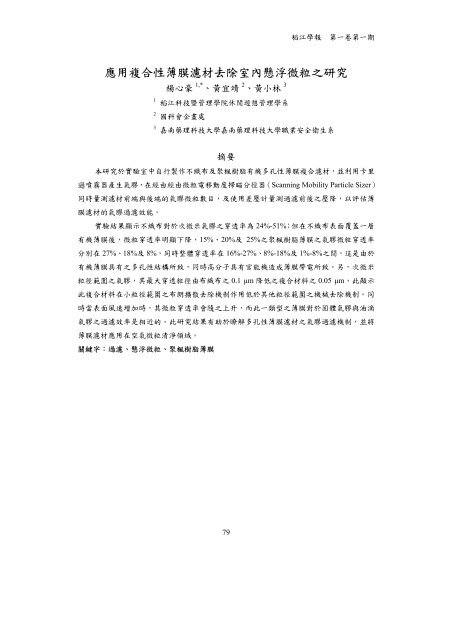

æç¨è¤åæ§èè濾æå»é¤å®¤å §æ¸æµ®å¾®ç²ä¹ç 究 - ç 究ç¼å±è - 稻æ±ç§æ ...

æç¨è¤åæ§èè濾æå»é¤å®¤å §æ¸æµ®å¾®ç²ä¹ç 究 - ç 究ç¼å±è - 稻æ±ç§æ ...

æç¨è¤åæ§èè濾æå»é¤å®¤å §æ¸æµ®å¾®ç²ä¹ç 究 - ç 究ç¼å±è - 稻æ±ç§æ ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

濾 粒 <br />

1,* 靖<br />

2 林<br />

1 理 理 <br />

2 <br />

3 理 理 <br />

3<br />

<br />

行 不 濾 利 里<br />

粒 度 Scanning Mobility Particle Sizer<br />

量 濾 粒 數 量 濾 降 <br />

濾 濾 <br />

不 率 24%-51% 不 <br />

粒 率 降 15%20% 25% 粒 率<br />

27%18% 8% 率 16%-27%8%-18% 1%-8%<br />

<br />

粒 粒 0.1 µm 降 料 0.05 µm<br />

料 粒 朗 粒 <br />

粒 率 類 <br />

濾 率 濾 濾 <br />

濾 粒 領 <br />

濾 粒 <br />

79

Removal of Indoor Particulates by using the<br />

Polysulfone-Nonwoven Composite membrane filters<br />

Shinhao Yang 1,* , Yi-Chin Huang 2 , Hsiao-Lin Huang 3<br />

1 Department of Leisure and Recreation Management, Toko University<br />

2 Planning and Evaluation Division, National Science Council<br />

3 Department of Occupational Safety and Health, Chia Nan University of Pharmacy & Science<br />

Abstract<br />

Filtration is one of the most effective and reliable methods for the collection of small size<br />

particulate matters from gas stream. The polysulfone-nonwoven composite membrane filter made<br />

from porous organic membrane and nonwoven matrix was used to study the filtration efficiency<br />

of aerosols in this study. Polydisperse aerosols were generated from a Collison Atomizer. The<br />

aerosols were accounted by Scanning Mobility Particle Sizer and the pressure gradient was<br />

measured by the pressure transducers. Thereafter, the filtration efficiency of the composite filter<br />

was determined by the difference of the numbers of the aerosols and the difference of pressure<br />

after filtration.<br />

The results showed that the aerosol penetration rates of nonwoven matrix were ranged from<br />

24% to 51%. However, the aerosol penetration rates decreased significantly after coating porous<br />

organic polysulfone membrane on nonwoven matrix. The aerosol penetration rates of the three<br />

composite filters coating with the polysulfone concentrations of 15 wt%, 20 wt%, and 25 wt%,<br />

respectively, were 27%, 18%, and 8%, respectively. The overall aerosol penetration rates of the<br />

three composite filters were 16%~27%, 8%~18%, and 1%~8%, respectively. It indicated that the<br />

performance of the composite filters was better than that of nonwoven matrix filters owing to<br />

their capability of trapping the aerosols by the porous structure and attracting the aerosols by the<br />

positive charge on the surface of polysulfone membrane. The most penetration particle size<br />

(MPPS) of aerosols shifted from 0.1 µm to 0.05 µm after coating polysulfone membrane on<br />

nonwoven matrix. The results presented that the effect of Brownian diffusion in removing small<br />

size of aerosols was reduced in the composite filters. Additionally, it found that the aerosol<br />

penetration rates of the composite filters for solid and oily aerosols increased with increasing<br />

surface velocity. This study could help us to understand the filtration mechanism of the<br />

composite filters, and furthermore the composite filters can be applied to the the field of aerosol<br />

removal in the future.<br />

Keywords: Filtration; suspended particulates; polysulfone-nonwoven composite membrane<br />

filter<br />

80

1. <br />

量 都 類 都 <br />

度 90%<br />

六 不 良 66.8%<br />

(1991) 87.2%(Indoor<br />

Environment)7.2% 5.6%(Outdoor Environment)<br />

(Lance, 1996) 來 (Indoor Air Quality, IAQ)<br />

粒 來 粒 <br />

粒 不 良 <br />

益 來 粒 <br />

類 濾 來 <br />

粒 濾 來 說 濾 濾 <br />

(fibrous)(fabric)(membrane) 濾 度 <br />

度 濾 不 <br />

濾 來 行 濾 年 <br />

濾 濾 濾 <br />

濾 兩 Nuclepore <br />

(polycarbonate pore filter) 列 行 不 洞 <br />

濾 濾 濾 濾 來 <br />

粒 (Cohen and Hering, 1995)<br />

濾 濾 不 濾 Nuclepore <br />

行 濾 濾 Spurny et al. (1969) 5 µm <br />

(Nuclepore ) 5cm/sec 行 濾 <br />

粒 0.05 µm 易 粒 Spurny et al. (1964) 濾 濾 <br />

沈 粒 Montassier et al. (1996) <br />

Nuclepore 行 率 MF 濾 流<br />

量 率 行 (1999)<br />

濾 行 <br />

濾 濾 濾 度 <br />

粒 不 Larbot et al. (2003) 利 行 <br />

度 兩 烈 濾 率 度 降 NaCl DOP<br />

粒 率 HEPA ULPA 濾 來 <br />

濾 不 不 離 <br />

81

力 濾 度 利 來 濾 <br />

PSF (Polysulfone) 1.24<br />

率 80%-90% 度 零 100 160<br />

度 度 (18.6 kg-cm/cm ) 175<br />

度 FDA<br />

行 <br />

行 奈 粒 濾 濾 <br />

2. <br />

<br />

1. 行 理 濾 濾 <br />

濾 <br />

2. 不 理 度 粒 率 <br />

3. 不 粒 粒 率<br />

4. 不 粒 率 <br />

3. <br />

3.1 濾 理 論<br />

濾 說 濾 粒 率 <br />

率 Single-Fiber Efficiency 濾 率 (Wang, 2001)Fiber<br />

流 粒 數 理 論 <br />

粒 數 率 (Hinds, 1982) 利 量 <br />

率 <br />

πd<br />

f<br />

( 1−α) ln P<br />

E = −<br />

(1)<br />

∑<br />

4Lα<br />

<br />

E ∑ 率<br />

d f <br />

α 濾 率<br />

L 濾 度<br />

P 率<br />

理 論 不 濾 立 率 不<br />

82

濾 Lathrache, 1987<br />

E Σ 1-1- ED 1-E IR 1-E I 1-E G 1-E O 1-E C 1- E IM <br />

=1-1-E m 1-E O 1-E C (2)<br />

沈 E D diffusion depositionE ID direct interception<br />

沈 E I impaction deposition 力 沈 E G gravitational settling<br />

力 E m mechanical capture force 力 E O <br />

dielectrophoretic force 倫 力 E C columbic force 力 E IM image force<br />

力 E E electrostatic capture force <br />

3.2 濾 類<br />

濾 polysulfone (Udel P-3500,<br />

Amoco Performance Products Inc.) NMP (N-methyl -2-pyrrolidinone)<br />

不 NMP 來 不 <br />

度 來 不 濾 15%20%25% 理 論 度 <br />

洞 不 洞 濾 <br />

3.3 粒 <br />

NaClDEHS<br />

利 里 (Collison Atomizer, Model 3076, TSI Inc) 粒 <br />

粒 (silica gel) 粒 <br />

NaCl 數 粒 0.080 µm GSD 1.614 數 粒 0.180<br />

µm GSD 1.609 粒 流 Kr-85 Neutralizer, Model<br />

3077, TSI Inc 粒 粒 粒 <br />

利 Aerosol Electrometer, Model 3068A, TSI Inc 流 <br />

<br />

3.4 濾 率 量 <br />

83

Compressed,<br />

Dry Air<br />

Diffusion<br />

Dryer<br />

Diluted<br />

Air<br />

Kr 85<br />

Aerosol<br />

Electrometer<br />

Air Supply<br />

System<br />

Collison<br />

Atomizer<br />

Filter<br />

Holder<br />

DMA<br />

Pump<br />

Pressure<br />

Gage<br />

PC<br />

Flow<br />

Meter<br />

SMPS System<br />

CPC, 3022<br />

1<br />

粒 率 量 濾 粒 度 SMPS,<br />

Scanning Mobility Particle Sizer, Model 3934, TSI IncPressure Gage, Model 2000,<br />

Dwyer Instruments Inc 流 量 濾 流 濾 <br />

量 濾 粒 度 粒 率 利<br />

量 量 濾 濾 降 利 流 濾 <br />

流 流 量 (0.05 0.1 m/s) 1 <br />

<br />

4. 論<br />

4.1 不 率<br />

2 利 NaCl 粒 0.1 m/s 不 濾 <br />

粒 率 不 濾 理 行 <br />

量 粒 率 不 <br />

粒 0.1 µm 率 51% 粒 率 <br />

24%-51% 濾 粒 0.3 µm <br />

84

濾 粒 0.1 µm 不 <br />

利 來 量 <br />

不 3.1×10 3 V/m<br />

100<br />

90<br />

Nonwoven<br />

80<br />

Aerosol Penetration (%)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10 -2 10 -1 10 0<br />

Aerosol Size (µm)<br />

2 不 濾 0.1 cm/s 粒 率<br />

4.2 濾 率<br />

3 利 NaCl 粒 0.1 m/s 15%<br />

濾 粒 率 粒 0.05-0.06 µm 率 <br />

27% 率 16%-27% 不 <br />

粒 率 降 若 0.3 µm 粒 來 15%<br />

率 來 不 率 50%<br />

降 <br />

度 量 15%<br />

1.9×104 V/m 不 <br />

<br />

<br />

85

100<br />

90<br />

Polysulfone 15%<br />

80<br />

Aerosol Penetration (%)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10 -2 10 -1 10 0<br />

Aerosol Size (µm)<br />

3 濾 0.1 cm/s 粒 率<br />

4.3 不 度 濾 率<br />

4 利 NaCl 粒 0.1 m/s 15%20% 25%<br />

濾 粒 率 不 度 理 濾<br />

粒 0.05-0.06 µm 率 27%18% 8%<br />

率 16%-27%8%-18% 1%-8% 理 度 便 粒 率<br />

降 量 降 0.1 m/s 15%20%<br />

25% 降 1520 24 cmH 2 0 理 度 <br />

降 度 洞 <br />

降 洞 粒 率 降 更 量 <br />

15%20% 25% 1.9×10 4 V/m<br />

2.3×10 4 V/m 2.9×10 4 V/m 更 度 <br />

更 率 度 降 <br />

86

80<br />

Aerosol Penetration (%)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

15% Polysulfone Membrance<br />

20% Polysulfone Membrance<br />

25% Polysulfone Membrance<br />

10<br />

0<br />

10 -2 10 -1 10 0<br />

Aerosol Size (µm)<br />

415%20% 25% 濾 0.1 cm/s 粒 率<br />

4.4 不 濾 率 <br />

100<br />

90<br />

15% Polysulfone Membrance<br />

Aerosol Penetration (%)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

0.1 m/s<br />

0.05 m/s<br />

10<br />

0<br />

10 -2 10 -1 10 0<br />

Aerosol Size (µm)<br />

515% 濾 0.05 0.1 cm/s 粒 率<br />

5 利 NaCl 粒 0.05 0.1 m/s 15%<br />

87

粒 率 0.05 m/s 率 10%-20%<br />

0.1 m/s 粒 率 粒 濾 濾<br />

力 力 降 兩 力 <br />

力 粒 <br />

力 降 <br />

4.5 不 類 濾 率 <br />

80<br />

70<br />

With NaCl Soild Aerosol<br />

With DEHS Oil Aerosol<br />

Aerosol Penetration (%)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

10 -2 10 -1 10 0<br />

Aerosol Size (µm)<br />

615% 濾 0.1 cm/s NaCl DEHS 粒 率<br />

6 利 NaCl 粒 DEHS 粒 0.1 m/s <br />

15% 粒 率 兩 率 16%-27%<br />

類 濾 <br />

濾 濾 略 [9] 不 <br />

<br />

5. 論<br />

1. 不 粒 0.1 µm 率 51% 粒<br />

率 24%-51%<br />

2. 15% 粒 0.05-0.06 µm 率 27%<br />

88

率 16%-27% 1.9×104 V/m<br />

3. 不 粒 率 降<br />

降 <br />

度 不 <br />

4. 理 度 洞 更 <br />

率 度 降 <br />

5. 濾 粒 率 <br />

6. 濾 <br />

參 <br />

(1999) 濾 年 <br />

北 <br />

良 (1991) , EPA-80-F101-09-24<br />

行 <br />

Cohen, B. S., & Hering, S. V. (1995). Air Sampling Instruments for Evaluation of Atmospheric<br />

Contaminants. 8th Edition, ACGIG, Cincinnati, Ohio.<br />

Hind, W. C. (1982). Aerosol Technology, John Wiley and Son, New York.<br />

Lance, W. (1996). Indoor Particles: A Review, Air and Waste Manage. Assoc. 46, 98-126.<br />

Larbot, A., Bertrand, M., Marre, S., Prouzet, E. (2003). Performance of Ceramic Filters for Air<br />

Purification. Sep. Puri. Technol. 32, 81-85.<br />

Lathrache, R., & Fissan, H. J. (1987). Enhancement of Particle Deposition in Filters due to<br />

Electrostatic Effects. Filtration and Separation, 24(6), 418-422.<br />

Martin, S. B., & Moyer, E. S. (2000). Electrostatic Respirator Filter Media: Filter Efficiency and<br />

Most Penetrating Particle Size Effects, Appl. Occup. Environ. Hyg. 15, 609-617.<br />

Montassier, N., Dupin, L., Boulaud, D. (1996). Experimental Study on the Collection Efficiency<br />

of Membrane Filters. J. Aerosol Sci. 27(Suppl. 1), S637-S638.<br />

Spurny, K. R., Lodge, Jr., J. P., Frank, E. R., Sheesley, D. C. (1969). Aerosol Filtration by Means<br />

of Nuclepore Filters: Structural and Filtration properties. Environ. Sci. Technol. 10, 453-464.<br />

Spurny, K., & Pich, J. (1964). The Separation of Aerosol Particles by Means of Membrane Filters<br />

by Diffusion and Inertial Impaction. Int. J. Air Wat. Pollut. 8, 193.<br />

Wang, C. S. (2001). Electrostatic Forces in Fibrous Filters-A Review, Powder Technology. 118,<br />

166-170.<br />

89