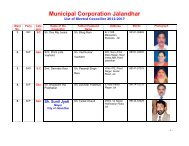

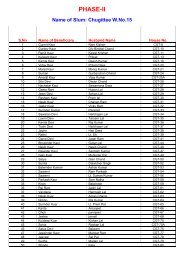

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.2 TANK :<br />

9<br />

The tank will be of rear tipping type and should have a total air volume capacity of 8000 Ltrs. The whole<br />

tank should be made of steel plates 6 mm thick and should confirm to IS 2062 grade ‘A’ standard. The<br />

tank should be of an all electrically welded construction.<br />

The tank should be compartmentalized as follows :<br />

4500 Ltrs for clean water and the balance 3500 Ltrs for sludge. Level Indicator size 18” X 8” of thick wall<br />

transparent acrylic tubing should be provided on both the sides of each of the compartments 2” drain<br />

valve should be provided at a suitable position on the clean water compartment. The tank should be<br />

mounted on the chassis. The inside of the tank should be coated with epoxy paint.<br />

The vacuum compartment should be provided with hydraulically operated rear door opening facility. The<br />

tank should be mounted on hinge supports for tilting about the rear end, while the front end should have<br />

rest pads for seating on chassis of the vehicle in the<br />

horizontal position.<br />

The tank should be provided with manhole at the water compartment for attending to the maintenance<br />

operation/repairing of the tank.. The tank should be provided with suitable suction line strainer and filter<br />

hose connections. The tank should be finished with three coats of epoxy paint of suitable enamel paint<br />

with primer on the inside and coats on the out side. The entire tank should be fabricated and finished to<br />

the best of quality standards and as per standard engineering practice.<br />

REAR DOOR:<br />

The rear door shall be top hinged open able with two double acting hydraulic cylinders. The door should<br />

be allowed to remain secure in the raised position by an incorporated pilot check valve in the hydraulic<br />

system. Adequate sealing and locking arrangement should be provided to render the door leak proof.<br />

Fitted at the rear end door, the tank should be provided with a 100 mm suction cum drain valve at the<br />

bottom most position.<br />

The drain/suction valve shall be of carbon steel, three peace construction having a stainless steel ball.<br />

These valves, unlike the normal cast iron valves have longer operation life and are far easier<br />

to maintain.<br />

Sludge should be sucked through this valve which could also be used to discharge the entire tank contents<br />

under gravity/pressure.<br />

Tank level indicators will be provided at a convenient location both the side on the shell of both, the<br />

sludge as well as the clean water<br />

compartments.<br />

The sludge tank may be emptied by gravity or by pressurized discharge.<br />

Emptying is via hydraulic tipping of the complete tank using a hydraulic cylinder mounted below. The<br />

tank tipping angle would be about 30 degrees. To prevent the tank from creeping down when in the raised<br />

position a line mounted pilot operated check valve is fitted into the hydraulic circuit.