Armstrong Timber Floor Finish â Water Based Urethane

Armstrong Timber Floor Finish â Water Based Urethane

Armstrong Timber Floor Finish â Water Based Urethane

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong><br />

<strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

<strong>Timber</strong><br />

DESCRIPTION<br />

• <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> is a dual component; non−hazardous water<br />

based polyurethane finish incorporating the latest nano hybrid floor coating technology, for exclusive<br />

use on internal timber floors. <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> enhances the<br />

natural beauty of feature timber floors in premium gloss or matt finishes.<br />

• The catalysed formulation approach aids in giving this product exceptional chemical resistance and<br />

endurance in heavy foot traffic conditions.<br />

• <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> is most effectively used in domestic<br />

households and commercial buildings including restaurants, clubs, bars, retail stores, theatre stages,<br />

offices, shopping centres and many others. These locations require a finish to give maximum<br />

resistance to wear, scuffing, scratching, spillage and chemical damage. Used in the home <strong>Armstrong</strong><br />

<strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> highlights the colour of feature wood floors.<br />

• <strong>Finish</strong>ed floors are easily maintained using simple washing and dust mopping procedures.<br />

• One of the great advantages in using <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> is the<br />

easy and safe application of the product. Low odour and low Volatile Organic Compounds (VOC’S)<br />

make this product safe to use, not only for the person applying the product but also for those living and<br />

working in the immediate environment.<br />

• Application is made easy by the use of a roller. This method allows the product to flow on evenly and<br />

achieve maximum build. <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> is a UV stable<br />

product that does not yellow over time and can be readily cut back when recoating is needed.<br />

FEATURES AND BENEFITS<br />

• Extremely wear resistant<br />

• Excellent for high traffic and commercial areas<br />

• UV – stable, non yellowing

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

• Easy to apply – brush, roller or weighted bar applicator<br />

• Chemical resistant (wine, cola, beer)<br />

• Environmentally and user friendly − low VOC, low odour<br />

TECHNICAL INFORMATION<br />

Type of <strong>Finish</strong>:<br />

Hybrid waterborne polyurethane timber seal/finish<br />

Solids Content: 30 ± 1%<br />

Viscosity: Approx. 18 − 20 sec # 4 @ 25 ºC<br />

pH value: 8.00 - 9.00<br />

Specific Gravity: 1.0014 ± 0.005<br />

Sheen (@ 60º): Gloss: 75 – 80%,<br />

Satin: 25 – 30%<br />

Drying Time:<br />

Application tools:<br />

Application Rate:<br />

Safety:<br />

Flash Point:<br />

Resistance to chemicals:<br />

Shelf Life:<br />

Storage/Transport:<br />

Hardener/Catalyst:<br />

Pack Size:<br />

Clean up:<br />

Approx. 3 hours @ 20 ºC / 60% RH<br />

Brush, roller, weighted bar applicator<br />

Approx.10 − 15 m 2 /litre<br />

Non-Hazardous. For more details see MSDS.<br />

Non-Flammable<br />

Very good resistance to household chemicals.<br />

At least 1 year from the date of production, in<br />

unopened original container.<br />

The temperature must not fall below +5 ºC or<br />

exceed +30ºC during storage and transport.<br />

Keep out of direct sunlight<br />

Recommended use - 1% of catalyst. See MSDS for details.<br />

4 litre<br />

<strong>Water</strong><br />

PRECAUTIONS<br />

• <strong>Floor</strong> temperature must be between 10 − 30 °C.<br />

• <strong>Floor</strong> moisture content must be between 5 − 15%. A moisture meter is recommended to indicate<br />

curing conditions.

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

• In hot and dry climates slightly reduce exposure to direct air to prevent rapid and uneven drying.<br />

• Do not cover the surface with non porous protective materials as the curing time can take up to 7 days.<br />

DIRECTIONS FOR USE<br />

Reference is made to the Australian Standard Code AS 4786.2-2005: <strong>Timber</strong> <strong>Floor</strong>ing – Sanding and<br />

<strong>Finish</strong>ing.<br />

NEW OR FRESHLY SANDED TIMBER FLOORS<br />

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> Primer - <strong>Water</strong> <strong>Based</strong> & <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> - <strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong><br />

INITIAL FLOOR PREPARATION: GOOD FINISH STARTS WITH GOOD PREPARATION!<br />

• Sand timber floor to a fine finish using accepted procedures.<br />

• Machine sand the surface to remove old treatments and impurities in the wood. Use a coarse sanding<br />

paper and sand the floor to an even and smooth finish. Make a second cut with 100−120 grit sand<br />

paper and then fine sand with 120−150 grit sand paper. This finishing will reduce the amount of grain<br />

raise. Vacuum thoroughly and tack the floor with a water-dampened cloth before applying <strong>Armstrong</strong><br />

<strong>Timber</strong> <strong>Floor</strong> Primer - <strong>Water</strong> <strong>Based</strong>.<br />

• Make sure all dust is removed. Do not forget to remove dust from skirting, windowsills, radiators and<br />

other exposed areas.<br />

• PLEASE NOTE: <strong>Floor</strong> temperature must be between 10−30 °C. <strong>Floor</strong> moisture content must be<br />

between 5−15%. A moisture meter is recommended to indicate curing conditions of the finish. In hot<br />

and dry climates slightly reduce exposure to direct air to prevent rapid and uneven drying.<br />

Ensure all contaminants are removed; try <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> Primer - <strong>Water</strong> <strong>Based</strong> on small<br />

area (1m 2 ) first!<br />

APPLICATION OF ARMSTRONG TIMBER FLOOR PRIMER - WATER BASED<br />

• All application tools must be clean and free of contamination.<br />

• Cut in edges using a paint brush or paint pad.<br />

• Apply first coat of armstrong timber floor primer - water based at the recommended rate using selected<br />

application method.

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

• Smooth the sealer in line with the timber grain and lay of the floor.<br />

• Ensure an even coating is obtained without puddles and misses.<br />

• For roller application use a paint tray and load the roller evenly with sealer. Roll out excess on tray<br />

ramp. Roll slowly on the surface to be coated by overlapping the roller strokes. <strong>Finish</strong> off lightly with<br />

the grain of the timber and the roller free of sealer.<br />

• For bar application pour a line of sealer along the starting wall in the direction of the lay of the floor.<br />

Pull the applicator at an angle along the length of the floor allowing the sealer to flow off the following<br />

edge in a ‘snow-plough’ action. At the end effect a 180º turn. Gently press down on the tool to pad out<br />

excess sealer. Feather out all turn marks. Place the applicator on the floor and pull in the return<br />

direction ensuring the leading edge overlaps the previous coating and a wet edge is maintained.<br />

• Apply second coat if required. An additional coat may be applied if floor is very porous.<br />

DRYING TIME OF PRIMER<br />

• Allow the first coat to dry for 1−2 hours. Second or third coats will take longer to dry − allow 2−4 hours.<br />

Allow floor to dry completely before applying first coat of selected finish. Drying time of ARMSTRONG<br />

TIMBER FLOOR PRIMER - WATER BASED depends on the environmental conditions of the area such<br />

as air- flow, humidity and temperature.<br />

• Area must be well ventilated.<br />

FINISHING<br />

Allow floor to dry completely before applying first coat of <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong>.<br />

PLEASE NOTE: <strong>Floor</strong> temperature must be between 10-30°C. <strong>Floor</strong> moisture content must be between<br />

5−15%. A moisture meter is recommended to indicate curing time of finish. In hot and dry climates slightly<br />

reduce exposure to direct air to prevent rapid and uneven drying.<br />

Ensure all contaminants are removed; try <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> - <strong>Water</strong> <strong>Based</strong> on small<br />

area (1m 2 ) first!

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

APPLICATION OF FINISH ARMSTRONG TIMBER FLOOR FINISH-WATER BASED<br />

URETHANE<br />

• Allow sufficient time for primer to dry before finish application.<br />

• All timber surfaces should be clean and properly prepared.<br />

• Add CATALYST if desired. The catalyst provides enhanced chemical and abrasion resistance<br />

properties. Add 1% of catalyst to <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> drum and<br />

mix continuously for 5−10 minutes. Use up all <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong> after catalyst addition. <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> has a<br />

working life of 24 hours once catalysed. Never re-use catalysed product.<br />

• All application tools must be clean and free of contamination.<br />

• Cut in edges using a paint brush or paint pad.<br />

• Apply first coat of <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> at the recommended rate<br />

using selected application method.<br />

• Smooth the seal in line with the timber grain and lay of the floor.<br />

• Ensure an even coating is obtained without puddles and misses.<br />

• For roller application use a paint tray and load the roller evenly with seal. Roll out excess on tray ramp.<br />

Roll slowly on the surface to be coated by overlapping the roller strokes. <strong>Finish</strong> off lightly with the grain<br />

of the timber and the roller free of seal.<br />

• For bar application pour a line of seal along the starting wall in the direction of the lay of the floor. Pull<br />

the applicator at an angle along the length of the floor allowing the seal to flow off the following edge in<br />

a ‘snow-plough’ action. At the end effect a 180º turn. Gently press down on the tool to pad out excess<br />

seal. Feather out all turn marks. Place the applicator on the floor and pull in the return direction<br />

ensuring the leading edge overlaps the previous coating and a wet edge is maintained.<br />

• Apply second coat. An additional coat may be applied where a higher film build is desired.<br />

DRYING TIME OF FINISH<br />

Allow the first coat to dry for 1−2 hours. Second and subsequent coats will take longer to dry, up to 4 hours.<br />

Drying time of <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> depends on the environmental<br />

conditions of the area such as humidity, air−flow and temperature. Allow floor to dry and cure overnight<br />

before opening to light traffic. Do not cover the surface with non porous protective materials as the curing<br />

time can take up to 7 days.

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

INTERCOAT ABRASION<br />

• Abrading between coats of <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> is not required for<br />

adhesion unless more than 48 hours have elapsed or any grain raise is still evident, in which case,<br />

lightly cut the surface back with a 150 grit screen disc. However, for the smoothest floor results free of<br />

impediments, lightly abrade prior to the final finish coat with a denibbing pad.<br />

• Always vacuum thoroughly and tack the floor with a water-dampened cloth after abrading.<br />

REFURBISHING PREVIOUSLY SEALED FLOORS<br />

Ensure all contaminants are removed; try <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> on<br />

small area (1m 2 ) first!<br />

• The floor is to be swept clean of all debris and dirt.<br />

• To remove all foreign matter and contamination, thoroughly scrub the entire floor surface with a solution<br />

of <strong>Armstrong</strong> Multi Purpose <strong>Floor</strong> Cleaner following label instructions. Using a wet & dry vacuum or<br />

mop & bucket, pick up slurry then thoroughly rinse with clean water.<br />

• If the floor has been previously treated with wax or polish this must be removed by chemical stripping.<br />

To strip the floor use <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> Stripper following label instructions.<br />

• It is important that exposure to water is kept to a minimum during the scrubbing or stripping processes.<br />

Allow the floor to dry completely.<br />

• Cut back previously sealed floors with a 100–120 grit screen disc to remove raised wood fibre, surface<br />

imperfections and provide an adequate surface for resealing.<br />

• Vacuum thoroughly and tack the floor with a water-dampened cloth.<br />

• Apply <strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong>-<strong>Water</strong> <strong>Based</strong> <strong>Urethane</strong> in accordance ‘APPLICATION OF<br />

FINISH’ above.<br />

CARE AND MAINTENANCE<br />

• Regular and correct maintenance will extend the life of your timber floor and present it at its best.<br />

• Attach protective pads to furniture legs.<br />

• Use mating at all external entries to contain and prevent dirt and grit from entering.<br />

• Sweep daily with an electrostatic mop.

<strong>Armstrong</strong> <strong>Timber</strong> <strong>Floor</strong> <strong>Finish</strong> – <strong>Water</strong> <strong>Based</strong><br />

<strong>Urethane</strong><br />

• Spot mop spillages as they occur.<br />

• Damp mop when required. Use <strong>Armstrong</strong> Multi Purpose <strong>Floor</strong> and Surface Cleaner neutral floor<br />

cleaner following label instructions.<br />

• Do not over wet your timber floor.<br />

• Do not expose your timber floor to heavy maintenance until full curing of the seal/finish is affected.<br />

• At periodic intervals your timber floor will require treatment by way of additional coats of timber<br />

seal/finish. We recommend that you thoroughly inspect your floor regularly and schedule a retreatment<br />

prior to major restoration or full sanding being required.<br />

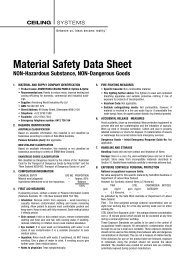

SAFETY<br />

Swallowed: Do NOT induce vomiting. Give a glass of water and contact doctor or the Poisonous<br />

Information Centre on (Australia 13 11 26 or New Zealand 0800 764 766).<br />

Eyes: If in eyes, hold eyelids open and irrigate with water for at least 15 minutes. See a doctor if effects<br />

persist.<br />

Skin: Remove contaminated clothing; wash affected area with soap and water