Fume cupboards - WALDNER Laboreinrichtungen GmbH & Co. KG

Fume cupboards - WALDNER Laboreinrichtungen GmbH & Co. KG

Fume cupboards - WALDNER Laboreinrichtungen GmbH & Co. KG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

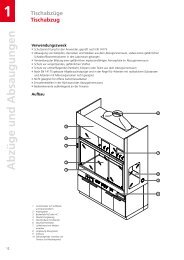

<strong>Fume</strong> <strong>cupboards</strong><br />

for high heat and acidic load<br />

With the title DIN EN 14175-7:2012 – <strong>Fume</strong> <strong>cupboards</strong>: <strong>Fume</strong> <strong>cupboards</strong> for high<br />

heat and acidic load (special application fume <strong>cupboards</strong>), the seventh part of<br />

the European series of EN 14175 standards will be issued in June 2012. The new<br />

standard is dealing with fume <strong>cupboards</strong> for special applications, including a high<br />

heat and/or acidic load. These special applications require additional design, safety,<br />

operation and maintenance properties apart from those already stipulated in<br />

the DIN EN 14175-1 to DIN EN 14175-6 standards. Utilization of these special application<br />

fume <strong>cupboards</strong> instead of general purpose fume <strong>cupboards</strong> usually is the<br />

result of a risk assessment. In the following an overview of the standard’s composition<br />

in structure and content and the requirements resulting from the high heat<br />

loads and acidic works to such special application fume <strong>cupboards</strong> will be given.<br />

Excerpt from the foreword of DIN<br />

EN 14175-7<br />

The European standard EN 14175-7 has<br />

been prepared by the technical committee<br />

WG 4 “<strong>Fume</strong> <strong>cupboards</strong>“ within CEN/TC<br />

332 „Laboratory equipment“. The German<br />

mirror committee in charge is the technical<br />

committee “Laboratory fume cupboard“<br />

which is part of the standardization committee<br />

“Laboratory appliances and laboratory<br />

furniture”. It was the leading body<br />

for the preparation of this European standard,<br />

for which the predecessor standard<br />

DIN 12924-2 was used as a template. This<br />

European standard shall obtain the status<br />

of a national standard, either by publishing<br />

an identical text or by acknowledgement<br />

until November 2012. Possibly conflicting<br />

national standards shall be withdrawn until<br />

November 2012. According to the internal<br />

CEN/CENELEC regulations the national<br />

standardization organizations of the following<br />

countries are bound to implement<br />

this European standard: Austria, Belgium,<br />

Bulgaria, Croatia, Cyprus, Czech Republic,<br />

Denmark, Germany, Estonia, Finland,<br />

France, Greece, Hungary, Iceland, Ireland,<br />

Italy, Latvia, Lithuania, Luxembourg, Malta,<br />

Netherlands, Norway, Poland, Portugal, Romania,<br />

Slovakia, Slovenia, Spain, Sweden,<br />

Switzerland, Turkey, and United Kingdom.<br />

Scope of DIN EN 14175-7 and alterations<br />

in comparison with the previous<br />

DIN 12924-2<br />

The DIN EN 14175-7 applies for the following<br />

special application fume <strong>cupboards</strong>:<br />

n <strong>Fume</strong> hoods for high heat loads<br />

n <strong>Fume</strong> hoods for high heat loads in<br />

combination with acidic digestions<br />

n <strong>Fume</strong> hoods for handling of perchloric<br />

acid<br />

n <strong>Fume</strong> hoods for handling of hydrofluoric<br />

acid

It specifies supplementary specifications<br />

and tests for these special application fume<br />

<strong>cupboards</strong> that are relevant to terms, safety<br />

and performance requirements, type test<br />

and onsite test methods as well as their<br />

marking.<br />

In comparison with the predecessor standard<br />

DIN 12924-2 the following essential<br />

alterations have been made:<br />

n Requirements and tests for the four special<br />

application fume cupboard types are<br />

separately structured and formulated<br />

throughout<br />

n Dimensional requirements have been deleted<br />

from the standard<br />

n Admissible materials for the sash have<br />

been limited<br />

n Marking for the purpose of conformity<br />

will be changed with the standard<br />

n Basic requirements for the supplier’s declaration<br />

of conformity have been specified<br />

Basic safety and performance<br />

targets<br />

For all four fume cupboard types dealt<br />

with in the standard the following basic<br />

safety and performance targets apply in<br />

accordance with EN 14175-2 with supplements<br />

such as e.g.:<br />

<strong>Fume</strong> <strong>cupboards</strong> for high heat load and<br />

acidic digestions<br />

n shall guarantee the safety and performance<br />

targets during works with high<br />

heat loads in the fume cupboard interior<br />

n shall prevent hazardous concentrations<br />

and precipitations of acids and caustic<br />

solutions that are released in the interior<br />

and shall withstand the increased requirements<br />

during the planned time of<br />

utilization.<br />

<strong>Fume</strong> <strong>cupboards</strong> for handling of perchloric<br />

acid<br />

Design and execution of the fume cupboard<br />

shall guarantee the avoidance of hazardous<br />

precipitations and hazardous reactions with<br />

the materials used for the fume cupboard<br />

construction during works with perchloric<br />

acid in the fume cupboard interior.<br />

Material requirements<br />

In case of fume <strong>cupboards</strong> for high heat<br />

loads the materials that are used, be it<br />

glass, plastic or other materials, shall be<br />

suitable with regard to their chemical resistance<br />

and heat load capacity for the respective<br />

working temperatures. For works with<br />

heat load or acidic digestions the materials<br />

shall be suitable with regard to the chemical<br />

resistance against acids and acid vapors<br />

and with regard to heat deformation for<br />

the respective working temperatures. Acid<br />

vapors occurring during digestions are extremely<br />

viscid and connect to surfaces they<br />

get in contact with. Materials shall have<br />

even and easy to clean surfaces. If glass is<br />

used as the material for the sash, official<br />

bodies or clients in some European countries<br />

require laminated safety glass as per the<br />

definition given in the EN ISO 1253-1:2011<br />

standard.<br />

In case of fume <strong>cupboards</strong> for handling of<br />

perchloric acid the materials used may not<br />

react with perchloric acid nor may create<br />

neither combustible nor explosive compounds.<br />

The selection of the materials shall<br />

be made with regard to the chemical resistance<br />

and deformation against perchloric<br />

acid at the planned working temperature.<br />

In case of fume <strong>cupboards</strong> for handling<br />

of hydrofluoric acid all parts of the fume<br />

<strong>cupboards</strong> and of the exhaust air ducts that<br />

are in contact with hydrofluoric vapors shall<br />

consist of materials resistant against hydrofluoric<br />

acid. The sash of those fume <strong>cupboards</strong><br />

shall be made of a suitable plastic<br />

material.<br />

<strong>Co</strong>nstructional requirements<br />

Beyond the constructional requirements stipulated<br />

in the EN 14175-2 standard it applies<br />

that material for and execution of the<br />

sash may neither interfere neither with the<br />

operation nor with the safety at the temperatures<br />

in the fume cupboard interior. In<br />

case of fume <strong>cupboards</strong> for acidic digestions<br />

the joints in the fume cupboard interior<br />

shall be limited to the necessary and<br />

sealings shall be durable, impermeable and<br />

permanently elastic. For the work surface<br />

in particular, seamless materials made of<br />

one block should be given preference. The<br />

fume cupboard’s construction shall provide<br />

the required access to clean the worktop<br />

surfaces, the sash and baffle plates as well<br />

as the appliances to avoid, reduce or remove<br />

vapors, in so far as these appliances<br />

are part of the fume cupboard.<br />

In case of fume <strong>cupboards</strong> for handling of<br />

perchloric acid the fume cupboard interior<br />

and the exhaust air zone shall be designed<br />

in such a way that they can be cleaned in<br />

all parts by either spurting out or by scouring<br />

through installed jets. Cleaning requirements<br />

for the part of the exhaust air duct<br />

system that is not part of the fume cupboard<br />

shall be considered. With regard to<br />

the fume cupboard’s execution the collection<br />

of sprinkling liquid from the exhaust air<br />

duct system should be taken into account.<br />

This requirement serves the avoidance of<br />

hazardous precipitation and not for the<br />

cleaning of the exhaust air. If fume <strong>cupboards</strong><br />

for handling of perchloric acid are<br />

equipped with integrated acid fume scrubbers<br />

or with integrated acid exhaust air<br />

sprinklers the design shall allow full access<br />

for cleaning and maintenance purposes.<br />

Airflow and control requirements<br />

Effects on the airflow, caused by heat load<br />

and heating devices as well as by integrated<br />

acid exhaust air scrubbers or integrated<br />

acid exhaust air sprinklers, shall be taken<br />

into account and shall also be limited.<br />

In addition to the fume cupboard function<br />

display with acoustic and visual alarm in accordance<br />

with EN 14175-2 the fume <strong>cupboards</strong><br />

shall be equipped for high heat load<br />

and with a temperature sensor at the fume<br />

cupboard top, which releases an alarm as<br />

soon as the exhaust air’s maximum temperature<br />

defined in the user manual is exceeded.<br />

It should be possible to redirect this<br />

alarm.<br />

Testing of fume <strong>cupboards</strong> with<br />

high heat load<br />

The type test shall be executed in accordance<br />

with EN 14175-3 and on-site tests<br />

shall be executed in accordance with EN<br />

14175-4 with the following supplements: Unter der Annahm<br />

During the tests two heating plates Unter shall Unter be der der Annahm<br />

kW für einen Annahm Abzu<br />

located in the fume cupboard interior. kW <strong>Co</strong>ntainment<br />

behavior and robustness shall be<br />

kW für für einen einen Abzu<br />

tested without heat load (with switchedoff<br />

heating plates) and with a heat load of<br />

4 kW per meter of the fume cupboard’s inside<br />

width each.<br />

Arrangement of heating plates and test gas<br />

outlets in accordance with EN 14175-7<br />

Nach dieser Berec<br />

Nach Nach dieser dieser Berec<br />

knapp 30°C anstei<br />

knapp knapp 30°C 30°C ansteig<br />

zug durchströmen<br />

zug zug durchströmend<br />

vom Material des<br />

vom vom Material Material des<br />

abgegeben wird. des T<br />

abgegeben abgegeben wird. wird. T<br />

dem, dass sich, auf<br />

dem, dem, dass dass sich, sich, auf<br />

innenraums im Str au<br />

innenraums innenraums im im Stra<br />

Innenseite des Fron<br />

Innenseite Innenseite des des Fron<br />

Die Hersteller von<br />

Die Die Hersteller Hersteller von<br />

Auswahl der verw<br />

Auswahl Auswahl der der verw<br />

anderen auch weit verw<br />

anderen anderen auch auch weit<br />

len, Rechnung trag wei<br />

len, len, Rechnung Rechnung trag<br />

Die Einflüsse hohe<br />

Die Die Einflüsse Einflüsse hohe<br />

z. B. mit den Mitte<br />

z. z. B. B. mit mit den den Mittel Mitte

Declaration of conformity<br />

A declaration of conformity shall clearly<br />

state the special field of application of the<br />

respective special application fume cupboard,<br />

together with the planned temperature<br />

range, and shall also confirm that the<br />

materials and the execution of the fume<br />

cupboard are suitable for the special application.<br />

Implementation of the standard’s<br />

requirements into practical work<br />

To implement the requirements of the DIN<br />

EN 14175-7 standard into practical work,<br />

particularly with regard to the effects of the<br />

high heat load, theoretical preliminary considerations<br />

and experimental examinations<br />

are very useful.<br />

The heat flow supplied through the heat<br />

capacity leads to an increase of temperature<br />

∆ T in the fume cupboard interior that<br />

can be calculated as per the following:<br />

· · <br />

<br />

· · ·<br />

· <br />

·· · <br />

Q= m∙QQ ∙ ∆T <br />

<br />

·· ·· ·<br />

· <br />

<br />

Q= V∙ρ∙QQ ∙ ∆T <br />

<br />

∆T= QV∙ρ∙QQ<br />

<br />

··<br />

<br />

<br />

<br />

·· ·· <br />

According to this calculation the temperature<br />

of the air intake in the fume cupboard<br />

would increase for almost 30° C. Measurements<br />

during the experiment show that the<br />

heating of the air that is flowing through<br />

the fume cupboard is slightly lower in reality,<br />

because part of the heat energy is absorbed<br />

by the fume cupboard casing’s material<br />

and released to the outside through<br />

its surface. Temperature measurement at<br />

different locations in the fume cupboard<br />

furthermore show that due to the heat radiation<br />

of the heating plates the surfaces<br />

of the fume cupboard interior in the radiation<br />

area, e.g. on the fume cupboard rear<br />

wall, will be heated up to a temperature of<br />

95° C, or on the inside of the sash up to a<br />

temperature of 65° C.<br />

Therefore the manufacturers of fume <strong>cupboards</strong><br />

for high heat loads shall take care<br />

of a sufficient temperature resistance when<br />

selecting the materials to be used. Furthermore<br />

they also have to take into account<br />

more extensive effects such as e.g. a strong<br />

heating of control units.<br />

The influences of high heat loads to the<br />

flow mechanics of the fume cupboard can<br />

be clearly illustrated by means of e.g. a numerical<br />

flow simulation (CFD).<br />

On the assumption of an exhaust airflow of<br />

By directly comparing “cold“ and “hot“ the<br />

e eines Abluftvolumenstroms 600 m³/h and a heat capacity von 600 of m³/h 6 kW und for einer a Heizleistung von 6<br />

computer simulation shows that the flow<br />

me e eines eines Abluftvolumenstroms fume Abluftvolumenstroms cupboard with a von von width 600 600 of m³/h m³/h 1500 und und mm einer einer Heizleistung Heizleistung von von 6<br />

ug mit einer Breite von 1500mm ergibt sich:<br />

6<br />

velocities in the fume cupboard are heavily<br />

influenced by the heat energy released<br />

ug g mit mit einer einer the Breite following Breite von von 1500mm result 1500mm is obtained: ergibt ergibt sich: sich:<br />

from the heating plates. The changes of the<br />

∆T= 6000 QQ600 Q³h∙1,2<br />

6000 <br />

6000 QQQ3∙1005 QQQ ∙K<br />

6000 <br />

<br />

flow velocities are inevitably accompanied<br />

<br />

<br />

<br />

600 <br />

by a clear change of the complete flow<br />

∆T= 29,85600 600 Q<br />

· 1,2 <br />

· <br />

· 1,2 1,2 · · · 1005<br />

1005<br />

<br />

1005<br />

<br />

·<br />

pattern in the fume cupboard. Thereof the<br />

·<br />

·<br />

obvious assumption can be deduced that<br />

2,5 <br />

the containment of a fume cupboard in<br />

2,5 2,5 <br />

chnung würde die Temperatur der einströmenden Luft im Abzug um<br />

echnung würde würde die die Temperatur Temperatur der der einströmenden einströmenden Luft Luft im im Abzug Abzug um<br />

igen. Messungen im Experiment zeigen, dass die Erwärmung der den Abden<br />

Luft in der Realität etwas geringer ist, da ein Teil der Wärmeenergie Ab‐<br />

um<br />

igen. igen. Messungen Messungen im im Experiment Experiment zeigen, zeigen, dass dass die die Erwärmung Erwärmung der der den den Abnden<br />

Luft Luft in in der der Realität Realität etwas etwas geringer geringer ist, ist, da da ein ein Teil Teil der der Wärmeenergie<br />

Abzugsgehäuses aufgenommen und über seine Oberfläche Wärmeenergie<br />

nach außen<br />

s Abzugsgehäuses Abzugsgehäuses aufgenommen aufgenommen und und über über seine seine Oberfläche Oberfläche nach nach außen<br />

Temperaturmessungen an verschiedenen Stellen im Abzug zeigen außerfgrund<br />

der Wärmestrahlung der Heizplatten, die Oberflächen des Abzugs‐<br />

außer‐<br />

außen<br />

Temperaturmessungen an an verschiedenen verschiedenen Stellen Stellen im im Abzug Abzug zeigen zeigen außerufgrund<br />

der der Wärmestrahlung Wärmestrahlung der der Heizplatten, Heizplatten, die die Oberflächen Oberflächen des des Abzugsrahlungsbereich,<br />

z. B. an der Abzugsrückwand auf bis zu 95° C oder Abzugstrahlungsbereich,<br />

z. z. B. B. an an der der Abzugsrückwand Abzugsrückwand auf auf bis bis zu zu 95° 95° C oder oder an an der<br />

an der<br />

ntschiebers auf bis zu 65° C erwärmen.<br />

der<br />

ontschiebers auf auf bis bis zu zu 65° 65° C erwärmen.<br />

n Abzügen für hohe thermische erwärmen. Lasten müssen also zum einen bei der<br />

n n Abzügen Abzügen für für hohe hohe thermische thermische Lasten Lasten müssen müssen also also zum zum einen einen bei bei der<br />

endeten Werkstoffe auf genügend Temperaturfestigkeit achten und zum der<br />

wendeten Werkstoffe Werkstoffe auf auf genügend genügend Temperaturfestigkeit Temperaturfestigkeit achten achten und und zum<br />

terreichenden Effekten, wie z. B. einer starken Erwärmung von Bedienteigen.<br />

Bedientei‐<br />

zum<br />

terreichenden iterreichenden Effekten, Effekten, wie wie z. z. B. B. einer einer starken starken Erwärmung Erwärmung von von Bedienteigen.<br />

er thermischer Lasten auf die Strömungsmechanik des Abzugs lassen sich<br />

er er thermischer thermischer Lasten Lasten auf auf die die Strömungsmechanik Strömungsmechanik des des Abzugs Abzugs lassen lassen sich<br />

ln der numerischen Strömungssimulation (CFD) anschaulich darstellen. sich<br />

eln der der numerischen numerischen Strömungssimulation Strömungssimulation (CFD) (CFD) anschaulich anschaulich darstellen. darstellen.<br />

accordance with EN 14175-2 which considerably<br />

depends on the routing of the<br />

flow and the distribution of the extraction<br />

in the fume cupboard interior, and which<br />

had been aerodynamically optimized under<br />

isothermal conditions, is influenced by<br />

the source of heat. <strong>Co</strong>ntainment measurements<br />

with switched-on heating plates<br />

are confirming this thesis. They show that<br />

no satisfying containment can be achieved<br />

with the common exhaust air flows of a<br />

general purpose fume cupboard in accordance<br />

with EN 14175-2.<br />

<strong>Co</strong>ntinuing measurements reveal that solely<br />

by increasing the exhaust air flow to<br />

about twice the normal values – which<br />

also corresponds to a duplication of the<br />

fume cupboard’s energy demand – does<br />

not represent a sufficient measure to safely<br />

operate the fume cupboard with high heat<br />

load by meeting all operating conditions<br />

stipulated in the standard.<br />

During experimental examinations it can<br />

be shown in a first step by means of e.g.<br />

a flow visualization with smoke, that by assimilating<br />

the interior room geometry and<br />

the distribution of the extraction, the fume<br />

cupboard’s exhaust air flow required for a<br />

safe operation under high heat load does<br />

not have to be duplicated in comparison<br />

with a general purpose fume cupboard.<br />

However, it will quickly become clear that<br />

an optimization of the flow routing “hot“<br />

the fume cupboard containment “cold“<br />

will be disturbed and vice versa. To solve<br />

such target conflicts and to find the utmost<br />

balance between energy demand and safety<br />

further aerodynamic examinations and<br />

the respective development works are required.<br />

Velocity vectors in the fume hood interior, with and without source of heat

heating plates on<br />

heating plates off<br />

Testing device for the robustness test<br />

Robustness of containment, with and without heating plates<br />

Summary<br />

While the previous series of EN 14175 standards<br />

exclusively described isothermal conditions<br />

in the fume cupboard, the newly<br />

issued part 7 offers the option to assess the<br />

safety of fume <strong>cupboards</strong> at high heat load.<br />

This closes an essential gap, as works with<br />

sources of heat in a fume cupboard are part<br />

of the daily routine in many laboratories.<br />

Now it is not least up to the manufacturers<br />

to translate the non-trivial requirements of<br />

the standard into innovative solutions and<br />

to also contribute to the safety and power<br />

efficiency for the operation of special application<br />

fume <strong>cupboards</strong> in laboratories.<br />

Visualization of flow, left: heating plates switched off, right: heating plates switched on<br />

<strong>WALDNER</strong> <strong>Laboreinrichtungen</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong> I Haidösch 1 I D-88239 Wangen im Allgäu<br />

Phone +49 7522/986-0 I Fax +49 7522/986-280 I www.waldner-lab.com