You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

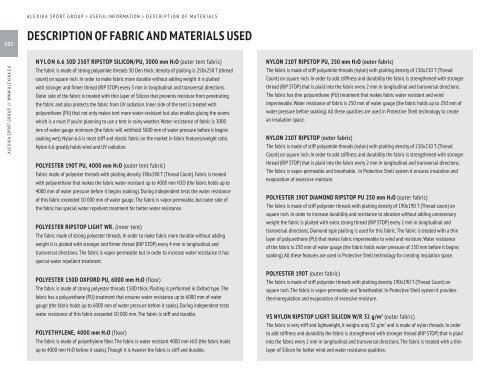

ALEXIKA SPORT GROUP > USEFUL <strong>IN</strong>FORMATION > DESCRIPTION OF MATERIALS<br />

102<br />

DESCRIPTION OF FABRIC AND MATERIALS USED<br />

ALEXIKA SPORT GROUP // WWW.ALEXIKA.EU<br />

N Y LON 6.6 30D 250T RIPSTOP SILICON/PU, 3000 mm H2O (outer tent fabric)<br />

The fabric is made of strong polyamide threads 30 Den thick; density of plaiting is 250x250 T (thread<br />

count) on square inch. In order to make fabric more durable without adding weight it is plaited<br />

with stronger and firmer thread (RIP STOP) every 3 mm in longitudinal and transversal directions.<br />

Outer side of the fabric is treated with thin layer of Silicon that prevents moisture from penetrating<br />

the fabric and also protects the fabric from UV radiation. Inner side of the tent is treated with<br />

polyurethane (PU) that not only makes tent more water-resistant but also enables gluing the seams<br />

which is a must if you’re planning to use a tent in rainy weather. Water-resistance of fabric is 3000<br />

mm of water gauge minimum (the fabric will withhold 3000 mm of water pressure before it begins<br />

soaking wet). Nylon 6.6 is most stiff and elastic fabric on the market in fabric features/weight ratio.<br />

Nylon 6.6 greatly holds wind and UV radiation.<br />

POLYESTER 190T PU, 4000 mm H2O (outer tent fabric)<br />

Fabric made of polyester threads with plaiting density 190x190 T (Thread Count). Fabric is treated<br />

with polyurethane that makes the fabric water-resistant up to 4000 mm H2O (the fabric holds up to<br />

4000 mm of water pressure before it begins soaking). During independent tests the water resistance<br />

of this fabric exceeded 10 000 mm of water gauge. The fabric is vapor-permeable, but outer side of<br />

the fabric has special water repellent treatment for better water resistance.<br />

POLYESTER RIPSTOP LIGHT WR. (inner tent)<br />

The fabric made of strong polyester threads. In order to make fabric more durable without adding<br />

weight it is plaited with stronger and firmer thread (RIP STOP) every 4 mm in longitudinal and<br />

transversal directions. The fabric is vapor-permeable but in order to increase water resistance it has<br />

special water repellent treatment.<br />

POLYESTER 150D OXFORD PU, 6000 mm H2O (floor)<br />

The fabric is made of strong polyester threads 150D thick. Plaiting is performed in Oxford type. The<br />

fabric has a polyurethane (PU) treatment that ensures water resistance up to 6000 mm of water<br />

gauge (the fabric holds up to 6000 mm of water pressure before it soaks). During independent tests<br />

water resistance of this fabric exceeded 10 000 mm. The fabric is stiff and durable.<br />

POLYETHYLENE, 4000 mm H2O (floor)<br />

The fabric is made of polyethylene fiber. The fabric is water resistant 4000 mm H2O (the fabric holds<br />

up to 4000 mm H2O before it soaks). Though it is heavier the fabric is stiff and durable.<br />

NYLON 210T RIPSTOP PU, 250 mm H2O (outer fabric)<br />

The fabric is made of stiff polyamide threads (nylon) with plaiting density of 210x210 T (Thread<br />

Count) on square inch. In order to add stiffness and durability the fabric is strengthened with stronger<br />

thread (RIP STOP) that is plaid into the fabric every 2 mm in longitudinal and transversal directions.<br />

The fabric has thin polyurethane (PU) treatment that makes fabric water resistant and wind<br />

impermeable. Water resistance of fabric is 250 mm of water gauge (the fabric holds up to 250 mm of<br />

water pressure before soaking). All these qualities are used in Protective Shell technology to create<br />

an insulation space.<br />

NYLON 210T RIPSTOP (outer fabric)<br />

The fabric is made of stiff polyamide threads (nylon) with plaiting density of 210x210 T (Thread<br />

Count) on square inch. In order to add stiffness and durability the fabric is strengthened with stronger<br />

thread (RIP STOP) that is plaid into the fabric every 2 mm in longitudinal and transversal directions.<br />

The fabric is vapor-permeable and breathable. In Protective Shell system it ensures insulation and<br />

evaporation of excessive moisture.<br />

POLYESTER 190T DIAMOND RIPSTOP PU 250 mm H2O (outer fabric)<br />

The fabric is made of stiff polyester threads with plaiting density of 190x190 T (Thread count) on<br />

square inch. In order to increase durability and resistance to abrasion without adding unnecessary<br />

weight the fabric is plaited with extra strong thread (RIP STOP) every 2 mm in longitudinal and<br />

transversal directions. Diamond type plaiting is used for this fabric. The fabric is treated with a thin<br />

layer of polyurethane (PU) that makes fabric impermeable to wind and moisture. Water resistance<br />

of the fabric is 250 mm of water gauge (the fabric holds water pressure of 250 mm before it begins<br />

soaking). All these features are used in Protective Shell technology for creating insulation space.<br />

POLYESTER 190T (outer fabric)<br />

The fabric is made of stiff polyester threads with plaiting density 190x190 T (Thread Count) on<br />

square inch. The fabric is vapor-permeable and ‘breatheable’. In Protective Shell system it provides<br />

thermoregulation and evaporation of excessive moisture.<br />

VS NYLON RIPSTOP LIGHT SILICON W/R 32 g/m 2 (outer fabric)<br />

The fabric is very stiff and lightweight, it weighs only 32 g/m 2 and is made of nylon threads. In order<br />

to add stiffness and durability the fabric is strengthened with stronger thread (RIP STOP) that is plaid<br />

into the fabric every 2 mm in longitudinal and transversal directions. The fabric is treated with a thin<br />

layer of Silicon for better wind and water resistance qualities.