Untitled - National Roofing Contractors Association

Untitled - National Roofing Contractors Association

Untitled - National Roofing Contractors Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Coal-tar roofing products are described by ASTM Standard<br />

0-450, Types I & III, "Coal Tar Pitch Used in <strong>Roofing</strong>,<br />

Dampproofing and Waterproofing." Types I & "' are<br />

suitable for use in the construction of coal tar built-up<br />

roofing, the difference being that Type III has less volatile<br />

components than Type I. The Equiviscous Temperature<br />

(EVT) concept is equaJly applicable to coal tar<br />

products, although the recommended viscosity base is<br />

considerabfy lower for the coal tar products than for roofing<br />

asphalts. In the event the information is not furnished<br />

by the supplier, the following temperature ranges appear<br />

to be appropriate for coal tar for ~h mechanicaJ spreader<br />

and mopping application techniques:<br />

. Coal Tar Pitch (Type I) approximately 360 F plus<br />

or minus 25 F<br />

. Coal Tar Bitumen (Type III) approximately 375 F<br />

plus or minus 25 F<br />

XXI. WATER CUTOFFS AND<br />

WEATHER PROTECTION<br />

Water cutoffs are temporary felt courses that are installed<br />

to prevent moisture from entering the insulation and<br />

membrane during construction. They should be applied<br />

at the end of each day's work and whenever work is halted<br />

for an indefinite period to protect the membrane from<br />

precipitation. They must be removed prior to installing<br />

additional insulation.<br />

Temporary flashings should be installed as weather protection<br />

If permanent flashings are not in place. All openings<br />

in the membrane should be sealed to prevent any<br />

moisture from entering the roof system before completing<br />

membrane application.<br />

Specifications requiring gravel installation each day are<br />

unrealistic and sometimes detrimental to the quality of<br />

the completed roof. Where working conditions permit,<br />

roofing felts should be "glazed" and sealed at the end<br />

of each day's work if final surfacing is not installed.<br />

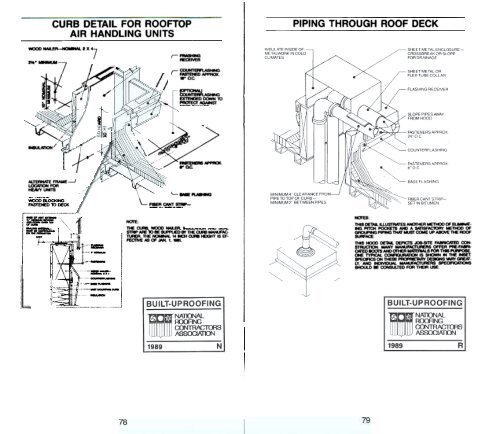

The most vulnerable part of any roof system is that point<br />

at which the horizontal roof deck and a vertical surface<br />

join. Most roof leaks occur at these flashing locations.<br />

The designers should carefully consider the design of<br />

flashing details at these locations. (See NRCA Construction<br />

Details in the NRCA <strong>Roofing</strong> and Waterproofing<br />

Manua/.)<br />

The term flashing can be divided into two groups:<br />

1. Composition Flashing (Base Flashing)<br />

The bending radius of present composition roofing<br />

materials is generally limited to 45 degrees. To allow<br />

for this bending radius, all vertical surfaces must<br />

have cant strips installed between the roof and the<br />

vertical surface. The height of the base flashing<br />

should be not lower than (a nominal) 8 inches and<br />

not higher than (a nominal) 14 inches above the<br />

finished roof surface. Walls requiring flashings<br />

higher than 14 inches should receive special<br />

moisture-proofing. A wood nailer strip or suitable detail<br />

allowing mechanical fastening of the base flashing<br />

at the top must be provided. Masonry surfaces<br />

should be primed with asphalt concrete primer.<br />

Expansion joint flashings (allowing expansion and<br />

contraction) should be constructed as detailed in the<br />

NRCA Construction Details. The wood curbing<br />

should be placed against the wall and secured only<br />

to the deck. The designer is cautioned to consider<br />

that building components are subjected to thermal<br />

movements at different rates and in different directions<br />

from the roof membrane. If the roof is to be tied<br />

into these components, special consideration should<br />

be given to the design of that juncture.<br />

2. Metal Flashing (Counterflashlng and Cap<br />

Flashing)<br />

Since metals have a high coefficient of expansion.<br />

metal flashing must be isolated from the roof mem-<br />

36 37

![Wm] - National Roofing Contractors Association](https://img.yumpu.com/36696816/1/190x245/wm-national-roofing-contractors-association.jpg?quality=85)