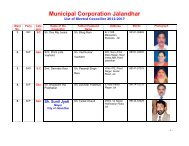

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The exhauster / compressor will be provided with:<br />

11<br />

a. Convection air-cooling system<br />

b. Forced Oil Lubrication system<br />

c. Incorporated Check valve<br />

d. Incorporated 4 – way valve<br />

TECHNICAL DATA<br />

Delivery : Min. 13850 LPM free air flow<br />

Max Rated Vacuum : 90%<br />

Operating Vacuum : 200 bar (80% Vacuum)<br />

Operating Pressure : 1.0 bar gauge (absolute)<br />

The 4 – way change – over valve shall enable the unit to change quickly from the pressure to the suction<br />

mode and vice – versa.<br />

A pump inlet Filter of adequate capacity shall be incorporated in the system for the protection of the pump<br />

against any ingress of foreign particles, in both the suction and the overpressure modes of operation.<br />

Pressure relief and vacuum relief valves shall be line mounted to protect the equipment and system from<br />

over pressure and excessive vacuum respectively. The valves shall be factory set to control the operating<br />

pressure and vacuum parameters of the system.<br />

1.6 SUCTION HOSE<br />

5 sections of 100 mm dia. and 3 Mtrs. Long, heavy duty, lightweight, PVC hose along with quick connect<br />

hose-end fittings, shall be provided for the suction application.<br />

One, light weight hose-end suction nozzle with a suitable quick connect coupling shall be supplied with<br />

the equipment as a standard accessory.<br />

Two lockable hose racks for the stowage of hoses shall be provided on either side of the equipment.<br />

1.7 PIPING<br />

System piping subject to high pressure should be of steel and forged steel fittings. These rubber<br />

connection hoses should not deform or get damaged due to compressed air heat generated when the<br />

equipment is used in the pressure mode.<br />

The pipes should be clamped sufficiently to absorb vibrations and should be easily accessible for<br />

maintenance.<br />

1.8 CONTROLS<br />

All indicators and control elements required for control and monitoring will be located at a convenient<br />

operating position on the equipment and on the left-hand side of the vehicle.