MACH 130 FP Mains Voltage 230V / 120V - Dr. Mach

MACH 130 FP Mains Voltage 230V / 120V - Dr. Mach

MACH 130 FP Mains Voltage 230V / 120V - Dr. Mach

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

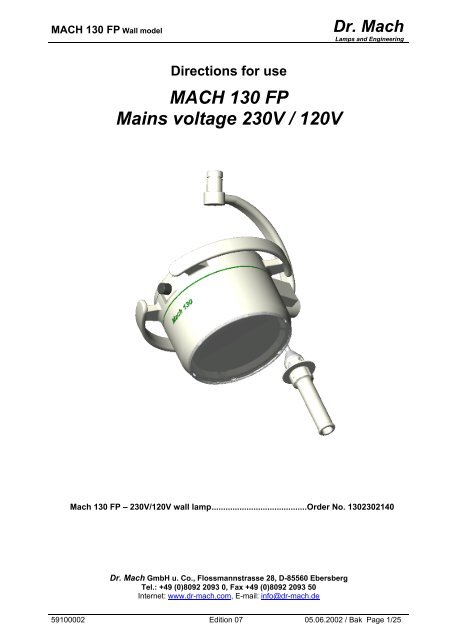

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

Directions for use<br />

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong><br />

<strong>Mains</strong> voltage <strong>230V</strong> / <strong>120V</strong><br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

<strong>Mach</strong> <strong>130</strong> <strong>FP</strong> – <strong>230V</strong>/<strong>120V</strong> wall lamp.........................................Order No. <strong>130</strong>2302140<br />

<strong>Dr</strong>. <strong>Mach</strong> GmbH u. Co., Flossmannstrasse 28, D-85560 Ebersberg<br />

Tel.: +49 (0)8092 2093 0, Fax +49 (0)8092 2093 50<br />

Internet: www.dr-mach.com, E-mail: info@dr-mach.de<br />

59100002 Edition 07 05.06.2002 / Bak Page 1/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

List of contents<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

1. Safety instructions ............................................................................................ Page 3<br />

2. Mounting layout wall attachment ...................................................................... Page 4<br />

3. Mounting the spring arm and the lamp ............................................................. Page 5<br />

3.1 Mounting the spring arm............................................................................. Page 5<br />

3.2 Removing the spring arm............................................................................ Page 5<br />

3.3 Mounting the lamp ...................................................................................... Page 6<br />

4. Operating the lamp <strong>Mach</strong> <strong>130</strong> <strong>FP</strong>..................................................................... Page 7<br />

4.1 ON/OFF switch ........................................................................................... Page 7<br />

4.2 Positioning .................................................................................................. Page 8<br />

4.3 Light field adjustment (focusing)................................................................. Page 8<br />

5. Cleaning............................................................................................................ Page 9<br />

5.1 Sterilizable handle ...................................................................................... Page 9<br />

5.2 Lamp head, protective disk......................................................................... Page 11<br />

6. Maintenance ..................................................................................................... Page 12<br />

6.1 Adjustments at the wall attachment............................................................ Page 12<br />

6.2 Adjustments at the lamp head .................................................................... Page 13<br />

6.3 Changing of spare parts ............................................................................. Page 14<br />

6.3.1 Changing the halogen bulbs.................................................................. Page 14<br />

6.3.2 Changing the fuses (<strong>230V</strong> / <strong>120V</strong>) ........................................................ Page 15<br />

6.3.3 Changing the ON/OFF switch ............................................................... Page 16<br />

6.3.4 Changing the filter disk.......................................................................... Page 17<br />

6.3.5 Changing the protective disk ................................................................. Page 18<br />

7. Data .................................................................................................................. Page 19<br />

7.1 Technical data ............................................................................................ Page 19<br />

7.2 Wiring.......................................................................................................... Page 19<br />

7.3 Environmental conditions............................................................................ Page 20<br />

8. Characteristics.................................................................................................. Page 20<br />

8.1 Specification of bulb ................................................................................... Page 20<br />

8.2 Specification of fuse ................................................................................... Page 21<br />

8.3 CE mark...................................................................................................... Page 21<br />

9. Disposal............................................................................................................ Page 21<br />

10. Spare parts ....................................................................................................... Page 22<br />

10.1 <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> <strong>230V</strong>/<strong>120V</strong> wall model....................................................... Page 22<br />

10.2 Wall attachment........................................................................................ Page 23<br />

10.3 Spare parts list.......................................................................................... Page 24<br />

59100002 Edition 07 05.06.2002 / Bak Page 2/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

1. Safety instructions<br />

Please pay attention to the directions for use when handling the lamp.<br />

Attention:<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

This device is not suitable for use in hazardous locations. The lamp is classified<br />

as a Group 1 device according to the regulations for EEMP.<br />

Repairs to the lamp and special installation work on the reflector or plug-in socket should<br />

only be carried out by ourselves or a company expressly authorised by ourselves.<br />

The manufacturer is only responsible for the safety of the lamp if repairs and alterations have<br />

been carried out by themselves or a company who can guarantee that the safety regulations<br />

have been observed.<br />

The manufacturer is not liable for personal or material damages if the lamp is misappropriately<br />

or incorrectly operated or misused.<br />

The lamp body may only be dismantled from the spring arm in reverse order to its assembly<br />

after the assembly locking device has been inserted and tightened since the arm is under<br />

spring tension.<br />

Make sure that the lamp is in perfect working order before every use.<br />

The lamps <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> may not be used without the dielectric filter disk.<br />

The dielectric filter disk between reflector and protective disk prevents a damaging heating of<br />

the illuminated area.<br />

59100002 Edition 07 05.06.2002 / Bak Page 3/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

Bracket<br />

2. Mounting layout<br />

Wall attachment<br />

Circlip<br />

Levelling washer (Remark!)<br />

Levelling washer<br />

Spring arm<br />

OT -lamp<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Remark:<br />

One levelling washer is always necessary.<br />

If the distance between wall bracket and spring arm is too big, use the second levelling washer.<br />

The circlip (Seegerring) must be easy to mount and has to snap in. It should turn easily in the groove.<br />

59100002 Edition 07 05.06.2002 / Bak Page 4/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

3. Mounting the spring arm and the lamp<br />

3.1 Mounting the spring arm<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

• Unscrew the cover 1 (with sliding contact plug) from the articulated arm.<br />

• Slide the articulated arm from below into the upper articulated arm.<br />

• Slide the levelling washer and safety ring onto the connection tube of the spring arm in the correct order.<br />

• Place the safety ring in position.<br />

Ensure that the safety ring slots properly in the groove of the coupling journal (tool: mounting pliers).<br />

• Place the cover back on the articulated arm and screw tight.<br />

3.2 Removing the spring arm<br />

• Disconnect the electrical connection (in case of direct electrical connection using the fuses).<br />

• Unscrew the cover 1 (with sliding contact plug) from the articulated arm.<br />

• Pull the cover 1 off upwards by lateral compressing.<br />

• Remove the levelling washer and safety ring with the mounting pliers and pull the suspension tube out<br />

in a downwards movement.<br />

59100002 Edition 07 05.06.2002 / Bak Page 5/25<br />

1

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

3.3. Mounting the lamp<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

When mounting the lamp and also at one-yearly intervals, a light coat of acid-free grease should be applied<br />

to the mounting journal and the journal groove F of the lamp, or possibly the already existing cardan bow.<br />

Caution:<br />

The lamp may only be dismounted (in reverse order to the mounting procedure) after the mounting<br />

safeguard has been positioned and screwed tight, as the arm is under spring tension.<br />

Element D<br />

Safeguard bushing<br />

• Loosen locking screw K using a cross screwdriver.<br />

• Disengage spring element D from the safeguard<br />

bushing using a screwdriver (by pushing in direction<br />

of the outer edge) and slide back the<br />

safeguard bushing.<br />

• Take out the segment and remove helmet L.<br />

• Push the lamp and the cardan bow into the bore<br />

of the spring arm, so that journal groove F is<br />

visible in slot E.<br />

• Insert the segment and slide the safeguard<br />

bushing downwards again as far as possible. Insert<br />

locking screw K (including lock washer) and<br />

screw tight.<br />

Then REMOVE MOUNTING SAFEGUARD in the<br />

articulated arm.<br />

• Unscrew cylinder screw H.<br />

• Take out the red safety angle G.<br />

To do so, carefully move the articulated arm<br />

upwards or downwards.<br />

Caution: Hold the arm, to avoid bouncing<br />

up!<br />

The mounting safeguard (called G in all<br />

mounting instructions) and the corresponding<br />

cylinder screw H must be kept carefully for<br />

maintaining and dismounting the lamp.<br />

59100002 Edition 07 05.06.2002 / Bak Page 6/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

67,68<br />

4. Operating the lamp <strong>Mach</strong> <strong>130</strong> <strong>FP</strong><br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Lamp features:<br />

• <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> with focusable light field size and<br />

integrated dielectric filter disk.<br />

The reflector is adapted to the dielectric filter<br />

disk.<br />

The lamp-types mentioned above are available as:<br />

• <strong>Mach</strong> <strong>130</strong> <strong>FP</strong>; mains voltage <strong>230V</strong>/<strong>120V</strong>; integrated<br />

toroid transformer<br />

4.1 ON/OFF switch<br />

The switch 67 (with push button 68) switches the<br />

lamp on and off.<br />

For switching the lamp on and off push button 68.<br />

59100002 Edition 07 05.06.2002 / Bak Page 7/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

GL<br />

45<br />

58<br />

44<br />

45<br />

4.2 Positioning<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Use the handle or the handle rail GL to position the<br />

lamp.<br />

The lamp is equipped with a handle with sterilizable<br />

handle sleeve 45.<br />

The sterilizable handle sleeve 45 can be removed.<br />

It is fixed by the couple 44 to the handle bar 58.<br />

4.3 Light field adjustment<br />

(focusing) – <strong>Mach</strong> <strong>130</strong> <strong>FP</strong><br />

The lamp models <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> have a focusing<br />

function. That means, you can either enlarge the<br />

diameter of the light field or bundle the light to a<br />

smaller area, depending on the circumstances.<br />

To activate the function of focusing turn the handle<br />

45 (see figure).<br />

59100002 Edition 07 05.06.2002 / Bak Page 8/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

V<br />

45<br />

Cleaning / disinfection and sterilisation<br />

5. Cleaning<br />

5.1 Sterilizable handle<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The lamps <strong>Mach</strong> <strong>130</strong>/<strong>Mach</strong> <strong>130</strong>F 22,8V UL/Uniflex<br />

R96 <strong>120V</strong> UL can be equipped as an option with a<br />

sterilizable handle 45.<br />

The sterilizable handle 45 is removable and sterilizable.<br />

Before using the first time and before every<br />

use the handle sleeve must be cleaned, disinfected<br />

and sterilised.<br />

The handle sleeve must be removed for sterilisation:<br />

• To remove press the lock V and pull off the<br />

sterilisable handle sleeve 45 while keeping the<br />

lock pressed.<br />

• To attach, push on and slightly twist the handle<br />

until the lock V engages securely.<br />

Handles often become unsterile during an OP;<br />

therefore always keep additional handles available<br />

for exchange.<br />

Basics<br />

Efficient cleaning / disinfection is an essential requirement for effective sterilisation of the handle.<br />

Within the scope of responsibility for the sterility of the products it should be noted that only sufficiently<br />

validated equipment and product specific processes are used for cleaning / disinfection and that the validated<br />

parameters are complied with in every cycle.<br />

In addition, the hospital / clinic hygiene regulations must be observed.<br />

Cleaning / disinfection<br />

Cleaning and disinfection must be carried out immediately after use.<br />

A mechanised process (disinfector) should be used for cleaning / disinfection. The efficiency of the process<br />

used must be recognised and validated in principle (e.g. listed under disinfectants and disinfection procedures<br />

tested and recognised by Robert-Koch-Institute / DGHM).<br />

When using other procedures (e.g. a manual procedure), proof and process efficiency in principle must be<br />

provided within the scope of validation.<br />

Proof in principle of the suitability of the handles for efficient cleaning / disinfection was provided using a<br />

cyclic cleaning system (Netsch-Bellmed T-600-IUDT/AN, programme 2 for small parts; code B).<br />

It is not allowed to use agents / disinfectants, which contain the following substances, as these may cause<br />

changes in the material:<br />

- High-concentration organic and inorganic acids<br />

- Chlorinated hydrocarbons<br />

- 2-ethoxyethanol<br />

59100002 Edition 07 05.06.2002 / Bak Page 9/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

When cleaning / disinfecting, the following procedures must be followed:<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Process Time (sec.)<br />

Zone 1 Pre-rinse, external, cold, 10 – 15°C 45<br />

Washing, acidic, external 35°C 120<br />

<strong>Dr</strong>aining time 10<br />

Re-rinse, external approx. 80°C *10<br />

<strong>Dr</strong>aining time *15<br />

Re-rinse, external approx. 80°C *15<br />

<strong>Dr</strong>aining time 15<br />

Zone 2 Washing, alkaline, external, 93°C 135<br />

<strong>Dr</strong>aining time 10<br />

Re-rinse, external, acidic, 90°C 10<br />

<strong>Dr</strong>aining time 15<br />

Re-rinse, external 90°C 15<br />

<strong>Dr</strong>aining time 15<br />

Zone 3 <strong>Dr</strong>ying, external 100 – 120°C 200<br />

Zone 4 <strong>Dr</strong>ying, external 100 – 120°C 200<br />

Door open / close & transport 60<br />

(sluice discharge)<br />

Cycle time overall ca. 290<br />

≈ 5 minutes<br />

* When occupying the disinfection zone (washing zone 2), the re-rinse and draining times will depend on<br />

the respective objects being washed therein!<br />

Sterilisation<br />

Only previously cleaned and disinfected handles may be sterilised.<br />

The handles are placed in a suitable sterilisation pack (one-way sterilisation pack, e.g. foil / paper sterilisation<br />

bags, single or double pack) in accordance with DIN EN 868 / ISO 11607 for steam sterilisation and<br />

then sterilised.<br />

Use only the sterilisation procedure listed below for sterilisation. Other sterilisation procedures (e.g. ethylene<br />

oxide, formaldehyde and low-temperature plasma sterilisation) are not permissible.<br />

Steam sterilisation procedure<br />

Validated in accordance with DIN EN 554/ISO 11134<br />

Maximum sterilisation temperature 134°C<br />

Proof in principle of the handles’ suitability for effective sterilisation was provided using a fractional vacuum<br />

process (Euroselectomat 666 by MMM Münchner Medizin Mechanik GmbH, sterilising temperature 134°C,<br />

holding time 7 min.)<br />

Inspection / durability<br />

The handles should be inspected for damage and changed before re-use, if required.<br />

The handles may be cleaned / disinfected, sterilised and re-used for a maximum of 1000 times. If the handles<br />

are re-used more than 1000 times, then this will be the responsibility of the hospital / clinic.<br />

59100002 Edition 07 05.06.2002 / Bak Page 10/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

15<br />

Alc. ≤ 20 %<br />

5.2 Lamp head, protective disk<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The lamp has a high-quality surface, which can be<br />

cleaned with conventional cleaning agents.<br />

The protective disk 15 is made of an high-quality<br />

plastic. Pay attention to the following during cleaning:<br />

- Wipe over the protective disk 15 with a wet<br />

cloth (never use a dry cloth!).<br />

- Only use disinfectant with less then 20% alcohol.<br />

Wipe the protective disk 15 after cleaning with an<br />

antistatic, non-fluffy cloth.<br />

59100002 Edition 07 05.06.2002 / Bak Page 11/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

6. Maintenance<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The lamp has been designed and built so that regular maintenance intervals are not necessary.<br />

In order to keep the system easy running throughout its life span we recommend that the hinges be<br />

greased once a year with an acid-free grease.<br />

The lamp body may only be dismantled from the spring arm in reverse order to its assembly after the assembly<br />

locking device has been inserted and tightened since the arm is under spring tension.<br />

Attention: Screw the transport safeguard into place in the spring arm before removing the lights.<br />

F<br />

F<br />

6.1 Adjustments at the wall attachment<br />

♦ Adjusting the spring force<br />

The spring arm is correctly adjusted when the light<br />

remains in position at every set height and can be<br />

moved more easily upwards than downwards.<br />

Should you discover that the light no longer remains<br />

at its set height, proceed as follows:<br />

• Turn off the lamp.<br />

• Push the two circular areas F on the sides carefully<br />

apart. Remove the cover from the front.<br />

• Move the spring arm into a position in which the<br />

hole nut is visible.<br />

Attention: If the max. height of the spring arm is<br />

limited, the hole nut may in certain circumstances<br />

remain invisible. In this case consult<br />

your dealer or <strong>Dr</strong>. <strong>Mach</strong> directly.<br />

• Place the key bolt that can be found below the<br />

cover on the top of the spring arm in the hole<br />

and turn accordingly. Use only the enclosed key<br />

bolt since a screwdriver could break.<br />

Proceed as follows depending on the movement of<br />

the light.<br />

a. Lamp moves down on its own - turn bolt in the<br />

direction of the „+“ mark.<br />

b. Lamp moves up on its own - turn bolt in the direction<br />

of the „−“ mark.<br />

59100002 Edition 07 05.06.2002 / Bak Page 12/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

screw driver<br />

JS<br />

X<br />

4<br />

10<br />

A<br />

♦ Height adjustment<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Adjust the height to prevent any impact from the<br />

articulated arm on the ceiling.<br />

• Spread the cover caps in the upper and lower<br />

slot J using a screwdriver and take them out.<br />

The drilled nut is visible now.<br />

• Turn the drilled nut using the key in the direction<br />

of the „ – “ mark (shown on the spring<br />

arm), until the required height position has<br />

been reached.<br />

Do not use a screwdriver, since it could break.<br />

Remark: 40-50 rotational movements are necessary<br />

for 10cm height adjustment.<br />

• Store the key bolt and replace the cover caps.<br />

6.2 Adjustments at the lamp head<br />

♦ Adjusting the movability of the handle<br />

for focusing – <strong>Mach</strong> <strong>130</strong> <strong>FP</strong><br />

In case you notice that the handle moves to easily<br />

or to heavily, it may be necessary to adjust its<br />

movability.<br />

To adjust the movability of the handle proceed as<br />

follows:<br />

• Turn off the lamp.<br />

• Loosen the housing cap arrest by pushing the<br />

arrest pin X (e.g. with a ball pen).<br />

• Remove cover 4 of the lamp.<br />

• You can adjust the movability of the handle by<br />

turning the levelling screw with a screwdriver.<br />

- Clockwise – stronger<br />

- Anticlockwise - easier<br />

It is not necessary to remove the cover 4, which<br />

closes the adjustment.<br />

♦ Manipulating the lamp<br />

The lamp bow 10 enables a perfect movability and<br />

positioning of the lamps <strong>Mach</strong> <strong>130</strong> <strong>FP</strong>.<br />

The brake force in the axis A is set. It is usually not<br />

necessary to adjust it.<br />

59100002 Edition 07 05.06.2002 / Bak Page 13/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

3<br />

47<br />

11<br />

12<br />

power<br />

supply<br />

X<br />

30<br />

6.3 Changing of spare parts<br />

6.3.1 Changing the halogen bulbs<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

<strong>Dr</strong>. <strong>Mach</strong> uses special halogen bulbs as illuminants.<br />

Only original <strong>Dr</strong>. <strong>Mach</strong> replacement bulbs may<br />

be used.<br />

The use of other bulbs can lead to a considerable<br />

reduction of the light power and increase in the<br />

thermal load.<br />

Attention: At delivery there is an additional<br />

halogen bulb and lamp socket (without cable)<br />

fixed near one of the arrest pins X.<br />

To change the bulbs proceed as follows:<br />

• Turn off the lamp.<br />

• Loosen the housing cap arrest by pushing the<br />

arrest pin X (e.g. with a ball pen).<br />

• Tilt up cap 3 and lift off from the facing arrest<br />

pin.<br />

• Loosen holding screw 47 of lamp head.<br />

Attention! If the bulb is changed immediately<br />

after operating the lamp, this screw<br />

may be hot.<br />

• Pull out the lamp base of its guide, without<br />

loosing the electrical connection.<br />

• <strong>Dr</strong>aw halogen bulb 12 (22,8-24V/50W) carefully<br />

from its socket.<br />

• Put in the new halogen bulb.<br />

• Mounting of the lamp base 11 and lamp housing<br />

cap 3 in reverse order.<br />

Do not touch the halogen bulb with naked<br />

hands.<br />

Remark:<br />

The halogen bulbs have a service life of approx.<br />

1000 hours without any deterioration in<br />

their luminosity.<br />

59100002 Edition 07 05.06.2002 / Bak Page 14/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

26,65 X<br />

X<br />

6.3.2 Changing the fuses<br />

<strong>Mach</strong> <strong>130</strong> <strong>FP</strong> <strong>230V</strong>/<strong>120V</strong><br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The fuses in the lamp housing prevent the transformer<br />

burning through in the event of a short circuit.<br />

The fuses are situated beneath the housing cap.<br />

Visible type UR 5x20/1,25A/250V/ AC/t<br />

for <strong>230V</strong>/<strong>120V</strong><br />

If the bulb is no longer on, check the bulb first, then<br />

the fuses.<br />

Attention: At delivery the lamp is supplied with<br />

an additional fuse as spare part. It is mounted<br />

with a cable fixer to the focusing adjusting lever<br />

30 (see page 9).<br />

To change the fuses, proceed as follows:<br />

• Turn off the lamp.<br />

• Loosing the housing cap arrest by pushing the<br />

arrest pin X (e.g. with a ball pen).<br />

• Tilt up the cap and lift off from the facing arrest<br />

pin.<br />

• Turn the black fuse holder 26 ¼ of a rotation anticlockwise<br />

with a screwdriver, change fuse 65, insert<br />

fuse holder under slight pressure and rotate<br />

in a clockwise direction (bayonet catch).<br />

• Replace the cap 3 in the same way as taking off,<br />

so that the arrest pins click into position.<br />

59100002 Edition 07 05.06.2002 / Bak Page 15/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

68 AD<br />

BM 67<br />

6.3.3 Changing the ON/OFF switch<br />

<strong>Mach</strong> <strong>130</strong> <strong>FP</strong><br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

You can turn the lamps <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> on and off<br />

using the push button switch 67.<br />

To change the ON/OFF switch proceed as follows:<br />

• Turn off the lamp.<br />

• Loosen the push button 68.<br />

• Loosen the fixing nut BM and pull the ON/OFF<br />

switch out of the lamp housing.<br />

• Disconnect the cables from the ON/OFF switch.<br />

Mount the new ON/OFF switch:<br />

• Push the cables through and nick them.<br />

• Connect the cables to the ON/OFF switch.<br />

• Insert the ON/OFF switch in the cover AD. The<br />

lateral cover plates remain open.<br />

• Mount the ON/OFF switch including the cover<br />

AD in the lamp housing, so that the electromechanical<br />

component points to the lamp housing.<br />

• Fix the nut BM for approx. 2 thread lengths.<br />

• Push the lateral cover plates of the cover AD<br />

between the lamp housing and the ON/OFF<br />

switch.<br />

The switch must be completely covered (protection<br />

against electric shock).<br />

The cables are on the downside of the cover.<br />

• Fix the nut BM.<br />

Attention! Do not overturn the thread!<br />

• Mount the push button 68.<br />

• Push the button 68 to stop and fix the socket<br />

head cap screw.<br />

Check the function of the lamp.<br />

59100002 Edition 07 05.06.2002 / Bak Page 16/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

3<br />

S<br />

X<br />

2<br />

S<br />

S<br />

16<br />

14<br />

X<br />

S<br />

4<br />

S<br />

6.3.4 Changing the filter disk<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The filter disk between reflector and dispersion lens<br />

prevents a damaging heating of the illuminated area.<br />

ATTENTION!<br />

The lamps may not be used without this filter.<br />

To change the filter disk 14 proceed as follows:<br />

• Turn off the lamp.<br />

• Loosen the housing cap arrest by pushing the<br />

arrest pin X (e.g. with a ball pen).<br />

• Tilt up cover 3 and lift off from the facing arrest<br />

pin.<br />

• Remove cover 4.<br />

• Loosen three screws S (for position of the<br />

screws see top view below.).<br />

Attention: Hold the bottom part of the lamp<br />

housing carefully, it is loosen now.<br />

• Remove bottom part 2 of the lamp housing.<br />

You can see the filter disk in front of you. It is kept<br />

by the four springs 16.<br />

59100002 Edition 07 05.06.2002 / Bak Page 17/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

16b 14 16b<br />

III<br />

II II<br />

I<br />

III III<br />

2<br />

52,53<br />

15<br />

16a<br />

I<br />

marking<br />

15<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

• Press filter disk 14 carefully against two springs<br />

16a (I).<br />

Attention: Touch the filter disk only with a<br />

non-fluffy cloth.<br />

• Press the other two springs 16b to the edge (II)<br />

and lift the filter disk (III).<br />

• Insert the new filter disk in reverse order. Make<br />

sure that the marking points to the upper side of<br />

the lamp housing as shown in the figure. The reverse<br />

side of the disk is steam finished.<br />

Only use filter disks, that have been cleaned<br />

properly.<br />

• Fix the bottom part 2 of the lamp housing with the<br />

three screws S.<br />

• Fix the cover 3, so that the two arrest pins snap<br />

in.<br />

6.3.5 Changing the protective disk<br />

In case you notice a impediment of the light quality<br />

because of a dull protective disk, it may be necessary<br />

to change the disk.<br />

To change the protective disk proceed as follows:<br />

• Turn off the lamp.<br />

• Remove the bottom part 2 of the lamp housing as<br />

described at point 4.4.4.<br />

• Loosen six screws 52/54 and remove them including<br />

the washers 53.<br />

Attention: Hold the protective disk 15 carefully,<br />

it is loosen now.<br />

• Remove the protective disk 15.<br />

• Insert the new protective disk, so that it is placed<br />

even to the bottom part of the lamp housing.<br />

• Fix the protective disk with six screws 52/54 and<br />

washers 53.<br />

Attention: Only use protective disks, that<br />

have been cleaned as described at point 3.2.<br />

• Fix the bottom part 2 of the lamp housing.<br />

• Fix the cover 3, so that the arrest pins snap in.<br />

59100002 Edition 07 05.06.2002 / Bak Page 18/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

7.1 Technical data<br />

7. Data<br />

<strong>Mains</strong> voltage 230 Volt<br />

~ Wechselstrom alternating current<br />

Pr Primärseitig <strong>230V</strong> / 0,43A primary side<br />

Sek Sekundärseitig 23V / 2,19A secondary side<br />

Leistungsaufnahme 50VA power consumption<br />

Hz Hertz-Frequenz 50 / 60Hz frequency Hertz<br />

Sicherung UR 5x20/1,25A/250V AC/t fuse<br />

Schutzgrad Typ „B“ class of protection<br />

<strong>Mains</strong> voltage 120 Volt<br />

~ Wechselstrom alternating current<br />

Pr Primärseitig <strong>120V</strong> / 0,86A primary side<br />

Sek Sekundärseitig 21V / 2,19A secondary side<br />

Leistungsaufnahme 50VA power consumption<br />

Hz Hertz-Frequenz 50 / 60Hz frequency Hertz<br />

Sicherung UR 5x20/1,25A/250V AC/t fuse<br />

Schutzgrad Typ „B“ class of protection<br />

7.2 Wiring<br />

Switch<br />

<strong>Mach</strong> <strong>130</strong> <strong>FP</strong> mains voltage <strong>230V</strong>/<strong>120V</strong><br />

built in toroid transformer<br />

Toroid<br />

transformer<br />

Halogen bulb<br />

1<br />

2<br />

3<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

59100002 Edition 07 05.06.2002 / Bak Page 19/25<br />

N<br />

L<br />

P

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

7.3 Environmental conditions<br />

Connections at the toroid transformer<br />

0V<br />

white<br />

0V<br />

black<br />

21V<br />

red<br />

<strong>120V</strong><br />

grey<br />

Operation<br />

23V<br />

brown<br />

<strong>230V</strong><br />

orange<br />

secondary<br />

primary<br />

Min. Max.<br />

Temperature +10°C +40°C<br />

Relative atmospheric humidity 30% 75%<br />

Air pressure 700 hPa 1060 hPa<br />

Transport / Storage<br />

Min. Max.<br />

Temperature -10°C +50°C<br />

Relative atmospheric humidity 20% 90%<br />

Air pressure 700 hPa 1060 hPa<br />

8.1 Specification of bulb<br />

22,8V 50W<br />

G 6,35<br />

HALOGEN<br />

8. Characteristics<br />

Protective conductor<br />

“<br />

ON/OFF” switch<br />

<strong>Voltage</strong>, power<br />

Socket<br />

Mode of operation<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

59100002 Edition 07 05.06.2002 / Bak Page 20/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

8.2 Specification of fuse<br />

8.3 CE-mark<br />

5x20<br />

T1,25A<br />

<strong>Mains</strong> voltage 230 Volt / 120 Volt<br />

Visible fuse UR 5x20<br />

Delay action 1,25A<br />

250V AC/t<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

The products <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> comply to the standards 93/42/EEC for medical products of<br />

the European Community’s Council.<br />

9. Disposal<br />

The lamp does not contain any danger goods.<br />

The components of the lamp should be properly disposed at the end of its shelf-life.<br />

Make sure, that the materials are carefully separated.<br />

For disposal proceed as follows:<br />

• The electrical conducting boards should be submitted to an appropriate recycling proceeding.<br />

• The lamp housing should be submitted to thermal disposal.<br />

• The rest of the components should be disposed according to the contained materials.<br />

59100002 Edition 07 05.06.2002 / Bak Page 21/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

16<br />

11<br />

13<br />

12<br />

19<br />

52,53<br />

26,65<br />

64<br />

68<br />

67<br />

66<br />

10. Spare parts<br />

10.1 <strong>Mach</strong> <strong>130</strong> <strong>FP</strong> mains voltage 230 Volt / 120 Volt<br />

built in toroid transformer<br />

15 14<br />

31<br />

48<br />

3<br />

47<br />

8<br />

1<br />

7<br />

6<br />

50<br />

5<br />

2<br />

15<br />

30 1x 65<br />

1x 12<br />

(spare part)<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

58<br />

44<br />

45<br />

4<br />

32,33,34<br />

38<br />

17,18<br />

4<br />

10<br />

30<br />

1x 65<br />

(spare part)<br />

48<br />

39<br />

59100002 Edition 07 05.06.2002 / Bak Page 22/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

10.2 Wall attachment<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

59100002 Edition 07 05.06.2002 / Bak Page 23/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

10.3 Spare parts list<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Item Qty. Name EDVNO Remarks<br />

01 1 Base frame 10030201<br />

02 1 Bottom part of lamp housing 10012001<br />

03 1 Cover of lamp housing 10011001<br />

04 1 Covering plate 10030216<br />

05 1 Retaining ring for reflector 10060202<br />

06 3 Clamping angle, complete 10061002<br />

07 1 Centre sleeve for reflector 10061202<br />

08 1 Guiding tube for focus 10030202<br />

09<br />

10 1 Lamp bow, complete 10100001<br />

11 1 Lamp holder focus 10050002<br />

12 2 Halogen bulb 22,8V/50W 67100201 1 additional halogen<br />

bulb as spare part<br />

13 1 Lamp socket with cable<br />

14 1 Dielectric filter disk 23250201<br />

15 1 Protective disk 21200201<br />

16 3 Retaining spring<br />

17 2 Arrest pin 10030205<br />

18 2 Pressure spring 10030212<br />

19 1 Shadower 10061003<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26 2 Fuse holder 67370001<br />

27<br />

28<br />

29<br />

30 1 Adjusting lever for focusing 10050202<br />

31 1 Sliding contact (plug) 07102004<br />

32 1 Plate spring 65982006<br />

33 1 Washer 10030210<br />

34 1 Nut 67900002<br />

35<br />

36<br />

37<br />

38 1 Adjusting screw 65212010<br />

39 1 Insertion of handle 10030204<br />

40<br />

41<br />

42<br />

43<br />

44 1 Coupling for sterilizable handle 10152001<br />

59100002 Edition 07 05.06.2002 / Bak Page 24/25

<strong>MACH</strong> <strong>130</strong> <strong>FP</strong> Wall model<br />

Spare parts list<br />

<strong>Dr</strong>. <strong>Mach</strong><br />

Lamps and Engineering<br />

Item Qty. Name EDVNO Remarks<br />

45 1 Handle sleeve, sterilizable 21150002 standard<br />

46<br />

47 1 Arrest screw (red) 10050206<br />

48 2 Cover 07100201<br />

49<br />

50 1 Glass-reflector (<strong>Mach</strong> <strong>130</strong>F) 10060201<br />

51<br />

52 6 Head cap screw M2,5x8-A2, DIN 912 65052077<br />

53 6 Washer A3,2 DIN 125-A2 65512017<br />

54<br />

55 6 Plate 21012203<br />

56<br />

57<br />

58 1 Handle bar focus (standard) 10013204<br />

59<br />

60<br />

61<br />

62<br />

63<br />

64 1 Fuse base (toroid transformer) 10030222<br />

65 3 Visible fuse UR<br />

5x20/1,25A/250V AC/t<br />

66 1 Toroid transformer <strong>230V</strong> / <strong>120V</strong> 50-60Hz 55VA 67010112<br />

67 1 Switch with fixing nut (UR) 67340008<br />

68 1 Push button UR 67340010<br />

69 1 Wall arm 800mm with gliding joint 74822001<br />

69 1 Wall arm 800mm with needle bearings 74821001<br />

70<br />

71 2 Cover 74012025<br />

72 1 Cover cap 74012027<br />

73 2 Levelling washer 74011012<br />

74 1 Circlip (Seegerring) 74011014<br />

75 2 Levelling washer 74011012<br />

76 1 Sliding sleeve for semi-circular spring 53070208<br />

77 1 Semi-circular spring 74011001<br />

78 1 Helmet<br />

79 1 Locking screw M4x10 DIN 7985 65152035<br />

80 1 Serrated lock washer A4,3 DIN 6798 65592008<br />

81 1 Spring arm 74801001-<br />

74801007<br />

82 1 Transport safety angle 74011019<br />

83 1 Attachment screw M4x8 DIN 7985 65152002<br />

84 1 Cover 2 (high stud) 74012030<br />

85 1 Cover 3 (with wire exit) 74012031<br />

86 2 Screw for cover 2,9x6,5 F-H-VZK DIN 7981ST 65132012<br />

87 2 Sliding contact plug 67330002<br />

88 2 Sliding contact sleeve 67330001<br />

67370008 <strong>230V</strong> /<strong>120V</strong>;<br />

1 additional fuse as<br />

spare part<br />

59100002 Edition 07 05.06.2002 / Bak Page 25/25