11 - ericssonhistory.com

11 - ericssonhistory.com

11 - ericssonhistory.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The corrugating process shortens the plastic duct by 6-7 %.<br />

The machine requires a space of 1.5 X 8 m indoors or outdoors. In the<br />

latter case the site must be well protected against rain and wind. Indoors the<br />

machine is bolted to the floor. No special foundation is required.<br />

The machine corrugates between 7 and 8 ducts per hour. One man can<br />

look after three machines. This means that the production per man and eighthour<br />

shift is about 1000 duct metres of corrugated plastic duct, for which<br />

about 180 non-corrugated 6 m ducts are required.<br />

The machine is driven via a rectifier from a single-phase <strong>com</strong>mercial<br />

lighting supply and has tappings for <strong>11</strong>0-240 V. The power requirement is<br />

about 0.2 kW. The burners are fed from a LP gas cylinder placed on the<br />

carriage. The LP gas cylinder suffices for about three days of operation.<br />

Corrugated Ducts<br />

Corrugated ducts have the following advantages <strong>com</strong>pared with noncorrugated.<br />

• Their radial rigidity is several times greater. The wall thickness can therefore<br />

be reduced, so allowing the use of cheaper ducts.<br />

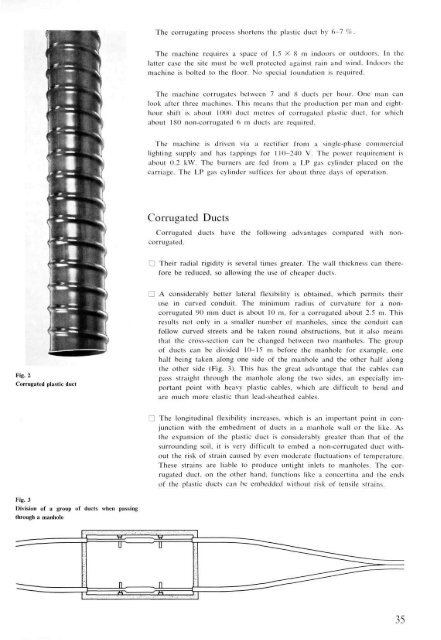

Fig. 2<br />

Corrugated plastic duct<br />

• A considerably better lateral flexibility is obtained, which permits their<br />

use in curved conduit. The minimum radius of curvature for a noncorrugated<br />

90 mm duct is about 10 m, for a corrugated about 2.5 m. This<br />

results not only in a smaller number of manholes, since the conduit can<br />

follow curved streets and be taken round obstructions, but it also means<br />

that the cross-section can be changed between two manholes. The group<br />

of ducts can be divided 10—15 m before the manhole for example, one<br />

half being taken along one side of the manhole and the other half along<br />

the other side (Fig. 3). This has the great advantage that the cables can<br />

pass straight through the manhole along the two sides, an especially important<br />

point with heavy plastic cables, which are difficult to bend and<br />

are much more elastic than lead-sheathed cables.<br />

• The longitudinal flexibility increases, which is an important point in conjunction<br />

with the embedment of ducts in a manhole wall or the like. As<br />

the expansion of the plastic duct is considerably greater than that of the<br />

surrounding soil, it is very difficult to embed a non-corrugated duct without<br />

the risk of strain caused by even moderate fluctuations of temperature.<br />

These strains are liable to produce untight inlets to manholes. The corrugated<br />

duct, on the other hand, functions like a concertina and the ends<br />

of the plastic ducts can be embedded without risk of tensile strains.<br />

Fig. 3<br />

Division of a group of ducts when passing<br />

through a manhole<br />

35