Making Safety an Ongoing Part of the Construction Process Through ...

Making Safety an Ongoing Part of the Construction Process Through ...

Making Safety an Ongoing Part of the Construction Process Through ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISBN 1-886431-09-4.<br />

© Copyright 1999-2005 IeJC. All Rights Reserved.<br />

Trends <strong>an</strong>d Current Best Practices in <strong>Construction</strong> <strong>Safety</strong> <strong>an</strong>d Health.<br />

Published 31 st August, 2005<br />

MAKING SAFETY AN ONGOING PART OF THE CONSTRUCTION<br />

PROCESS THROUGH PRE-TASK PLANNING<br />

by Jimmie Hinze<br />

In recent years, <strong>the</strong>re has been a greater involvement <strong>of</strong> construction workers in <strong>the</strong> safety<br />

process. This has been done successfully through several me<strong>an</strong>s, but very possibly <strong>the</strong><br />

most effective is pre-task safety pl<strong>an</strong>ning, more commonly known as pre-task pl<strong>an</strong>ning.<br />

As <strong>the</strong> name implies, pre-task pl<strong>an</strong>ning meetings are held immediately prior to<br />

performing a specific task. Since tasks will vary in duration, it is possible for a crew to<br />

have only one pre-task pl<strong>an</strong>ning meeting on one day but to have four or five such<br />

meetings on <strong>an</strong>o<strong>the</strong>r day. These meetings are held at <strong>the</strong> crew level, generally led by <strong>the</strong><br />

forem<strong>an</strong> <strong>of</strong> <strong>the</strong> crew. The crew discusses <strong>the</strong> work to be performed <strong>an</strong>d <strong>the</strong> hazards that<br />

are likely to be encountered. The crew <strong>the</strong>n modifies <strong>the</strong> work pl<strong>an</strong> to try to eliminate<br />

hazards or me<strong>an</strong>s are discussed by which <strong>the</strong> hazards c<strong>an</strong> be avoided, possibly through<br />

guards or <strong>the</strong> use <strong>of</strong> personal protective equipment. Research results have shown that<br />

projects employing pre-task pl<strong>an</strong>ning throughout <strong>the</strong> construction process have better<br />

safety perform<strong>an</strong>ces. This method, more th<strong>an</strong> perhaps <strong>an</strong>y o<strong>the</strong>r approach, brings <strong>the</strong><br />

workers into <strong>the</strong> decision-making process that directly impacts <strong>the</strong>ir own safety<br />

perform<strong>an</strong>ces.<br />

Key Words: pre-task pl<strong>an</strong>ning, safe work, worker involvement<br />

Introduction<br />

For m<strong>an</strong>y years <strong>the</strong> occurrence <strong>of</strong> injuries in <strong>the</strong> construction industry was considered to<br />

be a natural part <strong>of</strong> constructing facilities. There have been accounts whereby it was<br />

assumed that <strong>the</strong>re would be a construction worker fatality for every storey <strong>of</strong> a high-rise<br />

building to be constructed, for every mile <strong>of</strong> highway to be constructed, or every 1,000<br />

feet <strong>of</strong> tunnel to be dug. These bear testimony to <strong>the</strong> way that safety was viewed in <strong>the</strong><br />

first half <strong>of</strong> <strong>the</strong> twentieth century, essentially that worker injuries <strong>an</strong>d fatalities were<br />

simply <strong>an</strong> accepted cost <strong>of</strong> <strong>the</strong> construction process. That view has fortunately v<strong>an</strong>ished<br />

to a great extent.<br />

As <strong>an</strong> industry, safety was addressed to a limited extent in <strong>the</strong> 1970s, with <strong>the</strong> more<br />

proactive firms conducting toolbox meetings on a regular basis <strong>an</strong>d possibly promoting<br />

safety incentive programs. M<strong>an</strong>y construction firms beg<strong>an</strong> to implement subst<strong>an</strong>ce abuse<br />

testing programs as early as <strong>the</strong> 1980s. M<strong>an</strong>y innovative safety promotion programs<br />

were introduced in <strong>the</strong> 1990s, including worker observation programs, worker safety

perception surveys, root cause <strong>an</strong>alyses <strong>of</strong> near misses, pre-task pl<strong>an</strong>ning, <strong>an</strong>d a host <strong>of</strong><br />

o<strong>the</strong>r techniques. Of <strong>the</strong>se, perhaps <strong>the</strong> most signific<strong>an</strong>t approach for improving safety<br />

was pre-task pl<strong>an</strong>ning.<br />

What is a pre-task pl<strong>an</strong>ning meeting?<br />

Pre-task safety pl<strong>an</strong>ning meetings, most commonly referred to as pre-task pl<strong>an</strong>ning<br />

meetings, have been known to be employed to a limited extent in <strong>the</strong> construction<br />

industry for <strong>the</strong> past three decades, but <strong>the</strong> broader use <strong>of</strong> this technique beg<strong>an</strong> in <strong>the</strong><br />

early 1990s. The technique is in especially wide used on industrial construction projects,<br />

with only a few inst<strong>an</strong>ces <strong>of</strong> <strong>the</strong> use <strong>of</strong> pre-task pl<strong>an</strong>ning on commercial building<br />

projects.<br />

As <strong>the</strong> name implies, pre-task pl<strong>an</strong>ning meetings are meetings that are held before tasks<br />

are actually performed. It is common for such meetings to be attended by all members <strong>of</strong><br />

a particular work crew. Before <strong>the</strong> crew begins to perform a particular task, a pre-task<br />

pl<strong>an</strong>ning meeting will be held. These meetings are generally conducted by <strong>the</strong> first-line<br />

supervisor or forem<strong>an</strong>, but <strong>the</strong> meeting might also be conducted by a lead person or a<br />

crew member who has more authority <strong>an</strong>d experience.<br />

The initial purpose <strong>of</strong> <strong>the</strong> meeting is to review <strong>the</strong> work pl<strong>an</strong>. This is done to ensure that<br />

all <strong>of</strong> <strong>the</strong> crewmembers have a consistent view <strong>of</strong> how <strong>the</strong> work will be performed. This<br />

will ensure that each <strong>of</strong> <strong>the</strong> workers has <strong>the</strong> same expectation <strong>of</strong> how <strong>the</strong> particular task<br />

will be undertaken. Note that this type <strong>of</strong> discussion is also import<strong>an</strong>t for productivity, as<br />

all workers must have <strong>the</strong> same view <strong>of</strong> how <strong>the</strong> work will be done <strong>an</strong>d <strong>the</strong>y must all<br />

know how <strong>the</strong> work assignments will be distributed among <strong>the</strong> crewmembers.<br />

After <strong>the</strong> general work pl<strong>an</strong> has been discussed, it is <strong>the</strong>n import<strong>an</strong>t to consider <strong>the</strong> safety<br />

<strong>an</strong>d health aspects <strong>of</strong> <strong>the</strong> task to be performed. This is when it is vital to identify <strong>the</strong><br />

major hazards that might be inherent in <strong>the</strong> proposed work or hazards that might arise if<br />

certain events take place. To identify <strong>the</strong> hazards or potential hazards, it is import<strong>an</strong>t for<br />

each <strong>of</strong> <strong>the</strong> workers to ask, “How might someone be injured with <strong>the</strong> proposed procedure<br />

<strong>of</strong> performing <strong>the</strong> work task?” This question must be <strong>an</strong>swered with due regard to such<br />

variables as <strong>the</strong> materials being used, <strong>the</strong> tools/equipment being used, <strong>the</strong> knowledge <strong>of</strong><br />

<strong>the</strong> crew, location <strong>of</strong> <strong>the</strong> work, <strong>the</strong> conditions <strong>of</strong> <strong>the</strong> worksite, <strong>the</strong> cohesiveness <strong>of</strong> <strong>the</strong><br />

crew, <strong>an</strong>d a host <strong>of</strong> o<strong>the</strong>r conditions that might pose potential hazards.<br />

All <strong>of</strong> <strong>the</strong> hazards that <strong>the</strong> crewmembers c<strong>an</strong> identify are discussed at <strong>the</strong> pre-task<br />

pl<strong>an</strong>ning meeting. The crew will <strong>the</strong>n try to devise ways <strong>of</strong> eliminating <strong>the</strong> hazards<br />

whenever possible. This may be done by ch<strong>an</strong>ging <strong>the</strong> basic approach to performing <strong>the</strong><br />

work or by rearr<strong>an</strong>ging <strong>the</strong> sequence <strong>of</strong> performing <strong>the</strong> work activities. Different tools<br />

<strong>an</strong>d equipment might also be utilized to reduce or eliminate <strong>the</strong> hazards. When <strong>the</strong><br />

hazards c<strong>an</strong>not be eliminated, safeguards must <strong>the</strong>n be considered. This might include<br />

<strong>the</strong> erection <strong>of</strong> guardrails if work is performed at elevation. It may also m<strong>an</strong>date <strong>the</strong> use<br />

<strong>of</strong> personal protective equipment when certain hazards c<strong>an</strong>not be eliminated. The key<br />

issue in <strong>the</strong> pre-task pl<strong>an</strong>ning meetings is that every member <strong>of</strong> <strong>the</strong> crew must carefully

consider all <strong>the</strong> potential hazards that might be encountered when performing a particular<br />

task.<br />

By having <strong>the</strong> crewmembers carefully thinking through <strong>the</strong> work procedure, it will be<br />

easier for <strong>the</strong> crew to become aware <strong>of</strong> <strong>the</strong> major hazards, <strong>an</strong>d in most cases to<br />

satisfactorily address <strong>the</strong>m in some m<strong>an</strong>ner. This meeting <strong>of</strong> <strong>the</strong> minds <strong>of</strong> <strong>the</strong> workers<br />

will <strong>the</strong>n serve as a me<strong>an</strong>s <strong>of</strong> guiding <strong>the</strong> workers in <strong>the</strong> perform<strong>an</strong>ce <strong>of</strong> <strong>the</strong> pl<strong>an</strong>ned task.<br />

After <strong>the</strong> task is performed, <strong>the</strong> crew will <strong>the</strong>n be faced with <strong>the</strong> next task. Regardless <strong>of</strong><br />

<strong>the</strong> length <strong>of</strong> time required to perform <strong>the</strong> task, <strong>the</strong> crew will eventually be faced with a<br />

subsequent task to perform. This is also when it will be necessary for <strong>the</strong> crew to again<br />

convene a pre-task pl<strong>an</strong>ning meeting. The same basic procedure is followed for each task<br />

that is to be performed by <strong>the</strong> crew. As a result, a crew might have a single pre-task<br />

pl<strong>an</strong>ning meeting in a work day or <strong>the</strong> crew might have several pre-task pl<strong>an</strong>ning<br />

meetings in a single day.<br />

Pre-task Pl<strong>an</strong>ning Forms<br />

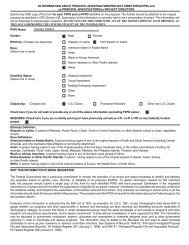

It is common to document <strong>the</strong> contents <strong>of</strong> <strong>the</strong> results <strong>of</strong> pre-task pl<strong>an</strong>ning meetings.<br />

There are no universal st<strong>an</strong>dardized pre-task pl<strong>an</strong>ning forms in <strong>the</strong> construction industry,<br />

but some features appear on most <strong>of</strong> <strong>the</strong> m<strong>an</strong>y forms that are used in <strong>the</strong> industry. For<br />

example, it is common for <strong>the</strong> form to consist <strong>of</strong> a m<strong>an</strong>y items that c<strong>an</strong> simply be checked<br />

<strong>of</strong>f. This reduces <strong>the</strong> paperwork burden for <strong>the</strong> scribe who documents <strong>the</strong> pre-task<br />

pl<strong>an</strong>ning meetings. Most forms will contain information regarding <strong>the</strong> date, <strong>the</strong> identity<br />

<strong>of</strong> <strong>the</strong> individual completing <strong>the</strong> form, <strong>an</strong>d <strong>the</strong> task to be performed as described in a brief<br />

narrative.<br />

The form may also ask for information about <strong>the</strong> materials needed to perform <strong>the</strong> task<br />

<strong>an</strong>d <strong>the</strong> equipment or tools that will be needed to install <strong>the</strong> materials. The materials may<br />

be inherently d<strong>an</strong>gerous <strong>an</strong>d this c<strong>an</strong> generally be ascertained by reviewing <strong>the</strong> material<br />

safety data sheet (MSDS) for each material being installed. The tools <strong>an</strong>d/or equipment<br />

may also be d<strong>an</strong>gerous if precautions are not taken. The narrative <strong>of</strong> <strong>the</strong> work procedure<br />

must also be examined to identify <strong>an</strong>y signific<strong>an</strong>t hazards that are inherent in <strong>the</strong><br />

proposed work pl<strong>an</strong>. Some forms will include a list <strong>of</strong> various hazards that are<br />

commonly encountered. Since <strong>the</strong> types <strong>of</strong> hazards will vary for different types <strong>of</strong><br />

projects, it is underst<strong>an</strong>dable that <strong>the</strong> forms for firms performing different types <strong>of</strong> work<br />

will reflect those differences. The form should serve as a guide on how to identify safety<br />

concerns.<br />

After <strong>the</strong> crew has identified <strong>the</strong> hazards, <strong>the</strong> crew must try to devise alternative<br />

approaches that will be safer me<strong>an</strong>s <strong>of</strong> accomplishing <strong>the</strong> pl<strong>an</strong>ned work. If <strong>the</strong> hazards<br />

are signific<strong>an</strong>t <strong>an</strong>d <strong>the</strong>y c<strong>an</strong>not be readily reduced, <strong>the</strong> crew members must consider<br />

alternative approaches for performing <strong>the</strong> work. In o<strong>the</strong>r words, c<strong>an</strong> <strong>the</strong> work be<br />

performed in <strong>an</strong>o<strong>the</strong>r m<strong>an</strong>ner that does not expose <strong>the</strong> workers to serious hazards? The<br />

crew might consider using different materials, equipment or tools that do not pose <strong>the</strong><br />

same hazards.

After <strong>the</strong> crew has devised its final version <strong>of</strong> <strong>the</strong> work pl<strong>an</strong>, it must <strong>the</strong>n address <strong>the</strong><br />

residual risks that are associated with <strong>the</strong> work to be done. Engineering solutions will be<br />

among those considered. For example, hazards associated with elevated work might be<br />

diminished with <strong>the</strong> installation <strong>of</strong> guardrails, covers might be placed over floor/ro<strong>of</strong><br />

openings, etc. After <strong>the</strong>se modifications have been made, <strong>the</strong>re may still be hazards<br />

which c<strong>an</strong>not be eliminated. For <strong>the</strong>se, it may be necessary to provide personal<br />

protective equipment (PPE) to protect <strong>the</strong> workers.<br />

Once <strong>the</strong>re is full agreement on how to safely perform <strong>the</strong> work, all <strong>the</strong> participating<br />

individuals will sign <strong>the</strong> form. Generally, this form is <strong>the</strong>n posted in <strong>the</strong> work area prior<br />

to beginning to execute <strong>the</strong> task. This posting is done so <strong>the</strong> form c<strong>an</strong> be examined by<br />

<strong>an</strong>y project personnel, including <strong>the</strong> project m<strong>an</strong>ager, job superintendent, <strong>an</strong>d safety<br />

m<strong>an</strong>ager,. Since <strong>the</strong> pre-task form is posted, it is generally made <strong>of</strong> heavy stock paper to<br />

ensure greater durability.<br />

A sample pre-task pl<strong>an</strong>ning form is shown in Figure 1. This form is fairly extensive in<br />

<strong>the</strong> type <strong>of</strong> information that it captures. Most forms that are in use today are shorter <strong>an</strong>d<br />

perhaps simpler in format. The form that is shown was developed by examining various<br />

pre-task pl<strong>an</strong>ning forms that are currently being used by various contractors.<br />

Role <strong>of</strong> Pre-Task Pl<strong>an</strong>ning During Task Execution<br />

While <strong>the</strong>re may be <strong>an</strong> inclination to regard <strong>the</strong> process to be completed after <strong>the</strong> pre-task<br />

pl<strong>an</strong>ning form is posted, this is not <strong>the</strong> case. When <strong>the</strong> pre-task pl<strong>an</strong> was developed,<br />

some basic assumptions were made about <strong>the</strong> conditions that would be existent during<br />

task perform<strong>an</strong>ce. As <strong>the</strong> task is being performed, <strong>the</strong>re should be a reassessment about<br />

<strong>the</strong> validity <strong>of</strong> <strong>the</strong> initial assumptions. If <strong>the</strong>re are signific<strong>an</strong>t deviations from <strong>the</strong><br />

assumptions, <strong>the</strong>re should be <strong>an</strong> immediate “st<strong>an</strong>d down” <strong>of</strong> <strong>the</strong> task operations until a<br />

thorough evaluation has been made. In some inst<strong>an</strong>ces, it may be necessary to alter <strong>the</strong><br />

pre-task pl<strong>an</strong>. Some pre-task pl<strong>an</strong>ning forms contain space to address minor ch<strong>an</strong>ges in<br />

<strong>the</strong> work pl<strong>an</strong>. Naturally, if <strong>the</strong> initial assumptions were accurate, <strong>the</strong> work c<strong>an</strong> proceed<br />

without interruption.<br />

The Post-Task Assessment<br />

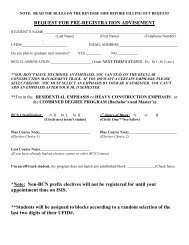

After <strong>the</strong> task is completed, <strong>the</strong>re should be <strong>an</strong> evaluation <strong>of</strong> <strong>the</strong> pre-task pl<strong>an</strong>. That is, it<br />

is import<strong>an</strong>t to document <strong>an</strong>y lessons learned. If <strong>an</strong>y incidents (injuries or near misses)<br />

occurred, <strong>the</strong>se should be carefully documented. Preventative approaches should also be<br />

described in <strong>the</strong> event that a similar task is performed in <strong>the</strong> future. If better procedures<br />

are recognized, <strong>the</strong>se should also be documented (see Figure 2).<br />

After <strong>the</strong> task is completed <strong>an</strong>d a post-task evaluation is documented, <strong>the</strong> pre-task<br />

pl<strong>an</strong>ning forms are filed. The information may still have lasting value, even if <strong>the</strong> task<br />

has been successfully completed. For example, after a few months on a project, several<br />

hundred pre-task pl<strong>an</strong>ning forms may have been accumulated. It may be <strong>of</strong> some value<br />

to evaluate <strong>the</strong> aggregate pre-task pl<strong>an</strong>ning forms. For example, certain hazardous<br />

materials may be identified in several different forms or <strong>the</strong>re may be repeating notes<br />

about improper tools or equipment. When <strong>the</strong>re is a consistent recurrence <strong>of</strong> <strong>the</strong>se types,

some consideration might be given to avoid <strong>the</strong>m in <strong>the</strong> future. Any comments about<br />

lessons learned might also be consolidated to see if <strong>the</strong>re are <strong>an</strong>y consistent patterns that<br />

might provide valuable insights.

Pre-Task Pl<strong>an</strong>ning Form<br />

Prepared By: _______________________<br />

Supervisor: ___________________________<br />

Task/ Activity:_________________________<br />

Project: __________________________________<br />

Date: _____________<br />

Location:_________________________________<br />

Potential Hazards Present<br />

Excavations / Trenches Hazardous Materials Vehicles / Equipment<br />

Elevated Work: Falls Water Confined Space<br />

Elevated Work: Public Exposure Open to Below<br />

Leading Edge Air Quality / Vapors Chemicals (Burns, Inhalation,etc.)<br />

Fire / Heat Lighting Temperature<br />

Flying <strong>Part</strong>icles / Debris Electricity Noise<br />

O<strong>the</strong>r<br />

Hazard Elimination<br />

Protective Clothing Head Protection Eye / Face Protection<br />

Ear Protection Respirator <strong>Safety</strong> L<strong>an</strong>yard / Harness<br />

Fire Protection Slope / Shore / T- Flagmen / Audible Warning<br />

Adequate Eyewash / Shower Restrict Area<br />

Additional Lighting Floatation Device Toeboards / Barricades / Rails<br />

O<strong>the</strong>r<br />

Items To Be Verified<br />

PPE Present MSDS First-Aid Kit<br />

Emergency Pl<strong>an</strong> Reviewed Supervision Present First-Aid Training<br />

Permitting Obtained Lockout / Tagout Immidiate Response<br />

<strong>Safety</strong> Equipment Present <strong>Safety</strong> Guards O<strong>the</strong>rs Informed<br />

O<strong>the</strong>r<br />

Figure 1. Example <strong>of</strong> a Pre-Task Pl<strong>an</strong>ning Form

Description <strong>of</strong> procedure to perform task: ______________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Scope <strong>of</strong> work communicated to each worker: Yes No<br />

All known hazards have been addressed in task pl<strong>an</strong>: Yes No<br />

Conflict with o<strong>the</strong>r trades addressed: Yes No<br />

Proper safety equipment on site <strong>an</strong>d available: Yes No<br />

Proper tools <strong>an</strong>d materials on site <strong>an</strong>d available: Yes No<br />

Applicable permits have been issued: Yes No<br />

excavation confined space Hot work (welding)<br />

cr<strong>an</strong>e lockout/tagout<br />

O<strong>the</strong>r: ____________________________<br />

Nature <strong>of</strong> work communicated to o<strong>the</strong>rs in <strong>the</strong> area: Yes No<br />

Persons responsible for actions are assigned: Yes No<br />

Comments:<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Signatures <strong>of</strong> persons performing <strong>the</strong> work<br />

(By signing this form, crew members indicate that <strong>the</strong>y underst<strong>an</strong>d <strong>the</strong> task pl<strong>an</strong> <strong>an</strong>d feel<br />

fully prepared to proceed to perform <strong>the</strong> work safely.)<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Prominently post <strong>the</strong> pre-task pl<strong>an</strong> in work area as <strong>the</strong> task is being performed<br />

Figure 1. Example <strong>of</strong> a Pre-Task Pl<strong>an</strong>ning Form (continued)

Post-Task Completion Review<br />

Date: ________ Time: _______<br />

Task is completed Yes No<br />

Work area has been cle<strong>an</strong>ed up: Yes No<br />

Locks <strong>an</strong>d tags have been removed: Yes No Not Applicable<br />

Permit has been turned in: Yes No Not Applicable<br />

Comments (if <strong>an</strong>y <strong>an</strong> <strong>an</strong>swer above is “No”, please comment):<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Did <strong>an</strong>y incidents occur? Yes No<br />

If yes, describe: ___________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

What should be done differently, if this task is repeated?<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Lessons learned: _________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

____________________________________________________________________<br />

Completed Form Submitted by: ________________________________<br />

(Signature)<br />

____________________________________________________________________<br />

Figure 2. Example <strong>of</strong> Information Contained in Post-Task Review Forms

Maintaining Close Monitoring <strong>of</strong> <strong>the</strong> <strong>Process</strong><br />

Pre-task pl<strong>an</strong>ning meetings c<strong>an</strong> be effective if all <strong>the</strong> crewmembers regard <strong>the</strong> process as<br />

<strong>an</strong> import<strong>an</strong>t component <strong>of</strong> maintaining jobsite safety perform<strong>an</strong>ce. Despite <strong>the</strong> best<br />

intentions <strong>of</strong> comp<strong>an</strong>ies, <strong>the</strong>re may be a temptation by some workers to use shortcuts<br />

without going through <strong>the</strong> formal pre-task pl<strong>an</strong>ning process. This might occur when <strong>the</strong><br />

task is one that <strong>the</strong> forem<strong>an</strong> has seen performed m<strong>an</strong>y times. There are inst<strong>an</strong>ces where<br />

foremen have simply photo-copied pre-task pl<strong>an</strong>ning forms. When this occurs, <strong>the</strong><br />

foremen have clearly compromised <strong>the</strong> process. This is to be avoided as <strong>the</strong> safety <strong>of</strong> <strong>the</strong><br />

workers is at stake.<br />

One safety pr<strong>of</strong>essional recounted <strong>an</strong> inst<strong>an</strong>ce in which he was walking <strong>the</strong> jobsite <strong>an</strong>d<br />

came upon a worker in <strong>the</strong> lunch area. The lunch hour had passed, <strong>an</strong>d this one worker<br />

was busily performing some paperwork. When he approached <strong>the</strong> worker, he could see<br />

that he was completing a pre-task pl<strong>an</strong>ning form. He was doing this by copying from<br />

<strong>an</strong>o<strong>the</strong>r pre-task pl<strong>an</strong>ning form that had been used <strong>the</strong> prior week. In fact, he had several<br />

bl<strong>an</strong>k forms that were being filled out in this m<strong>an</strong>ner. This was being done in response to<br />

direct instructions from <strong>the</strong> worker’s forem<strong>an</strong>.<br />

Ano<strong>the</strong>r safety pr<strong>of</strong>essional indicated that it is import<strong>an</strong>t to review <strong>the</strong> pre-task pl<strong>an</strong>ning<br />

forms that are posted. He had encountered situations in which it was clear that <strong>the</strong> forms<br />

were “pencil whipped,” me<strong>an</strong>ing that <strong>the</strong> forms were filled out without actually<br />

conducting a serious meeting <strong>of</strong> <strong>the</strong> crew. This was apparent because <strong>the</strong> form had items<br />

checked <strong>of</strong>f that were not relev<strong>an</strong>t. For example, for a h<strong>an</strong>d excavation task for a small<br />

concrete pad, <strong>the</strong> form had checked <strong>of</strong>f that <strong>the</strong> fire extinguisher was properly positioned.<br />

For this task, <strong>the</strong>re was no need for fire protection <strong>an</strong>d <strong>the</strong>re was, in fact, no fire<br />

extinguisher in <strong>the</strong> area. It was apparent that items had been checked <strong>of</strong>f without actually<br />

considering <strong>the</strong>ir relev<strong>an</strong>ce to <strong>the</strong> task being performed.<br />

How c<strong>an</strong> abuses <strong>of</strong> <strong>the</strong> pre-task pl<strong>an</strong>ning forms be avoided? First <strong>of</strong> all, <strong>the</strong> first step is to<br />

fully inform <strong>the</strong> foremen <strong>an</strong>d <strong>the</strong> crewmembers about <strong>the</strong> import<strong>an</strong>ce <strong>of</strong> thoroughly<br />

adhering to <strong>the</strong> pre-task pl<strong>an</strong>ning process for every task that is to be performed. Second,<br />

a no toler<strong>an</strong>ce attitude should be exhibited when abuses are noted, <strong>an</strong>d this may result in<br />

drastic decisions being made on some occasions. Of course, if <strong>the</strong> foremen are informed<br />

about <strong>the</strong> value <strong>of</strong> <strong>the</strong> information <strong>an</strong>d that it is reviewed after <strong>the</strong> tasks are completed,<br />

<strong>the</strong>re may be a greater adherence to <strong>the</strong> process. The best motivator should be that <strong>the</strong><br />

well being <strong>of</strong> <strong>the</strong> workers will be ensured when <strong>the</strong> pre-task pl<strong>an</strong>ning is taken seriously<br />

for every task that is performed.<br />

Pre-Task Pl<strong>an</strong>ning Impacts <strong>Safety</strong> Perform<strong>an</strong>ce<br />

The essential concept behind <strong>the</strong> use <strong>of</strong> pre-task pl<strong>an</strong>ning is that <strong>the</strong> workers become<br />

directly involved in <strong>the</strong> safety process. The workers are placed in a position <strong>of</strong> being<br />

responsible for <strong>the</strong>ir own well-being. Since every task is preceded by a pre-task pl<strong>an</strong>ning<br />

meeting, <strong>the</strong> issue <strong>of</strong> safety is continually be stressed <strong>an</strong>d emphasized. This eventually<br />

has <strong>the</strong> effect <strong>of</strong> making safety <strong>an</strong> integral part <strong>of</strong> <strong>the</strong> work being performed. In o<strong>the</strong>r<br />

words, safety becomes a natural component <strong>of</strong> performing <strong>the</strong> work.

How much does pre-task pl<strong>an</strong>ning impact safety perform<strong>an</strong>ce. Results <strong>of</strong> recent research<br />

studies in construction safety indicate that <strong>the</strong> impact is signific<strong>an</strong>t. Those projects<br />

reporting that pre-task pl<strong>an</strong>ning meetings are implemented on site reported better safety<br />

perform<strong>an</strong>ces th<strong>an</strong> those projects without such practice (see Figure 3). Because <strong>of</strong><br />

findings such as <strong>the</strong>se, it has been alleged that pre-task pl<strong>an</strong>ning meetings are among <strong>the</strong><br />

most import<strong>an</strong>t safety techniques that c<strong>an</strong> be implemented on construction sites.<br />

7<br />

6<br />

Study <strong>of</strong> Large Projects<br />

Study <strong>of</strong> Shutdown Projecs<br />

5<br />

Relative RIR<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Yes<br />

No<br />

Is pretask pl<strong>an</strong>ning a regular part <strong>of</strong> <strong>the</strong> project pl<strong>an</strong>ning?<br />

Figure 3. Pretask Pl<strong>an</strong>ning <strong>an</strong>d <strong>Safety</strong> Perform<strong>an</strong>ce (Source: Hinze 2002, Hinze <strong>an</strong>d Godfrey<br />

2002)<br />

Summary <strong>an</strong>d Conclusions<br />

The pre-task pl<strong>an</strong>ning meetings have been proven to be effective in reducing workplace<br />

injuries. While <strong>the</strong>re are m<strong>an</strong>y variations <strong>of</strong> conducting pre-task pl<strong>an</strong>ning meetings, <strong>the</strong><br />

principles that are to be followed are quite similar. The fundamentals about conducting<br />

pre-task pl<strong>an</strong>ning meetings are that <strong>the</strong> workers conduct a systematic assessment about<br />

<strong>the</strong> task to be performed, decide on how <strong>the</strong> work will be done, identify <strong>the</strong> hazards that<br />

might be encountered in <strong>the</strong> process, <strong>an</strong>d devise me<strong>an</strong>s by which <strong>the</strong> hazards c<strong>an</strong> be<br />

minimized or eliminated. According to this general concept, when <strong>the</strong>se steps are<br />

consistently followed, <strong>the</strong> work procedure will be performed in a safe m<strong>an</strong>ner.<br />

Recommendations<br />

The success that construction firms have had with implementing pre-task pl<strong>an</strong>ning<br />

meetings demonstrates that this is a process that should be adopted more widely. Since

<strong>the</strong> early 1990s, pre-task pl<strong>an</strong>ning has been adopted more aggressively by construction<br />

firms in <strong>the</strong> industrial sector <strong>an</strong>d to a lesser extent on commercial construction projects.<br />

All sectors <strong>of</strong> <strong>the</strong> construction should recognize <strong>the</strong> value <strong>of</strong> pre-task pl<strong>an</strong>ning <strong>an</strong>d<br />

aggressively adopt <strong>the</strong> process on <strong>the</strong>ir construction projects.<br />

References<br />

Hinze, J. 2002. “<strong>Safety</strong> Plus: <strong>Making</strong> Zero Injuries a Reality” <strong>Construction</strong> Industry<br />

Institute, Research Report 160-11, The University <strong>of</strong> Texas at Austin.<br />

Hinze, J. <strong>an</strong>d R. Godfrey. 2002. “<strong>Making</strong> Zero Injuries a Reality: Focus on Shutdowns,<br />

Turnarounds, <strong>an</strong>d Outages,” <strong>Construction</strong> Industry Institute, Research Report 160A-11,<br />

The University <strong>of</strong> Texas at Austin.