Proceedings of Topical Meeting on Optoinformatics (pdf-format, 1.21 ...

Proceedings of Topical Meeting on Optoinformatics (pdf-format, 1.21 ...

Proceedings of Topical Meeting on Optoinformatics (pdf-format, 1.21 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

38 OPTOINFORMATICS’05<br />

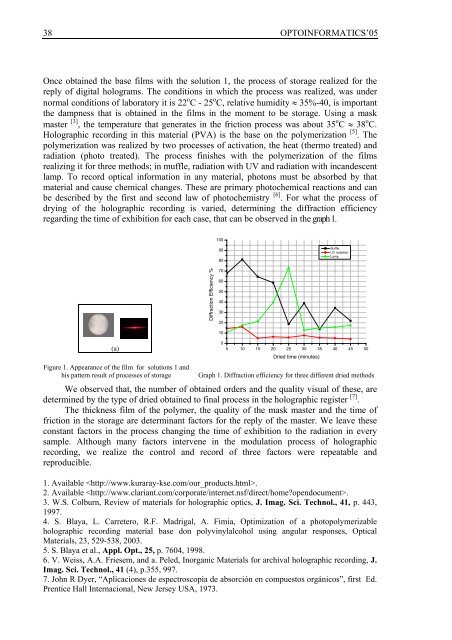

Once obtained the base films with the soluti<strong>on</strong> 1, the process <str<strong>on</strong>g>of</str<strong>on</strong>g> storage realized for the<br />

reply <str<strong>on</strong>g>of</str<strong>on</strong>g> digital holograms. The c<strong>on</strong>diti<strong>on</strong>s in which the process was realized, was under<br />

normal c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> laboratory it is 22 o C - 25 o C, relative humidity ≈ 35%-40, is important<br />

the dampness that is obtained in the films in the moment to be storage. Using a mask<br />

master [3] , the temperature that generates in the fricti<strong>on</strong> process was about 35 o C ≈ 38 o C.<br />

Holographic recording in this material (PVA) is the base <strong>on</strong> the polymerizati<strong>on</strong> [5] . The<br />

polymerizati<strong>on</strong> was realized by two processes <str<strong>on</strong>g>of</str<strong>on</strong>g> activati<strong>on</strong>, the heat (thermo treated) and<br />

radiati<strong>on</strong> (photo treated). The process finishes with the polymerizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the films<br />

realizing it for three methods; in muffle, radiati<strong>on</strong> with UV and radiati<strong>on</strong> with incandescent<br />

lamp. To record optical in<strong>format</strong>i<strong>on</strong> in any material, phot<strong>on</strong>s must be absorbed by that<br />

material and cause chemical changes. These are primary photochemical reacti<strong>on</strong>s and can<br />

be described by the first and sec<strong>on</strong>d law <str<strong>on</strong>g>of</str<strong>on</strong>g> photochemistry [6] . For what the process <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

drying <str<strong>on</strong>g>of</str<strong>on</strong>g> the holographic recording is varied, determining the diffracti<strong>on</strong> efficiency<br />

regarding the time <str<strong>on</strong>g>of</str<strong>on</strong>g> exhibiti<strong>on</strong> for each case, that can be observed in the graph 1.<br />

100<br />

90<br />

80<br />

Muffle<br />

UV radiati<strong>on</strong><br />

Lamp<br />

Diffracti<strong>on</strong> Efficiency %<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

( a )<br />

Figure 1. Appearance <str<strong>on</strong>g>of</str<strong>on</strong>g> the film for soluti<strong>on</strong>s 1 and<br />

his pattern result <str<strong>on</strong>g>of</str<strong>on</strong>g> processes <str<strong>on</strong>g>of</str<strong>on</strong>g> storage<br />

10<br />

0<br />

5 10 15 20 25 30 35 40 45 50<br />

Dried time (minutes)<br />

Graph 1. Diffracti<strong>on</strong> efficiency for three different dried methods<br />

We observed that, the number <str<strong>on</strong>g>of</str<strong>on</strong>g> obtained orders and the quality visual <str<strong>on</strong>g>of</str<strong>on</strong>g> these, are<br />

determined by the type <str<strong>on</strong>g>of</str<strong>on</strong>g> dried obtained to final process in the holographic register [7] .<br />

The thickness film <str<strong>on</strong>g>of</str<strong>on</strong>g> the polymer, the quality <str<strong>on</strong>g>of</str<strong>on</strong>g> the mask master and the time <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

fricti<strong>on</strong> in the storage are determinant factors for the reply <str<strong>on</strong>g>of</str<strong>on</strong>g> the master. We leave these<br />

c<strong>on</strong>stant factors in the process changing the time <str<strong>on</strong>g>of</str<strong>on</strong>g> exhibiti<strong>on</strong> to the radiati<strong>on</strong> in every<br />

sample. Although many factors intervene in the modulati<strong>on</strong> process <str<strong>on</strong>g>of</str<strong>on</strong>g> holographic<br />

recording, we realize the c<strong>on</strong>trol and record <str<strong>on</strong>g>of</str<strong>on</strong>g> three factors were repeatable and<br />

reproducible.<br />

1. Available .<br />

2. Available .<br />

3. W.S. Colburn, Review <str<strong>on</strong>g>of</str<strong>on</strong>g> materials for holographic optics, J. Imag. Sci. Technol., 41, p. 443,<br />

1997.<br />

4. S. Blaya, L. Carretero, R.F. Madrigal, A. Fimia, Optimizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a photopolymerizable<br />

holographic recording material base d<strong>on</strong> polyvinylalcohol using angular resp<strong>on</strong>ses, Optical<br />

Materials, 23, 529-538, 2003.<br />

5. S. Blaya et al., Appl. Opt., 25, p. 7604, 1998.<br />

6. V. Weiss, A.A. Friesem, and a. Peled, Inorganic Materials for archival holographic recording, J.<br />

Imag. Sci. Technol., 41 (4), p.355, 997.<br />

7. John R Dyer, “Aplicaci<strong>on</strong>es de espectroscopia de absorción en compuestos orgánicos”, first Ed.<br />

Prentice Hall Internaci<strong>on</strong>al, New Jersey USA, 1973.