Three-phase squirrel cage crane motors - Cantoni Group

Three-phase squirrel cage crane motors - Cantoni Group

Three-phase squirrel cage crane motors - Cantoni Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Three</strong>-<strong>phase</strong> <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong><br />

APPLICATION<br />

Crane <strong>motors</strong> are used for driving hoists, <strong>crane</strong>s, elevators and any machines of intermittent duty with electrical braking, of<br />

bi-directional rotation.<br />

The <strong>crane</strong> <strong>motors</strong> are manufactured as:<br />

- <strong>squirrel</strong> <strong>cage</strong> <strong>motors</strong> for S4-40% or S4-25% duty cycle,<br />

- wound rotor <strong>motors</strong> for S3-25%, S3-40%, S3-60%, S3-100% duty cycle (10 minutes cycle).<br />

Another duties are acceptable, but the rule of energy balance in every duty should be retained. The time of starting and<br />

breaking period should be included into the operation time. If the load is of variable type it should be reduced to stable for a<br />

definite period of time.<br />

Definitions of duty kinds and rating classes are given in Section 3 IEC 60034-1 standard.<br />

Totally enclosed <strong>motors</strong> IP 54 (IP55, IP56)<br />

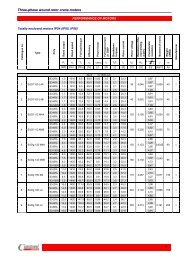

PERFORMANCE OF MOTORS<br />

Catalogue no.<br />

Type<br />

Rated output<br />

Rated speed<br />

Full load<br />

torque<br />

Efficiency<br />

Power factor<br />

Full load current at<br />

Locked rotor<br />

torque<br />

Locked rotor<br />

current<br />

Breakdown<br />

torque<br />

Moment of<br />

inertia<br />

Weight (IMB3)<br />

Manufacturer<br />

P n n n T n η n cos ϕ n I 1n T L/T n I L/I n T b/T n J m<br />

[kW] [min -1 ] [Nm] [%] [-] [A] 380V [A] 400V [A] 500V [-] [-] [-] [kgm 2 ] kg<br />

2p=6 n=1000 rpm<br />

1. SDg 132 S6 3,0 920 31,1 77,2 0,74 8,0 7,6 6,1 290 450 290 0,025 50 I<br />

2. SDg 132 M6A 4,0 920 41,5 80,6 0,77 9,8 9,3 7,4 330 530 330 0,033 66 I<br />

3. SDg 132 M6B 5,5 920 57,1 80,7 0,78 13,3 12,6 10,1 370 550 370 0,042 72 I<br />

4. SDg 160 M6 7,5 965 74,2 86,5 0,77 17,1 16,2 13,0 250 750 340 0,065 105 I<br />

5. SDg 160 L6 11,0 970 108,3 88,0 0,79 24,0 22,8 18,2 270 770 330 0,092 130 I<br />

6. SDg 180 L6 15,0 975 146,9 89,0 0,84 30,5 29,0 23,2 250 600 230 0,227 160 I<br />

2p=8 n=750 rpm<br />

7. SDg 132 S8 2,2 715 29,4 67,5 0,62 8,0 7,6 6,1 250 460 280 0,035 50 I<br />

8. SDg 132 M8 3,0 715 40,1 77,0 0,69 8,6 8,2 6,5 250 520 280 0,042 60 I<br />

9. SDg 160 M8A 4,0 710 53,8 81,0 0,72 10,4 9,9 7,9 240 530 290 0,056 90 I<br />

10. SDg 160 M8B 5,5 710 73,0 82,5 0,71 14,3 13,6 10,9 280 580 330 0,078 100 I<br />

11. SDg 160 L8 7,5 715 100,2 84,0 0,71 19,1 18,1 14,5 300 630 380 0,100 120 I<br />

12. SDg 180 L8 11,0 735 142,9 85,0 0,67 29,3 27,8 22,3 240 590 280 0,220 160 I<br />

Rated output is valid for S4-40% duty.<br />

MOUNTING ARRANGEMENTS, BEARING<br />

FOOT MOUNTING FOOT / FLANGE MOUNTING FLANGE MOUNTING BEARINGS<br />

Type / available execution Type / available execution Type / available execution D ND<br />

2p = 6 n=1000 rpm<br />

SDg 132 S6 B3;B6;B7;B8,V5;V6 SDLg 132 S6 B35,V15;V36 SDKg 132 S6 B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 132 M6A B3;B6;B7;B8,V5;V6 SDLg 132 M6A B35,V15;V36 SDKg 132 M6A B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 132 M6B B3;B6;B7;B8,V5;V6 SDLg 132 M6B B35,V15;V36 SDKg 132 M6B B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 160 M6 B3;B6;B7;B8,V5;V6 SDLg 160 M6 B35,V15;V36 SDKg 160 M6 B5,V1;V3 6309 2Z 6309 2Z<br />

SDg 160 L6 B3;B6;B7;B8,V5;V6 SDLg 160 L6 B35,V15;V36 SDKg 160 L6 B5,V1;V3 6309 2Z 6309 2Z<br />

SDg 180 L6 B3;B6;B7;B8,V5;V6 SDLg 180 L6 B35,V15;V36 SDKg 180 L6 B5,V1;V3 6311 2Z 6311 2Z<br />

2p = 8 n=750 rpm<br />

SDg 132 S6 B3;B6;B7;B8,V5;V6 SDLg 132 S6 B35,V15;V36 SDKg 132 S6 B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 132 M6A B3;B6;B7;B8,V5;V6 SDLg 132 M6A B35,V15;V36 SDKg 132 M6A B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 132 M6B B3;B6;B7;B8,V5;V6 SDLg 132 M6B B35,V15;V36 SDKg 132 M6B B5,V1;V3 6308 2Z 6308 2Z<br />

SDg 160 M6 B3;B6;B7;B8,V5;V6 SDLg 160 M6 B35,V15;V36 SDKg 160 M6 B5,V1;V3 6309 2Z 6309 2Z<br />

SDg 160 L6 B3;B6;B7;B8,V5;V6 SDLg 160 L6 B35,V15;V36 SDKg 160 L6 B5,V1;V3 6309 2Z 6309 2Z<br />

SDg 180 L6 B3;B6;B7;B8,V5;V6 SDLg 180 L6 B35,V15;V36 SDKg 180 L6 B5,V1;V3 6311 2Z 6311 2Z<br />

1

<strong>Three</strong>-<strong>phase</strong> <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong><br />

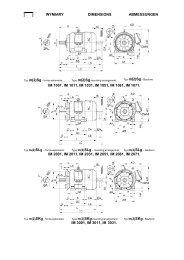

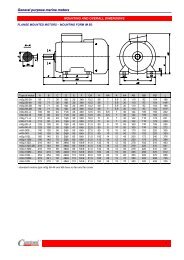

MOUNTING AND OVERALL DIMENSIONS<br />

FOOT MOUNTED MOTORS – MOUNTING ARRANGEMENT IM B3<br />

Type A B C D E F GA H HA K AA AB BB HD L<br />

SDg 132S 216 140 89 38k6 80 10h9 41,0 132 -0,5 16 12 56 278 182 310 463<br />

SDg 132M 216 178 89 38k6 80 10h9 41,0 132 -0,5 16 12 56 278 220 310 501<br />

SDg 160M 254 210 108 42k6 110 12h9 45,0 160 -0,5 20 15 60 305 256 370 612<br />

SDg 160L 254 254 108 42k6 110 12h9 45,0 160 -0,5 20 15 60 305 300 370 656<br />

SDg 180L 279 279 121 48k6 110 14h9 51,5 180 -0,5 26 15 70 350 320 408 705<br />

FOOT/FLANGE MOUNTED MOTORS – MOUNTING ARRANGEMENT IM B35<br />

Type A B C D E F GA H HA K AA AB BB HD L LA M N P T S<br />

SDLg 132S 216 140 89 38k6 80 10h9 41,0 132 16 12 56 278 182 310 463 12 265 230j6 300 4,0 15<br />

SDLg 132M 216 178 89 38k6 80 10h9 41,0 132 16 12 56 278 220 310 501 12 265 230j6 300 4,0 15<br />

SDLg 160M 254 210 108 42k6 110 12h9 45,0 160 20 15 60 305 256 370 612 13 300 250j6 350 5,0 19<br />

SDLg 160L 254 254 108 42k6 110 12h9 45,0 160 20 15 60 305 300 370 656 13 300 250j6 350 5,0 19<br />

SDLg 180L 279 279 121 48k6 110 14h9 51,5 180 26 15 70 350 320 408 705 13 300 250j6 350 5,0 19<br />

2

<strong>Three</strong>-<strong>phase</strong> <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong><br />

MOUNTING AND OVERALL DIMENSIONS<br />

FLANGE MOUNTED MOTORS – MOUNTING ARRANGEMENT IM B5, IMV1, IMV3<br />

Type D E F GA M N P LA T S HB L<br />

SDKg 132S 38k6 80 10h9 41,0 265 230j6 300 12 4,0 15 178 463<br />

SDKg 132M 38k6 80 10h9 41,0 265 230j6 300 12 4,0 15 178 501<br />

SDKg 160M 42k6 110 12h9 45,0 300 250j6 350 13 5,0 19 210 612<br />

SDKg 160L 42k6 110 12h9 45,0 300 250j6 350 13 5,0 19 210 656<br />

SDKg 180L 48k6 110 14h9 51,5 300 250j6 350 13 5,0 19 228 705<br />

3

<strong>Three</strong>-<strong>phase</strong> <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong><br />

<strong>Three</strong>-<strong>phase</strong> two speed <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong> with brake<br />

GENERAL INFORMATION<br />

Two speed <strong>crane</strong> <strong>motors</strong> with brake are mainly used as drives for hoists.<br />

The three <strong>phase</strong> two speed <strong>squirrel</strong> <strong>cage</strong> motor has an AC three <strong>phase</strong> brake type HZg built in (exception: motor<br />

SDKg 132M4/16-B). Electric brake when not supplied is blocked.<br />

Motors SDKg 132,160 2/12-GA,GB are delivered with two types of flange shields (see drawing):<br />

♦ version A – special design<br />

♦ version B – standard design<br />

Degree of protection of the motor and brake housing: IP54.<br />

MOUNTING ARRANGEMENT<br />

Two speed <strong>crane</strong> <strong>motors</strong> with brake are flange mounted, horizontal shaft, mounting arrangement IM 3001 (B5) according to<br />

IEC 34-7.<br />

PERFORMANCE OF MOTORS<br />

Catalogue no.<br />

Type of motor<br />

Number of poles<br />

Connection<br />

Rated output<br />

Rated speed<br />

Efficiency<br />

Power factor<br />

Full load<br />

current<br />

Locked rotor<br />

torque<br />

Locked rotor<br />

current<br />

Breakdown<br />

torque<br />

Moment of<br />

inertia<br />

P n n n η n cos ϕ n I 1n T L/T n I L/I n T b/T n J m T<br />

Weight (IMB3)<br />

Type of brake<br />

Braking torque<br />

Manufacturer<br />

[kW] [min -1 ] [%] [-] [A] 380V [A] 500V [-] [-] [-] [kgm 2 ] kg<br />

[Nm]<br />

2p=2/12 n=3000/500 rpm - two separated windings (non-reswitchable)<br />

13. SDKg 12 Y 0,50 425 36,0 0,64 3,3 2,5 180 180 220 0,0310 73 HZg 30 I<br />

132M2/12 (GA,GB) 2 Y 3,50 2800 79,0 0,95 7,1 5,4 260 600 340 112<br />

14. SDKg 12 Y 0,75 410 36,0 0,67 4,7 3,6 160 190 180 0,0380 88 HZg 30 I<br />

132L2/12 (GA,GB) 2 Y 5,50 2800 81,0 0,93 11,1 8,4 250 600 280 112<br />

15. SDKg 12 Y 1,35 430 45,5 0,62 7,3 5,5 200 230 210 0,0642 135 HZg 50 I<br />

160M2/12 (GA,GB) 2 Y 8,50 2820 83,5 0,95 16,3 12,4 260 640 270 132W1<br />

2p=4/16 n=1500/375 rpm - two separated windings (non-reswitchable)<br />

16. SDKg 16 Y 0,28 340 36,4 0,62 1,9 1,4 190 220 210 0,0360 65 HZg 30 I<br />

132S4/16 AG 4 Y 1,20 1465 63,3 0,75 3,8 2,9 200 580 320 112<br />

17. SDKg 16 Y 0,50 340 40,5 0,57 3,3 2,5 220 220 230 0,0470 75 HZg 30 I<br />

132S4/16 BG 4 Y 2,10 1445 72,1 0,85 5,2 4,0 190 550 270 112<br />

18. SDKg 16 Y 0,75 335 45,3 0,59 4,3 3,3 210 230 210 0,0600 85 HZg 30 I<br />

132M4/16 G 4 Y 3,20 1445 71,6 0,83 8,2 6,2 210 620 300 112<br />

19. SDKg 16 Y 1,00 330 44,5 0,62 5,5 4,2 205 235 215 0,0583 77 - - I<br />

132M4/16 B 4 Y 4,00 1435 71,4 0,85 10,0 7,6 225 590 315<br />

20. SDKg 16 Y 3,20 345 58,4 0,59 14,1 10,7 230 340 200 0,2700 215 HZg 200 I<br />

180M4/16 G 4 Y 13,00 1400 81,8 0,93 26,0 19,8 250 600 230 160<br />

Duty:<br />

2p=2 and 2p=4 S4-40% - 120 c/h – for FI2<br />

2p=12 and 2p=16 S4-25% - 240 c/h – for FI2<br />

designation FI2 means motor’s moment of inertia equal to outer moment of inertia (referred to the motor shaft)<br />

4

<strong>Three</strong>-<strong>phase</strong> <strong>squirrel</strong> <strong>cage</strong> <strong>crane</strong> <strong>motors</strong><br />

SPECIAL FLANGE MOUNTING IMB5 – TYPE A<br />

MOUNTING AND OVERALL DIMENSIONS<br />

Type D E F GA M N P S T EB EC HB L LA R V Bearings<br />

SDKg 132M2/12 GA 32j6 80 10h9 35 330 280j6 360 14 4 111 31,8 180 633 12 80 362<br />

SDKg 132L2/12 GA 32j6 80 10h9 35 330 280j6 360 14 4 111 31,8 180 669 12 80 362<br />

SDKg 160M2/12 GA 38k6 80 10h9 41 385 350j6 420 14 5 104 28,5 206 693 13 90 416<br />

6307 2Z<br />

6308 2Z<br />

6307 2Z<br />

6308 2Z<br />

6308 2Z<br />

6309 2Z<br />

STANDARD FLANGE MOUNTING ARRANGEMENT IMB5 – TYPE B<br />

Type D E F GA M N P S T HB L LA Bearings<br />

SDKg 132M2/12 GB 32j6 80 10h9 35 265 230j6 300 15 4 180 633 12 6308 2Z<br />

SDKg 132L2/12 GB 32j6 80 10h9 35 265 230j6 300 15 4 180 669 12 6308 2Z<br />

SDKg 160M2/12 GB 38k6 80 10h9 41 300 250j6 350 19 5 205 716 13 6309 2Z<br />

SDKg 132S4/16 AG 38k6 80 10h9 41 265 230j6 300 15 4 180 598 12 6308 2Z<br />

SDKg 132S4/16 BG 38k6 80 10h9 41 265 230j6 300 15 4 180 598 12 6308 2Z<br />

SDKg 132M4/16 G 38k6 80 10h9 41 265 230j6 300 15 4 180 636 12 6308 2Z<br />

SDKg 132M4/16 B 38k6 80 10h9 41 265 230j6 300 15 4 180 534 12 6308 2Z<br />

SDKg 180M4/16 G 48k6 110 14h9 51,5 300 250j6 350 19 5 222 837 13 6311 2Z<br />

5