Download PDF - Olyset Net

Download PDF - Olyset Net

Download PDF - Olyset Net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Registered trademark of Sumitomo Chemical Co. Ltd.<br />

The Next-Generation <strong>Net</strong> with Added Protection<br />

<strong>Olyset</strong> ® Plus is a durable long-lasting<br />

mosquito net with fast action against<br />

mosquitoes and additional efficacy<br />

against Pyrethroid-resistant mosquitoes.

<strong>Olyset</strong> Plus – meeting the world’s changing needs.<br />

Contents<br />

Introduction and Background....................................................................1<br />

Controlled Release Technology ................................................................5<br />

Biological Efficacy ......................................................................................6<br />

Technical Specifications ..........................................................................10<br />

Usage and Safety ......................................................................................12

Introduction and Background<br />

Introduction<br />

Mosquito nets have a long history of protecting people<br />

from malarial mosquitoes but it was not until the introduction<br />

of treating nets with pyrethroid insecticides that<br />

bed nets changed from being a physical barrier to being<br />

an insecticidally active tool which both deters and kills<br />

mosquitoes. The original method of dipping nets in<br />

insecticide solution was very labour intensive and<br />

logistically difficult in the field and the treatment rarely<br />

survived more than three washes. The situation changed<br />

dramatically with the introduction of factory-treated,<br />

wash-proof, long lasting insecticide treated nets (LLINs)<br />

in which the insecticide is either bound to the surface of<br />

the net fibre or incorporated inside the fibre itself.<br />

<strong>Olyset</strong> ® <strong>Net</strong> – Pioneering Technology with Added Durability<br />

Sumitomo Chemical was the first company to develop and<br />

pioneer fibre incorporation technology. We realised that<br />

incorporation of insecticide into the fibre, using controlled<br />

release technology that allows insecticide to migrate to<br />

the surface and maintain a regular supply, is better than<br />

`gluing` to the fibre surface which leaves the insecticide<br />

vulnerable to removal by abrasion or washing. In addition,<br />

the use of high-density polyethylene (HDPE) rather than<br />

polyester as the fibre material gives major advantages in<br />

both the strength and durability of the net. <strong>Olyset</strong> Plus,<br />

like the original <strong>Olyset</strong> <strong>Net</strong>, has a denier of >150 whereas<br />

commonly available polyester nets are 75 – 100 denier. As<br />

denier is one of the major contributors to strength and<br />

durability in the field, <strong>Olyset</strong> Plus is therefore approximately<br />

1.5 - 2 times stronger than typical 75 – 100 denier<br />

polyester LLINs.<br />

<strong>Olyset</strong> <strong>Net</strong> was the first LLIN to pass the World Health<br />

Organization Pesticide Evaluation Scheme (WHOPES).<br />

Since then, many more nets have passed WHOPES with<br />

either interim or full recommendation. However, all these<br />

nets—including <strong>Olyset</strong> <strong>Net</strong>—are manufactured using a<br />

single class of insecticides known as pyrethroids, on<br />

account of their excellent activity against mosquitoes and<br />

low mammalian toxicity.<br />

Emerging insecticide resistance – a real threat<br />

Due to the excellent results from using LLINs, donors<br />

campaigned and advocated for mass distribution of bednets<br />

throughout Africa and in many other endemic countries.<br />

Universal coverage (at least 80% coverage with LLINs of<br />

at-risk populations) was achieved in many African<br />

countries by early 2011. The pressure of only using<br />

pyrethroids in LLINs, and their extensive use in indoor<br />

residual spraying programs as well as in agriculture, has<br />

resulted in insecticide resistance in mosquito vector<br />

populations in some parts of the world, particularly in<br />

Africa. ‘At the time of this report, resistance to at least<br />

one insecticide has been identified in 64 countries with<br />

on-going malaria transmission. Resistance to pyrethroids<br />

Key Features<br />

• Fine mesh.<br />

• Softer feel.<br />

• Excellent biological performance<br />

against mosquitoes.<br />

• Enhanced knockdown and kill<br />

against pyrethroid-resistant<br />

mosquitoes.<br />

• Contains the synergist –<br />

piperonyl butoxide (PBO) on<br />

all surfaces.<br />

• Insecticide and synergist<br />

incorporated inside fibres.<br />

• Insecticide and synergist<br />

migrate to fibre surface<br />

continuously over many years.<br />

• Re-generation of both<br />

active ingredients.<br />

• Unique to market.<br />

• A second generation of the<br />

well proven <strong>Olyset</strong> <strong>Net</strong>.<br />

• Japanese technology.<br />

seems to be the most widespread.*’ The extent and<br />

threat of resistance to the use of LLINs and on actual<br />

malaria cases is not well understood and there are large<br />

programmes planned to monitor and check the impact<br />

on transmission.<br />

* WHO Global Plan for Insecticide Resistance Management in malaria<br />

vectors (GPIRM), 2012<br />

1

Figure 1. Possible scenario for resistance development<br />

in a mosquito population.<br />

Reproduced by kind permission of IRAC<br />

Figure 2. Distribution of pyrethroid resistance in Africa using<br />

data collected between 2000 to 2010.<br />

Sumitomo Chemical’s original <strong>Olyset</strong> <strong>Net</strong> remains one<br />

of the best and most durable LLINs on the market.<br />

However, Sumitomo recognised that for some markets<br />

improvements could be made by increasing the speed of<br />

action and efficacy against both susceptible and resistant<br />

mosquitoes. This led to the development of <strong>Olyset</strong> Plus.<br />

<strong>Olyset</strong> Plus introduces many new features, including<br />

the addition of piperonyl butoxide (PBO), a synergist<br />

which increases the performance of the active ingredient<br />

Permethrin and in particular enhances activity against<br />

pyrethroid-resistant mosquitoes (see below for more<br />

information on PBO).<br />

<strong>Olyset</strong> Plus is the first and only net on the market to<br />

incorporate PBO into every fibre and all surfaces of the<br />

net, providing enhanced knockdown and kill against<br />

pyrethroid-resistant mosquitoes.<br />

Insecticide Resistance<br />

Insecticide resistance is defined by the Insecticide<br />

Resistance Action Committee (IRAC) as: ‘a heritable change in<br />

the sensitivity of a pest population that is reflected in the repeated<br />

failure of a product to achieve the expected level of control when used<br />

according to the label recommendation for that pest species.’<br />

The development of insecticide resistance occurs for the<br />

following reasons:<br />

Key:<br />

An. pharoensis<br />

An. labranchiae<br />

An. funestus<br />

An. gambiae s.l.<br />

An. arabiensis<br />

An. gambiae s.s.<br />

Resistant<br />

Resistance suspected<br />

Susceptible<br />

Ranson et al, Trends in Parasitology, February 2011, Vol. 27, No. 2.<br />

• Natural selection allows pre-adapted insects with<br />

resistance genes to survive and pass this resistance trait<br />

onto off-spring.<br />

• As more product is applied, the resistant population<br />

keeps growing while the susceptible individuals are<br />

eliminated by the insecticide. The product therefore<br />

is no longer fully effective.<br />

Other key points to note :<br />

• Speed of resistance development depends on speed of<br />

reproduction, the persistence of the insecticide applied<br />

and the proportion of susceptible species.<br />

• Resistance has appeared in a wide range of public<br />

health vectors to most chemical classes of insecticides.<br />

• The resistance problem in vector control is exacerbated<br />

2

y extensive use and misuse of the same classes of<br />

insecticides in agriculture.<br />

The map (see Figure 2) indicates that there is a spread of<br />

pyrethroid resistance into many areas of Africa where<br />

LLINs are being deployed. While the impact of this resistance<br />

on the efficacy of LLINs and malaria transmission is<br />

still unknown, there is a growing consensus that high<br />

levels of resistance may in the future result in operational<br />

failure of mass LLIN distribution programmes. Insecticide<br />

resistance in malaria vectors is therefore one of the major<br />

issues concerning stakeholders today.<br />

There are several types of resistance mechanism:<br />

• Metabolic resistance.<br />

• Target site resistance (Knockdown resistance (Kdr)<br />

or nerve insensitivity).<br />

• Behavioural resistance.<br />

• Reduced penetration resistance.<br />

Amongst these mechanisms, metabolic resistance is<br />

probably the most important, although the impact of Kdr<br />

resistance is also significant. The only chance to overcome<br />

most types of resistance is by using a totally new class of<br />

insecticide which as yet is not available. Ideally, a new<br />

insecticide would have all the attributes of pyrethroids:<br />

<strong>Olyset</strong> Plus is the first and only net on the market to<br />

incorporate PBO into every fibre and all surfaces of<br />

the net, providing enhanced knockdown and kill<br />

against pyrethroid-resistant mosquitoes.<br />

fast action, high intrinsic activity against target insects,<br />

and low mammalian toxicity combined with ease of<br />

formulation. These characteristics make the task of<br />

identifying suitable chemistry an extremely challenging,<br />

costly and long-term undertaking.<br />

While companies such as Sumitomo Chemical are<br />

playing a leading role in the synthesis, screening and<br />

development of new chemistry for use in disease vector<br />

control, the best solution in the interim is to continue to<br />

formulate LLINs with pyrethroids and to use the synergistic<br />

properties of PBO to improve insecticidal activity<br />

against both susceptible and resistant mosquitoes.<br />

For further information on insecticide resistance,<br />

monitoring and management strategies see `Prevention<br />

and Management of Insecticide Resistance in Vectors of<br />

Public Health Importance` published by IRAC (CropLife<br />

International) – see (www.irac-online.org)<br />

What is <strong>Olyset</strong> Plus<br />

<strong>Olyset</strong> Plus is a durable polyethylene net containing 2%<br />

permethrin and 1% of the synergist piperonyl butoxide<br />

(PBO) which are incorporated in all fibres. In this way,<br />

all sides and also the roof are treated. Using Sumitomo<br />

Chemical’s unique <strong>Olyset</strong> controlled-release technology, net<br />

fibres have been designed to release the two ingredients at<br />

a constant ratio of 2:1 thus ensuring enhanced efficacy for<br />

the life of the net against all mosquitoes, including those<br />

which are resistant.<br />

It has been shown that while many mosquitoes<br />

approach the roof of the LLINs a similar proportion go to<br />

the sides to get at the sleeping host. (Ref. Severin, L.<br />

University d` Abomey – Calavi Calvi, pers. comm.)<br />

Based on the above, it is clear that any net seeking to<br />

provide enhanced levels of protection from susceptible and<br />

3

esistant insects should have PBO on all surfaces so that<br />

the mosquitoes cannot avoid contacting both insecticide<br />

and synergist at the same time.<br />

What is Piperonyl Butoxide<br />

Piperonyl butoxide (PBO) is a synergist which has long<br />

been used to improve the performance of pyrethroid<br />

insecticides especially household aerosols. Synergists are<br />

chemicals that lack insecticidal activity of their own but<br />

enhance the insecticidal performance of other chemicals.<br />

How does Piperonyl Butoxide combat resistance<br />

All insects, whether susceptible or resistant, have enzymes<br />

that can metabolise insecticides into harmless components.<br />

Some of these enzymes, known as cytochrome P450s, are<br />

powerful oxidising agents that can detoxify an active<br />

ingredient before the desired effect is achieved; PBO is a<br />

powerful inhibitor of these enzymes and therefore blocks<br />

this action.<br />

In resistant insects the activity of these enzymes can<br />

be greatly enhanced which can significantly reduce the<br />

efficacy of an insecticide. PBO acts on these enzymes in<br />

resistant insects and inhibits the breakdown or the<br />

metabolism of insecticides, rendering the insecticide more<br />

effective. PBO also increases the activity of pyrethroids to<br />

susceptible insects, so adding PBO to an LLIN has a benefit<br />

even in areas where there is no resistance.<br />

There are many scientific papers which demonstrate<br />

the impact of PBO on pyrethroid resistance, and some<br />

specifically highlight the impact on permethrin resistance.<br />

See for example: Evidence of multiple pyrethroid resistance<br />

mechanisms in the malaria vector Anopheles gambiae sensu stricto<br />

from Nigeria. Awolola, T.S. et al., Transactions of the Royal Society<br />

of Tropical Medicine and Hygiene Vol: 103, Issue: 11, Pages: 1139-<br />

1145 (2009).<br />

Piperonyl Butoxide Key Points:<br />

• Inhibitor of P450 enzymes.<br />

• Enhances insecticide penetration.<br />

• Used in many household aerosols and space sprays<br />

products.<br />

• Not an insecticide but a synergist.<br />

• Low mammalian toxicity.<br />

• Known and used for >50 years.<br />

<strong>Olyset</strong> Plus Regeneration<br />

Rapid regeneration of surface active ingredients after<br />

washing -- and therefore the provision of an almost<br />

continuously available insecticide plus PBO barrier against<br />

mosquitoes -- is required to maximise the protective effect.<br />

This is especially important in areas where resistant mosquitoes<br />

have been found. The rate at which permethrin<br />

and PBO migrate from the internal reservoir in the fibre<br />

to the surface of the net (known as the ‘bleed rate’) has<br />

been adjusted in <strong>Olyset</strong> Plus to provide a rapid rate of<br />

regeneration, making the net active again within 1 – 2<br />

days after washing.<br />

Full efficacy in less than 2 days after washing.<br />

4

Controlled Release Technology<br />

Incorporated Polyethylene Controlled-Release Fibres vs “Coated” Polyester Fibre<br />

Permethrin and PBO<br />

Year 1 Year 2 Year 3<br />

Standard <strong>Net</strong><br />

Above: <strong>Olyset</strong> Plus, permethrin and piperonyl<br />

butoxide migrate to the surface of the net fibre over<br />

a period of three years or longer, maintaining a<br />

biologically effective surface concentration.<br />

Insecticide particles<br />

“glued” to net surface<br />

Left: For “coated” LLINs, surface concentration<br />

of insecticide declines over time.<br />

Year 1 Year 2 Year 3

Biological Efficacy<br />

The objectives of testing <strong>Olyset</strong> Plus were as follows:<br />

• Confirm efficacy meets WHOPES standards.<br />

• Confirm the regeneration time for insecticide and<br />

synergist is rapid.<br />

• Evaluate efficacy against susceptible mosquitoes.<br />

• Evaluate efficacy against pyrethroid resistant<br />

mosquitoes.<br />

% mortality<br />

% KD at 60 minutes<br />

%<br />

Figure 3. <strong>Olyset</strong> Plus tested unwashed and at intervals after<br />

three times washing — mortality at 24 hours.<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

64<br />

74<br />

85 85 87 87 84<br />

0 1 2 3 4 5 6 7<br />

Days post-washing<br />

Rossignol, B. Luce, MN Lacroix and F. Chandre, DOC/LIN/IRD/01/11<br />

Figure 4. Effect of washing <strong>Olyset</strong> Plus net (WHO cone test)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100 100 100 99 99<br />

0 3 5 10 15 20 25<br />

Number of washes<br />

Rossignol, B. Luce, MN Lacroix and F. Chandre, DOC/LIN/IRD/01/11<br />

Figure 5. Speed of regeneration of <strong>Olyset</strong> Plus against field<br />

caught pyrethroid resistant mosquitoes (WHO cone test).<br />

100<br />

100<br />

<strong>Olyset</strong> Plus<br />

unwashed<br />

100<br />

73.2<br />

<strong>Olyset</strong> Plus<br />

washed<br />

KD<br />

Mortality<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

95 95<br />

1. Regeneration, wash resistance and efficacy of <strong>Olyset</strong> Plus against<br />

susceptible Anopheles gambiae.<br />

To evaluate speed of regeneration, <strong>Olyset</strong> Plus was tested<br />

unwashed and then washed and dried 3 times and tested<br />

each day afterwards. Results (Figure 3) demonstrate that<br />

the net rapidly recovers killing efficacy and retained 100%<br />

knockdown activity after washing. From this (noting the<br />

fact that confidence intervals for mortality between day 2<br />

and 7 overlapped) regeneration time was determined to be<br />

2 days.<br />

To evaluate wash resistance nets were tested after<br />

repeated washing using the cone test. From the data<br />

generated above the interval between washes was set at 2<br />

days to allow the net to fully regenerate. Results indicate<br />

that knockdown (KD) of mosquitoes exposed to <strong>Olyset</strong><br />

Plus hardly changes over 25 washes. As these tests were<br />

conducted only 24 hours after each washing, the rapid<br />

regeneration of active ingredient on the fibre surface is<br />

clearly shown (See Figure 4).<br />

2. Evaluation of <strong>Olyset</strong> Plus vs. <strong>Olyset</strong> Plus without PBO unwashed<br />

and one day post washing against field caught pyrethroid resistant<br />

mosquitoes.<br />

Tests were conducted using the World Health Organisation<br />

(WHO) cone method (3 minute exposure) against field<br />

caught Anopheles arabiensis which were metabolic mechanism<br />

pyrethroid resistant. <strong>Olyset</strong> Plus was very effective<br />

unwashed and had regenerated very rapidly after 1 day to<br />

give 100% KD and 73.2% mortality (See Figure 5).<br />

3. Evaluation of <strong>Olyset</strong> Plus two days after 20 washes against<br />

pyrethroid resistant mosquitoes using the WHO tunnel test.<br />

<strong>Olyset</strong> Plus was washed 20 times using the standard<br />

WHO method and then tested in the WHO tunnel test only<br />

2 days after the last wash against Anopheles gambiae G3<br />

strain (moderately metabolic resistant to pyrethroids).<br />

Mosquitoes were introduced at one end of the tunnel and<br />

a small animal at the other end. The netting sample was<br />

placed in between with nine holes cut in it according to<br />

the WHO protocol. If mosquitoes can pass through the<br />

holes in the net this indicates the net has little repellency<br />

6

or killing effect. Blood Feeding Inhibition (BFI) shows the<br />

percentage of mosquitoes prevented from reaching the animal<br />

and feeding. Mortality is the total number of mosquitoes<br />

killed in their attempts to feed.<br />

Figure 6. <strong>Olyset</strong> Plus 2 days after 20 washes against<br />

pyrethroid-resistant mosquitoes (WHO Tunnel test).<br />

100<br />

80<br />

94.6<br />

79.6<br />

Sumitomo Chemical was the first company to develop<br />

and pioneer fibre incorporation technology.<br />

%<br />

60<br />

40<br />

20<br />

0<br />

BFI<br />

Mortality<br />

Results (Figure 6) show that blood feeding inhibition<br />

was very high and mortality was almost 80% despite the<br />

mosquitoes being pyrethroid resistant. This test demonstrates<br />

how quickly efficacy is restored to <strong>Olyset</strong> Plus<br />

following 20 washes and only 2 days regeneration time.<br />

4. <strong>Olyset</strong> Plus vs. a Polyester LLIN against field caught pyrethroid<br />

resistant mosquitoes.<br />

These tests were conducted against field caught Anopheles<br />

arabiensis which are pyrethroid metabolic resistant. Both<br />

nets were new and unwashed. The polyester LLIN used was<br />

a commercially available net treated with deltamethrin,<br />

widely used in malaria control programmes.<br />

The standard WHO cone test (3 minute exposure) was<br />

used. The results (Figure 7) show that the resistant<br />

Anopheles were knocked down and killed by <strong>Olyset</strong> Plus<br />

but the impact of the commercially available pyrethroid<br />

net was much less, demonstrating the superior efficacy<br />

of <strong>Olyset</strong> Plus against resistant mosquitoes.<br />

5. Impact of the addition of PBO on <strong>Olyset</strong> Plus and performance after<br />

1 day post-wash against resistant mosquitoes.<br />

Tests were conducted against field caught Anopheles<br />

arabiensis which were pyrethroid metabolic resistant.<br />

To evaluate the impact of PBO, an experimental <strong>Olyset</strong> Plus<br />

net was made with no synergist present. Both nets were<br />

washed once and tested after 1 day using the WHO cone<br />

test (3 minute exposure).<br />

The results (Figure 8) show showed that while there<br />

was no noticeable impact on knockdown there was a<br />

dramatic difference in mortality as a result of the action<br />

of PBO blocking the metabolic resistance mechanism.<br />

%<br />

Figure 7. <strong>Olyset</strong> Plus vs. a Polyester LLIN against field<br />

caught resistant mosquitoes (WHO cone test).<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

80<br />

60<br />

%<br />

40<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

20<br />

0<br />

100<br />

73.2 75.6<br />

KD<br />

24.4<br />

Mortality<br />

Polyester LLIN<br />

<strong>Olyset</strong> Plus<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

Figure 8. Impact of PBO in <strong>Olyset</strong> Plus against resistant<br />

mosquitoes 1 day after washing (WHO cone test).<br />

100<br />

KD<br />

100<br />

14.6<br />

73.2<br />

Mortality<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

<strong>Olyset</strong> Plus without PBO<br />

<strong>Olyset</strong> Plus with PBO

%<br />

Figure 9. Blood Feeding Inhibition in hut trials against resistant<br />

mosquitoes in Benin.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

100<br />

80<br />

60<br />

%<br />

40<br />

%<br />

100 100<br />

Kisumu before<br />

washing<br />

100<br />

95.1<br />

Kisumu after<br />

washing<br />

(3x+7 days)<br />

84.6<br />

82<br />

70.2<br />

KDR +<br />

Metabolic<br />

before<br />

washing<br />

Ref: C.Pennetier, V.Corbel et al. DOC/IRD/CREC/02/10<br />

20<br />

0<br />

87.1<br />

KDR +<br />

Metabolic<br />

after washing<br />

(3x+7 days)<br />

97.4 100 88<br />

Metabolic<br />

before<br />

washing<br />

BFI<br />

<strong>Olyset</strong> <strong>Net</strong><br />

<strong>Olyset</strong> Plus<br />

96.1<br />

Metabolic<br />

after washing<br />

(3x+7 days)<br />

Figure 10. Experimental hut trials in Cameroon: <strong>Olyset</strong> <strong>Net</strong> and<br />

<strong>Olyset</strong> Plus<br />

.6<br />

Control<br />

97.4<br />

75.8<br />

<strong>Olyset</strong> <strong>Net</strong><br />

Unwashed<br />

100 97.5<br />

<strong>Olyset</strong> Plus<br />

Ref: C.Pennetier, V.Corbel et al. DOC/IRD/CREC/02/10<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

.5<br />

Control<br />

88.0<br />

38.0<br />

<strong>Olyset</strong> <strong>Net</strong><br />

3 washes + 7 days<br />

Figure 11. WHOPEs Phase II experimental hut trials,<br />

Malanville, Benin.<br />

83.2<br />

80.6<br />

<strong>Olyset</strong> Plus<br />

unwashed<br />

79.4<br />

67.3<br />

<strong>Olyset</strong> Plus 20<br />

times washed<br />

Ref: CREC/IRD WHOPES Phase II report 31/1/2012<br />

81.6<br />

Blood Feeding Inhibition<br />

Mortality corrected<br />

for control<br />

41.7<br />

<strong>Olyset</strong> <strong>Net</strong><br />

unwashed<br />

59.9<br />

36.3<br />

<strong>Olyset</strong> <strong>Net</strong> 20<br />

times washed<br />

Mortality<br />

96.1<br />

68.6<br />

<strong>Olyset</strong> Plus<br />

These studies also demonstrated that <strong>Olyset</strong> Plus<br />

regenerated very rapidly and was active again 1 day after<br />

washing.<br />

6. <strong>Olyset</strong> Plus compared with <strong>Olyset</strong> <strong>Net</strong> in experimental huts – Benin.<br />

Trials were conducted in Cotonou, Benin using experimental<br />

huts to compare activity of <strong>Olyset</strong> <strong>Net</strong> and <strong>Olyset</strong> Plus.<br />

The washing methodology and experimental protocol<br />

followed the WHO Guidelines for testing long lasting nets<br />

(WHO/CDS/WHOPES/GCDPP/2005.11). Both LLINs had six<br />

holes cut in them to simulate torn nets and a volunteer<br />

slept under the nets. Mosquitoes therefore had access to a<br />

blood meal or were inhibited from feeding and exited the<br />

hut to a veranda trap. Three An. gambiae strains were used<br />

– susceptible (Kisumu), Kdr + metabolic resistant and<br />

metabolic only resistant. The mosquitoes were released<br />

into the hut in known numbers on different nights and<br />

Blood Feeding Inhibition (BFI) recorded to demonstrate<br />

the varying degrees of protection the test nets provided.<br />

The results are shown in Figure 9 where it can be seen<br />

that with susceptible mosquitoes there was little difference<br />

before washing, while after washing the <strong>Olyset</strong> Plus<br />

The unwashed <strong>Olyset</strong> <strong>Net</strong> performed well especially<br />

considering the resistance present but <strong>Olyset</strong> Plus gave<br />

better mosquito mortality.<br />

was slightly more effective due to faster regeneration and<br />

also to the additional performance enhancement that<br />

comes from the synergistic effects of PBO. When both nets<br />

were tested against Kdr + metabolic resistant mosquitoes<br />

the performance was not dissimilar before washing but<br />

after washing there was a dramatic difference as the BFI<br />

was far higher with <strong>Olyset</strong> Plus showing a protective<br />

effect. The BFI in this <strong>Olyset</strong> Plus treatment was 87.1%<br />

which is good considering that with Kdr resistance<br />

(caused by insensitivity of the insect nervous system to<br />

insecticide) PBO would be expected to add little benefit.<br />

When tested against metabolic only resistant mosquitoes<br />

8

<strong>Olyset</strong> Plus gave very good BFI that was superior to <strong>Olyset</strong><br />

<strong>Net</strong> due to the presence of PBO.<br />

7. <strong>Olyset</strong> Plus compared with <strong>Olyset</strong> <strong>Net</strong> in experimental huts –<br />

Cameroon.<br />

Experimental hut trials to compare <strong>Olyset</strong> <strong>Net</strong> and <strong>Olyset</strong><br />

Plus were conducted in Pitoa, Cameroon. As above, the<br />

washing methodology and protocol followed WHO<br />

Guidelines. The local population of An. gambiae were<br />

pyrethroid metabolic mechanism resistant.<br />

Blood Feeding Inhibition (BFI) rates were recorded to<br />

demonstrate the varying degrees of protection the test<br />

nets provided. The results (Figure 10) demonstrate that<br />

the untreated control nets gave little protection before<br />

washing.<br />

The unwashed <strong>Olyset</strong> <strong>Net</strong> performed well especially<br />

considering the resistance present but <strong>Olyset</strong> Plus gave<br />

better mosquito mortality. After 3 washes and 7 days<br />

<strong>Olyset</strong> <strong>Net</strong> gave good levels of BFI (88%) while <strong>Olyset</strong> Plus<br />

gave even better protection with 96% BFI. <strong>Olyset</strong> Plus also<br />

had a better overall impact on mortality (69% vs 38% for<br />

<strong>Olyset</strong> <strong>Net</strong>).<br />

8. WHO Phase II Evaluation of <strong>Olyset</strong> Plus – Benin.<br />

As part of the evaluation of <strong>Olyset</strong> Plus, Phase II experimental<br />

hut trials were conducted in Benin by WHOPES.<br />

These were carried out in Malanville, in an area where<br />

increased resistance of malaria vectors to pyrethroids<br />

(22% mortality to 0.75% permethrin) has been recently<br />

reported. Results for wild, free flying An.gambiae are<br />

shown in Figure 11. These show that while both nets have<br />

given good initial levels of protection from blood feeding<br />

before washing, <strong>Olyset</strong> Plus continues to give excellent<br />

protection after 20 washes. Levels for <strong>Olyset</strong> <strong>Net</strong> while<br />

still good, have declined. Mortality data follows a similar<br />

trend, indicating that <strong>Olyset</strong> Plus is likely to have a<br />

greater mass killing effect on these resistant populations<br />

over time compared with <strong>Olyset</strong> <strong>Net</strong>.

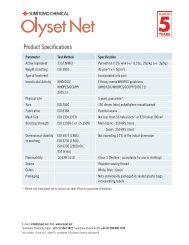

Technical Specifications<br />

<strong>Olyset</strong> Plus – meeting the world’s changing needs.<br />

Specifications<br />

Category<br />

Odour<br />

Colour<br />

Shape<br />

Dimensional Stability to<br />

washing (ISO 5077)<br />

<strong>Net</strong> attachment<br />

Active ingredient<br />

Packaging<br />

Synergist<br />

Insecticide and<br />

synergist location<br />

Storage stability<br />

Duration of Insecticide<br />

& Synergist efficacy<br />

from first use<br />

Specification<br />

Odourless<br />

Blue or white<br />

Rectangular or Conical<br />

Not exceeding 5% of the initial dimension<br />

Rectangular – A minimum of 6 suspension<br />

points (one at each of the four corners of<br />

the top panel and one equidistant at each of<br />

the sides) attached by fabric loops.<br />

Conical – single suspension point<br />

Permethrin 2.0% w/w (+/- 0.5%w/w),<br />

20g/kg (+/- 5g/kg)<br />

<strong>Net</strong>s individually packaged in sealed and<br />

tamper proof polypropylene bags<br />

incorporating a label<br />

Piperonyl Butoxide 1.0% w/w<br />

(+/- 0.25%w/w), 10g/kg (+/- 2.5g/kg)<br />

Incorporated into yarn<br />

In storage tests, net material contains<br />

>95% of the original a.i. content after<br />

2 weeks at 54ºC<br />

3 years (minimum)<br />

Fire Safety Classification Class 1<br />

16CFR 1610<br />

(Textiles – acceptable for use in clothing)<br />

Yarn<br />

150 denier (+/- 30) high density polyethylene<br />

monofilament fibre<br />

Mesh Size (holes/inch²) Not less than 80 holes per inch 2<br />

Weight of netting 40 g/m 2 (+/- 10g/m 2 )<br />

Weave type<br />

Raschel<br />

Bursting strength Main Fabric: 250KPa (min)<br />

Seam: 250KPa (min)<br />

Seams<br />

Polyester sewing thread<br />

Fabrication<br />

Warp Knitted<br />

ISO 13938-1-1999<br />

Sizes Available (cm)<br />

Rectangular <strong>Net</strong>s<br />

Description Length Width Height Number of<br />

Loops (min)<br />

Double 180 100 150 6<br />

Family 180 130 150 6<br />

Large Family/High 180/180 160/160 150/210 6<br />

Extra Family/High 190/190 180/180 150/210 6<br />

Conical <strong>Net</strong>s<br />

Description Circumference Height Roof Top Ring<br />

(diameter)<br />

Small 850 220 56 Flexible metal<br />

Medium 1050 220 56 Flexible metal<br />

Large 1250 250 65 Flexible metal<br />

Note : Rectangular and conical net sizes +/- 10% measured hanging up<br />

Active Ingredient Content of <strong>Olyset</strong> Plus<br />

Permethrin (Ref VBC/DS/84.51)<br />

The following information refers to permethrin, the active<br />

ingredient in <strong>Olyset</strong> Plus. Permethrin has been used for<br />

public health and agricultural insect control for over 30<br />

years and has an excellent track record. Registered uses of<br />

Permethrin include human skin applications for scabies<br />

control and as an insect repellent.<br />

SYNOPSIS: Permethrin is a broad spectrum, non-cumulative<br />

synthetic pyrethroid; and is a fast acting neurotoxin<br />

with good contact, limited stomach and no fumigant<br />

action. It is moderately stable in the environment and has<br />

good residual action on inert surfaces. Permethrin is<br />

non-systemic in plants; of low mammalian toxicity, and is<br />

readily metabolised with immediate loss of toxicity.<br />

Common name: Permethrin (ISO, BSI, ANSI)<br />

Identity:<br />

IUPAC: 3-Phenoxybenzyl(1RS)-cis,trans-3-(2,2-<br />

dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate.<br />

Molecular Formula: C21H20Cl2O3<br />

Molecular weight: 391.3<br />

10

Structural formula:<br />

Piperonyl Butoxide content<br />

Permethrin content<br />

Declared content is 20g/kg (+/-5g/kg, 2% w/w (1.5-2.5%<br />

limits), cis:trans isomer ratio 50/50 to 30/70).<br />

Ecotoxicology<br />

Exposure of non-target organisms to permethrin in <strong>Olyset</strong><br />

Plus is unlikely when used in accordance with the label<br />

instructions. Permethrin is toxic to fish under laboratory<br />

conditions, so contamination of fish-bearing water should<br />

be avoided. <strong>Net</strong>s should be gently washed in containers<br />

using a mild soap as necessary, and not in natural water<br />

sources such as streams, rivers, ponds and lakes.<br />

Piperonyl Butoxide<br />

The following information refers to piperonyl butoxide<br />

(PBO) a synergist used in <strong>Olyset</strong> Plus. PBO has been used for<br />

public health and agricultural insect control since 1947 and<br />

has an excellent track record. Registered uses of PBO<br />

include consumer aerosols, space sprays, shampoos for head<br />

lice and even skin applications for treatment of scabies.<br />

SYNOPSIS: Piperonyl butoxide is a synergist which<br />

enhances the activity of insecticides by inhibiting or<br />

blocking enzymes in the insect which would de-toxify<br />

the insecticide. It is particularly effective when used in<br />

conjunction with pyrethroids. It has low mammalian<br />

toxicity. It is non-cumulative in the environment.<br />

IUPAC: 5-[2-(2-butoxyethoxy) ethoxymethyl] -6-propyl-1,3-<br />

benzodioxole<br />

Molecular formula: C19H30O5<br />

Molecular weight: 338.438<br />

Declared content is 10g/kg (+/- 2.5g/kg), 1% w/w<br />

(0.75 – 1.25% limits).<br />

Ecotoxicology<br />

Researchers evaluated the disappearance of piperonyl<br />

butoxide in soil and water and determined that the chemical<br />

is short-lived in the environment. Piperonyl butoxide<br />

has a moderate to low potential to contaminate groundwater.<br />

Researchers consider piperonyl butoxide moderately<br />

toxic to fish and highly toxic to other aquatic organisms.<br />

It is not likely to accumulate in fish. Piperonyl butoxide<br />

is low to very low in toxicity when eaten by birds.<br />

Disposal Considerations<br />

The net should be changed when biological performance<br />

declines. Normally this will occur after approximately<br />

3 years. Disposal should conform to recommendations of<br />

International organizations and should comply with all<br />

federal, state and local regulations.<br />

Transport Information<br />

Hazard Class: Not classified as a hazardous material<br />

U.N. Number: Not applicable<br />

Storage<br />

Store in a cool, well-ventilated place away from sources<br />

of ignition and direct sunlight.<br />

Analytical<br />

Full analytical methodology is available for permethrin in<br />

CIPAC/4503/m Permethrin (June 2006). Piperonyl Butoxide<br />

Method extension of CIPAC 32+33+345/TK/M;<br />

Determination of Piperonyl Butoxide in Polyethylene<br />

Matrix by GC-FID 33/LN(M)/-<br />

11

Usage and Safety<br />

Usage and Care of <strong>Olyset</strong> Plus<br />

<strong>Olyset</strong> Plus nets are ready to use. Just unpack and hang<br />

over the bed, using the loops provided to attach string or<br />

cord and suspend from the roof. There is no need to ‘air’<br />

the net before use, unlike some other net products.<br />

Ensure the net hangs over the bed with sufficient netting<br />

hanging below the mattress or mat to tuck under at night.<br />

The net is factory-treated with insecticide and synergist<br />

and never needs re-treatment.<br />

<strong>Olyset</strong> Plus nets may be washed using soap and water to<br />

remove dirt. It is recommended that nets are washed a few<br />

times a year, as if a net becomes really dirty it could<br />

inhibit performance by masking the insecticide.<br />

To avoid damaging the net, gentle washing (with no<br />

bleach) is recommended. After washing the net should be<br />

dried in the shade before re-hanging over the bed. Once<br />

washed, the net will rapidly re-generate insecticide and<br />

synergist to the surface of the fibres, replacing any lost<br />

during washing.<br />

Safety<br />

Permethrin is a pyrethroid insecticide with low<br />

mammalian toxicity. Piperonyl butoxide is a synergist of<br />

low mammalian toxicity. Moreover, the majority of both<br />

chemicals are contained within the fibre matrix. However,<br />

sufficient active ingredient is still available on the net<br />

surface to provide excellent biological performance<br />

against mosquitoes.<br />

The risks from handling the net are negligible.<br />

Permethrin and piperonyl butoxide are virtually<br />

non-irritant, so no adverse effects should result from<br />

contact during handling or while sleeping under the net.<br />

World Health Organization Pesticide Evaluation Scheme (WHOPES)<br />

In accordance with Sumitomo`s ethical policies <strong>Olyset</strong> Plus<br />

has been submitted to WHOPES to be evaluated through<br />

all WHOPES test phases, and results so far are very positive.<br />

The WHOPES Working Group have met and after considering<br />

all the relevant scientific data have granted <strong>Olyset</strong> Plus<br />

an interim recommendation.<br />

WHO Risk Assessment of <strong>Olyset</strong> Plus (abstract)<br />

A risk assessment was conducted according to the WHO<br />

generic risk assessment model to support the use of a<br />

new long lasting insecticidal net (LLINs) to protect against<br />

malaria carried by mosquitoes. The polyethylene net<br />

contains permethrin 2% w/w and piperonyl butoxide<br />

and insecticidal synergist (1% w/w).<br />

Since the nets are manufactured and pre-treated with<br />

permethrin and piperonyl butoxide in the factory, the<br />

treatment of nets by the end user is not required.<br />

Therefore the only relevant exposure scenarios considered<br />

in this risk assessment were exposure during the washing<br />

of nets and exposure while sleeping under the nets,<br />

including exposure from potential oral ingestion by<br />

infants and children sucking or chewing the nets. The<br />

potential exposures of Permethrin and PBO during these<br />

activities were assessed using conservative assumptions,<br />

parameters and default values defined in the WHO model.<br />

All calculated exposures to permethrin and PBO<br />

achieved acceptable margins of safety for adults, children<br />

and infants for the relevant activities noted above.<br />

Therefore the combination of Permethrin and PBO in<br />

LLINs was considered safe.<br />

12

<strong>Olyset</strong> Plus nets are ready to use. Just unpack and hang over<br />

the bed, using the loops provided to attach string or cord and<br />

suspend from the roof. There is no need to ‘air’ the net before<br />

use, unlike some other net products.

Find out more at www.olyset.net<br />

<strong>Olyset</strong> Customer Service Department<br />

Horatio House<br />

77-85 Fulham Palace Road<br />

London W6 8JA<br />

United Kingdom<br />

Tel: +44 (0)208 600 7700<br />

Email: info@olyset.net<br />

<strong>Olyset</strong>® is a Registered trademark of Sumitomo Chemical Co.Ltd