IOM Manual

IOM Manual

IOM Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

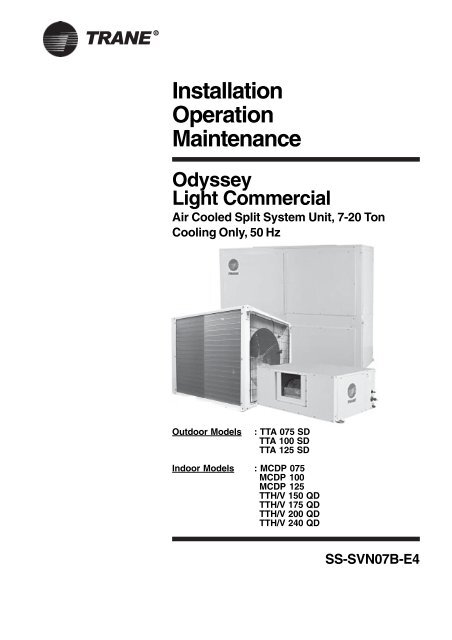

TRANE<br />

R<br />

Installation<br />

Operation<br />

Maintenance<br />

Odyssey<br />

Light Commercial<br />

Air Cooled Split System Unit, 7-20 Ton<br />

Cooling Only, 50 Hz<br />

Outdoor Models<br />

: TTA 075 SD<br />

TTA 100 SD<br />

TTA 125 SD<br />

Indoor Models : MCDP 075<br />

MCDP 100<br />

MCDP 125<br />

TTH/V 150 QD<br />

TTH/V 175 QD<br />

TTH/V 200 QD<br />

TTH/V 240 QD<br />

SS-SVN07B-E4

TRANE ®<br />

Important Note: Installation procedures<br />

should be performed in the sequence<br />

that they appear in this manual. This<br />

manual is customer' s property. Do not<br />

destroy or remove the manual from the<br />

unit. The manual should remain weather<br />

protected with the unit until all<br />

installation procedures are completed.<br />

Warning: Open and lock the disconnect<br />

switch before attempting any installation<br />

of maintenance. Failure to do so will<br />

cause severe injury even to death for<br />

electrical shock or contact with moving<br />

parts.<br />

Note: It is not the intention of this<br />

manual to cover all possible variations<br />

in systems that may occur or to provide<br />

comprehensive information concerning<br />

every possible contingency that may be<br />

encountered during an installation. If<br />

additional information is required or if<br />

specific problems arise that are not fully<br />

discussed in this manual, contact your<br />

local Sales office.<br />

Note: Warning and Cautions appear at<br />

appropriate places in this manual. Your<br />

personal safety and the proper<br />

operation of this machine require that<br />

you follow them carefully. The Company<br />

assumes no liability for installation or<br />

servicing performed by unqualified personnel.<br />

i

TRANE ®<br />

Contents<br />

General Information<br />

Outdoor Unit - TTA Model Nomenclature<br />

General Data - Outdoor Unit<br />

Dimensional Data - TTA Only<br />

Unit Installation - Outdoor Unit<br />

Space Clearance Data - Outdoor Unit<br />

Model Number Description<br />

General Data<br />

Dimensional Data<br />

Unit Installation - Indoor Unit<br />

System Refrigerant Piping<br />

System Refrigerant Charging Procedures<br />

Field Wiring Instructions<br />

Schematic Wiring Diagram<br />

Interfacing Wiring Diagram<br />

Wired Control Installation<br />

Wired Control<br />

System Operation<br />

Operation and Start-Up<br />

Maintenance<br />

Trouble Analysis<br />

Trouble Analysis - Discharge Chart<br />

Commissioning Log Sheet<br />

Installation Checklist<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8-9<br />

10-12<br />

13-16<br />

17-18<br />

19<br />

20<br />

21<br />

22-23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29-31<br />

32<br />

33<br />

34<br />

ii

TRANE ®<br />

General Information<br />

Foreword<br />

These instructions do not attempt to<br />

cover all variations in systems, nor to<br />

provide for every possible contingency<br />

to be met in connection with installation.<br />

Should further information be desired<br />

or should particular problems arise<br />

which are not sufficiently covered for the<br />

purchaser's purpose, the matter should<br />

be referred to the manufacturer.<br />

Reception<br />

On arrival, inspect the unit before<br />

signing the delivery note. Specify any<br />

damage on the delivery note, and send<br />

a registered letter of protest to the last<br />

carrier of the goods within 72 hours of<br />

delivery. Notify the local Trane Sales<br />

Office at the same time. The unit should<br />

be totally inspected within 15 days of<br />

delivery. lf any concealed damage is<br />

discovered, stop unpacking the<br />

shipment. Take photos of the damage<br />

material if possible. Notify the carrier<br />

immediately by phone and registered<br />

mail. Notify the local Trane Sales Office.<br />

Concealed damage must be reported<br />

within 15 days of delivery. Check the<br />

unit nameplate to confirm that the<br />

proper unit was shipped. Available<br />

power supply must be compatible with<br />

electrical characteristics specified on<br />

component nameplates.<br />

General Information<br />

This manual covers the installation,<br />

operation and maintenance of Trane<br />

Indoor / Outdoor units.<br />

Note<br />

Handling<br />

The unit will be supplied with a shipping<br />

base and protective packaging over the<br />

unit casing. The packaging should be<br />

kept on the unit during handling or<br />

storage on site.<br />

lf it is necessary to remove the<br />

packaging for inspection prior to<br />

completion of on site handling, retain<br />

packaging parts and reapply them by<br />

tapping in position to prevent damage<br />

to the casing. The unit as supplied has<br />

a shipping base which is suitable for<br />

handling by a fork lift truck. lf it is<br />

necessary to sling the unit, use<br />

spreader bars under the shipping base.<br />

Ensure that ropes do not cause<br />

abrasion to the surface of the unit.<br />

Warning<br />

Open and lock unit disconnect to<br />

prevent injury or death from electric<br />

shock or contact with moving parts<br />

before attempting any installation or<br />

maintenance.<br />

lnspection<br />

lnspect material carefully for any<br />

shipping damage. lf damaged, it must<br />

be reported to, and claims made against<br />

the transportation company. Replace<br />

damaged parts with authorized parts<br />

only. Check the unit nameplate to<br />

confirm that the proper unit was<br />

shipped. Available power supply must<br />

be compatible with electrical<br />

characteristics specified on component<br />

nameplates.<br />

"Warnings" and "Cautions" appear at<br />

appropriate places in this manual. Your<br />

personal safety and the proper<br />

operation of this machine require that<br />

you follow them carefully. The<br />

manufacturer assumes no liability for<br />

installations or servicing performed by<br />

unqualified personnel.<br />

1

Outdoor Unit -<br />

TTA Model Nomenclature<br />

T T A 0 7 5 S D 1 X A 0 S A B<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Digit 1,2<br />

T<br />

T<br />

TRANE ® 2<br />

Condensing Unit / Cooling only<br />

Digit 3<br />

A<br />

Air Cooled<br />

Digit 4,5,6<br />

Digit 7<br />

Digit 8<br />

Digit 9<br />

Digit 10<br />

Digit 11<br />

Digit 12<br />

Digit 13<br />

Digit 14<br />

0 7 5<br />

S<br />

D<br />

1<br />

X<br />

A<br />

0<br />

S<br />

A<br />

Nominal Cooling Capacity, MBH<br />

075 = 84 MBH<br />

100 = 106 MBH<br />

125 = 127 MBH<br />

Development Sequence<br />

Electrical Rating / Utilization Range<br />

D = 380 - 415V / 3Phase / 50 Hz<br />

Factory Mounted Control<br />

1 = DOL Starter<br />

Factory Installed Option<br />

X = None<br />

F = Corrosion Resistant Fin<br />

G = Coil Guard Assembly<br />

H = F & G<br />

Refrigerant Type<br />

A = R22<br />

B = R407C<br />

Future Use<br />

Operating Ambient<br />

S = Standard Ambient<br />

H = High Ambient Option<br />

Minor Design Sequence<br />

Digit 15<br />

Matching Flexibility<br />

Table - 4<br />

B<br />

OURDOOR UNIT<br />

TTA 075 S<br />

TTA 100 S<br />

TTA 125 S<br />

2 x TTA 075 S<br />

TTA 075 + TTA 100 S<br />

2 x TTA 100 S<br />

2 x TTA 125 S<br />

Service Indicator<br />

INDOOR UNIT<br />

MCDP 075<br />

MCDP 100<br />

MCDP 125<br />

1 x TTH/TTV 150<br />

1 x TTH/V 175<br />

1 x TTH/TTV 200 Q<br />

1 x TTH/TTV 240 Q

TRANE ®<br />

General Data - Outdoor Unit<br />

Table 1<br />

Performances (1)<br />

TTA 075<br />

TTA 100<br />

TTA 125<br />

Unit Capacity Steps (%)<br />

Total Compressor Power Input (1)<br />

Main Power Supply<br />

Utilization Range<br />

Compressor<br />

Number<br />

Type<br />

Unit MCA(2)<br />

RLA / LRA<br />

Motor RPM<br />

Sump Heater (Optional) per compressor<br />

Coil<br />

Type<br />

Tube Size<br />

Tube Type / Material<br />

Height<br />

Length<br />

Quantity [per TTA]<br />

Face Area [per TTA]<br />

Rows<br />

Fins Per Foot (fpf)<br />

Fan<br />

Type<br />

Number<br />

Diameter<br />

Drive Type<br />

Speeds Number<br />

Air Flow<br />

Motors Quantity<br />

Motors kW (2)<br />

FLA/LRA (2)<br />

Motor RPM<br />

Liquid and Suction connection<br />

Suction Connection<br />

Liquid Connection<br />

Unit Dimensions / Weight<br />

Width X Height X Length<br />

Weight Crated<br />

System Data<br />

Refrigerant Circuit [per TTA]<br />

KW<br />

V/Ph/Hz<br />

A<br />

A<br />

rpm<br />

W<br />

mm (in)<br />

mm<br />

mm<br />

m2<br />

mm (in)<br />

cmh (cfm)<br />

kw (hp)<br />

A<br />

rpm<br />

brazed<br />

brazed<br />

mm<br />

kg<br />

0-100<br />

6.9<br />

1<br />

17<br />

16.4/95<br />

2<br />

1.77<br />

1<br />

168<br />

1<br />

16200 (9535)<br />

1<br />

165<br />

1<br />

0-100<br />

9.1<br />

415/3/50<br />

400V +/- 10%<br />

1<br />

Hermetic Scroll<br />

21<br />

19.2/125<br />

2900<br />

90<br />

Plate Fin<br />

9.52 (3/8)<br />

Smooth Bore / Copper<br />

914<br />

965<br />

2<br />

1.77<br />

2<br />

144<br />

Propeller<br />

1<br />

660 (26)<br />

Direct Drive, 3 phase<br />

1<br />

15700 (9240)<br />

1<br />

0.6 (0.75)<br />

1.3 / 5.66<br />

910<br />

1 1/8"<br />

1/2"<br />

1115 x 945 x 935<br />

197<br />

1<br />

0-100<br />

10.2<br />

1<br />

24<br />

22.1/125<br />

2<br />

1.77<br />

2<br />

168<br />

1<br />

15400 (9064)<br />

1<br />

230<br />

1<br />

Refrigerant Charge<br />

Approximate per circuit<br />

kg<br />

5.4<br />

6.3<br />

6.7<br />

Notes<br />

[1] at 7 deg C SST and 35 deg C Ambient, 420V,<br />

[2] Minimum Circuit Ampacity (MCA) is 125% of the largest compressor RLA plus 100% of the other compressor RLA<br />

plus the sum of the condenser fan FLA.<br />

3

TRANE ® 4<br />

Dimensional Data -<br />

Outdoor Unit TTA 075/100/125

TRANE ®<br />

Unit Installation - Outdoor Unit<br />

Installation Clearances<br />

Provide enough space around the unit<br />

to allow unrestricted access to all<br />

service points. Refer to unit space<br />

clearance data for minimum required<br />

service and free air clearances.<br />

Observe the following points to insure<br />

proper unit operation.<br />

Refer to table 2 for reccomended<br />

spacing.<br />

a. Don't install the unit under low shield.<br />

Keep discharge air freely.<br />

Ground Level Mounting<br />

The unit base should be adequately<br />

supported and hold the unit near level.<br />

Any ground level location must comply<br />

with the required clearances. Place the<br />

unit on a 102 mm cement support plate.<br />

The support should extend 51mm<br />

beyond the unit base channel at all<br />

points. The unit and support should be<br />

Isolated from any adjacent structure to<br />

prevent possible noise or vibration<br />

problem.<br />

Important: Don't block discharge air.<br />

This can result in warm air recirculation<br />

through the coil.<br />

b. Don't locate the unit in a position<br />

where runoff water can drop into the fan<br />

discharge openings.<br />

c. Intake air can be supplied from 2<br />

sides of unit.<br />

Rooftop Mounting<br />

If the unit is roof mounted, be sure the<br />

structure is strong enough to support<br />

the overall weight of the unit and all<br />

accessories. Refer to Table 1 for unit<br />

weight details.<br />

Warning: Ensure the structure is strong<br />

enough to support the gross weight of<br />

unit and its accessories. Failure to do<br />

will result in severe injury or death and<br />

can seriously damage the unit and<br />

building.<br />

The unit should be elevated on a<br />

horizontal, field-fabricated 102 mm steel<br />

frame or 100 X 100 mm wooden<br />

mounting frame. Complete the frame<br />

and fix it firmly on the roof. The frame<br />

must support a minimum of three of the<br />

unit' s four sides and can span the roof<br />

supports to distribute the load on the<br />

roof.<br />

5

TRANE ® 6<br />

Space Clearance Data -<br />

Outdoor Unit<br />

TABLE 2 - TTA INSTALLATION CLEARANCE

TRANE ®<br />

Model Number Description<br />

MCDP Model Nomenclature<br />

M C D P 0 7 5 B 1 0 0 0 0 A A<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Digit 1,2,3<br />

Digit 4<br />

M C D<br />

P<br />

InDoor Unit, Horizontal Discharge / Cooling Only<br />

Development Sequence<br />

Digit 5,6,7<br />

0 7 5<br />

Nominal Cooling Capacity, MBH<br />

075 = 75 MBH<br />

100 = 100 MBH<br />

125 = 125 MBH<br />

MCDP Models<br />

MCDP 075<br />

MCDP 100 / 125<br />

MTR, Kw<br />

D = 0.75<br />

E = 1.1<br />

Digit 8<br />

B<br />

Electrical Rating / Utilization Range<br />

B = 220 - 240V / 1Ph / 50 Hz<br />

Digit 9<br />

Digit 10<br />

Digit 11<br />

Digit 12<br />

Digit 13<br />

Digit 14<br />

1<br />

0<br />

0<br />

0<br />

0<br />

A<br />

Factory Mounted Control<br />

1 = DOL Starter c/w Temperature Controller<br />

Future Use<br />

Future Use<br />

Future Use<br />

Future Use<br />

Minor Design Sequence<br />

Digit 15<br />

A Service Indicator<br />

TTH Model Nomenclature<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

T T H 1 2 5 Q D 1 D 0 0 0 B A<br />

Digit 1,2<br />

Digit 3<br />

Digit 4,5,6<br />

Digit 7<br />

Digit 8<br />

Digit 9<br />

T T<br />

H<br />

1 5 0<br />

Q<br />

D<br />

1<br />

InDoor Unit / Cooling Only<br />

Air Flow Configuration<br />

H = Horizontal Discharge<br />

V = Vertical Discharge<br />

Nominal Cooling Capacity, MBH<br />

150 = 150 MBH 200 = 200 MBH<br />

175 = 175 MBH 240 = 240 MBH<br />

Development Sequence<br />

Electrical Rating / Utilization Range<br />

B = 220 - 240V / 1Ph / 50 Hz<br />

Factory Mounted Control<br />

1 = DOL Starter c/w Temperature Controller<br />

Digit 10<br />

Digit 11<br />

Digit 12<br />

Digit 13<br />

G<br />

0<br />

0<br />

0<br />

Installed Motor kW<br />

Future Use<br />

Future Use<br />

Future Use<br />

TTH Models<br />

TTH 150/175<br />

TTH 200<br />

TTH 240<br />

Std. MTR, kW<br />

G = 2.2<br />

H = 3.0<br />

J = 4.0<br />

Oversize MTR; Kw<br />

J = 4.0<br />

K = 5.5<br />

K = 5.5<br />

Digit 14<br />

Digit 15<br />

B<br />

A<br />

Minor Design Sequence<br />

B = Second. (Year 2006, TTH/BDHB Casing Rationalization)<br />

Service Indicator<br />

7

TRANE ® 8<br />

General Data<br />

Odyssey Condensing Units General Data<br />

Performances (1)<br />

TTA 075<br />

TTA 100<br />

TTA 125<br />

2xTTA 075<br />

TTA075+100<br />

2xTTA 100 TTA100+125<br />

2xTTA125<br />

Unit Capacity Steps (%)<br />

Total Compressor Power Input (1)<br />

Main Power Supply<br />

Utilization Range<br />

Compressor<br />

Number<br />

Type<br />

Unit MCA Amps (4)<br />

RLA / LRA (2)<br />

Motor RPM<br />

Sump Heater (Optional) per compressor<br />

Liquid and Suction Connection<br />

Suction Connection<br />

Liquid Connection<br />

Coil<br />

Type<br />

Tube Size<br />

Tube Type<br />

Height<br />

Length<br />

Quantity [per TTA]<br />

Face Area [per TTA]<br />

Rows [std. Ambient]<br />

Fins Per Foot (fpf)<br />

Fan<br />

Type<br />

Number<br />

Diameter<br />

Drive Type<br />

Speeds Number<br />

Air Flow<br />

Motors Quantity<br />

Motors kW (2)<br />

FLA / LRA (2)<br />

Motor RPM<br />

Dimensions<br />

Height<br />

Width<br />

Length<br />

Weight Crated<br />

System Data<br />

Retrigerant Circuit [per TTA]<br />

Refrigerant Charge (3)<br />

Approximate per circuit<br />

TTA only<br />

Notes:<br />

[1] at 7 deg C SSt and 35 deg C Ambient, 420V,<br />

[2] Per Motor @ 400V<br />

[3] Per Circuit<br />

(kW)<br />

(A)<br />

(A)<br />

(rpm)<br />

(W)<br />

brazed<br />

brazed<br />

(mm)<br />

(mm)<br />

(mm)<br />

(m2)<br />

(mm)/(in)<br />

(mm)<br />

(mm)<br />

(mm)<br />

(kg)<br />

(kg)<br />

0-100<br />

6-9<br />

400/3/50<br />

1<br />

21.7<br />

12.4/95<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

1<br />

168<br />

1<br />

650 26<br />

165<br />

1<br />

7.8<br />

1-100<br />

9.1<br />

400/3/50<br />

1<br />

21<br />

15.9/125<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

2<br />

144<br />

1<br />

650 26<br />

197<br />

1<br />

8.8<br />

0-100<br />

10.2<br />

400/3/50<br />

1<br />

24<br />

17.9/125<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

2<br />

168<br />

1<br />

650 26<br />

230<br />

1<br />

9.5<br />

0-50-100<br />

13.8<br />

400/3/50<br />

400V+, -10%<br />

2<br />

2<br />

Hermetic Scroll<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

1<br />

168<br />

2<br />

650 26<br />

2<br />

650 26<br />

Direct Drive, 3 Phase<br />

1<br />

(m3/h)/(cfm) 15200 9535<br />

1<br />

1<br />

15700 9240<br />

1<br />

1<br />

15400 9064<br />

1<br />

1<br />

32400 19070<br />

2<br />

1<br />

31899 18775<br />

2<br />

kW/hp<br />

0.55/0.75<br />

(A)<br />

1.8/5.66<br />

(rpm)<br />

910<br />

330<br />

1<br />

Plate Fin<br />

9.52<br />

Smooth<br />

914<br />

965<br />

Propeller<br />

945<br />

1115<br />

935<br />

0-50-100<br />

16.0<br />

400/3/50<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

1 & 2<br />

168 & 144<br />

352<br />

1<br />

0-50-100<br />

19.3<br />

400/3/50<br />

2<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

2<br />

144<br />

2<br />

650 26<br />

0-50-100<br />

19.3<br />

400/3/50<br />

2<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

2<br />

144 & 168<br />

2<br />

650 26<br />

1<br />

1<br />

31899 18480 31099 18304<br />

2<br />

2<br />

394<br />

[4] Minimum Circuit Ampacity (MCA) is 125% of the largest compressor RLA.<br />

plus 100% of the other compressor RLA plus the sum of the condenser fan FLA.<br />

[5] Standard Ambient range of up to 45 C, with high ambient range of up to 50deg C with the HA Option.<br />

1<br />

427<br />

1<br />

0-50-100<br />

20.4<br />

400/3/50<br />

2<br />

1 1/8”<br />

1/2”<br />

2<br />

1.77<br />

2<br />

168<br />

2<br />

650 26<br />

1<br />

30800 18128<br />

2<br />

460<br />

1

TRANE ®<br />

General Data<br />

Odyssey Air Handling Units General Date<br />

MCDP075 MCDP100 MCDP125 TTH-V 150<br />

Evaporator Coil<br />

Evaporator Rated Air Flow [MCDs at Med, Speed<br />

@ Available ESP at norminal Airflow<br />

Configuration (1)<br />

Face Area<br />

Tube Material<br />

Tube Type<br />

Tube Size (OD)<br />

Rowas / FPF<br />

No. Of Circuits<br />

Refrigerant Flow Control<br />

Drain Connection Size<br />

Evaporator Fan / Motor<br />

Motor<br />

Utilization Range<br />

FLA (each) (2)<br />

LRA<br />

Diameter of Fan<br />

Width of Fan<br />

No of Fans<br />

Indoor Fan Type<br />

Nominal Fan Speed<br />

Cfm<br />

Cmh<br />

Pg<br />

High Pa [3]<br />

Med. Pa [3]<br />

Low. Pa [3]<br />

sq. ft /m2<br />

in / mm<br />

in<br />

Drive Type<br />

(Hi/Med/Low)(3)<br />

Std. kW<br />

in / mm<br />

in / mm<br />

RPM<br />

2400<br />

4078<br />

163<br />

263<br />

182<br />

51<br />

H<br />

5/0.46<br />

3/144<br />

1<br />

3/4<br />

5.8/5.5/4.4<br />

12.1/8.9/7<br />

0.75<br />

9/229<br />

7/176<br />

2<br />

1250/1300/1350<br />

3225<br />

5479<br />

111<br />

248<br />

238<br />

158<br />

H<br />

6.7/0.62<br />

3/144<br />

1<br />

3/4<br />

9/8,5/7,5<br />

23.8/16.9/13<br />

1.1<br />

9/229<br />

9/229<br />

2<br />

1235/1345/1410<br />

3237<br />

5500<br />

111<br />

248<br />

238<br />

158<br />

H<br />

6.7/0.62<br />

4/144<br />

1<br />

3/4<br />

9/8,5/7,5<br />

23.8/16.9/13<br />

1.1<br />

9/229<br />

9/229<br />

2<br />

1235/1345/1410<br />

4750<br />

8070<br />

125<br />

H and V<br />

10.22/0.95<br />

3/144<br />

2<br />

1.5<br />

4.70<br />

29.40<br />

2.2<br />

15/361<br />

15/361<br />

1<br />

836<br />

Liquid / Suction Line OD<br />

Approx. Operating Weight<br />

Unit Dimensions [uncrated]<br />

in<br />

kg<br />

HxWxD mm<br />

1/2 [1 1/8]<br />

82<br />

398x1217x996<br />

1/2 [1 1/8]<br />

114<br />

398x1593x995<br />

1/2 [1 1/8]<br />

120<br />

396x1593x995<br />

1/2 [1 1/8]<br />

190<br />

1423x1436x702<br />

Notes:<br />

1 H = Horizontal Only. V = Verticle Only. 2 Per Motor @ 400V [std kW] 3 For direct droves only.<br />

TTH-V 175<br />

5300<br />

9005<br />

125<br />

H & V<br />

10.22/0.95<br />

3/144<br />

2<br />

1.5<br />

4.70<br />

29.40<br />

2.2<br />

15/381<br />

15/381<br />

1<br />

843<br />

1/2 [1 1/8]<br />

190<br />

1423x1436x702<br />

TTH-V 200<br />

650<br />

11044<br />

188<br />

H & V<br />

15/1.39<br />

3/144<br />

2<br />

1.5<br />

6.20<br />

40.20<br />

3<br />

16/457<br />

18/457<br />

1<br />

823<br />

1/2 [1 1/8]<br />

315<br />

1673x1628x772<br />

TTH-V 240<br />

8000<br />

13592<br />

188<br />

H & V<br />

15/1.39<br />

3/144<br />

2<br />

1.5<br />

8<br />

38.20<br />

4<br />

18/457<br />

18/457<br />

1<br />

833<br />

1/2 [1 1/8]<br />

315<br />

1673x1628x772<br />

9

TRANE ® 10<br />

Dimensional Data -<br />

MCDP 075-125

TRANE ®<br />

Dimensional Data -<br />

TTH/V 150-175<br />

11

TRANE ®<br />

Dimensional Data -<br />

TTH/V 200-240<br />

12

TRANE ®<br />

Unit Installation - Indoor Unit<br />

Table 5 - Total unit weight and corner weight (kg)<br />

Shipping Net<br />

Corner Weights<br />

Model Maximum Maximum #1 #2 #3<br />

MCDP 075<br />

MCDP 100<br />

MCDP 125<br />

TTH 150<br />

TTV 150<br />

TTH 175<br />

TTV 175<br />

TTH 200<br />

TTV 200<br />

TTH 240<br />

TTV 240<br />

100<br />

134<br />

140<br />

215<br />

215<br />

215<br />

215<br />

342<br />

342<br />

355<br />

355<br />

82<br />

114<br />

120<br />

190<br />

190<br />

190<br />

190<br />

315<br />

315<br />

315<br />

315<br />

20<br />

28<br />

30<br />

47<br />

44<br />

47<br />

44<br />

79<br />

77<br />

82<br />

82<br />

20<br />

28<br />

30<br />

48<br />

50<br />

48<br />

50<br />

86<br />

79<br />

90<br />

90<br />

21<br />

29<br />

30<br />

48<br />

50<br />

48<br />

50<br />

86<br />

79<br />

90<br />

90<br />

#4<br />

21<br />

29<br />

30<br />

47<br />

46<br />

47<br />

46<br />

77<br />

79<br />

80<br />

80<br />

prevent the straps from crushing the<br />

unit cabinet or damaging the unit finish.<br />

Installation Consideration<br />

For proper installation and operation,<br />

check each of the following before<br />

mounting the units.<br />

a. Space Requirement and<br />

Clearance<br />

Allow adequate space for the unit and<br />

free air or service clearance. See Figure<br />

1a.<br />

lnstallation, Limitation and<br />

Important Recommendation<br />

The general location of the air handler<br />

is normally selected by the architect,<br />

contractor, and/or buyer. For proper<br />

installation, the following items must be<br />

considered.<br />

a. Available power supply must agree<br />

with electrical data on component<br />

nameplate.<br />

b. Air handler shipped wired for 380-415<br />

volt applications.<br />

c. lf external accessories are installed<br />

on the unit, additional clearance must<br />

be provided.<br />

d.All duct work should be properly<br />

insulated to prevent condensation<br />

and heat loss.<br />

e.Refrigerant gas piping must be<br />

insulated.<br />

Caution<br />

Properly insulate all refrigerant gas<br />

piping to prevent possible water<br />

damage due to condensation and to<br />

prevent capacity loss and possible<br />

compressor damage.<br />

- It is recommended that the outline<br />

drawings provided be studied and<br />

dimensions properly noted and<br />

checked against selected installation<br />

site. By noting in advance which<br />

knockouts are to be used, proper<br />

clearance allowances can be made for<br />

installation and possible future<br />

service.<br />

lf adding external accessories to the<br />

unit, additional clearances must be considered<br />

for the overall space needed.<br />

Lifting Recommendation<br />

Before preparing the unit for lifting, the<br />

center of gravity should be determined<br />

for lifting safety. Because of placement<br />

of internal components, the unit weight<br />

may be unevenly distributed.<br />

Approximate total unit weight and<br />

corner weights are given in Table 5.<br />

(and Figure 2a, 2b)<br />

Warning<br />

On site lifting equipment must be<br />

capable of lifting the weight of the unit<br />

with an adequate safety factor. The use<br />

of under-capacity lifting devices may<br />

result in personal injury or death and<br />

cause damage to the unit.<br />

The crated unit can be moved using a<br />

forklift of suitable capacity. For lifting<br />

the unit into an elevated mounting<br />

position, run lifting straps or slings<br />

under the unit and attach securely to<br />

the lifting device. Use spreader bars to<br />

protect the unit casing from damage.<br />

Test lift the unit to determine proper<br />

balance and stability.<br />

Caution<br />

Use spreader bars to prevent straps<br />

from damaging the unit. Install the bars<br />

between lifting straps, both underneath<br />

the unit and above the unit. This will<br />

Figure 1a<br />

Space requirement for TTV Vertical<br />

model.<br />

For servicing and routine<br />

maintenance, provide access to the unit<br />

through removable panels in the ceiling<br />

see Figure 1b.<br />

Figure 1b<br />

Space requirement for TTH Horizontal<br />

mode.<br />

13

TRANE ®<br />

Unit Installation - Indoor Unit<br />

b. Location, Mounting and<br />

Positioning<br />

Before installing any unit make sure<br />

proper preparation has been made at<br />

each unit locating for piping and<br />

electrical connections.<br />

Figure 2a<br />

Figure 2b<br />

Horizontal Suspension<br />

lf the air handler will be suspended, use<br />

a suspension mounting kit to isolate the<br />

unit from the structure. This is usually<br />

accomplished through the use of spring<br />

or rubber isolators. Mounting rods must<br />

be field supplied. Isolator selection is<br />

dependent upon total unit weight,<br />

including accessories. Approximate<br />

unit weights are provided in Table 5.<br />

See Figure 2b (for horizontal<br />

configuration) and see Figure 2a (for<br />

vertical configuration).<br />

Caution<br />

Before hanging the unit on suspension<br />

rods, reinforce the cabinet around the<br />

knockouts, using a large washer inside<br />

the cabinet. Washer should be between<br />

the skin of the air handler and the nut<br />

on the suspension rod.<br />

Align holes (knockouts) in the cabinet<br />

with structural supports and secure<br />

suspensions rods to the structure, then<br />

to the air handler cabinet. If knockout<br />

locations do not permit proper<br />

alignment with existing structure, it may<br />

be necessary to field fabricate cross<br />

members on existing structural beams.<br />

Note<br />

When other that bottom return is to be<br />

used, side panel removed for return<br />

duct installation, must be secured over<br />

the bottom opening.<br />

Auxiliary Drain Pan<br />

A field fabricated auxiliary drain pan<br />

should be installed under the unit for<br />

all horizontal applications, and when air<br />

handlers are installed above ceilings or<br />

in other locations where condensate<br />

overflow may cause damage. This drain<br />

pan will eliminate any excess<br />

condensation that may be due to<br />

extreme humidity or an obstructed drain<br />

in the primary drain pan. Drain lines<br />

from this pan must be installed, but<br />

should not be connected to the primary<br />

drain line from the unit, isolate the<br />

auxiliary drain pan from both the air<br />

handler and the structure.<br />

Positioning and Installation<br />

The final position must be dictated by<br />

required service access to unit, weight<br />

distribution over structural supports,<br />

and by the locations of electrical,<br />

refrigerant and condensate drainage<br />

connections. All refrigerant piping<br />

connections are made inside the<br />

cabinet. They may enter the cabinet<br />

through factory provided knockouts.<br />

Note<br />

TTH/V 150~240<br />

The air handler is designed so that<br />

refrigerant piping can only from the<br />

right hand side.<br />

Caution<br />

• Protect adjacent surfaces from heat<br />

damage, when brazing in and around<br />

the air handler.<br />

• These air handlers are shipped with<br />

a holding charge in the coil. Do not<br />

bleed holding charge until refrigerant<br />

lines ready to be connected.<br />

14

TRANE ®<br />

Unit Installation - Indoor Unit<br />

On air handlers that will have refrigerant<br />

lines entering the cabinet from the right<br />

side, the bulb(s) should be attached to<br />

the suction tube(s) inside the cabinet,<br />

in the same manner as above,<br />

approximately 10" from the right end of<br />

the unit.<br />

After attaching to the suction line(s),<br />

either inside or outside of the cabinet,<br />

wrap the cork impregnated insulation<br />

around the bulb(s) and suction tube(s).<br />

Refrigerant piping should then be<br />

insulated.<br />

Important<br />

Ensure that the refrigerant lines passing<br />

through the cabinet are not resting on<br />

sharp sheet metal edges.<br />

Figure 5<br />

Figure 3<br />

Filters<br />

Air handlers are shipped with 1"<br />

washable filters installed. To replace<br />

filters, slide old filters out and replace<br />

with new ones.<br />

Figure 4<br />

Condensate Piping<br />

These air handlers come standard with<br />

pan. Drain connections are provided<br />

on both sides of the air handler, See<br />

Figure 5.<br />

When it has been decided which nipple<br />

is to be used, remove the plug from<br />

that nipple only.<br />

Important<br />

Figure 6<br />

When air handler is installed in the<br />

vertical position and close proximity<br />

trapping of condensate is required, use<br />

of a subbase accessory to raise the air<br />

handler for clearance of the drain trap<br />

is recommended. For a typical drain<br />

trap assembly, see figure 6<br />

15

TRANE ® 16<br />

Unit Installation - Indoor Unit<br />

Duct Connections<br />

The supply and return ducts should be<br />

connected to the unit with flame<br />

retardant duct connectors to reduce<br />

vibration transmission. The return duct<br />

should be sized to the same dimensions<br />

as the return inlet of the unit.<br />

Electrical Connections<br />

Warning<br />

When installing or servicing this<br />

equipment, always exercise basic<br />

safety precautions to avoid the<br />

possibility of electric shock that could<br />

result in severe personal injury or death.<br />

1. All electrical lines, sizing, protection,<br />

and grounding must be in<br />

accordance with local codes.<br />

2. lf conduit is used, isolate whenever<br />

vibration transmission may cause a<br />

noise problem<br />

within the building structure.<br />

3. Ensure all connections are tight and<br />

no wires exposed.<br />

4. All accessories must be installed and<br />

wired according to the instructions<br />

packaged with that accessory.<br />

Thermostat & Control<br />

Connection<br />

- Mount the thermostat in the desired<br />

location.<br />

- Install color coded cables between<br />

outdoor unit, indoor unit and<br />

thermostat.<br />

- Connect control wiring to the terminal<br />

board located on the side of the fan<br />

control box.<br />

Figure 7<br />

Checkout Procedure<br />

Complete the "Installation Checklist"<br />

at the end of this manual once installed<br />

all field wiring connections. All<br />

operational checks (unit running) must<br />

be made after outdoor unit is installed<br />

and system interconnection is<br />

complete.<br />

Installation Checklist<br />

Complete this checklist once the unit is<br />

installed to verify that all recommended<br />

procedures have been accomplished<br />

before the system is started.<br />

Operational checks cannot be<br />

performed until the system<br />

interconnection is complete.<br />

• Verify that the unit electrical power is<br />

disconnected.<br />

• Inspect all field wiring connections.<br />

All connections should be clean and<br />

tight.<br />

• Inspect unit ground connection(s).<br />

Ground must comply with all<br />

applicable codes.<br />

• Inspect unit suspension arrangement<br />

(if used). Unit position must be<br />

secure. Remove any tools or debris<br />

found in or near the unit.<br />

• Inspect duct outlets. Outlets must be<br />

open and unrestricted.<br />

• Inspect unit drain lines. Pipe<br />

connections must be tight and drain<br />

line unrestricted.<br />

• Inspect fan assembly to insure all<br />

moving parts move freely.<br />

• lf unit is horizontally mounted, make<br />

sure secondary drain pan has been<br />

installed.<br />

• Inspect unit for proper filters, securely<br />

installed. All cabinet panels must be<br />

secured.<br />

• Inspect owner/operator on proper<br />

system operating and maintenanced<br />

procedure.

TRANE ®<br />

System Refrigerant Piping<br />

Structural Preparation for<br />

Outdoor Unit<br />

Holes must be made in the structure to<br />

run refrigerant lines. For the majority<br />

of ground-level installations, the holes<br />

can be made in the header that rests<br />

on top of the foundation. Alternatively,<br />

these holes may also be made in the<br />

foundation itself. On roof-mounted<br />

units, refrigerant lines should enter the<br />

building as close to the unit as possible;<br />

preferably within 76 to 102mm of the<br />

refrigerant connection on the unit, plus<br />

a 152 mm (long radius) 90 degree ell<br />

entering the building (See Figure 8).<br />

Table 2 - Recommended Interconnecting Lines - Condensing Units<br />

Model 0-20 21-40 41-60 61-80<br />

Liq. Suct. Liq. Suct. Liq. Suct. Liq. Suct.<br />

TTA075<br />

TTA100<br />

TTA125<br />

1/2<br />

1/2<br />

1/2<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1/2<br />

1/2<br />

1/2<br />

Route refrigerant piping for minimum<br />

linear length, minimum number of<br />

bends and fittings (no reducers) and<br />

minimum amount of line exposed to<br />

outdoor ambient.<br />

Length of Interconnecting Line (feet)<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1/2<br />

1/2<br />

1/2<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1/2<br />

1/2<br />

1/2<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

c. lnsulate all refrigerant lines and<br />

joints<br />

d. Pitch all horizontal suction lines<br />

down towards the unit to assist<br />

gravity oil drainage back to the<br />

compressor.<br />

Figure 8 Roftop Mounted Unit<br />

Refrigerant Piping<br />

Guidelines<br />

a.Maximum recommended line<br />

lengths: (per circuit)<br />

Maximum linear length 200 Ft.<br />

Maximum suction line lift 60 Ft.<br />

Maximum liquid line lift 60 Ft.<br />

e. Avoid creating large oil traps in<br />

horizontal suction lines as this will<br />

reduce oil circulating in the system<br />

and may eventually lead to failure of<br />

the compressor.<br />

f. A small oil trap at the end of a<br />

horizontal suction line before a long<br />

vertical riser (of more that 4 meters)<br />

has the advantage of assisting the<br />

high velocity gas to carry the oil up<br />

the vertical pipe.<br />

b. Maximum allowable pressure drops<br />

(R-22):<br />

Suction line<br />

6 psi.<br />

Liquid line<br />

35 psi.<br />

(without subcooler)<br />

Route refrigerant piping for<br />

minimum linear length, minimum<br />

number of bends and fittings (no<br />

reducers) and minimym amount of<br />

line exposed to outdoor ambients.<br />

17

TRANE ® 18<br />

System Refrigerant Piping<br />

Refrigerant Piping<br />

Procedures (Outdoor Unit)<br />

Each unit ships with a dry nitrogen. Due<br />

to this, the charge has to be removed<br />

and the entire system evacuated (at the<br />

proper time) to avoid possible<br />

contamination.<br />

1. Remove the compressor service<br />

access panel.<br />

2. Find the liquid and suction line<br />

service valves. Check that the<br />

piping connection stubs on the<br />

valves line up properly with the<br />

holes in the unit cabinet.<br />

3. Puncture the seal cap on the service<br />

connection stubs to release<br />

remaining refrigerant and nitrogen<br />

(See Figure 9)<br />

5. Cut, fit and braze tubing, starting at<br />

the outdoor unit and work toward the<br />

indoor unit.<br />

Note: Use long radius ells for all 90-<br />

degree bends. All brazing should be<br />

done using 14 to 56kPa dry nitrogen<br />

purge flowing through the pipe being<br />

brazed (See Figure 10).<br />

Caution: Wet-wrap all valves and<br />

protect painted surfaces from excessive<br />

heat. Heat can damage system<br />

components and the units finish.<br />

Note: Install a pressure-regulating valve<br />

between the nitrogen source and the<br />

gauge manifold (See Figure 10).<br />

Unregulated pressure will damage the<br />

unit components.<br />

Leakage Test<br />

Figure 9<br />

Warning: Do not heat the seal caps<br />

unless they have been punctured. If<br />

caps are intact, application of heat may<br />

generate excessive pressure in the<br />

connection stub, causing personal<br />

injury or death due to rupturing of<br />

components and damage to the service<br />

valve.<br />

After the brazing operation of refrigerant<br />

lines to both the outdoor and indoor unit<br />

is completed, the field-brazed<br />

connections must be checked for leaks.<br />

Pressurize the system through the<br />

service valve with dry nitrogen to<br />

1.4MPa. Use soap bubbles or other<br />

leak-checking methods to ensure that<br />

all field joints are leak free. If not,<br />

release pressure, repair and repeat leak<br />

test (See Figure 10).<br />

4. Heat and remove the seal cap and<br />

open the service valve slowly to<br />

release the Nitrogen from the unit.<br />

Caution: Do not remove the seal caps<br />

from refrigerant connections before unit<br />

prepared to braze refrigerant lines to the<br />

connections. Excessive exposure to<br />

atmosphere may allow moisture or dirt<br />

to contaminate the system, damaging<br />

valve seats and causing ice format ion<br />

in system components.<br />

Figure 10

TRANE ®<br />

System Refrigerant<br />

Charging Procedures<br />

Unit Evacuation<br />

1. Evacuate the unit after leakage test.<br />

2. Attach appropriate hoses from<br />

manifold gauge to suction and liquid line<br />

charging port (See Figure 11).<br />

Refrigerant Line Insulation<br />

and Isolation<br />

Insulate the suction line and refrigerant<br />

tubes together, and also insulate liquid<br />

lines exposed on extreme temperatura.<br />

Insulate liquid and suction line<br />

separately and isolate them from each<br />

other. Isolate all refrigerant tubes from<br />

the structures and air ducts.<br />

Note: Isolate the refrigerant tubes from<br />

the building to avoid possible noise and<br />

vibration.<br />

Figure 11<br />

Note: Unnecessary switching of hoses<br />

can be avoided and complete<br />

evacuation of all lines leading to sealed<br />

system can be accomplished with<br />

manifold center hose and connecting<br />

branch hose to a cylinder of refrigerant<br />

and vacuum pump.<br />

Figure 12<br />

3. Connect the center hose of manifold<br />

gauge to a vacuum pump.<br />

4. Evacuate the unit to hold a 46Pa<br />

vacuum.<br />

5. Close the valve to the vacuum pump<br />

and observe the gauge. If gauge<br />

pressure rises above 66Pa within a<br />

minute, it indicates that the vacuum<br />

is not completed or the system has a<br />

leak.<br />

6. If the gauge pressure does not rise<br />

above 66Pa within a minute, it<br />

indicates that the vacuum is<br />

completed.<br />

19

TRANE ® 20<br />

Field Wiring Instructions<br />

Table 6 - Electrical Data - Outdoor Unit<br />

Model<br />

Power supply<br />

Compr. 1<br />

RLA LRA Qty.<br />

Fan Motor @ 415V<br />

KW FLA Qty.<br />

UNIT<br />

MCA<br />

Max Fuse Size &<br />

MCB<br />

TTA 075<br />

TTA 100<br />

TTA 125<br />

360-440 V / 3Ph/50Hz<br />

360-440 V / 3Ph/50Hz<br />

360-440 V / 3Ph/50Hz<br />

12.4<br />

15.9<br />

17.9<br />

95<br />

125<br />

125<br />

1<br />

1<br />

1<br />

0.6<br />

0.6<br />

0.6<br />

1.3<br />

1.3<br />

1.3<br />

1<br />

1<br />

1<br />

16.8<br />

21.2<br />

23.7<br />

29<br />

37<br />

42<br />

Power Supply of the Indoor<br />

/ Outdoor Unit<br />

The installer must provide line voltage<br />

circuit (s) to the unit main power<br />

terminals as shown by the unit wiring<br />

diagrams in wiring. Power supply must<br />

include a disconnect switch in a location<br />

convenient th the unit. Ground the unit<br />

according to local codes and provide<br />

flexible conduit if codes require and/or<br />

if vibration transmission may cause<br />

noise problems.<br />

Important: All the wiring should be in<br />

accordance with local and national<br />

codes. Type and location of disconnect<br />

switch should conform to all general<br />

codes.<br />

Refer to the unit nameplate to detemine<br />

proper wire sizes and protective fusing<br />

requirements. Field wiring diagram for<br />

accessories are shipped in the<br />

accessory.<br />

Low Voltage<br />

Interconnecting Wiring<br />

Install indoor thermostat according to<br />

thermostat installation instructions.<br />

Colorful and rainproof multi-core cable<br />

installation should refer to internal<br />

wiring diagram in this manual. For field<br />

installation, refer to the related section<br />

in this manual for detailed wiring<br />

requirements to connect thermostat to<br />

indoor and outdoor units and wire<br />

routing.<br />

Caution: Use copper conductor only.<br />

Aluminum conductor can not match the<br />

unit terminals. Use of improper wiring<br />

material will damage the equipment.<br />

Warning: Open electrical disconnect<br />

switch and lock it close position to<br />

prevent accidental power application.<br />

Failure to do so may result in serious<br />

personal injury or death due to electrical<br />

shock.

TRANE ®<br />

Schematic Wiring Diagram<br />

Dol Starter With Crankcase<br />

Heater Sales Option 240Vac Control<br />

21

TRANE ® 22<br />

Interfacing Wiring Diagram<br />

1 Fan Speed + 1 or 2 Cool

TRANE ®<br />

Interfacing Wiring Diagram<br />

3 Fan Speed + 1 Cool<br />

23

TRANE ® 24<br />

Wired Control Installation<br />

Locate and attach the<br />

wired control as follows:<br />

1. Do not place the control near heat<br />

sources or expose to the direct rays<br />

of the sun.<br />

2. Do not expose the control to the<br />

indoor unit's supply air stream.<br />

3. Do not place in a confined space.<br />

4. Attach the remote control holder as<br />

shown in Figure 13.<br />

Dimension<br />

Figure 13<br />

Remote Control<br />

Mounting Bracket

TRANE ®<br />

Wired Control<br />

1. Fan<br />

Fan button is not applicable on this<br />

dual stage controller model. The fan<br />

is powered by a single speed motor.<br />

2. Power On/Off<br />

Press POWER button will turn on/ off<br />

the air conditioner. When turned on,<br />

it will operate according to the last program<br />

setting.<br />

3. Temperature Setting<br />

The temperature can be set the range<br />

of 15 O C - 30 O C.<br />

4. Sleep<br />

The facility to raise up the setting<br />

temperature 1 O C (in Cool mode for<br />

the purpose of comfort and energy<br />

saving.<br />

5. Operating Mode<br />

Press MODE button to select system<br />

operating modes. The air conditioner<br />

can be put in 2 modes Only. (COOL<br />

and FAN ).<br />

6. Compressor Status<br />

Dot LED after second digit of 7 -<br />

segment LED, if lit indicates the<br />

compressor is on.<br />

7. Timer<br />

The facility to turn on/off the air<br />

conditioner is 15 hours in advance<br />

TIMER OFF To set timer off by<br />

pressing TIMER button during air<br />

conditioning is on, TIME LED will blink<br />

and will show last hour time setting in<br />

blinking light. Pressing HOUR or<br />

HOUR to increase or decrease hour<br />

digit (between 1 to 15 can be set).<br />

TIMER ON Using same procedure to<br />

set timer off except press TIMER<br />

button during air conditioner is off.<br />

25

TRANE ® 26<br />

System Operation<br />

Notes:<br />

·If TIMER LED is off, HOUR and<br />

HOUR button do not function.<br />

·If TIMER LED is on, pressing<br />

HOUR and HOUR button will<br />

change display time setting to show<br />

hour set left with blinking light. If press<br />

HOUR and HOUR button will<br />

change display to new time setting.<br />

·If the air conditioner stops by power<br />

failure, setting of timer on/off will be<br />

cancelled.<br />

·If POWER button is pressed during<br />

setting if timer, setting of timer on/off<br />

will be cancelled and remote will turn<br />

on/off air conditioner as normal.<br />

·If POWER button is pressed again<br />

during setting time will be cancelled.<br />

Display Unit<br />

The following LEDs are used to<br />

indicates the status,<br />

A LED (in Fan Button) shows when the<br />

fan speed is put in AUTO mode, SLEEP<br />

LED shows the system is put in sleep<br />

mode,<br />

TIMER LED shows when set the timer<br />

on/off. FAN/COOL/LED shows the<br />

operating mode of the air conditioner.<br />

Temperature Display (7-segment LED,<br />

2 digits) show<br />

- The room temperature.<br />

- The setting temperature while blinking.<br />

- "rE", show the room sensor is open or<br />

short circuit.<br />

- "FE" show the freeze sensor is open<br />

or short circuit.<br />

- "Fr" show the evaporator coil is freeze.<br />

System Features<br />

1. Watchdog<br />

There is a circuit in the system to<br />

watch the operation of the<br />

microprocessor.<br />

2. Compressor Delay Proctection<br />

There is a time delay for the<br />

compressor starts to restart.<br />

3. Compressor Minimum on Time<br />

Once the compressor starts to<br />

operate, it will not stop unless the<br />

compressor on time is at least 24<br />

seconds.<br />

4. Non-Volatile Memory<br />

(Auto Restart)<br />

After power interruption, the control<br />

will resume its operation with same<br />

setting parameters except those<br />

related to the time.<br />

5. Freeze Function (Optional)<br />

The facility to stop the compressor if<br />

the indoor coil temperature is below<br />

0 o C.<br />

Operating Precautions<br />

This system must be installed properly<br />

by a qualified installer in accordance with<br />

installation instructions.<br />

Anti-Recycle Timer<br />

- The control system has a build-in 3<br />

minute anti-recycle timer which helps<br />

to preserve the life of system<br />

components.<br />

- Anti-Recycle Timer occur during<br />

operation of unit:<br />

· Temperature setting is adjusted<br />

back and forth.<br />

· ON/OFF switch is turned ON and<br />

OFF.<br />

· Room temperature reaches the<br />

set point.<br />

· Power failure.<br />

Once any of the above conditions<br />

occurs, the anti-recycle timer will start<br />

preventing the operation of the outdoor<br />

unit for approximately 3 minutes.<br />

Freeze Protection<br />

The system is protected against low<br />

indoor coil temperatures. Under certain<br />

conditions, the "COOL/DRY" LED will<br />

blink indicating the proctive function has<br />

been activated. There is no need to<br />

adjust the system.<br />

Stop the air conditioner at<br />

once if any the following<br />

occurs:<br />

- The power cord is too hot to be<br />

touched by hand.<br />

- The insulation of the power cord is<br />

exposed at any point.<br />

- The fuse is blown or circuit breaker<br />

trips frequently.<br />

- The functions of the switches are<br />

inaccurate.<br />

Operating air conditioner<br />

safety.<br />

- Do not insert a bar or similar object<br />

into the supply air outlet.<br />

- Do not pour water directly on the air<br />

conditioner to clean it. If the air<br />

conditioner is operating as wet,<br />

grounding may occur, damaging the<br />

unit.<br />

- Adjust the air flow so it does not blow<br />

directly on room occupants.<br />

- Do not use flammable sprays near the<br />

air conditioner because of danger of<br />

fire.<br />

- Do not use a steel or copper wire in<br />

place of fuses.

TRANE ®<br />

Operation and Start-up<br />

Preparation<br />

Perform the following checks and<br />

inspections before operating the unit:<br />

Inspection Checklist<br />

Unit is mounted securely to the ceiling<br />

support rods (mounting units).<br />

Ductwork connections are complete.<br />

Coil connections are complete and<br />

tight.<br />

Condensate drain pan connections<br />

are complete and tight.<br />

Electrical connections are completed.<br />

Wiring is correct and in accordance<br />

with the wiring diagram.<br />

Ground connection is completed.<br />

Check and retighten if necessary set<br />

screws on the drive, fan pulley, fan<br />

bearings and wheel.<br />

Rotate fan by hand, to ensure that it<br />

runs freely and that there is no<br />

interference.<br />

Check that fan is centrally located in<br />

the housing, axially and radially.<br />

Check and retighten, if necessary,<br />

drive and bearing bolts, motor clamp<br />

plate bolts and isolator bolts.<br />

Check to ensure that pulley are<br />

correctly aligned and that shafts are<br />

parallel.<br />

Check belt tension as per instruction<br />

given in the maintenance section.<br />

If it does not, the power supply should<br />

be switched off at once and all<br />

connections, as well as the power<br />

supply, be re-checked before restarting.<br />

d. In the event of excessive vibrations<br />

or unusual noises, the motor should<br />

be disconnected from the load and<br />

checked for poor alignment, loose<br />

mounting bolts, etc.<br />

e. When the motor has been operated<br />

under load for a short period of time,<br />

check that the operating current totally<br />

with the nameplate current.<br />

Start-Up Procedures<br />

After completing all times under "Pre-<br />

Start-Up", the unit may be started and<br />

the following checks and adjustments<br />

performed.<br />

a. Measure the motor voltage and amps<br />

on all phases to insure proper<br />

operation. Compare these readings<br />

with the motor nameplate.<br />

b. Disconnect load and start motor to<br />

check the direction of rotation. If the<br />

rotation need to be changed, stop the<br />

motor completely and change the<br />

direction of rotation.<br />

c. After connecting the load, the motor<br />

should start quickly and run smoothly.<br />

27

TRANE ® 28<br />

Maintenance<br />

Warning<br />

Disconnect electrical power source and<br />

secure in disconnected position before<br />

servicing the unit. Failure to do so may<br />

result in personal injury or death from<br />

electrical shock.<br />

Monthly Inspection<br />

1. Check condition of air filters and<br />

replace them if necessary.<br />

2. Check the drain pan to be sure that it<br />

is clean and free to carry the flow of<br />

condensate through the drain line.<br />

3. Check the coil surface for cleanliness.<br />

Clean if necessary.<br />

Yearly Inspection<br />

1. Replace filters.<br />

2.Check coil surface. Clean by<br />

vacuuming or flushing with cold<br />

water. Do not use steam or hot water.<br />

3. Carry out checks as detailed in<br />

inspection checklist in the Operation<br />

Section.<br />

4. Inspect the condition of the<br />

evaporator fan belt and replace if<br />

necessary. The belts fitted to TWE<br />

units cannot achieve design<br />

performance without the correct<br />

tensioning.<br />

5. Check condition of vibration isolators,<br />

replace if there is any sign of wear,<br />

loosening or material deterioration.<br />

6.Check fan bearings for noisy<br />

operation and excessive lubricant<br />

leakage. Replace if necessary.<br />

7. Inspect the condensate drain pan and<br />

condensate piping to make sure they<br />

are clear and will carry away all<br />

water.<br />

8. Inspect the control panel wiring to<br />

make sure connections are tight and<br />

insulation is intacted.<br />

Change/ Clean Filters<br />

Change or clean air filters at least twice<br />

a year. Filters will be required more<br />

frequent care under high load condition<br />

or dirty air. A clogged air filters reduces<br />

airflow, cooling capacity and increases<br />

energy usage.<br />

To clean permanent filters, the filter<br />

media and wash it in water to remove<br />

dust, dirt and lint, allow to dry thoroughly<br />

before re-installing in the units.<br />

Do not rub or wring.<br />

Permanent filters can also be cleaned<br />

by blowing with compressed air in<br />

opposite direction of filter airflow.<br />

Belt Maintenance<br />

Clean fan belts and pulleys with a dry<br />

cloth. Oil and grease must be kept off<br />

belts. The use of a belt dressing is not<br />

recommended. When replacing belts,<br />

use a matched set.<br />

Do not force belts onto pulleys, but<br />

adjust motor position to allow mounting<br />

and then re-tighten.<br />

Figure 14<br />

To measure belt tension, use a belt<br />

tensioner as shown in Figure 14.<br />

Determine actual deflection by<br />

depressing one belt tensioner and then<br />

adjust the belt tension to the correct<br />

pounds force and tighten all setscrews<br />

to the proper torques.

TRANE ®<br />

Trouble Analysis<br />

A. Compressor fails to starts<br />

Problems and symptoms<br />

Full voltage at motor terminal but motor<br />

will not run.<br />

Inoperative motor starter.<br />

Open contacts of safety control of<br />

thermal overload.<br />

Electric circuit test shows no current<br />

on line side of motor starter.<br />

Electric circuit test show current on line<br />

but not on motor side or fuse.<br />

Voltmeter does not read proper voltage.<br />

Motor starter holding coil is not<br />

energized.<br />

Probable cause<br />

Burned-out motor.<br />

Burned-out holding coil or broken<br />

contacts.<br />

Safety control of thermal overload<br />

relays has cut outs.<br />

a) Power failure.<br />

b) Disconnect switch open.<br />

Fuse down. Replace fuse<br />

Low voltage<br />

Open control circuit.<br />

Compresoor will not operate.<br />

Open contact on high pressure switch.<br />

Discharge pressure above cut-in<br />

setting.<br />

Frozen compressor due to locked or<br />

damaged mechanism<br />

Discharge pressure above cut-in<br />

setting of high pressure cut-out switch<br />

B. Compressor stops<br />

Problems and symptoms<br />

High pressure control has cut out.<br />

Thermal overload relay has cut out.<br />

Winding thermostat has cut out.<br />

Probable Cause<br />

See H.<br />

a) voltage too low<br />

b)cooling load or condensing<br />

temperature too high<br />

Refrigerant shortage<br />

29

TRANE ®<br />

Trouble Analysis<br />

C. Compressor shortcycles<br />

Problems and symptoms<br />

Suction pressure too low and frosting<br />

at driver.<br />

Motor starts and stops frequently<br />

Probable cause<br />

Restricted liquid liner driver.<br />

Faulty motor.<br />

Recommended action<br />

Replace driver core.<br />

Replace compressor.<br />

D. Compressor runs Continuously<br />

Problems and symptoms<br />

High temperature in conditioned space.<br />

Bubbles in sight glass<br />

E. Compressor loses oil<br />

Problems and symptoms<br />

Oil level too low (sight glass).<br />

Gradual drop of oil level.<br />

Excessively cold suction.<br />

Noisy compressor<br />

F. Compressor is noisy<br />

Problems and symptoms<br />

Abnormally cold suction line:<br />

compressor knocks. Valve bulb<br />

attachment.<br />

Compressor noisy<br />

G. System short of capacity<br />

Problems and symptoms.<br />

Expansion valve hissed.<br />

High pressure drop across filter-drier.<br />

Superheat too high.<br />

Superheat too high.<br />

Probable cause<br />

Excessively high cooling load<br />

a) Lack of refrigerant.<br />

b) Filter driver obstructed<br />

Probable cause<br />

Insufficient oil charge.<br />

Clogged filter drier<br />

Liquid flooding back to compressor<br />

Probable cause<br />

a) Liquid flood-back<br />

b)Expansion Valve stuck in open<br />

position.<br />

Incorrect direction of rotation<br />

Probable cause.<br />

Lack of refrigerant.<br />

Clogged filter-driver.<br />

Superheat set too high.<br />

Excessive pressure drop in the<br />

thermal expansion valve.<br />

Recommended action<br />

Check infiltration and insulation of<br />

conditioned space.<br />

a) Repair leak, add refrigerant.<br />

b) Replace driver core.<br />

Recommended action<br />

All oil.<br />

Replace.<br />

Readjust superheat setting and verify<br />

correct bulb mounting.<br />

Recommended action<br />

a) Check superheat and expansion.<br />

b) Repair or replace<br />

Inverse the direction of rotation<br />

Recommended action<br />

Add refrigerant.<br />

Clean or replace.<br />

Check superheat and adjust<br />

expansion valve<br />

Check superheat and reset thermal<br />

expansion valve<br />

30

TRANE ®<br />

Trouble Analysis<br />

H. Discharge pressure too high<br />

Problems and symptoms<br />

Too little or too warm condenser air.<br />

Restricted air flow.<br />

Excessive discharge pressure.<br />

Probable cause<br />

Excessively warm air leaving<br />

condenser.<br />

Cuts out on high pressure control.<br />

Air or noncondensible gas in system.<br />

Recommended action<br />

Clean coil, check fan and motor for<br />

proper operation.<br />

Remove air or non condensibles.<br />

J. Discharge pressure too high<br />

Problems and symptoms<br />

Bubbles in sight glass.<br />

Probable cause<br />

Lack of refrigerant.<br />

Recommended action<br />

Repair leak and charge.<br />

K. Discharge pressure too high<br />

Problems and symptoms<br />

Compressors run continuously.<br />

Abnormally cold suction line; liquid<br />

flood-back to compressor.<br />

Probable cause<br />

Excessive load on evaporator<br />

a) Expansion valve opens too far.<br />

b) Expansion valve stuck in open<br />

position.<br />

Recommended action<br />

Check system.<br />

a) Adjust superheat and check bulb<br />

attachment.<br />

b) Repair or replace.<br />

L. Discharge pressure too high<br />

Problems and symptoms<br />

Bubbles in sight glass.<br />

High pressure drop across filter-driver.<br />

No refrigerant flow through expansion<br />

valve.<br />

Loss of capacity.<br />

Superheat too high.<br />

This is by no means a complete<br />

analysis of the scroll refrigeration<br />

system. Instead, its intention is to<br />

Probable cause<br />

Lack of refrigerant.<br />

Clogged filter drier.<br />

Expansion valve power element has<br />

lost charge.<br />

Obstructed expansion valve.<br />

Too much pressure drop in evaporator.<br />

familiarize the operator with the<br />

operation of the scroll unit and provide<br />

the background necessary for him to<br />

Recommended action<br />

Repair leak, add refrigerant.<br />

Replace.<br />

Replace valve power element.<br />

Clean or replace.<br />

Check external equaliser of expansion<br />

valve.<br />

recognize and accurately correct or<br />

report any developing problem.<br />

31

Trouble Analysis -<br />

Discharge Chart<br />

System<br />

Faults<br />

Power Supply<br />

High Voltage Wiring<br />

Low Voltage Wiring<br />

Control Transformer<br />

Thermostat<br />

Low Voltage Fuse<br />

Curcuit Breaker<br />

Relay (Fan)<br />

Capacitor (Fan)<br />

Thermal Cutout<br />

Low Indoor Airflow<br />

High Indoor Airflow<br />

Refrig. Undercharge<br />

Refrig. Overcharge<br />

Excessive Evap. Load<br />

Check Valve (Leaking)<br />

Restriction LD Coll<br />

Restriction(TXV or CAP)<br />

Refrigerant Circuit<br />

TRANE ® 32<br />

Head Pressure Too High<br />

Head Pressure Too Low<br />

Suction Pressure Too High<br />

Suction Pressure Too Low<br />

Indoor Coil Frosting<br />

Liquid Floodback (TXV)<br />

Liquid Floodback (Cap.Tube)<br />

Electrical<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

I.D. Motor Won' t Start<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P Primary Causes - S Secondary Causes

TRANE ®<br />

Commissioning Log Sheet<br />

START-UP ENGINEER/TECHNICIAN NAME : _____________________________________________________<br />

PROJECT NAME<br />

:_____________________________________________________<br />

DEALER/CONTRACTOR<br />

:_____________________________________________________<br />

SALES OFFICE LOCATION<br />

:_____________________________________________________<br />

DATE COMMISSIONED<br />

:_____________________________________________________<br />

1. Nameplate information<br />

Model No: _____________________ Serial No. _____________________________________________________<br />

Voltage: _____________________ RLA: _____________________________________________________<br />

2. Compressor ( S)<br />

A. Voltage at Compressor Terminals<br />

Comp. No. 1: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 2: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 3: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 4: T1 ________________ T2 ________________ T3 ________________<br />

Voltage lmbalance: Comp. "1" ____________ Comp. "2" ____________<br />

Comp. "3" ____________<br />

Comp. "4" ____________<br />

B. Amp Draw<br />

Comp. No. 1: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 2: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 3: T1 ________________ T2 ________________ T3 ________________<br />

Comp. No. 4: T1 ________________ T2 ________________ T3 ________________<br />

3. Operating Conditions<br />

A. Circuit "A"<br />

Discharge Pressure. ___________________________ Suction Pressure. __________________________<br />

Liquid Line Pressure. ___________________________ Suction Line Temp. __________________________<br />

Liquid Line Temp. ___________________________ SuperHeat. __________________________<br />

Subcooling.<br />

___________________________ Evap. Entering Air Temp. (DB/WB) _______________<br />

Amblent Temp. ___________________________ Evap. Discharge Air Temp. (DB/WB) _______________<br />

B. Circuit "B"<br />

Discharge Pressure. ___________________________ Suction Pressure. __________________________<br />

Liquid Line Pressure. ___________________________ Suction Line Temp. __________________________<br />

Liquid Line Temp. ___________________________ SuperHeat. __________________________<br />

Subcooling.<br />

___________________________ Evap. Entering Air Temp. (DB/WB) _______________<br />

Amblent Temp. ___________________________ Evap. Discharge Air Temp. (DB/WB) _______________<br />

4. Controls<br />

A. All Fans Operating [ ] Yes ___________<br />

Properly? [ ] No ___________ Fan lnoperative<br />

5. Refrigerant Piping<br />

Evacuation Level ___________________ System Charge ___________________<br />

33

TRANE ® 34<br />

Installation Checklist<br />

Trane Air Cooled Condensing Unit<br />

This list must checked off by the installer to ensure correct installation before the unit start up.<br />

Unit acceptance<br />

Check for damage, if any, on transportation<br />

Check for equipment shipped against delivery slip<br />

Check lifting system<br />

Unit positioning<br />

Remove packaging<br />

Check position of unit<br />

Check unit is level<br />

Check clearance around condenser<br />

Check clearance required for maintenance access<br />

Check position of rubber pads<br />

Refrigerant circuit<br />

Check filter dryer and sight glass presence<br />

Check oil traps presence on discharge line ( if there vertical risers>3m)<br />

Check pitch for horizontal lines ( 1 cm/m)<br />

Check refrigerant presence<br />

Electrical equipment<br />

Check direction of rotation of compressors and fan motors<br />

Check installation and rating of mains power switch/fuse<br />

Check that electrical connections comply with specification<br />

Check that electrical connections match information on manufacturer' s identification plate<br />

Check electrical connections and connections to mains power switch<br />

General<br />

Check available cooling charge (50% of rated installation load)<br />

Check with other handling installation works<br />

Comments:........................................................................................................................................................................................................<br />

..............................................................................................................................................................................................................................<br />