Job Report Primary Crushing Plant with HAZEMAG Impact Crusher ...

Job Report Primary Crushing Plant with HAZEMAG Impact Crusher ... Job Report Primary Crushing Plant with HAZEMAG Impact Crusher ...

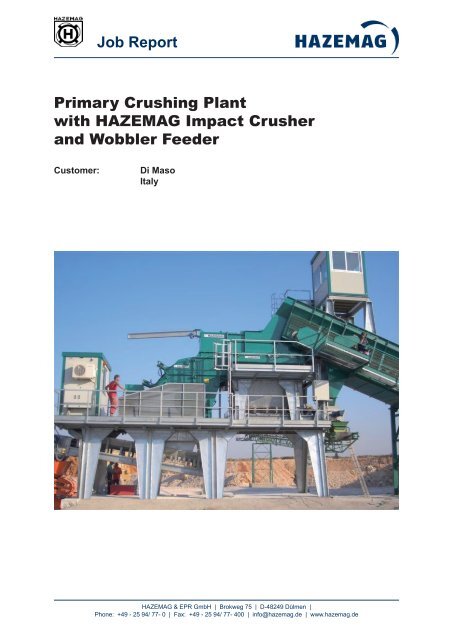

Job Report Primary Crushing Plant with HAZEMAG Impact Crusher and Wobbler Feeder Customer: Di Maso Italy HAZEMAG & EPR GmbH | Brokweg 75 | D-48249 Dülmen | Phone: +49 - 25 94/ 77- 0 | Fax: +49 - 25 94/ 77- 400 | info@hazemag.de | www.hazemag.de

<strong>Job</strong> <strong>Report</strong><br />

<strong>Primary</strong> <strong>Crushing</strong> <strong>Plant</strong><br />

<strong>with</strong> <strong>HAZEMAG</strong> <strong>Impact</strong> <strong>Crusher</strong><br />

and Wobbler Feeder<br />

Customer: Di Maso<br />

Italy<br />

<strong>HAZEMAG</strong> & EPR GmbH | Brokweg 75 | D-48249 Dülmen |<br />

Phone: +49 - 25 94/ 77- 0 | Fax: +49 - 25 94/ 77- 400 | info@hazemag.de | www.hazemag.de

<strong>Plant</strong> Description<br />

<strong>Job</strong> <strong>Report</strong><br />

The Di Maso company in Italy has just invested in the execution of a modern<br />

<strong>HAZEMAG</strong> crushing concept. In addition to the rugged primary impact crusher <strong>with</strong> its<br />

active hydraulic control system, a wobbler feeder has been added to relieve the load<br />

on the crusher and to ensure uniform feeding.<br />

The impact crusher Type AP-PH 1414 is the guarantee for a consistently high quality<br />

product, an excellent degree of operational safety <strong>with</strong> user-friendly maintenance. It is<br />

equipped <strong>with</strong> the very latest active hydraulic control system, by means of which the<br />

impact aprons are locked in position during operation to guarantee a uniform, highquality<br />

product. On entry of any tramp metal, however, the aprons retract immediately<br />

to allow the uncrushable material to pass through, returning to their pre-set position as<br />

soon as the danger has been averted. Moreover, the inlet plate of the impactor can be<br />

moved hydraulically to facilitate the elimination of any jammed material. The blow bars<br />

are well accessible and, thanks to a wedge retaining system, can be removed quickly<br />

and easily. Approximately 90% of the housing wear lining plates are identical and thus<br />

interchangeable.<br />

Upstream of the impactor is the <strong>HAZEMAG</strong> Wobbler Feeder which removes the fines<br />

from the feed material and by this relieves the load on the crusher, thus leading to<br />

reduced power consumption, a lower wear rate and a higher degree of operational<br />

safety. The wobbler feeder efficiency is not affected by moist or sticky material. Thanks<br />

to the horizontal flow system, the installation height is reduced to a minimum, allowing<br />

for uniform, smooth and controlled feeding. In this particular application, the material is<br />

screened off at 50 mm.<br />

Main <strong>Plant</strong> Operating Data:<br />

Feed material: Limestone<br />

Feed size: 0 - 800 mm<br />

Throughput: 300 t/h<br />

Product size: 0 - 50 mm, <strong>with</strong> some oversize<br />

<strong>HAZEMAG</strong> Wobbler Feeder<br />

<strong>HAZEMAG</strong> & EPR GmbH | Brokweg 75 | D-48249 Dülmen |<br />

Phone: +49 - 25 94/ 77- 0 | Fax: +49 - 25 94/ 77- 400 | info@hazemag.de | www.hazemag.de