South

South

South

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

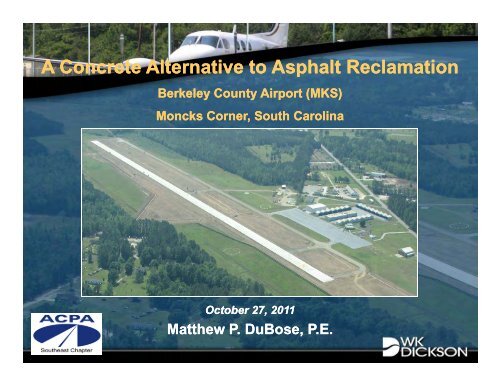

A Concrete Alternative to Asphalt Reclamation<br />

Berkeley County Airport (MKS)<br />

Moncks Corner, <strong>South</strong> Carolina<br />

October 27, 2011<br />

Matthew P. DuBose, P.E.

Project Team<br />

• Federal Aviation Administration<br />

• <strong>South</strong> Carolina Aeronautics<br />

Commission<br />

• Berkeley County (County Engineering)<br />

• W.K. Dickson & Co., Inc.<br />

Consultant<br />

• APAC-Tennessee<br />

Contractor (Contract #1)<br />

• Sanders Brothers Construction<br />

Contractor (Contract #2)<br />

• Many additional subconsultants and<br />

subcontractors

Airport Location<br />

• Airport located in Moncks Corner, <strong>South</strong> Carolina; <strong>South</strong> Carolina’s Lowcountry<br />

• Lowcountry area known for poor surface/storm drainage, flat grades<br />

Berkeley County Airport

Airport History<br />

• Original pavement data for Runway dated 1967<br />

• Original Runway 3,100’ long and 60’ wide; comprised of asphalt and sand-clay<br />

base<br />

• Extensions, a widening and an overlay have occurred over last four decades<br />

• Current facility consists of a runway that is 4,351’ long and 75’ wide and includes<br />

full parallel taxiway

Project History<br />

• Original CIP identified need for<br />

2” maintenance overlay<br />

• Discussions with Sponsor<br />

identified the desire to embark<br />

on aggressive, multi-stage<br />

Airport expansion<br />

• Ultimate desire was 5,000’ long<br />

x75’ wide runway<br />

• Additional projects include<br />

power line relocation,<br />

obstruction removal, existing<br />

pavement rehab, runway and<br />

taxiway extension and a<br />

drainage improvements project

Project History<br />

• Original design was 2 phases<br />

• Drainage Study, pavement evaluation, then design for both<br />

• Discussions with Sponsor and funding agencies one design project (prelim<br />

and final together)<br />

• Runway Pavement Rehabilitation & Drainage Improvements Project<br />

• 3 Schedules of Work; ability to award independently<br />

• Schedule I – Pavement Rehab / Reconstruction<br />

• Schedule II – Runway Edge Lighting System Replacement<br />

• Schedule III – Airfield Drainage Improvements

Project Process<br />

• 3 Schedules of Work 2 Contract Options<br />

• Schedule I – Pavement Rehab (Contract #1)<br />

• Schedule II – Runway Edge Lighting System Replacement (Contract #1)<br />

• Schedule III – Airfield Drainage Improvements (Contract #2)<br />

• Based on funding available once bids received, award one or both contracts<br />

• Prior to bids, team not optimistic to construct both contracts due to funding<br />

limitations

Runway Pavement Rehab - Design Criteria<br />

• Identify major components needed for<br />

design of new pavement:<br />

• Existing pavement sections and<br />

conditions<br />

• Existing CBR and subgrade<br />

conditions; destructive & non-<br />

destructive ti testing ti performed<br />

• Existing aircraft fleet mix, with eye to<br />

the future<br />

• Additional or extenuating<br />

circumstances (i.e. poor surface and<br />

subsurface drainage)

Runway Pavement Rehab - Design Criteria<br />

• Findings in subsurface investigation reveal three major sections of existing<br />

runway pavements

Runway Pavement Rehab - Design Criteria<br />

• Summary of sections of existing runway:<br />

• Section 1 – (Initial runway 3,100’) – 4.4” Asphalt, 0” Base<br />

• Section 2 – (Ext. #1) – 4.8” Asphalt, 4” Coquina Base<br />

• Section 3 – (Ext. #2) 2” Asphalt, 6” Crushed Aggr. Base<br />

• Based on FAARFIELD analysis, structurally-limiting section was initial runway<br />

construction (Section 1)

Runway Pavement Rehab - Design Criteria<br />

• Based on geotech report, subgrade conditions were very poor<br />

• Wet soils, low strength and stability<br />

• Design CBR = 6 and k-value = 120 pci based on conversations with Geotechnical<br />

Engineer

Runway Pavement Rehab - Design Criteria<br />

• Fleet Mix – developed from information compiled from FAA Form 5010, 2002<br />

Airport Layout Plan (ALP), Sponsor and general knowledge of Airport<br />

No.<br />

Name<br />

Gross Wt.<br />

lbs<br />

Annual<br />

Departures<br />

% Annual<br />

Growth<br />

1 Sngl Whl-5 5,000 18,000 5.00<br />

2 Sngl Whl-12.5 12,500 1,000 5.00<br />

3 Dual Whl-30 30,000 250 3.00<br />

4 Dual Whl-60 65,000 250 2.00<br />

• Ultimate desired design strength for new pavement was for 65,000 pounds, dual-<br />

wheel gear aircraft, per ALP

Runway Pavement Rehab - Design Criteria<br />

• Additional or Extenuating Conditions<br />

• Poor surface and subsurface drainage present<br />

• Use of concrete ditches, underdrains and small stormwater pumping station<br />

to address water-related related issues<br />

• Important to raise elevation of pavement grade, if possible

Runway Pavement Rehab - Design Criteria<br />

• Summary of Design Criteria:<br />

• 3 main sections of pavement, critical area is original Runway<br />

• Poor existing subgrades and CBR/k-values<br />

• Fleet mix based on typical general aviation fleet; most demanding aircraft is<br />

65,000# DWG<br />

• Surface and subsurface drainage issues<br />

• Complete reconstruction not monetarily feasible

Runway Pavement Rehab - Design Criteria<br />

• Based on aforementioned criteria, 2 primary designs for bidding:<br />

• Schedule IA – Cement-Based Full-Depth Asphalt Reclamation<br />

• Schedule IB – Portland Cement Concrete Overlay (Whitetopping)<br />

• All prelim and final designs per FAA Advisory Circular 150/5320-6E and<br />

FAARFIELD design software

Runway Pavement Rehab – Asphalt Reclamation<br />

• Cement application<br />

• Reclaim existing surface<br />

& base course (full-<br />

depth)<br />

• Recompact/re-grade to<br />

serve as new base<br />

• Overlay with asphalt<br />

Photo courtesy of The Barnhardt Group

Runway Pavement Rehab – Asphalt Reclamation<br />

• 4” Asphalt Surface<br />

Course<br />

• Double Chip Seal or<br />

“BST”<br />

• 7” (Min.) Reclaimed<br />

Base; Grade<br />

Correction Required<br />

• Subgrade CBR of 6

Runway Pavement Rehab – Asphalt Reclamation<br />

P-301 Cement Stabilized Reclaimed Base Course 36,260 SY $3.65 $132,349.00<br />

P-301 Portland Cement for Reclaimed Base Course 1,050 TON $110.00 $115,500.00<br />

P-301<br />

Added Coarse Aggregate for Reclaimed Base<br />

Course<br />

1,000 TON $44.85 $44,850.00<br />

P-401 Bituminous Surface Course 9,100 TON $110.00 $1,001,000.00<br />

• Bid with cement as separate item<br />

• Additional coarse aggregate anticipated for lack of base course in areas<br />

• Initial costs of pavement section alone ~ $1.3 million<br />

• Initial costs of all paving-related items ~ $1.48 million

Runway Pavement Rehab – PCC Overlay<br />

• Limiting Section 4.4”<br />

Asphalt, No Base<br />

• Design Flex Strength of<br />

685 psi<br />

• k-value of 120 pci<br />

• Grade Correction<br />

(Milling)<br />

• Sand “Bond-Breaker”

Runway Pavement Rehab – PCC Overlay

Runway Pavement Rehab – PCC Overlay<br />

• Concrete Joint Layout<br />

• Both 25’ &12.5’ wide paving lanes, 12.5’ square panels<br />

• Designed for dowels on<br />

outer lane<br />

• Same amount of dowels<br />

with either layout

Runway Pavement Rehab – PCC Overlay<br />

P-209 Crushed Aggregate Base Course 770 CY $60.70 $46,739.00<br />

P-401 Bituminous Surface Course 920 TON $176.00 $161,920.00<br />

P-501 Portland Cement Concrete Pavement 36,260 SY $32.90 $1,192,954.00<br />

• Crushed aggregate used as<br />

equipment platform<br />

• Asphalt needed d at Taxiway<br />

connections (+9”)<br />

• Initial costs of pavement section<br />

alone ~ $1.2 million<br />

• Initial costs of all paving-related<br />

items ~ $1.56 million

Runway Pavement Rehab – Life Cycle Analysis<br />

• Life Cycle Cost Analysis performed based on 30 years<br />

• Asphalt – 30 year life<br />

• Maintenance on joints/cracks in Years 8 & 23<br />

• 2” Overlay in Year 15<br />

• Present worth cost at end of life ~ $1.72 million<br />

• Concrete – 40 year life<br />

• Maintenance on joints in Years 10 & 20<br />

• Present worth cost at end of life ~ $1.54 million<br />

• “Savings” from salvage value at Year 30, more life anticipated

Runway Pavement Rehab – Life Cycle Analysis<br />

• Asphalt ~ $47.50 / Square Yard<br />

• Concrete ~ $42.51 / Square Yard<br />

• LCCA open to interpretation<br />

• Concrete best option in terms of price, useful life, avoidance of potential ti weather<br />

delays and grade-related drainage issues<br />

• Schedule IB Bid awarded to APAC-Tennessee<br />

• Contracts #1 & #2 awarded<br />

• Total FAA grant amount - $3,583,309

Runway Pavement Rehab – Construction<br />

• Construction commenced November 15, 2010 – big benefit to construct<br />

concrete alternative<br />

• Contractors for Contracts 1 & 2 working simultaneously<br />

• Contractor mobilization & staging area<br />

• Demo of existing pipes and utilities under Runway<br />

• Installation of new drainage structures<br />

• Grade correction on existing pavements<br />

• Underdrain system<br />

• Concrete paving<br />

• Shoulder work and taxiway connectors<br />

• Finalize concrete ditches, pump station and grading

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction<br />

• Concrete Mix<br />

• “Typical” P-501, increase in airentrainment<br />

granted to 3.5%<br />

• 650 psi flex strength<br />

• Delivered in ready-mix trucks,<br />

no batch plant<br />

• Initial i thoughts h were up to 4<br />

trucks delivering at a time,<br />

actual 2-3<br />

• Actual average was ~ 90-100<br />

cubic yards / hour;<br />

• On-site QC trailer & beam<br />

breaks

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction

Runway Pavement Rehab – Construction<br />

• LED Runway Edge Light<br />

• Medium Intensity<br />

• Entire system enclosed<br />

• All cans and conduit, weep holes at<br />

low points

Runway Pavement Rehab – Construction

Summary<br />

• ~ 36,200 square yards of concrete placed on Runway (~9,600 cubic yards)<br />

• Weather days non-issue with concrete compared to reclamation<br />

• Contract time was extended due to two change order issues<br />

• New LED Runway Lights – believed to be first in SC on general aviation<br />

Airport<br />

• New underdrain pump system – believed to be first in SC of its kind<br />

• Concrete a huge success due to monetary feasibility, useful life and grade<br />

issues with Lowcountry site

Questions Comments