group 15 Lighting, Horns and Instruments.pdf

group 15 Lighting, Horns and Instruments.pdf

group 15 Lighting, Horns and Instruments.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>15</strong>-1<br />

PART <strong>15</strong>.1<br />

PAGE<br />

General <strong>Lighting</strong> System, <strong>Horns</strong><br />

<strong>and</strong> <strong>Instruments</strong> Service <strong>15</strong>-1<br />

PART <strong>15</strong>-2<br />

<strong>Lighting</strong> System <strong>and</strong> <strong>Horns</strong> <strong>15</strong>.9<br />

PART <strong>15</strong>-3<br />

Switches, Circuit Breakers<br />

<strong>and</strong> Fuses <strong>15</strong>-17<br />

PART <strong>15</strong>-4<br />

PAGE<br />

<strong>Instruments</strong> <strong>15</strong>-26<br />

PART <strong>15</strong>-5<br />

Specifications <strong>15</strong>-44<br />

Section<br />

Page<br />

1 Diagnosis <strong>and</strong> Testing <strong>15</strong>-1<br />

Light Trouble Diagnosis Guide <strong>15</strong>-4<br />

Instrument Trouble Diagnosis Guide <strong>15</strong>-5<br />

Horn Trouble Diagnosis Guide <strong>15</strong>-5<br />

Turn Indicator Trouble Diagnosis Guide <strong>15</strong>-6<br />

Seq uential Turn Signal Trouble<br />

Diagnosis Guide <strong>15</strong>-6<br />

Windshield Wiper Trouble Diagnosis Guide <strong>15</strong>-7<br />

Windshield Washer Trouble Diagnosis Guide... <strong>15</strong>-8<br />

Horn Test <strong>15</strong>-1<br />

Headlight Switch <strong>and</strong> Beam Selector<br />

Switch Test , <strong>15</strong>-1<br />

Instrument Voltage Regulator Test <strong>15</strong>-2<br />

Section<br />

Page<br />

Fuel Gauge <strong>and</strong> Fuel-Level Sending<br />

Unit Test <strong>15</strong>-2<br />

Temperature Gauge Test <strong>15</strong>-2<br />

Oil Pressure Indicator Light Test <strong>15</strong>-2<br />

Oil Pressure Indicator Gauge Test <strong>15</strong>-2<br />

Charge Indicator Light Test <strong>15</strong>-2<br />

Ammeter Test <strong>15</strong>-3<br />

Speedometer Tests <strong>15</strong>-3<br />

Temperature Indicating Light Test <strong>15</strong>-3<br />

2 Common Adjustments <strong>and</strong> Repairs <strong>15</strong>-3<br />

Horn Adjustment <strong>15</strong>-3<br />

3 Cleaning <strong>and</strong> Inspection <strong>15</strong>-4<br />

Two Speed Wiper Motor <strong>15</strong>-4<br />

DIAGNOSIS AND TESTING<br />

DIAGNOSIS<br />

Refer to Figs. 4 through 12 for<br />

lighting system horns <strong>and</strong>- instruments<br />

trouble diagnosis.<br />

TESTING<br />

Refer to Wiring Diagram Manual<br />

Form 7795P-67 for locations of wiring<br />

harnesses. Schematics are shown in<br />

Group 19 of this manual.<br />

HORN TEST<br />

The only test necessary on the<br />

horn is for current draw.<br />

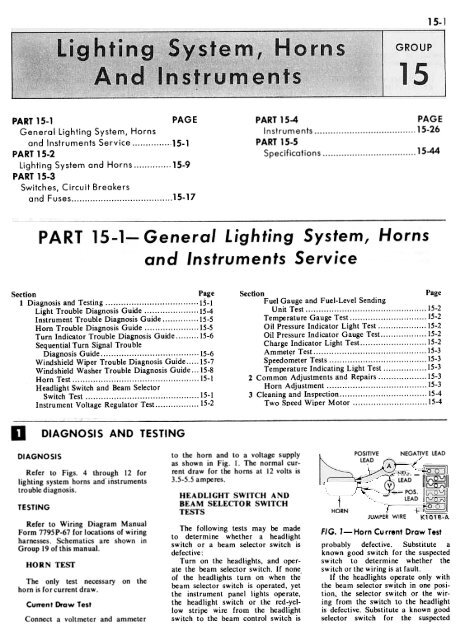

Current Draw Test<br />

Connect a voltmeter <strong>and</strong> ammeter<br />

to the horn <strong>and</strong> to a voltage supply<br />

as shown in Fig. 1. The normal current<br />

draw for the horns at 12 volts is<br />

3.5-5.5 amperes.<br />

HEADLIGHT SWITCH AND<br />

BEAM SELECTOR SWITCH<br />

TESTS<br />

The following tests may be made<br />

to determine whether a headlight<br />

switch or a beam selector switch is<br />

defective:<br />

Turn on the headlights, <strong>and</strong> operate<br />

the beam selector switch. If none<br />

of the headlights turn on when the'<br />

beam selector switch is operated, yet<br />

the instrument panel lights operate,<br />

the headlight switch or the red-yellow<br />

stripe wire from the headlight<br />

switch to the beam control switch is<br />

HORN<br />

FIG. l-Horn<br />

POSITIVE<br />

LEAD<br />

NEGATIVE LEAD<br />

(,~ LEAD -II~II<br />

.J -- pas.<br />

LEAD<br />

JUMPER WIRE<br />

,-- ~.u--<br />

Current Draw Test<br />

probably defective. Substitute a<br />

known good switch for the suspected<br />

switch to determine whether the<br />

switch or the wiring is at fault.<br />

If the headlights operate only with<br />

the beam selector switch in one position.<br />

the selector switch or the wiring<br />

from the switch to the headlight<br />

is defective. Substitute a known good<br />

selector switch for the suspected

<strong>15</strong>-2<br />

GROUP <strong>15</strong>-<strong>Lighting</strong> System, Horn~ And <strong>Instruments</strong><br />

switch to determine whether the<br />

switch or the wiring is at fault.<br />

INSTRUMENT VOLTAGE<br />

REGULATOR TEST<br />

Turn the ignition switch on,<br />

check for voltage at the gauge feed<br />

wire (black with green stripe) at one<br />

of the gauges. The voltage should<br />

oscillate between zero <strong>and</strong> about 10<br />

volts. If it does not, the constant<br />

voltage regulator is defective, or<br />

there is a short to ground between<br />

the voltage regulator <strong>and</strong> the gauges.<br />

If a gauge unit is inaccurate or<br />

does not indicate, replace it with a<br />

new unit. If the gauge unit still is<br />

erratic in its operation, the sending<br />

unit or wiring to the sending unit is<br />

faulty.<br />

If both the fuel gauge <strong>and</strong> the<br />

te mperature gauge indicate improperly<br />

<strong>and</strong> in the same direction, the<br />

constant ~oltage regulator could be<br />

defecti~e, as it supplies both gauges.<br />

FUEL GAUGE AND FUEL<br />

LEVEL SENDING UNIT<br />

TEST<br />

Disconnect the wire from the fuel<br />

level sending unit <strong>and</strong> connect it to<br />

a known good sending unit. Using a<br />

jumper for a ground, connect it to<br />

the sending unit mounting plate <strong>and</strong><br />

car frame. Raise the float arm to<br />

the upper stop, the instrument panel<br />

gauge should read full. Lower the<br />

float arm to the bottom stop, the<br />

gauge should read empty.<br />

If the gauge reads properly, the<br />

sending unit in the gas tank is defective.<br />

If the gauge unit still indicates improperly<br />

or is erratic in its operation,<br />

the gauge unit or the wiring to the<br />

gauge unit is faulty. Repair the wire<br />

or replace the gauge unit.<br />

TEMPERATURE<br />

GAUGE TEST<br />

Start the engine <strong>and</strong> allow it to<br />

run at 1200 rpm for 30 minutes.<br />

Place a thermometer in the coolant<br />

at the radiator filler cap. The temperature<br />

should read a minimum of<br />

1800 F., <strong>and</strong> the gauge in the instrument<br />

panel should indicate within<br />

the normal b<strong>and</strong>.<br />

If the gauge does not indicate,<br />

short the temperature sender unit<br />

terminal wire to ground (ignition<br />

switch on). Do not leave the sender<br />

wire grounded longer than necessary<br />

to make the test, as the gauge may<br />

be damaged. If the gauge now indicates,<br />

the sender unit is defective or<br />

not properly sealed to the engine. Be<br />

sure to ~e an electrically conductive<br />

sealer C3AZ-19554-B. If the gauge<br />

does not indicate, the gauge, the<br />

wires leading to the gauge, or the<br />

constant voltage regulator are at<br />

fault.<br />

OIL PRESSURE INDICATOR<br />

LIGHT TEST<br />

To test the indicator light, turn on<br />

the ignition switch. Do not start the<br />

engine. The light should come on.<br />

Start the engine. Th~ light should go<br />

out, indicating that the oil pressure<br />

has built up a safe value.<br />

To test the oil pressure switch on<br />

the engine, turn the ignition switch<br />

on, engine not running, the indicator<br />

light should come on. If the indicator<br />

light does not come on, short the<br />

terminal of the oil pressure switch<br />

unit to ground. If the light now<br />

comes on, the oil pressure switch is<br />

defective or not properly sealed to<br />

the engine. Be sure to use electrically<br />

conductive sealer C3AZ-19S54-B.<br />

If the light still does not come on,<br />

the bulb is burned out or the wires<br />

from the bulb to the ignition switch<br />

<strong>and</strong> oil pressure switch are defective.<br />

OIL PRESSURE INDICATOR<br />

GAUGE TEST<br />

Remove the oil pressure sender<br />

unit <strong>and</strong> temporarily attach an oil<br />

pressure gauge in its place. Operate<br />

the engine to determine the oil pressure.<br />

If the oil pressure is normal,<br />

the gauge should indicate within the<br />

normal b<strong>and</strong>.<br />

If the gauge did not indicate, momentarily<br />

short the oil pressure<br />

sender wire to ground. Do not leave<br />

the sender wire grounded longer<br />

than necessary to make the test, as<br />

the gauge may be damaged. If the<br />

gauge now indicates, the sender unit<br />

is defective or not properly sealed to<br />

the engine. Be sure to use electrically<br />

conductive sealer C3AZ-<br />

I 9554-B. If the gauge does not indicate,<br />

the jauge. the wires leading<br />

to the gauge or the constant voltage<br />

regulator are at fault.<br />

The sending unit used with the<br />

warning indicator light system is not<br />

interchangeable with the sending unit<br />

used with the gauge system. Refer<br />

to the Ford Car Master Parts Catalog<br />

for proper parts usage.<br />

Misuse of the sending units will<br />

result in inoperative oil pressure<br />

warning systems <strong>and</strong> damaged sending<br />

units or gauges.<br />

CHARGE INDICATOR<br />

TEST<br />

LIGHT<br />

To test the charge indicator light,<br />

turn the ignition switch on with the<br />

engine stopped. The light should<br />

come on. If it does not, the bulb is<br />

burned out, or the wiring to the light<br />

is defective.<br />

An open resistor wire in the Ford<br />

alternator charging system wiring<br />

harness will usually cause the charge<br />

indicator light to stay on until the<br />

engine speed is increased to several<br />

thous<strong>and</strong> rpm. This effect will be noticed<br />

each time the engine is started.<br />

In some cases the light will not go<br />

out at all.<br />

The charge indicator light may be<br />

tested with the use of a test light<br />

containing a trade number 67 or<br />

1<strong>15</strong>5 bulb.<br />

Disconnect the regulator plug<br />

from the regulator. Turn the ignition<br />

switch to ACC position. Touch one<br />

test probe from test light to the ignition<br />

terminal <strong>and</strong> the other to the<br />

regulator base. The test light will<br />

come on if the circuit is in proper<br />

working order. If the <strong>15</strong> ohm resistor<br />

or circuit is open, the indicator<br />

light will operate at full brightness<br />

<strong>and</strong> the test light will be out.<br />

Block - Red<br />

~Stri~e ".<br />

p"",<br />

;HT<br />

'//0<br />

r;:-<br />

w Strip e I<br />

"-- "'V ~,.<br />

RED LIGHT PROVE OUT<br />

SWITCH CONTACTS<br />

CLOSE IN START POSITI~<br />

~ I<br />

IGNITION SWITCH<br />

TERMINAL<br />

K<strong>15</strong>81.~<br />

FIG. 2- Temperature Indicator Light<br />

System

PART <strong>15</strong>-1-General <strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong> Service<br />

<strong>15</strong>-3<br />

AMMETER TEST<br />

To test the ammeter, turn the<br />

headlights on with the engine<br />

stopped. The meter pointer should<br />

move toward the D or discharge<br />

scale. If no movement of the needle<br />

is observed, check the rear of the<br />

meter housing to see if the battery<br />

to circuit breaker wire connections<br />

are loose. If the connections are<br />

tight, <strong>and</strong> the meter does not indicate<br />

a discharge, the meter is inoperative.<br />

If the meter pointer moves<br />

toward the C or charge scale when<br />

the headlights are turned ON, the<br />

wi re connections at the meter are reversed.<br />

When the headlights are<br />

turned on, the battery is reversed, or<br />

the wire passes through the loop in<br />

the wrong direction. Feed the wire<br />

through in the opposite direction to<br />

correct this condition, after checking<br />

first to make sure that the battery is<br />

not reversed.<br />

SPEEDOMETER TESTS<br />

To test the odometer accuracy,<br />

drive the car over a measured mile.<br />

Speedometer accuracy can be<br />

checked by comparing the speedometer<br />

in question against one known<br />

to be accurate, while two cars are<br />

moving at the same speed, or by<br />

timing the car on a measured mile.<br />

The Ford Car Master Parts

<strong>15</strong>-4 GROUP 1 S-Lighti ng System, <strong>Horns</strong> And <strong>Instruments</strong><br />

CLEANING AND INSPECTION<br />

TWO-SPEED WIPER MOTOR<br />

I. Clean the gear housing of all<br />

old grease. Do not allow any cleaning<br />

fluid to contact the armature<br />

shaft <strong>and</strong> output shaft bearings.<br />

2. Wipe all other parts with a<br />

clean cloth.<br />

3. Inspect the gear housing for<br />

cracks or distortion. Replace a<br />

cracked or distorted housing.<br />

4. Check all shafts, bushings, <strong>and</strong><br />

gears for scored surfaces. Replace<br />

defective parts <strong>and</strong> add new grease<br />

to the housing <strong>and</strong> gears.<br />

ALL HEADLIGHTS DO<br />

NOT LIGHT<br />

1. Loose battery cable.<br />

2. Loose quick disconnect or broken<br />

wire from the battery to the<br />

headlight switch.<br />

3. Defective headlight switch.<br />

4. Disconnected or broken wire<br />

from the headlight switch to the<br />

beam selector switch.<br />

S. Loose or broken wire to the<br />

bulbs.<br />

6. Defective beam selector switch.<br />

7. All headlight bulbs burned out.<br />

This may be caused by a defective<br />

or improperly adjusted alternator<br />

voltage regulator (Group 13).<br />

INDIVIDUAL LIGHTS<br />

DO NOT LIGHT<br />

LIGHTS BURN OUT<br />

REPEATEDLY<br />

FIG. 4-Light Trouble Diagnosis Guide<br />

1. Burned out bulb.<br />

2. Loose or broken wires to the<br />

bulb.<br />

I. Loose or corroded electrical<br />

connections.<br />

2. Excessive vibration.<br />

3. Poor ground<br />

3. Improperly adjusted or defective<br />

alternator voltage regulator<br />

(Group 13).

PART 1S-1-General <strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong> Service<br />

<strong>15</strong>-5<br />

OIL PRESSURE INDICATOR<br />

LIGHT INOPERATIVE<br />

1. Indicator bulb burned out.<br />

2. Loose or broken wire from the<br />

light to the indicator switch.<br />

3. Defective oil pressure sender<br />

unit (in this part).<br />

CHARGE INDICATOR<br />

LIGHT INOPERATIVE<br />

CHARGE INDICA TOR<br />

LIGHT STAYS ON AT<br />

IDLE<br />

OIL PRESSURE INDICATOR<br />

GAUGE INOPERATIVE<br />

AMMETER GAUGE<br />

INOPERA TIVE<br />

FUEL GAUGE ERRATIC<br />

OR INOPERATIVE<br />

1. Burned out bulb.<br />

2. Loose or broken wires.<br />

1. Loose or broken drive belt.<br />

2. Parallel resistance wire (<strong>15</strong><br />

-ohm) burned out.<br />

3. Loose connections or broken<br />

wires.<br />

1. Loose or broken wire from the<br />

constant voltage regulator to the oil<br />

pressure gauge.<br />

2. Grounqed or broken wire from<br />

1. Defective gauge (in this part).<br />

2. Loose or broken wires.<br />

1. Loose or broken wire from the<br />

constant voltage regulator to the fuel<br />

gauge.<br />

2. Defective fuel gauge.<br />

3. Loose, broken, or shorted wire<br />

from fuel gauge to the fuel tank<br />

sending unit.<br />

3. Defective alternator regulator.<br />

4. Regulator out of adjustment.<br />

5. Grounded wiring from alterna.<br />

tor to regulator.<br />

6. Defective alternator.<br />

the engine oil pressure sending unit.<br />

3. Defective gauge.<br />

4. Defective oil pressure sending<br />

unit.<br />

3. Charging system malfunction<br />

4. Defective constant voltage regulator.<br />

5. Defective fuel tank sending<br />

unit.<br />

6. Poor ground between fuel tank<br />

<strong>and</strong> body.<br />

TEMPERATURE GAUGE<br />

ERRATIC OR INOPERATIVE<br />

1. Loose or broken wire from constant<br />

voltage regulator to the temperature<br />

gauge.<br />

2. Defective temperature gauge.<br />

3. Loose or broken wire from the<br />

temperature sending unit to the tem-<br />

perature gauge.<br />

4. Defective temperature sending<br />

unit.<br />

5. Defective constant voltage regulator.<br />

FUEL, TEMPERATURE, AND<br />

OIL PRESSURE GAUGES<br />

ERRATIC<br />

1. Loose or corroded constant<br />

voltage regulator ground.<br />

2. Defective constant voltage regulator.<br />

3. Broken or loose wire from or<br />

to the constant voltage regulator.<br />

4. Defective ignition switch.<br />

FIG. 5.<br />

Instrument Trouble Diagnosis Guide<br />

FIG. 6.<br />

Horn Trouble Diagnosis Guide

<strong>15</strong>-6 GROUP <strong>15</strong>-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

OUTSIDE TURN SIGNAL<br />

LIGHTS INOPERATIVE<br />

1. Burned out bulbs, or loose<br />

socket connections.<br />

2. Open connection at turn signal<br />

flasher.<br />

3. Loose or broken wire from<br />

ignition switch to flasher.<br />

4. Defective flasher.<br />

5. Loose or broken wire from<br />

flasher to turn signal switch.<br />

6. Defective turn signal switch.<br />

7. Broken, shorted, or loose wires<br />

from switch to lights.<br />

INSTRUMENT PANEL<br />

TURN SIGNAL LIGHTS<br />

OPERATE INCORRECTLY<br />

I. Burned out bulb, or improper<br />

connection at socket.<br />

2. Loose, broken, or shorted wires<br />

from switch to lights.<br />

3. Inoperative outside turn signal<br />

lights (See above).<br />

TURN SIGNAL<br />

CANCELS IMPROPERLY<br />

I. Cam improperly positioned on<br />

steering wheel hub.<br />

2. Coil spring on switch plate assembly<br />

loose or weak.<br />

FIG. 7<br />

St<strong>and</strong>ard Turn Signal Trouble Diagnosis Guide<br />

All TURN SIGNALS<br />

INOPERA TIVE<br />

I. Defective fuse.<br />

2. Open circuit between fuse panel<br />

<strong>and</strong> turn signal switch.<br />

3. Poor ground for turn signal<br />

relay <strong>and</strong> sequential flasher in luggage<br />

compartment.<br />

4. Defective turn signal switch.<br />

5. Open circuit between turn signal<br />

relay (dash panel) <strong>and</strong> turn signal<br />

switch.<br />

6. Open circuit in turn signal relay<br />

(dash panel).<br />

7. No electrical feed (open wire)<br />

between the turn signal relay (instrument<br />

panel) <strong>and</strong> the sequential flasher<br />

in the luggage compartment.<br />

8. Defective sequential turn signal<br />

flasher assembly (luggage compartment).<br />

LEFT OR RiGHT FRONT<br />

TURN SIGNAL DOES NOT<br />

OPERATE (TURN INDICATOR<br />

LIGHT REMAINS ON AND<br />

REAR LIGHTS OPERATE)<br />

1. Turn signal filament of bulb<br />

burned out.<br />

2. Corrosion or foreign matter on<br />

bulb or socket terminal.<br />

3. Open circuit between the bulb<br />

<strong>and</strong> the t urn signal relay.<br />

4. Defective turn signal relay or<br />

wiring in the luggage compartment.<br />

5. Loose connectors in wiring from<br />

luggage compartment to bulb(s).<br />

REAR TURN SIGNALS<br />

INOPERA TIVE-ONE SIDE,<br />

BOTH SIDES, OR INDIVIDUAL<br />

BULBS (FRONT LIGHTS<br />

FLASH CORRECTLY)<br />

I. Turn signal filament of bulb<br />

burned out.<br />

2. Open circuits in rear turn signal<br />

wiring between turn signal relay<br />

in luggage compartment <strong>and</strong> turn signal<br />

bulbs.<br />

3. Incorrect operation of the turn<br />

signal relay.<br />

4. Open circuit between the sequential<br />

flasher assembly <strong>and</strong> the turn signal<br />

relay.<br />

5. Defective sequential flasher<br />

assembly.<br />

FIG. 8.<br />

.Sequential-Turn SiQnal Trau ble DiaQnosis Guide -External Signals

PART <strong>15</strong>-1-General <strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong> Service<br />

<strong>15</strong>-7<br />

LEFT INDICATOR BULB<br />

FLASHES FOR RIGHT OR<br />

LEFT TURN, OR LEFT ONLY<br />

INDICATOR BULB FLASHES<br />

FOR EMERGENCY FLASHER<br />

1. Open solenoid feed circuit between<br />

turn signal switch <strong>and</strong> the<br />

turn signal indicator relay (4 wire).<br />

2. Wire No. 50 (green-white stripe)<br />

<strong>and</strong> wire No. 49 (white-blue stripe),<br />

are reversed in connector to turn<br />

signal indicator relay (4 wire).<br />

3. Defective turn signal indicator<br />

relay (4 wire).<br />

BOTH INDICA TOR BULBS<br />

FLASH IN EITHER DIRECTION<br />

1. Open circuit between solenoid<br />

of emergency warning relay <strong>and</strong> the<br />

turn signal switch.<br />

2. Defective<br />

relay.<br />

emergency<br />

warning<br />

LEFT OR RIGHT INDICATOR<br />

BULB INOPERATIVE<br />

I. Defective bulb.<br />

2. Inadequate ground at bulb.<br />

socket.<br />

3. Open feed circuit between turn<br />

signal indicator relay (4 wire), <strong>and</strong><br />

bulb.<br />

4. Defective turn signal indicator<br />

relay (4 wire).<br />

BOTH INDICA TOR BULBS<br />

WILL NOT LIGHT<br />

I. Defective bulbs.<br />

2. Open circuit between turn signal<br />

relay (3 wire), <strong>and</strong> the turn signal<br />

indicator relay (4 wire).<br />

3. Open circuit between the turn<br />

signal indicator relay (4 wire), <strong>and</strong><br />

the bulbs.<br />

4. Defective turn signal relay (3<br />

wire).<br />

S. Defective turn signal indicator<br />

relay (4 wire).<br />

ONE INDICA TOR BULB<br />

LIGHTS STEADY, BUT<br />

DOES NOT FLASH<br />

I. Defective turn signal bulb or<br />

bulbs in system.<br />

BOTH INDICA TOR BULBS<br />

LIGHT STEADY, BUT DO<br />

NOT FLASH<br />

I. Defective turn signal indicator<br />

bulb or bulbs in system.<br />

2. Defective turn signal relay (3<br />

wire).<br />

FIG. 9.<br />

.Sequential Turn Signal Trouble Diagnosis Guide Instrument Ponel Bulbs<br />

FIG. 10- Windshield Wiper Trouble Diagnosis Guide

<strong>15</strong>-8 GROUP <strong>15</strong>-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

I. Defective electrical switch assembly<br />

at the foot pedal.<br />

2. Open circuit between foot pedal<br />

switch <strong>and</strong> wiper motor.<br />

3. Defective windshield wiper<br />

switch.<br />

4. Open circuit between windshield<br />

wiper switch <strong>and</strong> wiper motor.<br />

5. Defective wiper motor.<br />

FIG. ll-Foot-Pedal Windshield Washer System Diagnosis Guide<br />

1. No fluid in washer reservoir or<br />

lines.<br />

2. Broken or clogged water lines.<br />

3. Open circuit between switch <strong>and</strong><br />

pump.<br />

4. Open circuit between washer<br />

pump <strong>and</strong> wiper motor.<br />

5. Defective wiper switch.<br />

6. Defective washer pump.<br />

7. Defective switch on wiper motor.<br />

8. Burned, corroded, or damaged<br />

switch plate in wiper motor.<br />

9. Defective wiper motor.<br />

FIG. 12- Electric Windshield Woshe r Pump-DioQnosis<br />

Guide

~<br />

,gnatsuM Cougar<br />

thgiliaT thgiliaT Lens-Cougar<br />

Lens-Mustang<br />

,gnatsuM-thgiL Cougar<br />

thgiliaT thgiliaT Body-Cougar<br />

Body-Falcon<br />

noitatS Wagons<br />

thgiliaT Dor-Fairlane<br />

thgiliaT Body-Mustang<br />

thgiliaT Dor-Cougar<br />

pukcaB Light Body-Cougar, Mustang<br />

thgiliaT Dor-Mustang<br />

Taillight Body Lens <strong>and</strong> BulbsenalriaF<br />

Model 71 ,<br />

<strong>and</strong><br />

Falcon, Fairlane, Mercury Intermediate<br />

Transmission Control Selector Light-<br />

Console Transmission Control Selector<br />

Taillight Lens-Falcon, Mercury<br />

Tail Intermediate <strong>and</strong> Stop Light Bulbs-Except<br />

License Plate Light Assy. -Except<br />

<strong>15</strong>-9<br />

<strong>15</strong>-14<br />

<strong>15</strong>-14<br />

<strong>15</strong>-14<br />

<strong>15</strong>-14<br />

<strong>15</strong>-14<br />

...<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-<strong>15</strong><br />

<strong>15</strong>-16<br />

<strong>15</strong>-16<br />

esneciL raguoC Plate <strong>and</strong> Bulb Station <strong>and</strong>/or Wagons<br />

Lens<br />

,<strong>15</strong>-16<br />

<strong>15</strong>-16<br />

DESCRIPTION AND OPERATION<br />

Refer to Wiring Diagram Manual<br />

Form 7795P-67 for locations of wiring<br />

harnesses. Schematics are shown<br />

in Group 19 of this manual.<br />

ORANGE<br />

(VACUUM<br />

SOURCE)<br />

-<br />

WHITE<br />

;1::;;; -,<br />

k,<br />

~.. 0 A 0 .."-- ./""<br />

~---,:,:'/' , C5<br />

'/ "'-:=:--<br />

~ ~~~ /'-. -~~<br />

YELLOW<br />

~\\\\<br />

J"" ~.<br />

RII"D"~~ "'!:LLOW<br />

,<br />

BUMP<br />

-~~<br />

1675~ "":,\ PI:<br />

VAC<br />

MOT<br />

~<br />

'.I~:::24 J¥~<br />

'V~ I'" '<br />

\ ,-<br />

/ .--/ YELLOW<br />

~BUMPER<br />

379352-5<br />

1 ';,<br />

GREEN<br />

HEADLIGHTS<br />

The Falcon <strong>and</strong> Mustang use two<br />

No.2 type sealed-beam headlights.<br />

SOLENOID VAOJUM<br />

i<br />

I<br />

RESERVOIR<br />

13A185<br />

VENT<br />

~;C;"'oi<br />

,.<br />

GREEN<br />

CONNECTOR<br />

13A169<br />

YELLOW<br />

,"<br />

;) "" \ ~ ..."' MOTOR<br />

\ ...<br />

'1'\i:<br />

~;:~~;:- I:'~'<br />

~~~~~<br />

~I<br />

PIN \<br />

13A173<br />

j

<strong>15</strong>-10 GRO UP lS-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

light is in the lower position <strong>and</strong> the<br />

No. 2 light is in the upper position.<br />

The Cougar uses four sealed-beam<br />

headlights. The No. I light is in<br />

the inner position <strong>and</strong> the No.2<br />

light is in the outer position.<br />

A conventional beam selector<br />

switch is located on the floorboard<br />

at the left of the driver.<br />

Quick disconnect terminals are also<br />

provided at the left <strong>and</strong> right of<br />

the radiator support assembly. The<br />

terminals are color coded. Like<br />

colored terminals are connected together.<br />

HEADLIGHT COVERS<br />

-COUGAR<br />

The headlight covers are opened<br />

<strong>and</strong> closed by the use of vacuum<br />

motors. Refer to Fig. I for location<br />

of the headlight cover operating components<br />

<strong>and</strong> installation. Note the<br />

vacuum hose routing, connections <strong>and</strong><br />

color codes.<br />

The headlight switch, when pulIed<br />

fulI out, connects the headlight circuit<br />

to a solenoid. The solenoid operates<br />

vacuum ports in a distribution valve<br />

which applies vacuum to the cover<br />

operating vacuum motors. The solenoid<br />

also opens a vacuum relief (exhaust)<br />

port to that side of the vacuum<br />

motor diaphragm to which vacuum<br />

is not applied. The vacuum exhaust<br />

port is vented through a tube into<br />

the passenger compartment in order<br />

to prevent engine oil fumes from entering<br />

the distribution valve.<br />

Two cover hinge springs, attached<br />

to each cover, function as over-center<br />

type springs, which help hold the<br />

covers in the open or closed position.<br />

Vacuum applied to either side of the<br />

vacuum motor diaphragm during<br />

opening or closing, overcomes this<br />

spring tension.<br />

Two reserve vacuum reservoirs<br />

provide vacuum storage which permits<br />

limited cycling of the headlight<br />

covers without the car engine running.<br />

In case of vacuum loss or solenoid<br />

failure, the covers can be opened or<br />

closed manually as follows: To open<br />

or close the covers, push in the<br />

plunger located on the vacuum distribution<br />

valve (View C, Fig. I), located<br />

behind the left headlights in the<br />

engine compartment; then, if the<br />

covers do not open, open them by<br />

h<strong>and</strong> while the plunger is in the in<br />

position. To reset the system for automatic<br />

operation, press inward on the<br />

end of the plunger so that the plunger<br />

return spring returns the plunger to<br />

the out position.<br />

The headlight covers should be<br />

open (raised) when washing the car<br />

to clean the headlights for safer nighttime<br />

driving.<br />

HORNS<br />

A pair of tuned horns are used.<br />

The horn button closes the circuit to<br />

the horns. One of the horns has a<br />

high-pitched tone; the other has a<br />

low-pitched tone.<br />

IN-VEHICLE ADJUSTMENTS AND REPAIRS<br />

HEADLIGHT ALIGNMENT<br />

All headlight adjustments should<br />

be made with a half-full tank<br />

plus or minus one gallon, with a person<br />

seated in the driver's seat <strong>and</strong> a<br />

person seated in the passenger seat,<br />

the car unloaded <strong>and</strong> the trunk empty<br />

except for the spare tire <strong>and</strong> jacking<br />

equipment, <strong>and</strong> recommended pressure<br />

in all tires. Before each adjustment,<br />

bounce the car by pushing on<br />

the center of both the front <strong>and</strong> rear<br />

bumpers, to level the car.<br />

To align the No. I headlights by<br />

means of a wall screen, select a level<br />

portion of the shop floor. Layout<br />

the floor <strong>and</strong> wall as shown in Fig. 2.<br />

Establish the headlight horizontal<br />

centerline by subtracting 20 inches<br />

from the actual measured height of<br />

the headlight lens center from the<br />

floor <strong>and</strong> addin~ this difference to the<br />

20-inch reference line obtained by<br />

sighting over the uprights to obtain<br />

dimension B (upper diagram Fig.<br />

3). Draw a horizontal line 2 inches<br />

below, <strong>and</strong> parallel to the headlight<br />

horizontal centerline. Then draw the<br />

headlight vertical centerlines on the<br />

screen as measured on the vehicle<br />

(dimension A, upper diagram Fig. 3).<br />

NO.1 HEADLIGHT HIGH<br />

BEAM ADJUSTMENT<br />

Adjust each No. I headlight beam<br />

as shown in Fig. 3 upper diagram.<br />

Cover the No.2 lights when making<br />

this adjustment.<br />

Some states may not approve of<br />

the 2-inch dimension for the No.1<br />

headlights. Check the applicable state<br />

law, as a 3-inch dimension may be<br />

required.<br />

NO.2 HEADLIGHT LOW<br />

BEAM ADJUSTMENT<br />

To align the No.2 headlights. a<br />

new wall chart is used. Dimension B<br />

for the No.2 lights will be different<br />

than B for the No. I lights. but dimension<br />

A which is measured on the car<br />

will be the same as for the No. I<br />

lights. Note that the line of adjustment<br />

of the No.2 lights is the horizontal<br />

centerline of the No.2 lights.<br />

Turn the headlights to low beam <strong>and</strong><br />

adjust each No.2 light as shown in<br />

Fig. 3.<br />

Each headlight can be adjusted by<br />

means of two screws located under<br />

the headlight trim ring. Always bring<br />

each beam into final position by<br />

turning the adjusting screws clockwise<br />

so that the headlights will be<br />

held against the tension springs when<br />

the operation is comoleted (Fig. 4).

PART lS-2-<strong>Lighting</strong> System And <strong>Horns</strong> <strong>15</strong>-<br />

FIG. 2.<br />

Floor <strong>and</strong> Wall Layout<br />

HEADLIGHTS 25 FEET<br />

FROM WAll<br />

NO.1<br />

LIGHT HIGH BEAM DIAGRAM<br />

14 DIMENSION "A" .\<br />

NO.2<br />

LIGHT LOW BEAM DIAGRAM<br />

Kl192-C<br />

FIG. 3-Headlight<br />

Wall Screens

~<br />

..c<br />

0 '"<br />

N<br />

~<br />

Co...<br />

rc<br />

) .-<br />

m<br />

~<br />

!!!<br />

j:illi<br />

,<br />

'"<br />

'"<br />

«,<br />

~<br />

'"<br />

~<br />

I-<br />

::> 7<br />

:;t;j<br />

,., ,::<br />

~~<br />

~<br />

~<br />

""" ~<br />

.-<br />

~<br />

'"<br />

w<br />

><br />

0"<br />

/ '<br />

'" , ~<br />

, t1. ~ "'O uO "'- ,,;1<br />

f-<br />

~<br />

~<br />

'"<br />

::""<br />

-~<br />

~ Z-o<br />

~<br />

-0.<br />

~.<br />

~<br />

w<br />

~~<br />

«;;<br />

'"<br />

-'<br />

, I-<br />

0< .<br />

"- W<br />

w I<br />

a~<br />

~'" 0:<br />

J:<br />

PART 1 S-2-<strong>Lighting</strong> System And <strong>Horns</strong> <strong>15</strong>-13<br />

REMOVAL AND INST ALLA TION<br />

HEADLIGHTS<br />

On the Cougar it will be necessary<br />

to open the hood <strong>and</strong> release the vacuum<br />

valve (place the valve in manual<br />

position) <strong>and</strong> manually open the headlight<br />

cover.<br />

1. Remove the screws <strong>and</strong> remove<br />

the headlight trim ring (Fig. 4).<br />

2. Place a h<strong>and</strong> over the headlight<br />

assembly <strong>and</strong> unhook the spring<br />

from the retaining ring.<br />

3. Remove the retaining ring by<br />

unhooking the ring from the clip located<br />

directly across the bulb from<br />

the spring hook.<br />

4. Pull the headlight bulb forward<br />

<strong>and</strong> disconnect the wiring assembly<br />

plug.<br />

5. Plug in the new bulb <strong>and</strong> place<br />

it in position, locating the bulb glass<br />

tabs in the positioning slots.<br />

6. Hook the retaining ring over<br />

the clip, then over the bulb <strong>and</strong> secure<br />

it with the existing ball-ring<br />

spring.<br />

7. Align the bulb with the wall<br />

screen.<br />

8. Install the trim ring in position<br />

<strong>and</strong> install the retaining screws.<br />

HEADLIGHT COVER VACUUM<br />

MOTOR-COUGAR<br />

REMOVAL<br />

Refer to Group 17 of this manual<br />

for illustration showing grille attaching<br />

parts.<br />

1. Open the hood <strong>and</strong> remove the<br />

four screws which retain the center<br />

grille panel to the hood latch support<br />

brace.<br />

2. Remove the headlight cover return<br />

springs.<br />

3. Remove two capscrews which<br />

retain the grille center.<br />

4. Remove two retaining screws<br />

from the grille outer end.<br />

5. Remove the two stud nuts which<br />

retain the grille outer end.<br />

6. Pull the grille assembly out<br />

from around the headlights.<br />

7. Disconnect the vacuum motor<br />

lower vacuum hose from the vacuum<br />

motor. Remove the through bolt <strong>and</strong><br />

nut from the bottom of the vacuum<br />

motor.<br />

8. Disconnect the headlight wiring<br />

connectors from the headlights <strong>and</strong><br />

lift out the vacuum motor assembly.<br />

INSTAllATION<br />

1. Position the vacuum motor assembly<br />

<strong>and</strong>, reaching under the car,<br />

install the retaining through bolt<br />

<strong>and</strong> nut. Connect the lower vacuum<br />

hose to the vacuum motor.<br />

2. Connect the upper vacuum hose<br />

to the vacuum motor <strong>and</strong> connect the<br />

headlight wiring connector plug.<br />

3. Position the grille in the<br />

grille opening <strong>and</strong> install the two<br />

retaining stud nuts.<br />

4. Install the two grille top retaining<br />

screws <strong>and</strong> the two capscrews<br />

which retain the grille center.<br />

5. Install the two headlight cover<br />

return springs.<br />

6. Install the vacuum motor to<br />

headlight cover retaining clip.<br />

7. Position the center grille panel<br />

to the grille <strong>and</strong> install the four center<br />

panel retaining capscrews.<br />

8. Start the engine <strong>and</strong> check<br />

headlights <strong>and</strong> headlight covers for<br />

proper operation.<br />

WIRING ASSEMBLY-DASH<br />

TO HEADLIGHT JUNCTION<br />

(14290 WIRING HARNESS)<br />

-FAIRLANE, FALCON,<br />

MERCURY INTERMEDIATE<br />

I. Disconnect the battery ground<br />

cable from the battery.<br />

2. Disconnect the harness plug connector<br />

at the dash panel.<br />

3. Open the wiring retainer along<br />

the left fender apron.<br />

4. Disconnect the alternator wiring<br />

connector. Remove the ground wire<br />

retaining screw at the alternator regulator.<br />

Disconnect the left headlight<br />

<strong>and</strong> parking light wiring connectors.<br />

5. Remove the wiring leads (blackyellow<br />

stripe <strong>and</strong> yellow wires) from<br />

the starting motor solenoid. Open the<br />

wiring retaining clips on the right<br />

fender apron. Disconnect the right<br />

headlight <strong>and</strong> the right parking light<br />

wiring connectors.<br />

6. Open the wiring retaining clips<br />

across the top of the radiator support<br />

<strong>and</strong> work the harness out from right<br />

to left. Remove the harness out<br />

through the hole at the alternator<br />

regulator.<br />

7. Position the new wiring assembly<br />

in the engine compartment, working<br />

from left to right through the routing<br />

hole in the left radiator side support<br />

near the alternator regulator.<br />

8. Connect the wiring leads to the<br />

starting motor solenoid. Install the<br />

wiring in the retaining clips on the<br />

right fender apron. Connect the headlights,<br />

parking light <strong>and</strong> horn connectors.<br />

Position the wiring in the retaining<br />

clips across the radiator support.<br />

9. Connect the left headlights,<br />

parking light <strong>and</strong> horn. Connect the alternator<br />

regulator wiring connector.<br />

Install the ground wire <strong>and</strong> radio<br />

suppressor ground wire retaining<br />

screw.<br />

10. Place the wiring harness in the<br />

wiring retainers along the left fender<br />

apron <strong>and</strong> connect the wiring connector<br />

at the dash panel.<br />

11. Connect the battery ground cable<br />

to the battery.<br />

12. Check operation of the headlights,<br />

parking lights <strong>and</strong> horns.<br />

WIRING ASSEMBLY-DASH TO<br />

HEADLIGHT JUNCTION-<br />

COUGAR AND MUSTANG<br />

1. Disconnect the battery ground<br />

cable.<br />

2. Disconnect two multiple connectors<br />

<strong>and</strong> one single connector under<br />

the instrument panel, push the<br />

grommet <strong>and</strong> connectors through the<br />

hole into the engine compartment.<br />

3. Disconnect the dual brake warning<br />

connector at the brake differential<br />

valve.<br />

4. Open the harness retaining clips,<br />

disconnect the wires from the starter<br />

relay, <strong>and</strong> disconnect the alternator<br />

wiring connector.<br />

5. Disconnect the headlight <strong>and</strong><br />

parking light connectors, the voltage<br />

regulator wires <strong>and</strong> radio suppressor,<br />

<strong>and</strong> the horn leads. On the Cougar<br />

disconnect the headlight housing vacuum<br />

solenoid wire.<br />

6. Remove the screws retaining the<br />

headlight <strong>and</strong> regulator ground wires,<br />

open all harness retaining clips <strong>and</strong><br />

remove the harness from the vehicle.<br />

7. Route the new harness <strong>and</strong><br />

close all the retaining clips.<br />

8. Install the screws retaining the<br />

headlight <strong>and</strong> regulator ground wires.<br />

9. Connect the horns, the starter,<br />

the alternator <strong>and</strong> the headlight <strong>and</strong><br />

parking light wires.<br />

10. Connect the voltage regulator,<br />

wire connector, radio suppressor <strong>and</strong><br />

the dual brake warning connector.<br />

On the Cougar also connect the headlight<br />

vacuum solenoid wire.<br />

11. Push the multiple connectors<br />

through the dash, seat the dash grommet<br />

<strong>and</strong> connect the multiple connectors<br />

at the instrument panel.<br />

12. Connect the battery <strong>and</strong> check<br />

the operation of all connected parts.<br />

PARKING<br />

LIGHT HOUSING-ALL<br />

1. Open the hood <strong>and</strong> disconnect<br />

the connector between the radiator<br />

support <strong>and</strong> grille.

<strong>15</strong>-14 GROUP <strong>15</strong>-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

2. Remove the lead wires from the<br />

retaining clips <strong>and</strong> pull the wire<br />

down.<br />

3. Remove the two screws or retaining<br />

nuts from the housing retainer<br />

<strong>and</strong> remove the lamp assembly <strong>and</strong><br />

housing retainer from the bumper or<br />

stone deflector extension.<br />

4. Remove the lens, gasket <strong>and</strong><br />

bulb from the lamp housing.<br />

5. Install the bulb, gasket <strong>and</strong><br />

lens in the housing.<br />

6. Position the housing <strong>and</strong> retainer<br />

to the bumper or stone deflector<br />

extension <strong>and</strong> install the retaining<br />

screws or nuts.<br />

7. Re-route the lead wires back<br />

to the connector at the radiator support<br />

<strong>and</strong> connect the connector.<br />

8. Position the lead wire in the<br />

retaining clips as required.<br />

PARKING LIGHT<br />

To replace the bulb, remove the<br />

lens retaining screws <strong>and</strong> the lens.<br />

HORNS<br />

Disconnect the horn wire from the<br />

terminal. Remove the horn mounting<br />

bracket to horn retaining screws <strong>and</strong><br />

remove the horn.<br />

To install, mount the horn in position,<br />

then connect the horn wire to<br />

the horn terminal.<br />

HORN BUTTON<br />

1. Disconnect the horn wire connector,<br />

that has a yellow <strong>and</strong> a yellow-green<br />

wire in it, under the instrument<br />

panel, to the left of the<br />

steering column.<br />

2. Press down evenly on the horn<br />

button <strong>and</strong> turn counter-clockwise<br />

until it lifts out from the steering<br />

wheel.<br />

3. Remove the horn button <strong>and</strong><br />

spring.<br />

4. The horn button contacts are integral<br />

with the turn signal switch <strong>and</strong><br />

are removed with the switch.<br />

5. Install the horn button spring<br />

<strong>and</strong> button.<br />

6. Connect the horn wire connector<br />

under the instrument panel.<br />

DOME AND COURTESY<br />

LIGHT (S)<br />

On the Mustang Hardtop, the dome<br />

light bulb can be removed by removing<br />

the screws retaining the dome<br />

light lens. To replace the dome light<br />

bulb in the Falcon, Fairlane <strong>and</strong><br />

Mercury Intermediate it is only necessary<br />

to snap out the dome light lens.<br />

To replace the courtesy light bulb<br />

for Mustangs (except Hardtops) pry<br />

the light assembly out of the lower<br />

rear quarter panel. On the Cougar<br />

the courtesy light is located in the<br />

upper rear quarter panel <strong>and</strong> the<br />

bulb can be replaced by snapping out<br />

the light assembly lens.<br />

INSTRUMENT LIGHTS<br />

The instrument cluster bulbs are<br />

retained in plug-in type sockets. The<br />

instrument cluster light bulbs can<br />

be replaced by pulling out the individual<br />

ligr,t sockets from the rear<br />

of the instrument cluster.<br />

On the Mustang <strong>and</strong> Cougar, bulbs<br />

on the right side of the cluster can<br />

be replaced by reaching under the instrument<br />

panel. Bulbs on the left side<br />

of lhe cluster are replaced by removing<br />

the four heater control retaining<br />

screws <strong>and</strong> positioning the heater control<br />

outward to provide access.<br />

WARNING LIGHT BULBS<br />

ROOF CONSOLE-XR-7 COUGAR<br />

I. Remove two console retaining<br />

screws.<br />

2. Pry the console downward to<br />

free the console retaining clips (two)<br />

from the roof.<br />

3. Replace either of the four bulbs<br />

(seat belt, door, parking brake or low<br />

fuel) as required.<br />

4. Snap the console into place <strong>and</strong><br />

install the two retaining screws.<br />

TRANSMISSION CONTROL<br />

SELECTOR LIGHT (ON<br />

STEERING COLUMN)-FALCON,<br />

FAIRLANE AND MERCURY<br />

INTERMEDIATE<br />

I. Disconnect the battery ground<br />

cable from the battery.<br />

2. Remove the horn ring <strong>and</strong> steering<br />

wheel.<br />

3. Remove the light bulb socket<br />

retaining scrl:w <strong>and</strong> pullout the bulb<br />

<strong>and</strong> socket assembly. Replace the<br />

bulb.<br />

4. Position the bulb <strong>and</strong> socket assembly<br />

<strong>and</strong> install the socket retaining<br />

screw.<br />

5. Install the steering wheel <strong>and</strong><br />

horn ring.<br />

6. Connect the battery ground cable<br />

to the battery.<br />

TRANSMISSION CONTROL<br />

SELECTOR LIGHT-MUSTANG<br />

AND COUGAR<br />

I. Remove the four retaining<br />

screws from the selector lever cover<br />

<strong>and</strong>'dial indicator on the floor,<br />

2. Lift the lever cover assembly<br />

<strong>and</strong> replace the bulb.<br />

3. Position the cover to the floor<br />

<strong>and</strong> install the four cover retaining<br />

screws.<br />

TRANSMISSION CONTROL<br />

SELECTOR LIGHT (ON<br />

CONSOLE)-MUSTANG AND<br />

COUGAR<br />

I. Pry the top finish pad cover<br />

from the console.<br />

2. Remove the two retaining<br />

screws from inside the glove box <strong>and</strong><br />

remove the upper finish panel.<br />

3. Position the selector lever in the<br />

one position <strong>and</strong> remove the light socket<br />

<strong>and</strong> bulb from its retainer.<br />

4. Replace the bulb <strong>and</strong> install the<br />

socket in the retainer.<br />

5. Position the finish panel <strong>and</strong> install<br />

the retaining screws.<br />

6. Snap the finish pad cover into<br />

position.<br />

TAilLIGHT lENS-COUGAR<br />

1. Remove the luggage compartment<br />

rear trim panel.<br />

2. Remove the four bulb <strong>and</strong><br />

socket assemblies from the light body.<br />

3. Remove the six nuts retaining<br />

the light assembly to the body back<br />

panel.<br />

4. Remove the light assembly <strong>and</strong><br />

place it on a work bench.<br />

S. Remove ten nuts <strong>and</strong> remove<br />

the lens <strong>and</strong> door from the light body.<br />

Remove the lens from the door.<br />

6. Position the new lens in the<br />

door.<br />

7. Position the lens <strong>and</strong> door assembly<br />

to the light body <strong>and</strong> install<br />

the ten retaining screws.<br />

8. Position the light assembly to<br />

the car body <strong>and</strong> install the six light<br />

assembly retaining nuts.<br />

9. Plug in the light socket <strong>and</strong><br />

bulbs.<br />

10. Install the luggage compartment<br />

rear trim panel.<br />

TAILLIGHT LENS-MUSTANG<br />

I. Open the rear deck <strong>and</strong> remove<br />

the spare tire.<br />

2. Remove the bulb socket from<br />

the rear I ight body.<br />

3. Remove the six plastic covers<br />

from the ends of the bezel assembly<br />

studs <strong>and</strong> also remove the six retaining<br />

nuts.<br />

4. Pull the light body <strong>and</strong> lens<br />

from the studs <strong>and</strong> remove the assembly<br />

from the vehicle.<br />

5. Remove the six retaining screws<br />

from the lens <strong>and</strong> remove the lens<br />

from the body.

PART <strong>15</strong>-2-<strong>Lighting</strong> System And <strong>Horns</strong> <strong>15</strong>-<strong>15</strong><br />

6. Position the lens to the light<br />

body <strong>and</strong> install the six retaining<br />

screws.<br />

7. Position the light body assembly<br />

to the bezel studs <strong>and</strong> install the<br />

six retaining nuts. Install the plastic<br />

covers on the ends of the studs.<br />

8. Plug the bulb <strong>and</strong> socket assembly<br />

into the light body.<br />

9. Replace the spare tire <strong>and</strong><br />

close the rear deck lid.<br />

TAILLIGHT LENS AND/OR<br />

BULB-FALCON, MERCURY<br />

INTERMEDIATE-MODEL 71<br />

1. Remove four screws retaining<br />

the lamp assembly to the quarter<br />

panel.<br />

2. Remove the lens from the lamp<br />

assembly. Remove bulb if necessary.<br />

3. Position the lens to the lamp<br />

assembly.<br />

4. Position the lamp assembly to<br />

the quarter panel <strong>and</strong> install the retaining<br />

screws.<br />

TAIL AND STOP LIGHT<br />

BULBS-EXCEPT STATION<br />

WAGONS<br />

The tail <strong>and</strong> stoplight bulbs may<br />

be replaced, by opening the rear deck<br />

lid <strong>and</strong> pulling the socket <strong>and</strong> bulb<br />

assembly from the rear lamp body.<br />

On the Cougar, it will be necessary<br />

to remove the luggage compartment<br />

liner in order to remove light sockets.<br />

TAILLIGHT BODY. .COUGAR<br />

I. Remove the luggage compartment<br />

rear trim panel.<br />

2. Remove the four bulb <strong>and</strong> socket<br />

assemblies from the light body.<br />

3. Remove the six nuts retaining<br />

the light assembly to the body back<br />

panel <strong>and</strong> remove the assembly.<br />

4. Remove the outer seal from the<br />

light body <strong>and</strong> also remove the four<br />

rubber ring gaskets from the bulb<br />

openings.<br />

5. Remove the ten retaining nuts<br />

<strong>and</strong> remove the lens <strong>and</strong> door assembly<br />

from the light body.<br />

6. If replacement of the light body<br />

is necessary transfer the six studs<br />

to the new light body.<br />

7. Cement the le~s seal to the<br />

light body.<br />

'I<br />

8. Position the lens I, <strong>and</strong> door assembly<br />

to the light b~y <strong>and</strong> install<br />

the ten retaining nuts. \.<br />

9. Install the rubber ring gaskets<br />

in the bulb openings. Cement the<br />

outer seal to the light body.<br />

10. Position the light assembly to<br />

the car body <strong>and</strong> install the six light<br />

assembly retaining nuts.<br />

II. Plug in the light socket <strong>and</strong><br />

bulbs.<br />

12. Install the luggage compartment<br />

rear trim panel. Check the operation<br />

of the lights.<br />

TAILLIGHT BODY-FALCON<br />

I. Open the rear deck lid. Disconnect<br />

the bulb <strong>and</strong> socket from the<br />

back of the taillight housing.<br />

2. Remove the four light body retaining<br />

screws <strong>and</strong> remove the light<br />

body from the quarter panel.<br />

3. Separate the gasket <strong>and</strong> lens<br />

from the light body.<br />

4. Cement the gasket to the light<br />

body. Position the lens to the light<br />

body <strong>and</strong> position the light body to<br />

the quarter panel <strong>and</strong> install the<br />

four retaining screws.<br />

5. Connect the socket <strong>and</strong> bulb to<br />

the light housing.<br />

6. Close the rear deck <strong>and</strong> check<br />

the operation of the light.<br />

TAilLIGHT BODY, lENS AND/<br />

OR BUlBS-FAIRlANE<br />

MODEL 71<br />

1. Remove the four door retaining<br />

screws <strong>and</strong> remove the door.<br />

2. Remove the four screws retaining<br />

the light assembly to the quarter<br />

panel. Remove the bulb socket from<br />

the light assembly <strong>and</strong> remove the<br />

light assembly.<br />

3. Remove the light body gasket.<br />

4. Remove the six lens retaining<br />

screws <strong>and</strong> remove the lens from the<br />

light body.<br />

5. Remove four screws <strong>and</strong> two<br />

back-up light lens retainers <strong>and</strong> gaskets<br />

from the taillight lens.<br />

6. Position the gaskets <strong>and</strong> backup<br />

lens to the rear light lens. Position<br />

the retainers <strong>and</strong> install the four lens<br />

retaining screws.<br />

7. Install a new lens in the light<br />

body <strong>and</strong> install the six lens retaining<br />

screws.<br />

8. Position the light body gasket.<br />

Position the light body to the quarter<br />

panel, insert the light bulb <strong>and</strong> socket<br />

assemblies into the light body <strong>and</strong><br />

install the four light body retaining<br />

screws.<br />

9. Position the rear light door to<br />

the light body <strong>and</strong> install the four retaining<br />

screws.<br />

TAILLIGHT BODY<br />

-MUSTANG<br />

I. Remove the spare wheel <strong>and</strong><br />

tire assembly.<br />

2. Unplug the bulb <strong>and</strong> socket from<br />

the light body.<br />

3. Remove the six plastic covers<br />

from the light body <strong>and</strong> bezel (doors)<br />

retainin~ studs.<br />

4. Remove the six nuts from the<br />

light body <strong>and</strong> bezel (doors) retaining<br />

studs.<br />

s. Pull the light body back <strong>and</strong> off<br />

the studs. The light bezels (doors) can<br />

be replaced if necessary at this time<br />

as the studs are on the bezel <strong>and</strong><br />

these studs <strong>and</strong> nuts retain the light<br />

assembly to the body panel.<br />

6. Remove the gasket seal from the<br />

front of the lens.<br />

7. Remove the six lens retaining<br />

screws from the light body <strong>and</strong> remove<br />

the lens from the light body.<br />

8. Install a new gasket in the light<br />

body. Position the lens to the body<br />

<strong>and</strong> install the six lens retaining<br />

screws.<br />

9. If the bezels (doors) were removed,<br />

position the bezels to the body<br />

panel, using new seals.<br />

10. Position the seal to the lens <strong>and</strong><br />

light body assembly.<br />

11. Position the light body assembly<br />

on the retaining studs <strong>and</strong> install<br />

the six retaining nuts. Install the six<br />

plastic stud covers.<br />

12. Plug the bulb <strong>and</strong> socket assembly<br />

into the light body.<br />

BACKUP LIGHT BODY-<br />

COUGAR AND MUSTANG<br />

I. Open the luggage compartment<br />

<strong>and</strong> remove the luggage compartment<br />

rear trim panel (Cougar only).<br />

2. Fold back the carpet <strong>and</strong> remove<br />

the cover over the quarter panel.<br />

3. Disconnect the backup light<br />

connector, push the grommet through<br />

the side of the inner panel, <strong>and</strong> pull<br />

the lead through the hole.<br />

4. Remove the nuts <strong>and</strong> retainer<br />

<strong>and</strong> remove the backup light from the<br />

lower body panel extension.<br />

5. Transfer the lens, bulb <strong>and</strong> gasket<br />

to the new light body, <strong>and</strong> install<br />

sealer to the new light.<br />

6. Position the light assembly to<br />

the lower body panel extension,<br />

position the retainer, <strong>and</strong> install the<br />

mounting nuts.<br />

7. Route the lead through the hole<br />

<strong>and</strong> push the grommet into place.<br />

8. Connect the backup light connector,<br />

check the operation of the<br />

light, install the quarter panel cover,<br />

<strong>and</strong> position the carpet.<br />

9. Install the luggage compartment<br />

rear trim panel (Cougar only).<br />

TAilLIGHT DOOR-FAIRlANE<br />

All EXCEPT MODEL 71<br />

I. From inside the luggage compartment,<br />

remove the bulb <strong>and</strong> socket<br />

<strong>and</strong> disconnect the two wiring connectors.<br />

2. Remove the five light "~~emhlv

<strong>15</strong>-16<br />

GROUP <strong>15</strong>-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

to quarter panel retaining nuts <strong>and</strong><br />

remove the light assembly.<br />

3. Remove one nut <strong>and</strong> one screw.<br />

Disconnect the back-up light bulb<br />

<strong>and</strong> remove the light body from the<br />

door <strong>and</strong> lens assembly.<br />

4. Remove four screws retaining<br />

the backup light lens <strong>and</strong> taillight<br />

lens to the door with the retainer.<br />

Remove both lenses.<br />

S. Position the taillight lens <strong>and</strong><br />

backup lens to the door. Install the<br />

four retaining screws.<br />

6. Position the light body to the<br />

door. Plug in the backup light bulb<br />

<strong>and</strong> install the one nut <strong>and</strong> screw.<br />

7. Position the light assembly to<br />

the quarter panel <strong>and</strong> install the five<br />

retaining nuts.<br />

8. Plug the taillight bulb <strong>and</strong> socket<br />

assembly into the light body <strong>and</strong><br />

connect the two wiring connectors.<br />

TAILLIGHT DOOR-COUGAR<br />

1. Remove the luggage compartment<br />

rear trim panel.<br />

2. Remove the four bulb <strong>and</strong><br />

socket assemblies from the light body.<br />

3. Remove the six nuts retaining<br />

the light assembly to the body back<br />

panel.<br />

4. Remove the light assembly <strong>and</strong><br />

place it on a work bench.<br />

5. Remove ten nuts <strong>and</strong> remove<br />

the lens <strong>and</strong> door from the light body.<br />

Remove the lens from the door.<br />

6. Position the lens in the<br />

door.<br />

7. Position the lens <strong>and</strong> door assembly<br />

to the light body <strong>and</strong> install<br />

the ten retaining screws.<br />

8. Position the light assembly to<br />

the car body <strong>and</strong> install the six light<br />

assembly retaining nuts.<br />

9. Plug in the light socket <strong>and</strong><br />

bulbs.<br />

10. Install the luggage compartment<br />

rear trim panel.<br />

TAilliGHT<br />

DOOR-MUSTANG<br />

1. Open the rear deck <strong>and</strong> remove<br />

the spare tire.<br />

2. Unplug the bulb <strong>and</strong> socket<br />

from the light body.<br />

3. Remove the six plastic covers<br />

from the light body <strong>and</strong> bezel (door)<br />

retaining studs.<br />

4. Remove the six nuts from the<br />

light body <strong>and</strong> bezel (doors) retaining<br />

studs <strong>and</strong> pull the light body from<br />

the studs.<br />

5. Remove the three door assemblies<br />

from the back panel <strong>and</strong> remove<br />

the seals from the doors.<br />

6. Install the three rubber seals<br />

on the door assemblies <strong>and</strong> install the<br />

door assemblies to the back panel.<br />

7. Position the light body to the<br />

retaining studs <strong>and</strong> install the six<br />

retaining nuts.<br />

8. Install the six plastic stud<br />

covers.<br />

9. Plug the bulb <strong>and</strong> socket assembly<br />

into the light body.<br />

10. Install the spare tire, <strong>and</strong><br />

check the operation of the lights.<br />

LICENSE PLATE LIGHT<br />

ASSEMBLY-EXCEPT COUGAR<br />

AND STATION WAGONS<br />

I. Open the rear deck lid <strong>and</strong><br />

disconnect the license plate light<br />

lead wire <strong>and</strong> feed the wire through<br />

the rear panel.<br />

2. Remove the two screws attaching<br />

the light assembly to the bumper<br />

<strong>and</strong> remove the assembly.<br />

3. Remove the lens bezel, lens<br />

<strong>and</strong> gasket retaining screw <strong>and</strong> remove<br />

the bulb from the assembly.<br />

4. Install the bulb in the assembly.<br />

Position the gasket, lens <strong>and</strong> lens<br />

bezel to the assembly <strong>and</strong> install<br />

the retaining screw.<br />

5. Position the light assembly to<br />

the bumper <strong>and</strong> install the two retaining<br />

screws.<br />

6. Feed the lead wire thru the<br />

rear panel <strong>and</strong> connect the connector.<br />

LICENSE PLATE BULB<br />

AND/OR LENS<br />

On all vehicles except the Cougar<br />

<strong>and</strong> station wagon, the license plate<br />

bulb or lens can be replaced by removing<br />

one screw that retains the<br />

lens, lens bezel <strong>and</strong> gasket to the<br />

light assembly.<br />

On station wagons the bulb or lens<br />

may be replaced by prying the lens<br />

assembly from the bumper <strong>and</strong> then<br />

removing the bulb <strong>and</strong> socket assembly<br />

from the lens.<br />

For the Cougar license plate light<br />

only, it is necessary to open the rear<br />

deck <strong>and</strong> remove the luggage compartment<br />

liner <strong>and</strong> then pull the<br />

light socket from the rear panel.

Headlight Beam Selector Switch<br />

etaidemretnI<br />

dna Cougar.<br />

<strong>15</strong>-17<br />

Section<br />

Page<br />

1 Description <strong>and</strong> Operation <strong>15</strong>-17<br />

Headlight Switch <strong>15</strong>-17<br />

Fuse Panel <strong>15</strong>-17<br />

Mechanical Stoplight Switch <strong>15</strong>-17<br />

2 Removal <strong>and</strong> Installation <strong>15</strong>-22<br />

Headlight Switch-Except Mustang<br />

Headlight <strong>and</strong><br />

Cougar Switch-Mustang <strong>and</strong> Cougar <strong>15</strong>-22<br />

Ignition Switch-All Models<br />

Parking Brake Warning Switch-Cougar<br />

Dome Stoplight Dual Brake Light Switch-All Warning Switch Light Switch-All.<br />

,<br />

<strong>15</strong>-22<br />

<strong>15</strong>-22<br />

,<strong>15</strong>-23<br />

<strong>15</strong>-23<br />

<strong>15</strong>-23<br />

,<strong>15</strong>-23<br />

<strong>15</strong>-24<br />

lartueN roiretnI pU-kcaB Map Light Start Light Switch-Mustang Switch-Cougar (Roof XR-7 Console)<br />

Turn Indicator Switch <strong>and</strong> Wire Assembly...<br />

Windshield Wiper/Washer Switch-Fairlane .<br />

Windshield Wiper/Washer Switch-Falcon ..<br />

Windshield Wiper Switch-Mercury<br />

Windshield Wiper Switch-Mercury<br />

etaidemretnI (Intermitent Wipers)<br />

Windshield Wiper Switch-Mustang<br />

.<strong>15</strong>-24<br />

.<strong>15</strong>-24<br />

<strong>15</strong>-24<br />

<strong>15</strong>-24<br />

.<strong>15</strong>-24<br />

<strong>15</strong>-24<br />

<strong>15</strong>-25<br />

.<strong>15</strong>-25<br />

.<strong>15</strong>-25<br />

,.<strong>15</strong>-25<br />

DESCRIPTION AND OPERATION<br />

Refer to Wiring Diagram Manual<br />

Form 7795P-67 for locations of wiring<br />

harnesses. Schematics are shown<br />

in Group 19 of this manual.<br />

HEADLIGHT SWITCH<br />

A combination headlight switch<br />

<strong>and</strong> two circuit breakers is used (Fig.<br />

I). The headlight circuit is protected<br />

by an 18 ampere circuit breaker<br />

for the Mercury Intermediate <strong>and</strong><br />

Fairlane, a 12 ampere circuit breaker<br />

for the Falcon <strong>and</strong> the Mustang.<br />

The tail, parking, license plate light<br />

<strong>and</strong> horn circuits are protected by a<br />

<strong>15</strong> ampere circuit breaker.<br />

FUSE PANEL<br />

The fuse panel for the Falcon,<br />

Fairlane <strong>and</strong> Mercury Intermediate<br />

is mounted on the dash panel above<br />

the headlight dimmer switch. On the<br />

Mustang <strong>and</strong> Cougar the fuse panel is<br />

mounted above the accelerator pedal.<br />

Figs. 2 through 6 show the fuse locations<br />

in the panel <strong>and</strong> their respective<br />

values.<br />

MECHANICAL<br />

SWITCH<br />

STOP LIGHT<br />

The mechanical stoplight switch<br />

SFE 14 AMP FUSE:<br />

BACK.UP LIGHTS \<br />

WINDSHIELD WASHER<br />

SEA T BELT WARNING<br />

RADIO<br />

TURN SIGNALS<br />

SFE 14 AMP FUSE<br />

HEATER<br />

~<br />

14A HTR<br />

s;::]<br />

r 1<br />

~~s-f:--[T<br />

0 CIG<br />

l LTR. ~<br />

" ~u~~ Wt.RN<br />

0<br />

~<br />

7 o;A nnAA"<br />

nA<br />

/ AGA 2.5 AMP FUSE:<br />

INST. PANEL<br />

CLUSTER LIGHTS<br />

CLOCK LIGHT<br />

TACH().\ETER<br />

LIGHT<br />

ASH TRAY LIGHT<br />

TRANS. SELECTOR<br />

DIAL LIGHT<br />

RADIO LIGHT<br />

SFE 7.5 AMP FUSE:<br />

D~E, COORTESY,<br />

CARGO, MAP<br />

GLOVE BOX AND<br />

LUGGAGE C~P'T<br />

LIGHTS<br />

SFE 20 AMP FUSE:<br />

CIGAR LIGHTER<br />

EMERGENCY WARNING<br />

FLASHER<br />

CLOCK FEED,<br />

KNOB RELEASE BUTTON<br />

~<br />

MERCURY INTERMEDIATE<br />

K1451-A<br />

K 2133-A<br />

FIG.<br />

Headlig ht Switch<br />

FIG. 2-Fuse Panel-Mercury Intermediate

<strong>15</strong>-18<br />

GROUP <strong>15</strong>-Lighti ng System, <strong>Horns</strong> And <strong>Instruments</strong><br />

differs from the hydraulic switch formerly<br />

used. The switch assembly is<br />

installed on the pin of the brake pedal<br />

arm so that it straddles the master<br />

cylinder push rod. The switch assembly<br />

is a slip fit on the pedal arm pin<br />

<strong>and</strong> thus the switch assembly moves<br />

with the pedal arm whenever the<br />

brake pedal is depressed.<br />

The brake pedal arm pin has a designed-in<br />

clearance with the eye of<br />

the master cylinder push rod (Fig.<br />

7). Because of this clearance, whenever<br />

the brake pedal is pushed forward,<br />

the stop light switch contacts,<br />

moving with the pedal arm, are actually<br />

pushed against the end of the<br />

master cylinder push rod, through the<br />

switch actuating pin. It is this movement<br />

of the switch with respect to<br />

the actuating pin <strong>and</strong> master cylinder<br />

push rod that closes the switch<br />

contacts completing the circuit to the<br />

stoplights.<br />

When the brake pedal is released,<br />

the spring in the stop light switch returns<br />

the actuating pin to its normal<br />

position <strong>and</strong> the circuit to the stop<br />

lights opens.<br />

FALCON<br />

K 2134.'"<br />

FIG. 3-Fuse Panel. .Falcon

PART <strong>15</strong>-3-Switches, Circuit Breakers And Fuses <strong>15</strong>-19<br />

SFE 14 AMP FUSE:<br />

BACK.UP LIGHTS<br />

WINDSHIELD WASHER<br />

SEAT BELT WARNING<br />

RADIO<br />

TURN SIGNALS<br />

0<br />

0<br />

SFE 14 .AMP FUSE:<br />

HEATER<br />

14A ACCY<br />

- -<br />

14AHTR<br />

[]<br />

r'-"<br />

~7'<br />

- -<br />

2.5INST. LT,<br />

\--J.<br />

EMER. WARN.<br />

/<br />

s:::J<br />

0 CIG<br />

L TR.-<br />

d'f-<br />

...<br />

...#'<br />

0<br />

7.SA D()y4,E<br />

20A<br />

AGA 2.5 AMP FUSE<br />

INST. PANEL<br />

CLUSTER LIGHTS<br />

CLOCK LIGHT<br />

ASH TRAY LIGHT<br />

TACHOMETER LIGHT<br />

RADIO LIGHT<br />

TRANS. SELECTOR<br />

DIAL LIGHT<br />

'SFE 7.5 AMP FUSE:<br />

DOME, COURTESY,<br />

CARGO, MAP<br />

GLOVE BOX,<br />

LUGGAGE COMP'T.<br />

LIGHTS<br />

DOOR OPEN WARNING<br />

LIGHT (TAXI)<br />

SFE 20 AMP FUSE:<br />

CIGAR LIGHTER<br />

EMERGENCY WARNING<br />

FLASHER<br />

CLOCK FEED<br />

FAIRLANE<br />

FIG. 4-Fuse Panel-Fairlane

<strong>15</strong>-20 GROUP <strong>15</strong>-<strong>Lighting</strong> System, <strong>Horns</strong> And <strong>Instruments</strong><br />

SFE 14 AMP FUSE:<br />

BACK.UP liGHTS<br />

SEAT BEL T WARNING<br />

(MODEL 65 ONLY)<br />

RADIO<br />

TURN SIGNALS<br />

DOOR AJAR WARNING<br />

0<br />

0<br />

- -<br />

14AACCY<br />

~<br />

0<br />

AGA 2.5 AMP FUSE:<br />

INST. PANEL<br />

CLUSTER LIGHTS<br />

RADIO LIGHT<br />

TACHa.-4.ETER<br />

LIGHT<br />

SFE 14 At.\P FUSE:<br />

HEATER<br />

DEFROSTER<br />

14AHTR<br />

s::J 0 CIG<br />

LTR. -<br />

2.5INST. LT<br />

~<br />

p""<br />

7.5A DOME<br />

SFE 7.5 .AMP FUSE:<br />

Da.J.E, COORTESY<br />

MAP LIGHT<br />

GLOVE BOX AND<br />

LUGGAGE Ca.J.P'T<br />

LIGHTS<br />

CLOCK LIGHT<br />

SEAT BELT<br />

WARNING<br />

SF E 14 AMP FUSE:<br />

CIGAR LIGHTER<br />

EMER. WARN.<br />

20A<br />

COUGAR<br />

FIG. 5-Fuse Panel. -Cougar

PART <strong>15</strong>-3-Switches, Circuit Breakers And Fuses <strong>15</strong>-21<br />

SFE 14 AMP FUSE:<br />

BACK.UP<br />

LIGHTS<br />

RADIO<br />

P RN D L LIGHT<br />

TURN<br />

SIGNAL<br />

SFE 14 AMP FUSE:<br />

HEATER<br />

DEFROSTER<br />

14A HTR<br />

7.SA DOME<br />

AGA 2.5 AMP FUSE:<br />

INST. PANEL<br />

CLUSTER LIGHTS<br />

TACHOMETER LIGHT<br />

RADIO LIGHT<br />

(THIS CIRCUIT IS<br />

CONN ECTED INTO THE<br />

<strong>15</strong> AMP C.B. IN THE<br />

HEADLIGHT SWITCH)<br />

SFE 7.5 AMP FUSE:<br />