Simba W7 C - Atlas Copco

Simba W7 C - Atlas Copco

Simba W7 C - Atlas Copco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Atlas</strong> <strong>Copco</strong> Production drilling rigs<br />

<strong>Simba</strong> <strong>W7</strong> C<br />

Technical specification<br />

www.atlascopco.com<br />

<strong>W7</strong> C<br />

<strong>W7</strong> C<br />

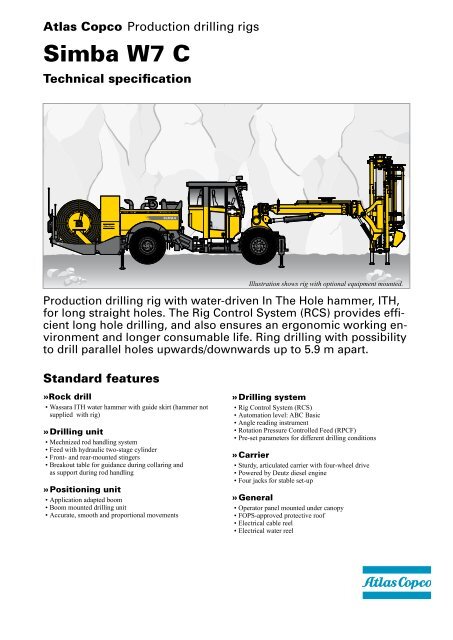

Production drilling rig with water-driven In The Hole hammer, ITH,<br />

for long straight holes. The Rig Control System (RCS) provides efficient<br />

long hole drilling, and also ensures an ergonomic working environment<br />

and longer consumable life. Ring drilling with possibility<br />

to drill parallel holes upwards/downwards up to 5.9 m apart.<br />

Standard features<br />

Illustration shows rig with optional equipment mounted.<br />

»Rock drill<br />

• Wassara ITH water hammer with guide skirt (hammer not<br />

supplied with rig)<br />

»Drilling » unit<br />

• Mechnized rod handling system<br />

• Feed with hydraulic two-stage cylinder<br />

• Front- and rear-mounted stingers<br />

• Breakout table for guidance during collaring and<br />

as support during rod handling<br />

»Positioning »<br />

unit<br />

• Application adapted boom<br />

• Boom mounted drilling unit<br />

• Accurate, smooth and proportional movements<br />

»Drilling » system<br />

• Rig Control System (RCS)<br />

• Automation level: ABC Basic<br />

• Angle reading instrument<br />

• Rotation Pressure Controlled Feed (RPCF)<br />

• Pre-set parameters for different drilling conditions<br />

»Carrier »<br />

• Sturdy, articulated carrier with four-wheel drive<br />

• Powered by Deutz diesel engine<br />

• Four jacks for stable set-up<br />

»General »<br />

• Operator panel mounted under canopy<br />

• FOPS-approved protective roof<br />

• Electrical cable reel<br />

• Electrical water reel

Specifications<br />

»Electrical »<br />

system<br />

<strong>Simba</strong> <strong>W7</strong> C<br />

FEED<br />

BMH 200-series BMH 235 BMH 236<br />

Total length 3 300 mm 3 510 mm<br />

Drill pipe length 1 500 mm 1 800 mm<br />

»Boom »<br />

• Boom................................................................... BUT 45 PDS<br />

• Feed extension......................................................... 1 200 mm<br />

• Boom extension....................................................... 1 000 mm<br />

• Max. lifting angle...................................................... +55º/-42°<br />

• Max. swinging angle.........................................................±35°<br />

• Weight, boom only.......................................................3400 kg<br />

• Rotary actuator..................................................................360°<br />

»Drilling » unit<br />

• Rod Handling System, RHS 27............................... 27+1 rods<br />

• Adaptable to 5′ and 6′ rods<br />

• Adaptable to TDS 76, TDS 89 drill rods<br />

• Stingers on feed<br />

--Two forward, BSJ 8-115<br />

--Two backwards, BSJ 8-200<br />

• Mechanized drilling up to 51 m<br />

»Control » system<br />

• Rig Control System (RCS) – versatile and upgradeable to a<br />

higher degree of automation<br />

• Exposed components are designed and tested acc. to IP 65<br />

• USB-memory stick for transfer of data and storage of drill<br />

parameters<br />

• Integrated diagnostic system<br />

• Angle reading instrument<br />

»Power » pack<br />

• Hydraulic pumps for rotation, positioning and feed<br />

• Pumps unloaded at start<br />

• System pressure, max.................................................. 250 bar<br />

• Hydraulic oil tank, volume max/min........................ 250/200 l<br />

• Low oil level indicator and shut-down<br />

• Oil temperature gauge on oil tank, electronically supervised<br />

• Smart oil leakage shut-down system<br />

• Filtration, absolute......................................................... 16 μm<br />

• Oil filter indicator<br />

• Water cooled oil cooler in stainless steel<br />

• Mineral hydraulic oil<br />

• Total installed power....................................................193 kW<br />

• Main motors ..................................................................55 kW<br />

• Water pump, 400 V DC...............................................130 kW<br />

• Voltage..................................................................400–1000 V<br />

• Frequency..................................................................50/60 Hz<br />

• Starting method.........................star/delta (400–690 V/55 kW)<br />

• Electronic overload protection for electric motors<br />

• Digital volt/amperage meter in electric cabinet<br />

• Phase sequence indicator<br />

• Earth fault indicator<br />

• Battery charger<br />

• Transformer....................................................................8 kVA<br />

• Working lights, mounted on roof..........................2 x 1 000 W<br />

• Cable reel with limit switch<br />

»Carrier »<br />

• Engine<br />

--Deutz TCD 4-cylinder 2013 L04 2 V (Stage III A/EPA Tier<br />

3) 120 kW/572 Nm<br />

• Hydrodynamic transmission.................................Clark 32000<br />

• Front axle.................................................................. Dana 114<br />

• Rear axle .........................................Dana 114, ±8° oscillation<br />

• Articulated steering................................... ±38° steering angle<br />

• Tyres.......................................................................14.00xR24<br />

• Clearance outside axles................................. 8º rear, 23º front<br />

• Automatic differential lock on front axle, limited slip<br />

• Hydrostatic power steering system<br />

• Four-wheel drive<br />

• Hydraulic jacks, front ......................................... 2 extendable<br />

• Hydraulic jacks, rear...............................................................2<br />

• Service brakes. 2 separate circuits (hydraulically applied, fully<br />

enclosed wet disc brakes)<br />

• Emergency and parking brakes.............. SAHR, 6 disc system<br />

• Fuel tank, volume.............................................................110 l<br />

• Electric system..................................................................24 V<br />

• Batteries....................................................................2x125 Ah<br />

• Tramming lights................................................................LED<br />

• Gradeability at max. load on drive wheels......................... 1:4<br />

• Horn, beacon, reverse alarm and brake lights<br />

• FOPS-approved protective roof<br />

• Swingable operators seat with safety belt<br />

• LED illuminated stairs for platform<br />

• Central lubrication system<br />

• Rig alignment laser RAL 650<br />

• Fire extinguisher<br />

• Spirit level....................one for longitudinal, one for sideways<br />

• Shelf for drill bits and tools<br />

• Exhaust catalyser<br />

• Silencer<br />

»Water » system<br />

• Water booster pump on board<br />

• Capacity............................................................ max 350 l/min<br />

• Filter unit....................................................................... 50 μm<br />

• Automatic filter surveillance and cleaning<br />

• Air separator/Pulsation damper<br />

• Recycling system<br />

• Water pressure gauge<br />

• Water hose reel..........................................................3’’/120 m<br />

• Minimum water inlet pressure......................................... 2 bar

Specifications<br />

<strong>Simba</strong> <strong>W7</strong> C<br />

DRILL STEEL<br />

Rock drill Hole diameter, mm Drill pipe diameter, mm Drill pipe lenght, mm<br />

Hammer W100 115 102 1 500/1 800<br />

Hammer W120 165 102 1 500/1 800<br />

Optional equipment<br />

»Positioning »<br />

system<br />

• Automatic lubrication for positioning system<br />

• Central lubrication for positioning system<br />

»Automation<br />

»<br />

• <strong>Simba</strong> ABC Regular<br />

• <strong>Simba</strong> ABC Total<br />

• Drill Plan Handling<br />

• Full Drill Data Handling<br />

• Rig Remote Access<br />

• Breakthrough Automatic Stop<br />

• Text Message System<br />

• Remote Cradle Control/Remote Feed Control<br />

• Mine Navigation<br />

• Void Detection<br />

• Total station navigation<br />

»Carrier »<br />

• Fire suppression system, manual<br />

• Fire suppression system, automatic (check-fire)<br />

• Fire suppression system, full automatic<br />

• Particle filter UNIKAT<br />

• Solid tyres<br />

» »Miscellaneous<br />

• Manual rig washing kit<br />

• Hose and cable guide at water/cable reel<br />

• Link-one parts book<br />

• Remote operating kit<br />

• Additional panel<br />

• Manual spotlight<br />

»Electrical »<br />

system<br />

• Electrical cable on reel, Buflex<br />

• Plug PC5<br />

• Socket PC5<br />

• Switch gear<br />

• Electrical outlet, 16 A<br />

• Extra transformer, 15 kVA<br />

• Extra working lights, 2 x 80 W, 24 V (on tripod)<br />

• Electrics according to local standards<br />

»Cabin »<br />

• FOPS-approved cabin:<br />

--Swingable seat<br />

--Media player<br />

--Boot washing kit<br />

--Air conditioning unit without heating<br />

• Stainless steel cabin<br />

• Air conditioner with heating<br />

• Front window, 24 mm<br />

• FOPS-approved grizzly bar for front window<br />

• Cabin lift/tilt system, 375 mm/15º<br />

• Reversing camera with monitor<br />

• Joystick controlled spotlight<br />

• Low profile

Measurements<br />

<strong>Simba</strong> <strong>W7</strong> C<br />

side view<br />

www.atlascopco.com<br />

8.5°<br />

Coverage area<br />

TBA<br />

3100<br />

Dimensions<br />

in mm<br />

DIMENSIONS<br />

mm Width 2 550<br />

WEIGHT<br />

150<br />

Height tramming 3 100<br />

Length tramming 12 100<br />

Ground clearance 340<br />

gross weight<br />

<strong>W7</strong> C<br />

TURNING RADIUS<br />

depending on surface<br />

3744<br />

1200 (900)<br />

Feed extension<br />

1 000<br />

5844<br />

mm Outer 8 300<br />

Inner 4 700<br />

kg Total 32 000<br />

Boom side 17 000<br />

Engine side 15 000<br />

10 o<br />

3 500 1 000<br />

2100<br />

1150 Stinger extension<br />

55 o 90 o<br />

360 o<br />

2 000<br />

Stinger extension<br />

4300<br />

11893<br />

<strong>W7</strong> C<br />

2200<br />

30 o 35 o<br />

980<br />

6049<br />

Illustration shows rig with optional equipment mounted.<br />

1 000<br />

RECOMMENDED CABLE SIZE AND LENGTH<br />

Voltage Type Dimension, mm 2 Diameter,<br />

mm<br />

400 V Buflex 3x240+3x50 68 60<br />

440–460 V Buflex 3x240+3x50 68 60<br />

500–550 V Buflex 3x185+3x35 56 90<br />

660–690 V Buflex 3x120+3x25 46 135<br />

1 000 V Buflex 3x95+3x16 45 150<br />

Recommendations are given for surrounding temperature of 40 o C.<br />

1000 5200 770<br />

Length,<br />

m<br />

© Copyright 2012, <strong>Atlas</strong> <strong>Copco</strong> Rock Drills AB, Örebro, Sweden. All product names in this publication are trademarks of <strong>Atlas</strong> <strong>Copco</strong>. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos<br />

may show equipment with optional extras. No warranty is made regarding specifications or otherwise. Specifications and equipment are subject to change without notice. Consult your <strong>Atlas</strong> <strong>Copco</strong> Customer Center for specific information.<br />

9851 2942 01 02/2012