics and OBD II Scan Tool<br />

OBD II Technical History

Since the late '70's early '80's vehicles have been equipped with sophisticated electronics to control vehicle<br />

emissions and performance. Through the years several systems have been used, and keeping up with the<br />

differences from year to year was a real chore, to say the least. Multiple scanners that attached to the vehicles<br />

on-board computer systems were needed, and it was not uncommon for the scanner to become obsolete from<br />

model year to model year. These were the days of the "pre-OBD I "(On-Board Diagnosis-First design) systems.<br />

Beginning in '88 CARB (California's Air Resources Board) and the EPA (Environmental Protection Agency)<br />

required vehicle manufactures to include a "self diagnostic" program capable of identifying an emission related<br />

fault in the On-Board Computer systems. The first generation of On-Board Diagnostics came to be known as<br />

OBD I. The CARB conducted studies on the OBD I vehicles and found that the system was not capable of<br />

detecting an emission related component unless it had failed. The components that had not failed completely<br />

were unable to set a DTC. Also, it was found that some systems not being monitored had failed and yet the<br />

vehicle would pass an Emissions Test as the failed part would not be a factor unless the vehicle was being<br />

driven or under a load. The CARB and the EPA passed new laws that would address the problems found during<br />

the OBD I case study. These new laws and requirements are known as OBD II. Since mid-'94-'95 some vehicles<br />

were equipped with the second design, OBD II systems. In '94-'95 only select models were equipped with this<br />

new system, and in '96 every vehicle sold in the United States were equipped with the OBD II system. You might<br />

be asking, ok, so what? Well, this was the single and largest improvement made to diagnosis and repair of the<br />

On-Board Computer systems since their introduction. The DLC (Data Link Connector) that a scanner attaches<br />

to, is virtually the same for every vehicle, and the "Generic" DTC's (Diagnostic Trouble Code) are the same for<br />

every vehicle. The terminology was changed to terms that would be used by all manufactures. Before this, the<br />

computer (PCM), for example, could have been called a Processor, ECU, Control Module, ECM, etc. To know<br />

what the name of a part on a specific system was called or how it functioned, or was located, was tough when<br />

you worked on multiple vehicle models.<br />

Do you remember the early home computers? The box that connected to your TV set and allowed you to play<br />

games and do light bookkeeping? Then the 286, 386, 486 computers each being a little faster and better than<br />

there predecessor? Look at the OBD II system on your vehicle the same way, faster and "smarter" than any<br />

other system used in computer equipped vehicles. This is good news for everyone. The vehicles perform better<br />

(fuel economy, performance, longevity) and the "self-diagnostics" are simply amazing. If 20 years ago someone<br />

would have told me that the on-board computer would be able to tell me that the fuel cap was loose or that a<br />

specific cylinder was misfiring I would have laughed.<br />

Does my vehicle have OBD II?<br />

To determine if your vehicle is equipped with the OBD II system is fairly simple. The DLC (Data Link Connector)<br />

must be located within three feet of the driver and must not require any tools to be revealed. Look under the<br />

dash and behind ashtrays. All cars and light trucks manufactured since late 1995 should be OBD2 compliant.<br />

Two factors will show if your vehicle is definitely OBD2 equipped :<br />

• There will be a note on a sticker or nameplate under the hood: "OBD2 compliant”<br />

•<br />

•! There will be an OBD2 connector as shown below

Pin 2 - J1850 Bus<br />

Pin 4 - Chassis Ground<br />

Pin 5 - Signal Ground<br />

Pin 6 - CAN High (J-2284)<br />

Pin 7 - ISO 9141-2 K Line<br />

Pin 10 - J1850 Bus<br />

Pin 14 - CAN Low (J-2284)<br />

Pin 15 - ISO 9141-2 L Line<br />

Pin 16 - Battery Power<br />

<strong>SL55</strong> OBD II Access DLC Connector<br />

How do I know the OBD II is functioning correctly?<br />

When a problem within the system that will effect the vehicle's emission output is noted, the MIL (Check Engine)<br />

will illuminate to alert the driver that a problem exists within the system. Also, the system will set a DTC<br />

(Diagnostic Trouble Code) that can be retrieved using an OBD II Scanner or Code Reader. The DTC will lead to<br />

the direction in which the fault occurred. This is one area that is misunderstood. The DTC is a "helpful tool" that<br />

will be key in determining what happened within the system. One thing to keep in mind, the DTC is a STARTING<br />

point in most cases. For example, a PO301 would be a misfire was detected on #1 cylinder. The first thing that<br />

comes to mind is the spark plug, and there is a good chance the spark plug could be failing, but, a defective fuel<br />

injector, spark plug wire or COP (Coil Over Plug) unit is failing and cause the DTC to set. Then all of the other<br />

possibilities, basically everything that would have to do with the cylinder performing is a possible reason for the<br />

DTC to set.<br />

What is the difference in a Generic and Enhanced DTC<br />

Every OBD II vehicle has to comply to strict emission standards. When the vehicle is new, this is easily achieved,<br />

but what about after 50,000 or even 100,000 miles? Every OBD II vehicle is required to able to determine if a<br />

fault within the system that would cause excessive emissions to be expelled from the tailpipe in the form of a<br />

DTC.<br />

The Generic DTC's are a list of mandatory trouble codes that must be present and able to be displayed should a<br />

fault arise. There are many Generic DTC's and not all of them will be used on every vehicle. The ones used<br />

depends on the yr/make/model/engine of the vehicle. The Generic DTC's are also designed to be able to be<br />

retrieved using a standard OBD II Scanner or code reader.

The Enhanced DTC's are DTC's that are vehicle specific. Simply put these are DTC's that have been added by<br />

the manufacture to further "Enhance" the diagnosis capabilities of the vehicle. Without this option every vehicle<br />

would be a clone to one another. A simple example of an Enhanced DTC would be:<br />

Ford Vehicles.<br />

!P1227<br />

! ! Waste-gate Failed Closed<br />

Keep in mind that if your vehicle is '96 and newer, Federal Law requires that ALL vehicles (cars and light trucks)<br />

sold in the United States MUST BE OBD II Compliant. This includes ALL Domestic, Asian and European<br />

vehicles.<br />

How To Test OBD II On-Board Diagnostic Systems<br />

On-board diagnostic systems are more sophisticated than ever. OBD2, a new standard introduced in the<br />

mid-'90s, provides almost complete engine control while also monitoring chassis, body and accessory devices.<br />

Computers may seem more complicated than oil and grease, but The Part Pros are here to help you test your<br />

system and locate any problems in the diagnostic network.<br />

Since all vehicles are not the same please refer to the manual supplied with the OBD2 code reader for vehicle<br />

specific instructions.<br />

Important info about OBD II<br />

! •! Can diagnose/check engine problems in all CAN and OBD2 vehicles (1996 and newer) and many of the<br />

most popular OBD1 (1981 to 1995) vehicles<br />

! •! Features unique patented all-in-one screen display and LED display for quick emissions check<br />

! •! Automatic refresh updates data every 30 seconds when connected to the vehicle - an easy way to verify<br />

repair completion<br />

! •! Code definition can be displayed in English, French and Spanish<br />

! •! Can be Flash updated with a standard Windows® PC<br />

! •! Features memory/battery backup for off-car review and analysis<br />

Connecting<br />

Connecting the OBD2 Code Reader is as simple as locating the DLC connector.<br />

Reading the LCD Display<br />

Before you start testing, take a good look at the LCD display. The illustration above explains what the various<br />

icons mean and how the DTC (Diagnostic Trouble Code) will be displayed. The unit is self-powered by three-<br />

AAA batteries and will let you know when they are running low. When connected/receiving power from the<br />

vehicle, the CAR Icon will display.<br />

The OB2 code reader is a very simple tool to use. Once it is connected, turn the power on. Once the ignition is<br />

switched to the on position, the code reader is checking the system for any stored DTCs.<br />

The meaning of each DTC can be found in the manual supplied with your code reader.<br />

Example: ! the code reader displays a DTC PO309, Cylinder 9 misfire was detected.<br />

Once you know what the problem is, you have to determine what's causing it. In this case the intake manifold<br />

gasket was faulty. Once the repairs have been made, it is time to clear the DTC and check the system to verify<br />

the repair.<br />

Clearing the Diagnostic Trouble Code (DTC)<br />

Clearing the DTC is very simple. Press the ERASE button on the code reader. A message will display on the<br />

screen; "SURE" for conformation. If you wish to clear the DTC press and hold down the ERASE button again<br />

until a message appears on the screen "DONE". If you did not wish to clear the codes and hit Erase by mistake<br />

at the screen message "SURE" simply press the link button to return without erasing any DTCs.

When you clear the DTC(s) from the PCM (Power train Control Module)you also clear ALL of the other gathered<br />

information that the PCM has collected, including Freeze Frame, Drive Cycle data, manufacture specific<br />

enhanced data end everything stored in memory is erased - just like if you cleared the Cache files on your PC.<br />

The vehicle's PCM will need to re-learn the information that was erased. Don't be alarmed!! This is easily<br />

accomplished just by driving the vehicle. All you have to do is get driving.<br />

My Equus Innova 3030e Scan Tool<br />

Note : Saves a lot of money, as over $150, each time the dealer checks for codes.<br />

Engine - DIY Advice and Part Sources<br />

Engine Oil Temps.<br />

210 º F - normal street use?<br />

230 º F - track use?<br />

260 º F - heart attack range?<br />

Engine Oil Pressure<br />

10 psi for every 1000 rpm?<br />

Warm - Max - 92 psi ?<br />

Min - 64 psi?<br />

Air/Intake Manifold Leak<br />

Air/manifold intake leak: causing rough idling.

Oil Filter Element<br />

• Mercedes-Benz ?<br />

• AC Delco ?<br />

• Bosch ?<br />

Engine Oil<br />

• Mobil 10w-40w Synthetic<br />

• Royal Purple 10W40 Fully Synthetic (? US Gal ?US qt (? litres?)<br />

Royal Purple Synthetic<br />

Royal Purple Motor Oil Combines premium base oils with proprietary additive technologies to create high<br />

performance motor oils that optimise engine performance and provide superior protection. No special<br />

procedures are necessary when upgrading to Royal Purple. Royal Purple motor oil is fully compatible with<br />

mineral or other synthetic oils.<br />

Royal Purpleʼs API licensed motor oil delivers superior protection and improves performance in gasoline and<br />

diesel engines. Royal Purpleʼs API SN licensed motor oil meets ILSAC GF-5 and Dexos11 performance<br />

requirements. For those seeking enhanced performance in vehicles not under warranty, we recommend our HPS<br />

Series of high performance motor oils with our proprietary Synerlec additive technology. Royal Purple motor oil is<br />

compatible with other mineral and synthetic motor oils. Itʼs available in the following weights :<br />

• 0W-20<br />

• 0W-40<br />

• 5W-20<br />

• 5W-30<br />

• 5W-40<br />

• 10W-30<br />

• 10W-40<br />

• 15W-40<br />

• 20W-50

<strong>SL55</strong> Oil and Filter Change Procedure<br />

Parts needed :<br />

• ? litres of 10W-40 Oil<br />

•<br />

•<br />

An DIY oil change is easy, but removing the engine cover/splash guard, while on stands, is a chore (investigate if<br />

possible to reach oil filter without removing belly pan?) :<br />

• Drive car on to<br />

•<br />

An alternative method to remove old engine oil<br />

Use suction pump (like this “Topsider”) to extract oil through dipstick tube (most car dealerships do it this way<br />

including Mercedes-Benz), and it has been tested to prove that you can actually remove more oil by this method,<br />

than by draining. It also saves having it on ramps, etc., and possibly not level when draining, and also saves<br />

much time having to remove and refit so many bolts for the under pans.<br />

It may be possible to permanently remove a small portion of the engine cover/splash guard to enable access to<br />

the oil filter and doesnʼt need access to the oil drain. An aluminium panel could be screwed in place which would<br />

be much easier to remove.<br />

Engine Oil Leaks<br />

Take a close look for oil seepage from the timing chain cover, etc. If you require to replace any gaskets, take<br />

the extra precaution of coating the gasket and bolts with a thin layer of "Magic Lube".

APPLICATIONS: For Motors, O-Rings, Gaskets, Bearings and Water Filters.<br />

Magic Lube is a Teflon based non-melting, non-toxic formula that is waterproof for use in both wet and dry<br />

environments. A wide temperature range, of 0 Degrees F to 425 Degrees F, makes Magic Lube ideal for use<br />

under the most adverse conditions.<br />

It forms a durable adhesive film of lubricant that prevents metal to metal contact even under severe shock loads.<br />

Magic Lube is a superior lubricant compatible for use with most Metals, Rubbers, and Plastics. Magic Lube has<br />

been USDA. H-1 Rated to be environmentally safe and corrosion free.<br />

<strong>SL55</strong> Spark Plugs (16)<br />

The book recommends new spark plugs every 40K miles, so you should wait until that mileage is reached,<br />

irrespective of timeline. It is recommended to replace with NGK Iridium plugs and you should never have to<br />

replace them again .<br />

Old Plugs - Condition Chart (circle each plug number as you remove them)<br />

Dry/OK?<br />

1___2___3___4___5___6___7___8 ! 1___2___3___4___5___6___7___8<br />

Burnt?<br />

1___2___3___4___5___6___7___8 ! 1___2___3___4___5___6___7___8<br />

Oiled?<br />

1___2___3___4___5___6___7___8! ! 1___2___3___4___5___6___7___8<br />

Sooty?<br />

1___2___3___4___5___6___7___8! ! 1___2___3___4___5___6___7___8<br />

• MB ?<br />

• NGK ? Laser Platinum<br />

• NGK ? Iridium (cannot currently locate an Iridium match)<br />

• Gap-?” (? mm)<br />

• Thread-?mm<br />

• Hex Size-?ʼʼ ?” ?mm<br />

• Reach-?” ?” ?mm<br />

• Torque -<br />

NOTE : 6 = Heat range (6 is almost smack in the middle of the full range of plugs, 1 = hot, 12 = cold)<br />

Why Iridium?

• Enhanced spark precision, thanks to the 0.4mm Iridium centre electrode<br />

• Iridium is six times harder than Platinum<br />

• Iridium is eight time stronger than Platinum<br />

• Longer life - has a melting point 1,200 degrees higher than Platinum, and twice that of pure Gold<br />

• Iridium plugs perform at peak efficiency longer than any other plug design on the market today<br />

• Better spark - U-Groove ground electrode technology produces a more efficient flame combustion and<br />

maintains a quality spark even at low voltage levels<br />

• Tested power increase by 1.4% along with a 5% improvement in fuel consumption<br />

Spark plug Installation (needs updated) :<br />

• Not really difficult to do, but you have to take the air boxes out along with the upper intake.<br />

• Remove each coil pack by removing the two bolts/washers on each, then using special coil pack remover<br />

tool (see below).<br />

• Swap old spark plug for new, and tighten (do not over tighten). Tighten by hand and then torque to 10Nm<br />

or no more than 1/8th of a turn.<br />

• Do not forget to put anti-seize compound on the spark plug threads.<br />

• Refitting the coil-pack tighten to 10Nm (do one at a time so there's no chance of getting a coil in the wrong<br />

cylinder).<br />

Air Filters (2)<br />

Air filters are clearly essential for engine life. Properly fitted they will improve power by ensuring a good supply of<br />

clean, cold air. There is a lot of hype about filters improving power. Some certainly do but only when they<br />

improve upon the existing set up. Fitting a cone type filter such as a K and N 57i or BMC VAS may well improve<br />

flow, and possibly throttle response but if the filter then draws hot air from the engine it will not improve power. In<br />

fact it could well reduce power. The same applies for air box drilling.<br />

We have read of lot of information on filters over the years. We personally feel cotton gauze are the best ONCE<br />

they have had time to develop a layer of dirt to increase filtration efficiency. In terms of flow we feel they are<br />

superior. However in terms of dirt filtration we were surprised to read the results of this test which showed that<br />

foam were much better in multilayer style than cotton gauze for filtration efficiency alone.<br />

http://www.ducatigarage.netfirms.com/filtertest.html - to read the full test<br />

IN BRIEF from an airflow perspective<br />

Bronze Medal<br />

As you would expect, the paper element finished third It captured around 120 grams of dirt over an 11 minute run<br />

before the filter became clogged and registered the pressure differential drop on a manometer of 6 inches of<br />

water.<br />

The starting reading was 17.84 inches of water, and the ending differential was 23.84 inches of water.<br />

Silver Medal<br />

The RamAir (similar to Pipercross) multi-stage foam filter finished first in dirt holding holding capacity. It captured<br />

a massive 199.81 grams of dirt but with a larger starting and ending pressure differential. This means the foam<br />

filter works well out the box but less well with a layer of dirt.<br />

Gold Medal<br />

The K&N cotton gauze filter (BMC air filters and Green also use cotton gauze) finished second in terms of filter<br />

efficiency with it capturing 140.08 grams of dirt over a 22.8 minute run before the filter clogged up and registered<br />

the pressure differential change of 6 inches of water. HOWEVER the start pressure drop was just 16.8 inches of<br />

water making this the all round filter. The starting differential pressure was 16.80 inches of water and the ending<br />

pressure differential was 22.80 inches of water.<br />

BMC Filters including the Carbon Dynamic Air box. This device ensures a supply of cold air to the filter and using<br />

a venturi effect and front air intake actually increases the velocity and volume of air being drawn into the engine.

If the air box is not listed for your vehicle we can either custom design and install a setup for you or if you are too<br />

far away you can order a range of pipes and clamps that should enable you to install a CDA on any vehicle. We<br />

still offer cone filters from BMC, K&N and Green but remember with these to focus on getting a good cold air<br />

feed.<br />

In addition have a look at our Heat Management products. If you can reduce under bonnet temperatures then<br />

you can probably increase power.<br />

• OEM<br />

• Green Air Filter - Part # 2247 (2 required) + 15 hp. Constructed with 100% polyurethane on all four sides,<br />

this high flow, oiled OE replacement performance filter will out flow stock paper filter for improved<br />

horsepower and torque. Five layers of progressively finer mesh cotton gauze media provide maximum<br />

airflow for best performance results. Washable and reusable for multiple cleaning cycles, the tall open<br />

evenly space pleats provide excellent dust holding capacity for longer service cycle between cleanings.<br />

Integrated urethane bump seal insures tight, no leak seal over the life of the filter.<br />

•<br />

Cleaning the Throttle Valve<br />

Note : images below, show procedure on an Aston Martin V8 Vantage engine, but procedure is similar for other<br />

cars with throttle valves.<br />

The throttle valve, over a period of time, can build up a sticky oily residue. This can cause issues with low rev<br />

throttle response, but easily rectified and only takes about 10 minutes. You need a medium-sized flat-bladed<br />

screwdriver, and carburettor/injector cleaner aerosol.<br />

• Pull the black pipe off, so that you can see the throttle flap.

• Wearing goggles, and using carburettor/injector cleaner aerosol, spray the metal flap, also opening the<br />

flap with your fingers, so that the edges and intake area is properly cleaned. The excess cleaner will just<br />

evaporate away, and as this is flammable the usual precautions should be followed.<br />

• Now, just refit the pipe and clip, making sure it is fastened correctly.<br />

MAF Basic Test<br />

Before replacing your mass flow sensor, you can do a basic test.<br />

Cleaning the MAF (Mass Air Flow) Sensor<br />

If a check engine light comes on and you find a P0101 code with your scan tool, that means a problem with your<br />

MAF (Mass Air Flow) sensor. The car will probably be stumbling when you hit the gas. A quick test, with the MAF,<br />

if your finding the power from engine is down, just unplug the MAF (if engine comes back to full power, then it is<br />

the MAF).<br />

Easy to replace (takes less than 5min) :<br />

• Pull the front air box cover up, and then towards you.<br />

• Pull off the 2 plastic air tubes.<br />

• Lift the whole air box up and off.<br />

• The MAF is the plastic housing that the air gets forced in from the air box.<br />

• Disconnect the wiring harness<br />

• Unclip the plastic holder and pry the holding clip back with a flat screwdriver.<br />

• Install in reverse.<br />

MAF around $168 from Auto Parts at AutohausAZ - OEM Auto Parts. I was quoted over $1000 for the dealership<br />

to replace it. Cheapest place should be Bosch, as they made it.<br />

Changing Fuel Filter<br />

On<br />

Oxygen Sensors

The O² sensors are made by BOSH, so its very easy to find them on the internet, for around $81 front and $177<br />

rear each, yet the dealer quotes $1,488 for all 4, parts only, and not installed.<br />

The O² sensors are installed in treaded holes in the catalytic converters, and are pretty easy to change (but a<br />

little bit fiddly to access). For the fronts, you just have to remove the bottom covers, then use a bent 22mm<br />

wrench and pull/replace a connector.<br />

Cooling System<br />

? US Gal - Mix of water and coolant with anti-freeze (CUNA NC 956-16 Shell Glycoshell) (Specification -25<br />

degrees C).<br />

Antifreeze if it is blue is Texaco. You can find it if you shop around. Sometimes at Advance Auto Parts. If it is<br />

green you have no idea most times but you can use the Prestone universal for now.<br />

Best bet is to make sure the fluid is kept fresh ever year. If you are going to do it yourself. Make sure the shop<br />

doing the belt service drains the entire system when the belts are done. Some guys don't drain the system at the<br />

dealership so keep that in mind. The level is in the owners manual.<br />

Upper Coolant Hose<br />

When car cold the upper radiator hose is collapsed, but when you loosen the overflow tank cap it "inflates"<br />

again.<br />

Abnormal. When hot the pressure builds up in the cooling system and this lifts the spring on the expansion tank<br />

cap. The pressure exits via the small pipe by the cap. When it cools the pressure drops and a vacuum is formed<br />

which draws air back in (or coolant if there is an overflow bottle attached). Possible faults :<br />

• Check the overflow pipe for blockage from the tank to the outlet<br />

• It could also be a faulty tank cap<br />

• Or the top hose has lost its resistance and become weak (if hose is easily squashed and feels soft,<br />

replace it)<br />

Cooling Fan<br />

The cooling fan in the engine doesnʼt work at 100%, normally happens to the 95-98, minor problem but I think<br />

the age has something to do with it.<br />

Over-Heating or Low Coolant Warning Light<br />

Engine Water Temperature should run right on 90 degrees.<br />

There may be a number of issues here. The first relates to bubbles in the coolant system and the second to a<br />

drop in coolant level due to heat expansion in the flexible joints of the plumbing. For the first, try Porsche Pete's<br />

Boxster Board for a procedure to "burp" your system. For the second, there may or may not be an official fix -<br />

check your dealer and PNA. However, Porsche did something and it seems that cars from April 99 on, and<br />

maybe earlier, have the fix. Another possibility may be that under very hard acceleration coolant is actually<br />

temporarily sucked out of the reservoir to the point where the warning is displayed. Topping off the car and<br />

restarting may clear the light.<br />

I have recently heard that one of the PAG factory machines had a fault up until April 99 that may have resulted in<br />

sub-standard casings and the resulting overheating problem. This is entirely unsubstantiated at present but if<br />

true would mean that cars built before April 99 will not all suffer from this problem. This has certainly been borne<br />

out by my own experience and that of others who have older cars but who have never experienced this<br />

unfortunate ailment.<br />

Changing the ratio of coolant to water and adding Redline Water Wetter, may also be a fix. Reducing coolant<br />

and increasing water will cool better (water cools more efficiently than coolant) but this probably puts your<br />

radiator at more risk from oxidation. Different folks assess this risk differently and I do not feel qualified to give an

opinion on it. However, this possible fix is certainly cheaper, if it indeed works, than some alternatives (oil<br />

coolers, additional radiators, etc).<br />

Exhaust System

Muffler Delete (new tips)<br />

Rear mufflers can wear out/corrode/etc. and are very expensive to replace (more than $2,000 each). A cheaper<br />

replacement option is to have a muffler fabrication shop replace with dual tip Magnaflow mufflers.<br />

• The magnaflow tips are staggered (outside is shorter)<br />

• The tips are inside bevelled<br />

• They are super quiet and do not drone on highway

Catalytic Converters<br />

Catalytic converters are quite expensive items for any car, they need checking as a car with either poor cats or<br />

cats removed will fail an MOT, however we have also had reports on cars that run without the cats fitted may not<br />

be insured as they are not road legal, for the potential 5bhp of extra breathing capacity - its just not worth it.

Transmission<br />

? US Gal (? litres) Shell M1375.4 DEXTRON III<br />

Checking the Gearbox Oil<br />

•! Detach<br />

Changing the Gearbox Oil<br />

Transmission Service (Fluid and Filter)<br />

Air Conditioning - DIY Advice and Part Sources<br />

System requires regular recharging<br />

System Coolant ! 0.29 US Gal (1,100cc)! ! R134a<br />

Compressor Oil!! 0.033 US Gal (125cc)! ! Type SP 10 (Sanden)!<br />

A/C - Low and High Ports<br />

High side service is located<br />

A/C Drains<br />

If some debris.<br />

Trinary Switch<br />

Trinary switches provide compressor protection against high side pressures that are too high or too low. There<br />

are 2 styles of pressure switch, binary and trinary.<br />

The binary switch simply splices between the compressor clutch and evaporator thermostat and taps into the<br />

high pressure line. When pressures exceed safe limits, the switch opens the circuit to the compressor clutch thus<br />

disengaging the compressor until pressure return to normal.<br />

The trinary switch operates much the same as the binary in that it shuts down the compressor when pressures<br />

rise. However, the trinary also controls an electric fan on the radiator that pulls additional air across the<br />

condenser to bring pressures down.<br />

us engaging the fan and an open circuit on the compressor connections which disengages the compressor).<br />

Location<br />

On the

Evaporator<br />

Evaporator<br />

348 (1989-1995) A/C Charging (as example)<br />

I just recently performed the A/C service on my 1995 348, in doing so I discovered a product that works better<br />

than traditional R134a. So I decided I would put together my first How to, for all of you do-it-yourselfers there on<br />

FChat.<br />

The product I used was called Arctic Freeze Refrigerant R-134a+ It is made by Interdynamics; it replaces lost<br />

refrigerant & oil to the A/C system and was developed for NASA. If you would like to do some reading up on the<br />

differences of R134a to R134a+, here is a link to a .pdf file that I used.<br />

http://www.originenergy.com.au/business/files/r134at.pdf<br />

I can attest to it being a much better product to give your Ferrariʼs A/C better cooling. A link to their website and<br />

product page is below.<br />

http://www.id-usa.com/product.asp?CID=7&PID=215<br />

About R12 and R134<br />

All 1993 and newer vehicles, are supposed to use Refrigerant #134a and 134a oil. R134 uses different oil than<br />

the older R12 system, and since R134 doesnʼt get quite as cold, the R134 system typically uses more Freon.<br />

Many manufacturers didnʼt want to redesign the A/C, so they continued to use the older systems, filling them<br />

instead with R134, and retrofitting them with the newer style ports. Please be aware of the type of system you<br />

have before beginning, an easy way to tell is looking at the Charge ports.<br />

Charge port for an R12 system<br />

Charge port for an R134 system<br />

If you have charge port for R12, take it to a qualified service centre (either to be converted to R134 or charged<br />

with R12, which is unavailable to the public). Note - the cost of replacing all the failed parts from mixing the 2<br />

different types of refrigerant and oils will cost well into the thousands.

To refill a partially discharged system<br />

You will need Freon, and the appropriate charge hose. These are available at your local auto parts store. Some<br />

cans come with the hose, and a relatively useless gauge. The gauge is unreliable, and shouldnʼt be used to<br />

guess the amount of Freon in the system, as itʼs only measuring pressure, and not the level of the Freon.<br />

Pressure varies with the outside temperature, and the temperature of the parts, and the barometer outside the<br />

car, making the gauge next to useless.<br />

• Locate the dryer (on the 1995 Ferrari 348 the dryer is located on the passenger side of the trunk, under<br />

the carpeting). It looks something like this:<br />

•<br />

• On the top of it is a little glass window (verify that your Ferrari has this window).<br />

• If it does not, please take it to a service centre to be filled (they will carefully meter out the Freon and add<br />

the exact amount).<br />

• Start the engine, and turn the Air conditioner on full.<br />

• Attach the can of Freon to the low pressure charge port.<br />

• Look at the glass window on top of the dryer (there may be foam, or bubbles, or very slow bubbles<br />

depending on the level of charge).<br />

• Open the can of Freon very slowly until you feel the top of it get cold.<br />

• As the system charges, the window will go from fast foam to slow foam to bubbles to slow bubbles to<br />

“clear”.<br />

• Once it reaches “clear”, the system is charged.<br />

• Fill it slowly, as itʼs easy to overcharge if youʼre in a rush (just barely crack the can until it starts to get cold<br />

and watch the window carefully).<br />

• After all the bubbling / foaming stops the system is full.<br />

• Shut off the can.<br />

• Run the system for an additional 10 minutes (if any bubbles crop up, add a tiny amount of Freon until they<br />

are gone).<br />

If the system is fully discharged:<br />

• First you must vacuum out the system to remove any moisture.<br />

• If the system has been wide open for some time (like if you had disconnected the A/C lines and left it that<br />

way) then it is recommended for maximum performance, that you replace the dryer/accumulator. If you<br />

donʼt I advise you spend additional time vacuuming out the system.<br />

• Vacuuming out the system requires an A/C vacuum pump, and also the R134 Charge hose. Both should<br />

be available at a local auto parts supplier.<br />

• You should vacuum out the system for at least 5 minutes (longer if the system has been open for any<br />

period of time).<br />

• Verify the system is holding a vacuum (this can be done using an A/C pressure gauge). If the system still<br />

had Freon in it before you began, itʼs generally safe to assume that there was no large leak, and that the<br />

system is still holding vacuum.<br />

• Check the service manual, before charging the system, to verify the capacity of the air conditioning system<br />

(do not overcharge the system). Most R134 systems will take somewhere in the range of 18-24 oz. of<br />

Freon. To gauge the amount of Freon, first look at the capacity of the cans (most of them are 12oz).<br />

• If you have replaced the Compressor, or otherwise had the system cleaned with A/C solvents you must<br />

add the amount of compressor oil specified in the service manual.<br />

• If you have not replaced anything, you should add 2-3 oz of R134 compatible oil (add the oil first, before<br />

adding Freon).

Body - DIY Advice and Part Sources<br />

Rust Prevention<br />

When youʼve got a mint-condition 360, but you want to use it as your everyday car and cover about 10,000 miles<br />

a year in it, youʼve got to work out how youʼre going to do that and still keep it looking good. You can lovingly<br />

wash and wax it, but what about whatʼs going on underneath the car, and how do you keep the dreaded rust at<br />

bay?<br />

The best way of protecting the car against the inevitable assault from water and, even worse, the tons of salt that<br />

councils will no doubt be throwing down once the big freeze begins, is a full cavity wax injection with a full under<br />

seal.<br />

• First it is power-washed and then fully steam-cleaned underneath<br />

• The car is then thoroughly fan-dried<br />

• Next the treatment is carried out<br />

• Any areas of surface rust are carefully treated with a rust cure<br />

• Then every single cavity is injected with Dinitrol 3125 (all the doors, the sills, the wings, the rear side<br />

panels, the bonnet, the chassis members. . . the lot)<br />

• Then the underside is sprayed with the 3125, followed by a coating of Dinitrol 4941 (a glossy black under<br />

seal that never dries hard but maintains a waxy feel to it)<br />

• The car is then allowed to dry before collection (so takes about 3 days)<br />

• Total cost around $1,000, but should last five years (cheaper than replacing a wing/fender or sill)<br />

Note : the combination treatment of Dinitrol 3125 with Dinitrol 4941 is considered more effective than Waxoyl.<br />

Rust Inhibitor (POR-15)<br />

Injecting something, even a good phosphate conversion etchant, is like prescribing sex to a nymphomaniac; at<br />

best it's temporary relief. Also, most etchants need to be neutralised, usually by a thorough water rinse,<br />

otherwise the phosphoric acid will cause rust to resume more aggressively.<br />

You need to kill the rust, which the POR15 metal ready etch does, by converting it to zinc phosphate. You then<br />

seal it with a coating that's impervious to oxygen and moisture, which the POR15 paint does. Then it can be<br />

repainted & won't resume, as the paint further seals the surface. Bondo doesn't work because it doesn't block<br />

moisture. However, you can use bondo over something like POR15, then the paint will seal the bondo well<br />

enough so that problems won't develop.<br />

Sandblast or grind out the rust affected areas, apply POR-15 followed with 2 coats of rubberised undercoating.<br />

POR-15 dries rock hard. POR-15 flat black paint can be used as the top coat.<br />

Rust Inhibitor (LPS-3)<br />

Spray LPS-3 rust inhibitor spray on the inside of the door and look for a couple of used, galvanised doors.<br />

Underbody Protection (Wurth SKS Stoneguard)<br />

Without doubt, Wurth's water-based black undercoating. You can spray or brush it on. It goes on grey, then dries<br />

to a PERFECT satin black match. Matches OEM Porsche, BMW, Mercedes and other European auto makers'<br />

"body schutz" or undercoating.<br />

Can be built up because it doesn't run on vertical surfaces. SKS is water based, fast drying and flexible when<br />

dry. May be painted or left as applied. It is best applied with a Wurth SKS Gun, but may be applied with a brush.<br />

11335 Wurth SKS Stone Guard - Beige, 1000 ml bottle<br />

11336 Wurth SKS Stone Guard - Black, 1000 ml bottle<br />

11337 Wurth SKS Stone Guard - Grey, 1000 ml bottle<br />

11338 Wurth SKS Stone Guard Spray Gun<br />

They now have the stuff in 14 oz spray cans (aerosol). Manufactured in Germany.

Mail order company : http://www.autogeek.net/w890971.html<br />

This rust-proof coating is sprayed on in minutes, dries in just a few hours (two to three), and offers heavy duty<br />

protection for years. Wurth Stone Guard Black protects the wheel wells, rocker panels and undercarriage of your<br />

automobile from inevitable damage from stones, debris, salt water, and road chemicals that eat away at the<br />

finish, paving the way for rust. Wurth Stone Guard Black, a rubber/plastic ultra-protective spray-on coating is<br />

easy to apply, tough as nails, and can be painted over, so as to match the colour of the car. One or two thin<br />

coats in your wheel wells and on the undercarriage provides permanent protection from originators of rust. The<br />

handy spray can means no messy cleanup or applicator tools. The textured, hard but flexible material deflects all<br />

manners of shrapnel that can abrade, nick and chip away at the under-surface of your car. Best of all, itʼs<br />

waterproof, so rust doesnʼt stand a chance.<br />

Tech notes<br />

Be sure to use in a well ventilated area. Allow to cure naturally for two to three hours. You may layer coats until<br />

you attain the desired texture. Remove overspray with Wurth Clean-Solve.<br />

To use<br />

For best results, thoroughly clean surface that will be treated of dirt, grease and grime. This ensures that Stone<br />

Guard adheres properly. Mask surrounding areas. Spray surface in short, even strokes until the desired texture<br />

or thickness is reached. Allow to dry completely and naturally (two to three hours).<br />

Weatherstrip Maintenance (Cures squeaks, etc.)<br />

Iʼve been looking into which products would be best for weatherstrip maintenance and have decided to avoid<br />

silicone-containing products altogether. Through a series of e-mails and research, my personal choices are :<br />

• 303 Aerospace Protectant (with UV screening) for routine use on all exposed rubber and other select<br />

surfaces<br />

• DuPont Krytox Lubricants for problem areas that squeak (rubber and plastic alike), such as the header rail<br />

in convertibles, cup holders, etc.

Proper use of 303 Aerospace Protectant requires :<br />

• the areas to be treated be clean of any dirt or oils<br />

• then thoroughly wet the surface with Protectant and allow to soak for approximately five minutes (rubber)<br />

before wiping dry with a soft, lint-free cloth<br />

• reapplication is recommended “every 30 to 80 days of exposure” or when the water repellency begins to<br />

diminish<br />

This product is widely available at a reasonable price. Shelf life is a minimum of five years. Two sources are<br />

Autopia Car Care and Autogeek.<br />

Krytox Weatherstrip Lubricant may be applied after the 303 treatment, if necessary :<br />

• treatment areas for Krytox should receive limited exposure to dust and dirt, as it may remain somewhat<br />

tacky and can attract dust (it could also rub off on clothing if applied too heavily).<br />

• unlike the 303 product, Krytox is not wiped off after application, rather a thin layer is massaged into the<br />

rubber and left in place.<br />

• available as both an oil and light grease, choice depends on area being treated and/or personal<br />

preference.<br />

• care must be taken not to get any on glass or painted surfaces, not because of potential damage but<br />

because itʼs difficult to remove once itʼs on there.<br />

• reapplication isnʼt necessary nearly as often as with 303 Aerospace Protectant.<br />

• Shelf life is indefinite.<br />

Distribution of Krytox, is rather limited and cost is quite high :<br />

• GM sells a 1 oz. applicator bottle for between $69 and $88 US<br />

• itʼs referenced in the “2007 Chevrolet Corvette Owner Manual” in the section entitled “Recommended<br />

Fluids and Lubricants,” under “Weatherstrip Conditioning”: “GM Part No. U.S. 3634770, in Canada<br />

10953518.”<br />

• Also recommended is “Dielectric Silicone Grease (GM Part No. U.S. 12345579, in Canada 992887)”; more<br />

about silicone in a moment.<br />

• Chrysler dealerships sell the same one ounce bottle of Krytox Weatherstrip Lubricant (MOPAR Part No.<br />

04773427) for about $85 US<br />

• Volkswagen offering costs even more<br />

• Ecklerʼs, where a small tube of “Krytox Weatherstrip Saver” grease (Item #A2524) sells for $44.99<br />

• Jaguar endorsed use of Krytox fluid for interior squeaks ten years ago as outlined in Service Advisory<br />

“910-01 APR 98.”<br />

Wiper Blades (2)<br />

• Part # ?<br />

•<br />

Vario Roof<br />

Roof Squeak Fix (McLube Spray)<br />

Here's my cure, from my wife's 09. The dealer lubed the roof after it developed a problem, but that was a shortterm<br />

solution. Honestly I think that the detailers just got too aggressive.<br />

The magic 'stuff' is McLube spray and McLube One Drop oil. They're available for the marine market, from<br />

chandleries and various online sources. Magic. I've used it a lot on boats. I use both products.<br />

1) Cover your seats - cheap insurance. Retract the top and open the hatch. If there is dust or dirt inside the roof<br />

or the hatch sills, vacuum it out. Get the remainder with detailers spray and a rag.

2) Clean excess gunk from ALL bits of the track with a Q-tip. I didn't use cleaner or solvent. Wouldn't recommend<br />

it. Look hard. Find every bit of the track you can, from the top, from inside. Retract the roof a small amount to get<br />

to the aft track bits. Be sure to get in (as best you can) to the diffusers/seals both fore and aft of the glass. The<br />

rear is especially tough, barely possible.<br />

3) Do the same for all moving parts of the hatch hinges and the lock flange. There hinge mechanism is pretty<br />

complex. Actually quite cool.<br />

4) Use the McLube oil on a Q-tip, to coat the tracks (not the sills, the black track), the hatch hinges and the<br />

flange. You don't need a lot of oil, just coat the surface. Excess just attracts dust. Again look hard at the track.<br />

Find & lube every bit you can - from inside & out, partially & fully retracted roof.<br />

5) Cycle the roof and the hatch. Repeat the lube process.<br />

6) For the moving bits of the diffusers/seals you can't reach, use the McLube spray with the red tube extension.<br />

Both diffuser pieces have hinges. I think that the rear diffuser/seal (between the roof and the hatch) is the source<br />

of 90% of the problems. So look closely - anywhere that hard plastic sits against a solid piece of the roof.<br />

The McLube spray dries clean. It will not attract dust and grime. Its possible that the McLube spray would do the<br />

whole job. No need for the oil. I'd consider trying that if your car is in a dusty environment. But since Porsche<br />

used a more viscous product, I use the bearing oil.<br />

Total time? Maybe 20 minutes<br />

Result? - Silence. No issues.<br />

Oh and don't wear jeans. You'll be leaning over the car a lot, easy to scratch your paint.<br />

Problem With Fuel Tanks Baffles<br />

If you have a loose fuel tank baffle it can be fixed and will save you at least $4,000. All work is undertaken in the<br />

boot (trunk) with the roof closed and took around 1 hour and is best done with as little fuel in the tank as<br />

possible, my gauge showed a quarter tank. There are currently two fixes :<br />

Fix 1 :<br />

• Remove the boot separator (4 press studs, 1 either side and 2 on top and lastly 2 bolts where the hinges<br />

attach to either side of the boot, these will be under small plastic covers which just unclip)<br />

• Lift out the boot/trunk floor.<br />

• Remove the carpet cover at the back of the boot (there are just 2 screw fixings under plastic covers near<br />

it's base, it's not attached at the top just wedged in). This panel is overlapped by the boot side panels but<br />

only by half an inch so can be bent a little either side and coxed out. If you're uncomfortable doing this,<br />

you'll have to remove quite a lot of the boot linings to get the side pieces off, and really it's not worth it.<br />

• Now you'll see the bulk head covering the fuel tank and the cut out at the top for the fuel gauge (you'll<br />

soon be seeing the mythical baffle). The sender is slightly covered by a fixing strip that the boot separator<br />

attaches to.<br />

• Remove the plastic trim strip (again just 3 push clips)<br />

• The sender is a bayonet fit in to the top of the tank and only needs a quarter turn to remove, but make<br />

sure you unclip the sender wire first.<br />

• Before removing, the sender, remember to make a mark on the tank and sender to help when refitting it as<br />

it only works in one position.<br />

• You may be able to simply remove the sender by jamming a couple of bolts into the holes and turning by<br />

hand, if it has not been over-tightened. However, if too tight, the only easy way to remove the sender is to<br />

fashion a makeshift “F-shaped” tool to locate in two holes in the top of the sender (use a 1/4” tube/bar<br />

about 6” long, with 2 screws attached on one end approximately 2” apart).<br />

• Also found that with a pair of "bent needle nose" pliers you can stick one tip in each hole of the fuel sender<br />

and just twist. No need to buy or make a tool to turn the fuel sender unit.<br />

• Once you have the sender out, you'll be able to see the baffle.<br />

• A small torch/flashlight will let you see clearly.<br />

• Poking a piece of bar inside the tank and prodding the baffle, will let you see what causes the banging and<br />

why.

• The baffle runs east/west through the tank and is about 3/4 the height of the tank. It's fixed at the bottom<br />

and should be fixed at either side (end). This is where the weld will have failed, allowing the baffle to hinge<br />

front and back (acceleration and braking), knocking on the wall of the tank.<br />

• There's no way to remove it without cutting the tank in half. It's about 36" wide by 12" tall.<br />

• The baffle kinks about 45 degrees near it's top forward to the front of the car and it's this edge that hits the<br />

wall of the tank.<br />

• To fix, note there are a few slots cut along the top of the baffle where it kinks forward.<br />

• Drill a 5mm hole in the top of the tank just above the sender (Many may not want to do this, so you'll need<br />

to be very creative to work out another way)<br />

• Take a regular coat hanger and just bent a hook at the end (I actually doubled up the wire by folding it in<br />

two first for a bit of extra strength). You can work out lengths and angles by first pushing the wire through<br />

the sender hole and locating one of the slots (there are 3 to choose from, and you have good access and<br />

vision with the slots being practically level with the sender hole).<br />

• Get the hook in one slot and out of the one next to it for a secure hold.<br />

• Push the wire through the hole you drilled (the hole has to be above the sender to avoid fouling it when it<br />

goes back in). A good idea is to use a piece of rod or anything you can push through the slot to pull the<br />

baffle toward you slightly to give some tension to the wire hook, then all you need to do is bend off the<br />

wire where it exits the hole (this is where doubling up the wire will work out well).<br />

• Tape the wire in place.<br />

• Use a little sealant in the hole to seal it fully.<br />

• Replace the sender, check that it works and refit the boot/trunk parts.<br />

Fix 2 :<br />

• Getting to the sender portal is easy....10 minutes<br />

• Take out the spare tyre stuff and carpet to bare metal<br />

• Unscrew the two screws at bottoms sides of centre back carpeted panel<br />

• Remove 1 silver screw on each side holding luggage cover in place<br />

• Reach to front of luggage cover and unsnap about 6 snaps<br />

• Remove luggage cover<br />

• Pry loose and remove centre carpeted panel<br />

• Sender unit is exposed<br />

• Disconnect the two plugs.<br />

• To open the portal you need to make a tool (find a 1" by 2" piece of wood and drill 2 screws through, so<br />

they stick out at least 1" through the wood, about 2.5" apart to fit into the grey holes at 12 oʼclock and 6<br />

oʼclock on the sender unit).<br />

• Fit your new tool into the grey holes and rotate your tool like it is a wrench (counterclockwise from 12<br />

oʼclock to about 10 oʼclock).<br />

• Also found that with a pair of "bent needle nose" pliers you can stick one tip in each hole of the fuel sender<br />

and just twist. No need to buy or make a tool to turn the fuel sender unit.<br />

• The sender unit is now loose.<br />

• Remove the sender unit....now you have your window through which to perform the operation.<br />

• Getting the right spring in the right spot....that's a little harder.<br />

• Look at the picture of the gas tank above, picturing a vertical divider wall running vertically, the length and<br />

height of the tank about 3" from the drivers side of the tank (the spot welds at the top have failed and as<br />

the gas sloshes, this divider wall knocks between the front wall the internal end of the gas filler).<br />

• Just make sure you take every precaution to not drop anything in the tank (use some fine wire connected<br />

to all, that can be cut and removed, once everything is hooked up).<br />

• Using a heavy duty coat hanger (a metal garden tomato stake works well) to hook on and pull the baffle<br />

away from the front wall of the tank (hooked over the baffle plate, where there is actually a handy slot in<br />

the baffle plate, just below the bend).<br />

• Drill a hole in the plastic of the sender unit, and hook the spring into this hole. Note, you must drill the<br />

hole in the dark grey area near the top, so not to interfere with the operation of the float<br />

mechanism.<br />

• Spring selection is critical. A good spring size is about 6” to 8” (hooked on each end), of around 1”<br />

diameter, and that is fairly stiff (to hold baffle steady), but allows you stretch it to about 9” (to clip over

affle). The material for spring shouldn't matter really, as the gas should preserve it and there is very little<br />

air.<br />

• Attach the spring to the sender unit and insert the whole sender unit assembly loosely into the tank.<br />

• Alongside the sender unit and first coat hanger (pulling on loose baffle), insert a twistable rod LED light,<br />

and a second coat hanger/forked tool (to hook the loose end of the spring over the baffle), maintaining<br />

pulling pressure on the baffle with the first coat hanger.<br />

• Work the second coat hanger/forked tool to hook the loose end of the spring over the far edge of the baffle<br />

plate (will take a few tries to figure out how to manipulate everything through the small opening)<br />

• It will take about 3 hours to disassemble, fix, and reassemble.<br />

Fix 3 (similar to above, with improvement) :<br />

The only item I did not like about your fix was the drilling part (rest of it was brilliant). I hate drilling anything on<br />

the car.<br />

• Removal was easy<br />

• With the help of small led flash light (not torch) look inside and see the mysterious baffle<br />

• You will notice a different anchor point for the spring, so you donʼt have to drill your tank (you can feel it<br />

after you stick your finger inside the tank)<br />

• You will notice there is rear baffle (which you wouldnʼt be able to anchor anything there using your<br />

fingers), but for this job you will need L-shaped pliers<br />

• Use the pliers to bend the wire into the desired shape (as shown on drawing), and 15 minutes later youʼll<br />

have the trunk going back together<br />

• Should cost about $300 for a mechanic to help (it sure beats $4000 bill from Mercedes dealer.)<br />

• If you live in New York Area you can call them at 631 789 4085 ask for Sebastian.

Instruction How To Access Fuel Tank Sender and Repair Using Spring<br />

Takes a little less than an hour and no more knocking sound.

Remove trunk partition and store safely

Remove two of the 2-piece fasteners from each side of the plastic piece on top of back carper panel.

Alternative Fuel Tank Repair<br />

There is an alternative way to accomplish the same as the “spring method”. An MB tech (independent) removes<br />

gas tank and sends to a local gas tank repair shop that knows how to repair. Basically :<br />

• they drill a hole in the tank just below the sender (very small hole the diameter of a piece of coat hanger<br />

wire for example)<br />

• they push a piece of coat hanger (for example) through this small hole<br />

• then remove the sender so they can reach in with pliers and put a hook on the end of the coat hanger (to<br />

hook on the baffle)<br />

• they then push in the coat hanger "hook" and hook the baffle with it<br />

• then they pull on the hanger hard, bend it at a 90deg angle, and weld the junction between the hole and<br />

coat hanger, to hold it in place (if the coat hanger is a tight fit in the hole, you could probably use silicone<br />

or better, JB Weld, to seal any very minor gap, and then just duct tape down the piece of hanger along the<br />

outside of the gas tank so it doesn't move around too much).<br />

Another Simple Alternative Solution<br />

• take a broomstick (donʼt even have to remove the broom from the end)<br />

• stick it into the tank, through the fuel sender hole<br />

• note in the pics of the tank, the baffle has a bend in it (where the "pulling tool" is inserted as described<br />

earlier)<br />

• rather than hooking a pulling tool there, so you can get a spring higher up on the baffle top edge, bang as<br />

hard as you can on that pulling-tool area and you'll flatten the baffle<br />

• remember the baffle has a huge bend in it where the pulling tool is inserted, so if you hit it hard a couple of<br />

times, it flattens out the baffle (or maybe even bends it the other way a bit).<br />

• for good measure, hit the baffle along that fold line/crease about 6" to the left, and approximately 6" to the<br />

right also (just hit it in a couple of spots so you flatten it)<br />

• now the baffle is "larger" because itʼs flattened, and it doesn't make a noise at all, as itʼs wedged in the<br />

tank and doesn't move.

• the fuel gauge will still work as the baffle will now be farther away from the sender than when it was and<br />

there will be no noises.<br />

Yet Another Fuel Baffle Repair Method<br />

Here is another alternative method using the exact step by step removal photos (above), but this an unbelievably<br />

easy fix without using any metal springs, etc.<br />

You will need :<br />

• a length of very strong thin webbing, similar to the strap material used to secure the loads on the back of<br />

lorries/trucks, but a thinner version (easy to buy from various DIY shops, etc.)<br />

• a single length of rigid pliable copper sheathed cable (simply strip out a neutral cable from a roll of<br />

everyday twin and earth mains cable)<br />

• LED torch/flashlight (do not use a normal bulb torch for obvious reasons)<br />

• a three pronged grabber will help enormously<br />

At the end of the fix, the webbing is the material to do two things :<br />

• bends the baffle back and away from the wall and<br />

• is tied off to hold the baffle away from the wall.<br />

Procedure :<br />

• obviously the tank has to be virtually empty (its the fumes that can spark)<br />

• tape one end of the webbing to one end of the sheathed cable<br />

• make a long U bend in the other end of the copper cable and fish the cable into the fuel sender hole and<br />

hook in and around the top of one of the slots in the top of the fuel baffle (you will see using the led torch)<br />

• Using a three-pronged grabber to grab the end of the copper cable, once hooked around the baffle slot<br />

and drag the cable back out of the sender (it takes a while and you need patience)<br />

• then pull the cable until you have both ends of the webbing (the baffle is now in your control with the<br />

webbing)<br />

• then gently pull the webbing until you are happy the baffle is bent back enough, but mindful that there may<br />

be other welds on the bottom of the baffle that may break.<br />

• the trick is then fishing the webbing up and around the horizontal bar (that you will be able to feel when<br />

you put you fingers into and up inside the fuel sender hole)<br />

• now simply knot the webbing<br />

• close the fuel sender<br />

• Reassemble boot/trunk, etc.<br />

• total fix time is around 2 hours (people talk of 15 mins. etc, but this is a little tricky with the fishing cable)<br />

Legal Action Against Mercedes-Benz<br />

SL Fuel tank needed urgently for our court case inspection. We are in the middle of a court case involving the<br />

issue with the SL fuel tank problem with the buffer. My old tank was needed for the independent inspection but<br />

regrettably was discarded by my garage. So to all of you out there let me know who has one or about to replace<br />

his old one. We need it very urgently and I am willing to come and collect it. I donʼt have to tell you what will<br />

happen if we win and I am very confident.<br />

Erik Hoffman<br />

07802 302302<br />

erikhoffman@live.com<br />

UPDATE - Judge Awarded against Mercedes-Benz UK

Interior - DIY Advice and Part Sources<br />

Airbags<br />

If airbag light come on<br />

Heated Seats<br />

Faulty heated seat :<br />

• Check out fuse<br />

•<br />

Front Seats Motorised Function<br />

Note : Only the driver's seat goes<br />

Front Seat Removal<br />

Removing the seat is really<br />

Exit-Entry Convenience Feature

CD will not Eject<br />

I had the same problem (found out later that there were 2 discs inside the slot). Try this, helped me, before You<br />

take for repair: Lift the lid of the slot. You´ll see a small white plastic pin on left side ( I think there´s similar on the<br />

right side too ). Take a small screwdriver and push gently the pin ( it should move about 1/2 inch ). Now at same<br />

time push the eject button. That way I fixed mine, while my dealer could not do anything.<br />

Steering Wheel Removal<br />

Do not activate the ignition with the air bag disconnected. If you do, it will put the SRS light on (dealer has to<br />

remove it).<br />