Grignard Reaction - Triphenylmethanol

Grignard Reaction - Triphenylmethanol

Grignard Reaction - Triphenylmethanol

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

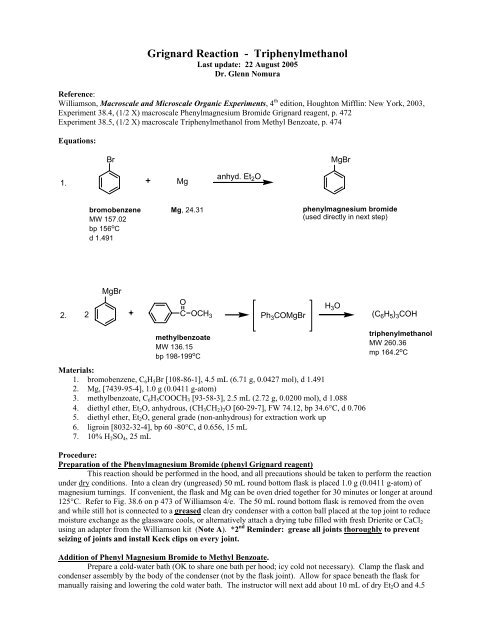

<strong>Grignard</strong> <strong>Reaction</strong> - <strong>Triphenylmethanol</strong><br />

Last update: 22 August 2005<br />

Dr. Glenn Nomura<br />

Reference:<br />

Williamson, Macroscale and Microscale Organic Experiments, 4 th edition, Houghton Mifflin: New York, 2003,<br />

Experiment 38.4, (1/2 X) macroscale Phenylmagnesium Bromide <strong>Grignard</strong> reagent, p. 472<br />

Experiment 38.5, (1/2 X) macroscale <strong>Triphenylmethanol</strong> from Methyl Benzoate, p. 474<br />

Equations:<br />

Br<br />

MgBr<br />

1.<br />

Mg<br />

anhyd. Et 2 O<br />

bromobenzene<br />

MW 157.02<br />

bp 156 o C<br />

d 1.491<br />

Mg, 24.31<br />

phenylmagnesium bromide<br />

(used directly in next step)<br />

2.<br />

MgBr<br />

O<br />

2 C<br />

OCH 3<br />

Ph 3 COMgBr<br />

H 3 O<br />

(C 6 H 5 ) 3 COH<br />

methylbenzoate<br />

MW 136.15<br />

bp 198-199 o C<br />

Materials:<br />

1. bromobenzene, C 6 H 5 Br [108-86-1], 4.5 mL (6.71 g, 0.0427 mol), d 1.491<br />

2. Mg, [7439-95-4], 1.0 g (0.0411 g-atom)<br />

3. methylbenzoate, C 6 H 5 COOCH 3 [93-58-3], 2.5 mL (2.72 g, 0.0200 mol), d 1.088<br />

4. diethyl ether, Et 2 O, anhydrous, (CH 3 CH 2 ) 2 O [60-29-7], FW 74.12, bp 34.6°C, d 0.706<br />

5. diethyl ether, Et 2 O, general grade (non-anhydrous) for extraction work up<br />

6. ligroin [8032-32-4], bp 60 -80°C, d 0.656, 15 mL<br />

7. 10% H 2 SO 4 , 25 mL<br />

triphenylmethanol<br />

MW 260.36<br />

mp 164.2 o C<br />

Procedure:<br />

Preparation of the Phenylmagnesium Bromide (phenyl <strong>Grignard</strong> reagent)<br />

This reaction should be performed in the hood, and all precautions should be taken to perform the reaction<br />

under dry conditions. Into a clean dry (ungreased) 50 mL round bottom flask is placed 1.0 g (0.0411 g-atom) of<br />

magnesium turnings. If convenient, the flask and Mg can be oven dried together for 30 minutes or longer at around<br />

125°C. Refer to Fig. 38.6 on p 473 of Williamson 4/e. The 50 mL round bottom flask is removed from the oven<br />

and while still hot is connected to a greased clean dry condenser with a cotton ball placed at the top joint to reduce<br />

moisture exchange as the glassware cools, or alternatively attach a drying tube filled with fresh Drierite or CaCl 2<br />

using an adapter from the Williamson kit (Note A). *2 nd Reminder: grease all joints thoroughly to prevent<br />

seizing of joints and install Keck clips on every joint.<br />

Addition of Phenyl Magnesium Bromide to Methyl Benzoate.<br />

Prepare a cold-water bath (OK to share one bath per hood; icy cold not necessary). Clamp the flask and<br />

condenser assembly by the body of the condenser (not by the flask joint). Allow for space beneath the flask for<br />

manually raising and lowering the cold water bath. The instructor will next add about 10 mL of dry Et 2 O and 4.5

Exp 29.5 Alkylation of m-Xylene 2<br />

mL (or 6.71 g) of bromobenzene. Since the <strong>Grignard</strong> reaction normally will not start on its own, the instructor will<br />

come to your hood to press on the Mg turnings with a flattened glass rod. A white turbidity will develop as the<br />

<strong>Grignard</strong> reagent first begins to form. The exothermic formation of <strong>Grignard</strong> will cause the Et 2 O to reflux rapidly.<br />

Allow the reflux to continue at a rapid boil until the Mg has nearly disappeared. The reaction solution will darken to<br />

amber as the concentration of PhMgBr builds. Cool the flask with the cold bath intermittently for 1-2 seconds at a<br />

time to control the reflux rate. As the auto refluxing begins to slow down, heat the flask with a hot water bath drawn<br />

from the sink for another 5-10 minutes. At this point install a clean dry addition funnel at the top of the condenser.<br />

Either you or the instructor should add 2.5 mL (ca. 2.5 g) of methyl benzoate and 10 mL of dry Et 2 O. Agitate the<br />

solution to mix the contents. Open the stopcock and drip about ¼ the volume of methyl benzoate solution into the<br />

reaction with cooling from a cold bath. The methyl benzoate and PhMgBr react within seconds, causing the Et 2 O to<br />

reflux. Drip the remaining solution in at a rapid rate with continued cooling. Note the color transitions of the<br />

reaction as methyl benzoate is added. Heat the reaction for an additional 5-10 minutes from a warm water bath.<br />

Work Up<br />

Quenching the <strong>Reaction</strong>: Into a large beaker, add ca 15 g (ca. 30 mL) of crushed ice and 25 mL of 10%<br />

H 2 SO 4 . Detach the reaction flask from the condenser. Use a glass rod and swirling motions to loosen the thick<br />

white Mg salt complex. While the white emulsion is still fluid, pour the entire contents of the flask in a single<br />

motion into the H 2 SO 4 and ice mixture. Complete the transfer by pouring some of the H 2 SO 4 and Et 2 O back to the<br />

flask with swirling. The H 2 SO 4 hydrolyzes the white Mg alkoxide product complex and any remaining unreacted<br />

Mg metal turnings within about 10 minutes.<br />

* [this is a potential stopping point for continuation the next lab period; the instructor will advise the class]<br />

Separatory Funnel Extraction: If Et 2 O has evaporated from the reaction at this point or upon standing<br />

between lab periods, add more Et 2 O back (visual estimate OK). Transfer everything quantitatively to a separatory<br />

funnel using small portions of additional Et 2 O to complete the transfer. Shake the separatory funnel carefully with<br />

frequent venting of gases especially at the early stage of shaking (instructor will demonstrate). Draw off the<br />

aqueous layer into a beaker and extract the Et 2 O with a second portion of dilute H 2 SO 4 and draw off the aqueous<br />

layer. Shake the Et 2 O with saturated NaCl (ca. 1/3 the volume of Et 2 O layer) to remove some of the water dissolved<br />

in the Et 2 O. Pour the Et 2 O out the top of the separatory funnel (Note B) into a clean dry 125 mL Erlenmeyer flask.<br />

Crystallization by Concentrating the Solution: Add dessicating agent provided in lab, such as, CaCl 2 , or<br />

Na 2 SO 4 , or MgSO 4, (ca. 1/5 the volume of the Et 2 O layer, Note C). Transfer the Et 2 O to a tared Erlenmeyer flask<br />

(Note D). Add 15 mL of ligroin to the Et 2 O, cover the Erlenmeyer flask loosely with a piece of foil, add a glass rod<br />

rather than a boiling chip for ebullation, and warm the flask gently on a hot plate to concentrate the solution. Be<br />

careful to monitor the setting of the hot plate to avoid splattering. The Et 2 O (bp 34°C) distills at a faster rate than<br />

ligroin (bp 60 - 80°C). As the solution becomes more concentrated in ligroin, the triphenylmethanol product, which<br />

is less soluble in ligroin, will begin to separate. If the solution becomes cloudy (“cloud point”) then remove the<br />

flask from the hot plate and set it on a paper towel on your bench with an inverted beaker covering it to protect it<br />

from drafts. If no cloud point develops, then remove the flask from the hot plate when the solution has reduced to<br />

ca. 20 mL (visual estimate) (Note E).<br />

Isolation Steps<br />

Buchner Funnel Filtration: You may perform this vacuum filtration in the hood or on the open bench<br />

(although hood is preferred due to the organic vapors). *Remember to clamp the filter flask. Use the correct<br />

sized paper for your Buchner funnel and wet the paper with ligroin just before pouring the crystal mixture through.<br />

Also stir the crystals with a glass rod to create a suspension prior to pouring the crystal mixture through the Buchner<br />

funnel. Dry the crystals thoroughly and determine the % yield. Finally, determine the melting point of your product<br />

and compare the result to the literature value. Submit the product in a labeled vial.<br />

Summary of Final Steps:<br />

1. Weigh the triphenylmethanol and determine the yield<br />

2. Determine the mp of the recrystallized triphenylmethanol product.<br />

3. Submit the product in a vial labeled with your name and experiment name “<strong>Grignard</strong>”.

Exp 29.5 Alkylation of m-Xylene 3<br />

Notes:<br />

A. Fresh indicating Drierite is anhydrous CaSO 4 impregnated with a blue moisture indicator that turns<br />

pink upon absorbing moisture. The instructor can show the class how the drying tube can be<br />

connected to the pre-assembled hot glassware so that dry air enters the glassware during cooling.<br />

B. The Et 2 O is poured out the top of the separatory funnel to minimize collection of water droplets<br />

together with the Et 2 O. Residual water droplets exist on the inside walls of the separatory funnel and<br />

Teflon valve area. You should first dry the ground glass joint of the separatory funnel with a paper<br />

towel before pouring out the top.<br />

C. As always, cover the mouth of the Erlenmeyer flask with aluminum foil or Parafilm when drying. An<br />

open vessel reabsorbs moisture on standing.<br />

D. If the Et 2 O is cloudy, this would likely be due to fine particles of dissicant in suspension, in which case<br />

the Et 2 O should be filtered. If the Et 2 O is clear, then carefully decant the Et 2 O leaving the dessicant<br />

behind; usually the dessicant is clumped from moisture absorption at the bottom of the glassware and<br />

is therefore easy to separate. Wash the dessicant with a small portion of Et 2 O to complete the transfer.<br />

E. Crystallization techniques are an art. Generally, the best crystal quality is obtained when the hot<br />

solution is allowed to cool slowly as opposed to immersing the hot flask in an ice bath right away,<br />

which would result in a powdery separation “crashing out” of product. You may encounter<br />

supersaturation of your solution upon standing. In this case, the flask may cool without formation of<br />

crystals. By gently immersing a glass rod into the solution and scratching the glass surfaces, you can<br />

induce nucleation (the instructor will help you with this if you wish).<br />

Waste & Clean Up:<br />

Into Mr. White: All aqueous washings; organic residues; and acetone rinses of dirty equipment<br />

Prep Room Instructions:<br />

For a class of 24 students<br />

1. bromobenzene 150 mL<br />

2. methyl benzoate 50 mL<br />

3. magnesium turnings 24 g<br />

4. Et 2 O, anhydrous 1 L (fresh bottle each class for ensured dryness of solvent)<br />

5. Et 2 O, general solvent 1 L<br />

6. Drierite or CaCl 2 , anhy. general supply; used for drying tubes<br />

7. sat. NaCl (brine solution) 1 L<br />

8. dessicant 1 st choice: Na 2 SO 4 ; 2 nd choice CaCl 2 or MgSO 4<br />

9. boiling chips bottle<br />

10. foil roll<br />

11. cotton small quantity for covering joint openings<br />

12. filter papers 42 mm & 5.6 cm sizes for Buchner funnels; plus larger sizes, eg. 12 cm

Exp 29.5 Alkylation of m-Xylene 4<br />

Grading:<br />

_____ 20 pts Qz 5<br />

_____ 10 pts Notebook entry (format, details of procedure, observations throughout)<br />

Evaluation Categories<br />

_____ 20 pts Bench Skills for this experiment:<br />

anhydrous reaction techniques<br />

correct assembly precautions of Williamson glassware (grease, Keck clips)<br />

maintaining control of reaction temps using baths<br />

addition of methyl benzoate solution from addition funnel atop condenser<br />

quenching the reaction over ice and 10% H 2 SO 4<br />

separatory funnel extraction & washing steps<br />

crystallization of triphenylmethanol from hot Et 2 O - ligroin<br />

Buchner funnel setup (clamping precaution)<br />

Buchner funnel isolation & drying of triphenylmethanol<br />

determination of % yield<br />

determination of mp<br />

general safety & GLP (good laboratory practices):<br />

eg. safety googles, waste handling, clean up, careless breakage, etc.<br />

_____ 25 pts Product Quality:<br />

• visual appearance such as color, uniformity, comparison to average results<br />

in class and/or reference materials<br />

• melting point<br />

_____ 25 pts % Yield<br />

100 total