Nanoassemblies of sulfonated polyaniline multilayers - ARPAL

Nanoassemblies of sulfonated polyaniline multilayers - ARPAL

Nanoassemblies of sulfonated polyaniline multilayers - ARPAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

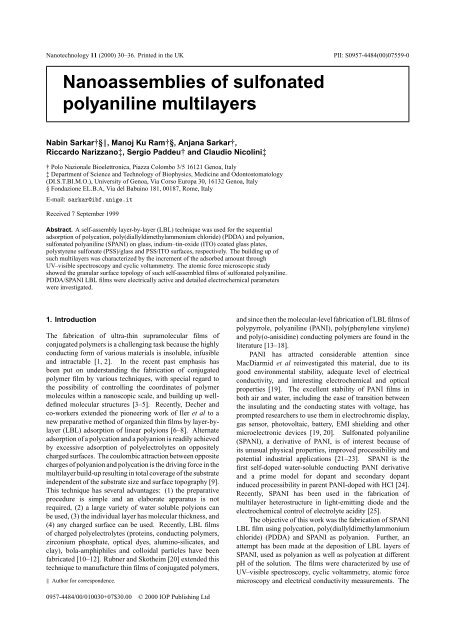

Nanotechnology 11 (2000) 30–36. Printed in the UK<br />

PII: S0957-4484(00)07559-0<br />

<strong>Nanoassemblies</strong> <strong>of</strong> <strong>sulfonated</strong><br />

<strong>polyaniline</strong> <strong>multilayers</strong><br />

Nabin Sarkar†§‖, Manoj Ku Ram†§, Anjana Sarkar†,<br />

Riccardo Narizzano‡, Sergio Paddeu† and Claudio Nicolini‡<br />

† Polo Nazionale Bioelettronica, Piazza Colombo 3/5 16121 Genoa, Italy<br />

‡ Department <strong>of</strong> Science and Technology <strong>of</strong> Biophysics, Medicine and Odontostomatology<br />

(DI.S.T.BI.M.O.), University <strong>of</strong> Genoa, Via Corso Europa 30, 16132 Genoa, Italy<br />

§ Fondazione EL.B.A, Via del Babuino 181, 00187, Rome, Italy<br />

E-mail: sarkar@ibf.unige.it<br />

Received 7 September 1999<br />

Abstract. A self-assembly layer-by-layer (LBL) technique was used for the sequential<br />

adsorption <strong>of</strong> polycation, poly(diallyldimethylammonium chloride) (PDDA) and polyanion,<br />

<strong>sulfonated</strong> <strong>polyaniline</strong> (SPANI) on glass, indium–tin-oxide (ITO) coated glass plates,<br />

polystyrene sulfonate (PSS)/glass and PSS/ITO surfaces, respectively. The building up <strong>of</strong><br />

such <strong>multilayers</strong> was characterized by the increment <strong>of</strong> the adsorbed amount through<br />

UV–visible spectroscopy and cyclic voltammetry. The atomic force microscopic study<br />

showed the granular surface topology <strong>of</strong> such self-assembled films <strong>of</strong> <strong>sulfonated</strong> <strong>polyaniline</strong>.<br />

PDDA/SPANI LBL films were electrically active and detailed electrochemical parameters<br />

were investigated.<br />

1. Introduction<br />

The fabrication <strong>of</strong> ultra-thin supramolecular films <strong>of</strong><br />

conjugated polymers is a challenging task because the highly<br />

conducting form <strong>of</strong> various materials is insoluble, infusible<br />

and intractable [1, 2]. In the recent past emphasis has<br />

been put on understanding the fabrication <strong>of</strong> conjugated<br />

polymer film by various techniques, with special regard to<br />

the possibility <strong>of</strong> controlling the coordinates <strong>of</strong> polymer<br />

molecules within a nanoscopic scale, and building up welldefined<br />

molecular structures [3–5]. Recently, Decher and<br />

co-workers extended the pioneering work <strong>of</strong> Iler et al to a<br />

new preparative method <strong>of</strong> organized thin films by layer-bylayer<br />

(LBL) adsorption <strong>of</strong> linear polyions [6–8]. Alternate<br />

adsorption <strong>of</strong> a polycation and a polyanion is readily achieved<br />

by excessive adsorption <strong>of</strong> polyelectrolytes on oppositely<br />

charged surfaces. The coulombic attraction between opposite<br />

charges <strong>of</strong> polyanion and polycation is the driving force in the<br />

multilayer build-up resulting in total coverage <strong>of</strong> the substrate<br />

independent <strong>of</strong> the substrate size and surface topography [9].<br />

This technique has several advantages: (1) the preparative<br />

procedure is simple and an elaborate apparatus is not<br />

required, (2) a large variety <strong>of</strong> water soluble polyions can<br />

be used, (3) the individual layer has molecular thickness, and<br />

(4) any charged surface can be used. Recently, LBL films<br />

<strong>of</strong> charged polyelectrolytes (proteins, conducting polymers,<br />

zirconium phosphate, optical dyes, alumino-silicates, and<br />

clay), bola-amphiphiles and colloidal particles have been<br />

fabricated [10–12]. Rubner and Skotheim [20] extended this<br />

technique to manufacture thin films <strong>of</strong> conjugated polymers,<br />

‖ Author for correspondence.<br />

and since then the molecular-level fabrication <strong>of</strong> LBL films <strong>of</strong><br />

polypyrrole, <strong>polyaniline</strong> (PANI), poly(phenylene vinylene)<br />

and poly(o-anisidine) conducting polymers are found in the<br />

literature [13–18].<br />

PANI has attracted considerable attention since<br />

MacDiarmid et al reinvestigated this material, due to its<br />

good environmental stability, adequate level <strong>of</strong> electrical<br />

conductivity, and interesting electrochemical and optical<br />

properties [19]. The excellent stability <strong>of</strong> PANI films in<br />

both air and water, including the ease <strong>of</strong> transition between<br />

the insulating and the conducting states with voltage, has<br />

prompted researchers to use them in electrochromic display,<br />

gas sensor, photovoltaic, battery, EMI shielding and other<br />

microelectronic devices [19, 20]. Sulfonated <strong>polyaniline</strong><br />

(SPANI), a derivative <strong>of</strong> PANI, is <strong>of</strong> interest because <strong>of</strong><br />

its unusual physical properties, improved processibility and<br />

potential industrial applications [21–23]. SPANI is the<br />

first self-doped water-soluble conducting PANI derivative<br />

and a prime model for dopant and secondary dopant<br />

induced processibility in parent PANI-doped with HCl [24].<br />

Recently, SPANI has been used in the fabrication <strong>of</strong><br />

multilayer heterostructure in light-emitting diode and the<br />

electrochemical control <strong>of</strong> electrolyte acidity [25].<br />

The objective <strong>of</strong> this work was the fabrication <strong>of</strong> SPANI<br />

LBL film using polycation, poly(diallyldimethylammonium<br />

chloride) (PDDA) and SPANI as polyanion. Further, an<br />

attempt has been made at the deposition <strong>of</strong> LBL layers <strong>of</strong><br />

SPANI, used as polyanion as well as polycation at different<br />

pH <strong>of</strong> the solution. The films were characterized by use <strong>of</strong><br />

UV–visible spectroscopy, cyclic voltammetry, atomic force<br />

microscopy and electrical conductivity measurements. The<br />

0957-4484/00/010030+07$30.00 © 2000 IOP Publishing Ltd

<strong>Nanoassemblies</strong> <strong>of</strong> <strong>sulfonated</strong> <strong>polyaniline</strong> <strong>multilayers</strong><br />

surface morphology <strong>of</strong> such bilayer films was investigated<br />

using atomic force microscopy. The electrochemical kinetics<br />

<strong>of</strong> such LBL films was also investigated by electrochemical<br />

surveying.<br />

2. Experimental details<br />

2.1. Solution preparation and deposition<br />

The emeraldine base form <strong>of</strong> PANI was synthesized as<br />

reported in [26]. The emeraldine base powder was dried, and<br />

<strong>sulfonated</strong> by dissolving in fuming sulfuric acid at 4–5 ◦ C<br />

with constant stirring for 2 h. Later, this solution was added<br />

drop-wise to methanol for the precipitation <strong>of</strong> the product<br />

and the temperature was maintained between 10 and 20 ◦ C.<br />

Precipitation was completed by the addition <strong>of</strong> acetone. The<br />

green powder was collected on a Buchner funnel, and washed<br />

repeatedly with methanol until the filtrate showed a value <strong>of</strong><br />

pH 7. The precipitate was dried under vacuum for 72 h [27].<br />

Microscopic glass, indium–tin-oxide (ITO) coated<br />

glass plates were used as substrate for the fabrication <strong>of</strong><br />

PDDA/SPANI multilayer films. Substrates were activated<br />

following a procedure reported previously [16]. The first<br />

layer <strong>of</strong> activated surface was deposited by <strong>sulfonated</strong><br />

polystyrene (PSS, M w = 70 000) solution for 15 min,<br />

prepared by using 2 mg ml −1 <strong>of</strong> PSS in water, which provided<br />

the charges necessary to adsorb the first layer <strong>of</strong> PDDA.<br />

SPANI (0.1 g) was dissolved in 10 ml <strong>of</strong> 0.1 N NaOH solution<br />

and diluted to 30 ml by distilled water. Then, this solution was<br />

filtered to remove any trace <strong>of</strong> undissolved SPANI particles.<br />

Later, this solution was adjusted to pH = 6 by the dropwise<br />

addition <strong>of</strong> 1 M HCl solution. The polyelectrolyte<br />

PDDA was purchased from Aldrich with M w = 200 000–<br />

350 000, and used in an aqueous solution (2 mg ml −1 ). The<br />

multilayer structure was fabricated by alternate dipping <strong>of</strong><br />

treated substrates in the PDDA and SPANI solution for 10 min<br />

each by rigorous washing in a solution <strong>of</strong> pH 2, and dried<br />

by nitrogen gas. The alternating layers <strong>of</strong> PDDA and SPANI<br />

were also deposited onto various substrates, prior to one layer<br />

deposition <strong>of</strong> PSS, polyanion. Such treated substrate was<br />

used to build <strong>multilayers</strong> structures <strong>of</strong> SPANI and PDDA.<br />

Later, SPANI solutions at pH = 5 as polycation, and at<br />

pH = 10 as polyanion were used for the deposition <strong>of</strong> SPANI<br />

LBL films on PSS-deposited glass or ITO-coated glass plates,<br />

respectively. SPANI (0.1 g) was dissolved in 10 ml <strong>of</strong> 0.1 N<br />

NaOH solution, and diluted to 30 ml by distilled water. Then,<br />

this solution was filtered to remove any trace <strong>of</strong> undissolved<br />

SPANI particles. This solution was divided into two parts,<br />

one was adjusted to pH = 5 and other to pH = 10 by slow<br />

addition <strong>of</strong> 1 M HCl. The pH 5 SPANI solution acted as<br />

polycation and the pH 10 solution acted as polyanion during<br />

deposition <strong>of</strong> multilayer films. Alternating layers <strong>of</strong> SPANI<br />

(pH = 5) and SPANI (pH = 10) were deposited onto the<br />

glass and ITO-coated glass plates, prior to the deposition <strong>of</strong><br />

one layer <strong>of</strong> PSS solution, by alternating submersions <strong>of</strong> the<br />

film samples in the electrolyte solutions to build a multibilayer<br />

structure. Between each deposition, the films were<br />

washed with a solution <strong>of</strong> pH 2 using HCl acid and dried by<br />

blowing nitrogen gas.<br />

2.2. Optical measurements<br />

The UV–visible spectra <strong>of</strong> LBL films deposited on the optical<br />

glass substrates were recorded by using the UV–visible<br />

spectrophotometer (Jasco model 7800).<br />

2.3. Electrical and electrochemical measurements<br />

The electrical characterization was performed using an<br />

electrometer (Keithley model 6517). Current–voltage (I–<br />

V ) characteristics were obtained by an applied potential<br />

(step <strong>of</strong> 0.05 V). Similar interdigitated electrodes were used<br />

for the electrical measurements [16]. The electrochemical<br />

measurements on LBL deposited SPANI films on ITO-coated<br />

glass plates were made by Potentiostat/Galvanostat (EG &<br />

G PARC, model 263A) with a supplied s<strong>of</strong>tware (M270).<br />

A standard three-electrode configuration was used, where<br />

PDDA/SPANI and SPANI (deposited at pH 5 and 10) films<br />

on PSS/ITO-coated glass plates acted as a working electrode,<br />

with platinum as a counter and Ag/AgCl as a reference<br />

electrode.<br />

2.4. Atomic force microscopy<br />

The surface morphology <strong>of</strong> the SPANI/PDDA LBL films was<br />

investigated by an atomic force microscope (AFM), which<br />

was a home-built instrument (Polo Nazionale Bioelettronica),<br />

working in contact mode in air at a constant contact force.<br />

Our AFM was operated in air, at constant deflection (i.e.<br />

vertical contact force) with triangular shaped gold-coated<br />

Si 3 N 4 . The tips <strong>of</strong> the microlevers had standard aspect ratio<br />

(about 1:1) and the levers had nominal force constant <strong>of</strong><br />

0.03 N m −1 . The constant force set point was about 0.1 nN,<br />

while the images acquired were 256×256 pixel maps. During<br />

the acquisition the row scanning frequency was set to 4 Hz,<br />

i.e. a physical tip–sample motion speed <strong>of</strong> 8, 4, 2 µm s −1 in<br />

the 2, 1, 0.5 µm scan size images, respectively. Some images<br />

presented features that were saturated in the post-processing<br />

redistribution <strong>of</strong> the available grey levels. Henceforth, it was<br />

possible to observe the finest structure <strong>of</strong> the samples. The<br />

images shown in this paper are representative <strong>of</strong> the samples,<br />

as similar looking images appeared in four different regions<br />

<strong>of</strong> the analysed samples, positioned at the vertices <strong>of</strong>a4mm<br />

side square, centred on the specimen [16, 28].<br />

3. Results and discussion<br />

3.1. UV–visible<br />

Figure 1(a) shows the optical absorption spectra <strong>of</strong><br />

PDDA/SPANI deposited on a PSS/glass slide as a function<br />

<strong>of</strong> the number <strong>of</strong> bilayers. As PDDA is not absorbing in<br />

the considered spectral region, the UV–visible absorption<br />

can only be emanating due to the SPANI layers. A typical<br />

UV–visible absorption spectrum <strong>of</strong> SPANI has three distinct<br />

absorption bands in the regions 340, 430–450 and 800–<br />

900 nm. These spectra depict the features characteristic<br />

<strong>of</strong> the SPANI forms, implying that the polymer is in the<br />

protonated form. The band at 340 is attributed to the<br />

π–π ∗ band-gap absorption and 430–450 and 800–900 are<br />

due to the protonation <strong>of</strong> SPANI. The constant absorbance<br />

31

N Sarkar et al<br />

Figure 2. Plot <strong>of</strong> absorbance at 340 nm for SPANI in<br />

PDDA/SPANI LBL films as a function <strong>of</strong> layers. Plot <strong>of</strong><br />

absorbance at 340 nm for SPANI deposited on glass substrates as<br />

polyanion and as polycation.<br />

Figure 1. (a) The optical spectra <strong>of</strong> PDDA/SPANI films as a<br />

function <strong>of</strong> number <strong>of</strong> bilayers made in 6 pH and washed by a<br />

solution <strong>of</strong> pH 2 using HCl, namely (1) 2 bilayer, (2) 5 bilayers<br />

(3) 10 bilayers, (4) 5 bilayers, (5) 20 bilayers. (b) Plot <strong>of</strong><br />

UV–visible absorbance at 340 nm versus time <strong>of</strong> deposition for the<br />

SPANI deposited on PDDA surface at pH 6, and washed by using<br />

a solution <strong>of</strong> pH 2.<br />

magnitude change for each layer is indicative <strong>of</strong> the uniform<br />

deposition <strong>of</strong> SPANI/PDDA. The adsorption time on PDDA<br />

is an important parameter in obtaining a complete layer <strong>of</strong><br />

SPANI on PDDA surface. Figure 1(b) shows the absorption<br />

magnitude at 340 nm <strong>of</strong> SPANI on PDDA surface as a<br />

function <strong>of</strong> time. It reveals a deposition <strong>of</strong> SPANI on the<br />

PDDA/PSS surface by simply immersing in the solution, but<br />

a complete layer <strong>of</strong> SPANI required an immersion period <strong>of</strong><br />

5–6 min. A small increase in the absorption magnitude was<br />

noticed for a period <strong>of</strong> 10 min <strong>of</strong> immersion, while saturation<br />

in the absorption was obtained at an exposure time <strong>of</strong> 60 min.<br />

In the light <strong>of</strong> these results each layer <strong>of</strong> <strong>sulfonated</strong> SPANI<br />

was deposited for an exposure time <strong>of</strong> 5 min in the resulting<br />

solution.<br />

The deposition <strong>of</strong> PDDA/SPANI bilayers was monitored<br />

by the change in absorption magnitude at 340 nm as shown<br />

in figure 2 (curve 1). The linear variation in absorbance<br />

versus the number <strong>of</strong> bilayers indicates a regular deposition<br />

<strong>of</strong> PDDA/SPANI LBL films. The deposited bilayers films<br />

were undoped using 0.1 M NaOH solution, and the UV–<br />

visible spectra were registered. A linearity in absorption<br />

magnitude at 330 nm versus the number <strong>of</strong> bilayers was<br />

observed (figure not shown). The UV–visible spectra <strong>of</strong><br />

SPANI bilayers deposited when used as polyanion and<br />

polycation were performed. Figure 2 (curve 2) reveals a<br />

linearity for the absorption magnitude at 340 nm versus the<br />

number <strong>of</strong> bilayers but shows a smaller optical absorption<br />

magnitude than for the PDDA/SPANI LBL films. Such<br />

variation in absorption magnitude could be due to a smaller<br />

transfer <strong>of</strong> the material for the SPANI used as polycation and<br />

polyanion. The UV–visible studies suggested that films could<br />

(a)<br />

(b)<br />

Figure 3. AFM images <strong>of</strong> PDDA/SPANI LBL films deposited on<br />

glass substrates as a function <strong>of</strong> bilayers, namely: (a) 5 bilayers<br />

and (b) 20 bilayers <strong>of</strong> 250 nm × 250 nm in size.<br />

be better formed by selection <strong>of</strong> polycation (PDDA) for LBL<br />

deposition <strong>of</strong> SPANI. So, further studies were performed in<br />

PDDA/SPANI bilayers films.<br />

3.2. AFM observations<br />

The morphology <strong>of</strong> multilayer films <strong>of</strong> SPANI/PDDA on<br />

glass surface was investigated by AFM as shown in figure 3.<br />

32

<strong>Nanoassemblies</strong> <strong>of</strong> <strong>sulfonated</strong> <strong>polyaniline</strong> <strong>multilayers</strong><br />

to that in figure 3(a). The height <strong>of</strong> the 5 bilayers <strong>of</strong><br />

PDDA/SPANI LBL film was observed to vary between 20<br />

to 10 nm.<br />

3.3. Electrical and electrochemical properties<br />

(a)<br />

(b)<br />

Figure 4. Three-dimensional images <strong>of</strong> AFM <strong>of</strong> 5 bilayers,<br />

PDDA/SPANI LBL, films deposited on glass substrate: (a) The<br />

image dimension is 2 × 2 µm 2 in size. (b) The image dimension is<br />

500 × 500 nm 2 in size.<br />

In order to evaluate the morphological evolution <strong>of</strong> a SPANI,<br />

we undertook the AFM measurements on PDDA/SPANI<br />

structure as a function <strong>of</strong> bilayers. The AFM images in<br />

figure 3 present the surface topography <strong>of</strong> 250 × 250 nm 2<br />

dimension <strong>of</strong> 5 and 20 bilayers <strong>of</strong> PDDA/SPANI LBL<br />

films. These pictures reveal that the topological surfaces<br />

<strong>of</strong> PDDA/SPANI bilayer films are covered by particles size<br />

varying from 30 to 62.5 nm in diameter. The horizontal and<br />

vertical radii measured for the marked grain in figure 3(a)<br />

are measured as 32.5 and 33.2 nm, whereas figure 3(b)<br />

shows horizontal and vertical radii as 30 and 16 nm,<br />

respectively. The RMS values <strong>of</strong> each AFM image <strong>of</strong><br />

5 bilayers and 20 bilayers have been calculated as 7.4 and<br />

5.1 nm. Interestingly, variation in size can be observed in 5-<br />

bilayer PDDA/SPANI films, whereas 20-bilayer films show<br />

nearly equal grain size and compact film. The obtained<br />

thickness and size <strong>of</strong> the grains are greater than those<br />

attributed to true PANI bilayers [16]. The distribution <strong>of</strong><br />

the grain size decreases with increase in number <strong>of</strong> bilayers<br />

in figure 3 which is in contrary to the results <strong>of</strong> Langmuir–<br />

Blodgett or LBL films <strong>of</strong> PANI [29]. The size <strong>of</strong> the grains<br />

depend upon the nature <strong>of</strong> SPANI molecules in LBL films.<br />

Figure 4 shows two three-dimensional images <strong>of</strong> 5-bilayer<br />

PDDA/SPANI LBL film <strong>of</strong> 2 × 2 µm 2 and 500 × 500 nm 2<br />

in size. These images show a variation in the particle similar<br />

The electrical conductivity <strong>of</strong> PDDA/SPANI was measured<br />

to be 10 −3 Scm −1 . The films undoped in 0.1 M NaOH<br />

solution showed a decrease in conductivity value to 0.75 ×<br />

10 −9 Scm −1 (figure not shown).<br />

The cyclic voltammogram <strong>of</strong> PDDA/SPANI LBL films<br />

in 0.1 M HCl electrolyte solution are shown as a function <strong>of</strong><br />

bilayers in figure 5(a). The peaks <strong>of</strong> cyclic voltammograms<br />

are associated to redox processes <strong>of</strong> SPANI films. The inset<br />

in figure 5(a) reveals the linearity in the peak current as<br />

a function <strong>of</strong> bilayers. The oxidation peak potentials are<br />

observed at 664.2, 455.3, 179.3 mV, whereas the reduction<br />

peak potentials are attributed at 580.8, 430.3 and 31.38 mV,<br />

respectively. The variation in the separation between any two<br />

redox potentials could be the consequence <strong>of</strong> the steric effect<br />

associated with the bulky sulfonic substituents and a higher<br />

S/N ratio for SPANI as compared to the emeraldine base<br />

form <strong>of</strong> PANI. An alternative interpretation could be that the<br />

sulfonic acid group attached to phenyl rings lowers the energy<br />

level <strong>of</strong> the valence band or the highest occupied molecular<br />

orbital in the polymer molecule increasing the band gap<br />

between the conduction and valence bands. Therefore,<br />

more energy is needed to remove an electron from the<br />

polymer chain and consequently the half-width potential<br />

(E 1/2 ) increases in PDDA/SPANI LBL films. The cyclic<br />

voltammogram <strong>of</strong> SPANI is similar to PANI [16, 28]. The<br />

reduced state <strong>of</strong> SPANI contains fixed negative charges or<br />

is compensated by mobile cations when oxidation <strong>of</strong> the<br />

negative charges are used to compensate the formed radical<br />

cations where mobile cations are expelled. Figure 5(b)<br />

shows the cyclic voltammogram <strong>of</strong> 5-bilayer PDDA/SPANI<br />

LBL films on ITO glass plates at different scan rates. The<br />

PDDA/SPANI <strong>multilayers</strong> films show a diffusion-controlled<br />

system similar to PANI [16]. Other interesting features<br />

such as the electrochromic effect (colour from faded yellow<br />

to violet) <strong>of</strong> the films was also observed by sweeping the<br />

potential from −0.2 to 0.8 V for PDDA/SPANI films.<br />

The redox kinetics process in PDDA/SPANI films was<br />

studied in HCl, H 2 SO 4 to CH 3 COOH media as shown<br />

in figure 6(a). The redox changes are associated to<br />

variations in electronic resonant structure <strong>of</strong> the polymer<br />

backbone caused by oxidation and protonation forms <strong>of</strong><br />

SPANI conducting polymer. The overall process involves<br />

loss <strong>of</strong> two electrons and deprotonation for SPANI films. The<br />

redox processes and lower switching <strong>of</strong> SPANI conducting<br />

polymer may be dependent on the redox ionic conductivity <strong>of</strong><br />

the polymer matrix. It was shown that HCl ions show a faster<br />

electrochromic effect (switching half-time H 1/2<br />

f<br />

= 200 ms)<br />

than that found in H 2 SO 4 (H 1/2<br />

f<br />

= 220 ms) and CH 3 COOH<br />

(H 1/2<br />

f<br />

= 420 ms). Table 1 shows the electrochemical<br />

parameters <strong>of</strong> the LBL films in different acid media. The<br />

redox processes in CH 3 COOH acid are slower than that <strong>of</strong><br />

H 2 SO 4 or HCl acids. The weak acid also has longer diffusion<br />

time. Later, the lifetime <strong>of</strong> the SPANI films were estimated<br />

by applying the pulse continuously at 100 mV s −1 . The CV<br />

33

N Sarkar et al<br />

Figure 5. (a) Cyclic voltammogram <strong>of</strong> PDDA/SPANI LBL films<br />

on glass ITO coated plate in 0.1 M HCl acid medium as a function<br />

<strong>of</strong> bilayers deposited, namely: (1) 5 layers, (2) 10 layers,<br />

(3) 15 layers and (4) 20 layers. Inset shows the variation <strong>of</strong> peaks<br />

potential (180 mV) versus number <strong>of</strong> bilayers. (b) Cyclic<br />

voltammograms <strong>of</strong> 5 bilayers PDDA/SPANI LBL films on ITO<br />

glass plates at different scan rate: (1) 2 mV s −1 ,(2)5mVs −1 ,<br />

(3) 10 mV s −1 , (4) 20 mV s −1 , (5) 50 mV s −1 , (6) 100 mV s −1 .<br />

was recorded in figure 6(b) to understand the mechanism<br />

and lifetime <strong>of</strong> SPANI films. There is a change in the peak<br />

potential after 10 4 as well as 10 5 cycles but the shape <strong>of</strong> the<br />

CV always follows the Nernst equation (closed and reversible<br />

to 3×10 5 cycles). It closely follows the shape <strong>of</strong> CV after 10 5<br />

cycles, which diffuses ions and maintains the electroactivity<br />

in close comparison to electrochemical films. The lifetime <strong>of</strong><br />

<strong>sulfonated</strong> films was observed to be greater than 10 5 cycles.<br />

Figure 7 shows the redox current versus time for<br />

15 bilayers <strong>of</strong> PDDA/SPANI film. It reveals to nearly equal<br />

oxidation and reduction system, when the potential is swept<br />

from −0.2 to 0.9 V. The redox changes are associated with<br />

the electronic resonant structure <strong>of</strong> the polymer backbone<br />

caused by the oxidation and reduction processes <strong>of</strong> the<br />

SPANI films. The redox switching <strong>of</strong> the SPANI conducting<br />

polymer may be dependent on the redox ionic conductivity<br />

<strong>of</strong> the polymer matrix. Figure 7 (inset) shows the plot <strong>of</strong><br />

oxidation current versus time and reduction current versus<br />

time plot for 15 bilayers SPANI films. The slope obtained for<br />

SPANI shows that redox processes are diffusion controlled.<br />

The value <strong>of</strong> the slope was obtained to be 0.64 and 0.57.<br />

To investigate the ion diffusion process on switching time,<br />

we considered the current transient for the redox switching<br />

process. The diffusion coefficient was estimated by using the<br />

Bulfer–Volmer equation, where two electrons participated in<br />

the reaction mechanism <strong>of</strong> the PANI system. The diffusion<br />

coefficient for the redox process was estimated to be 1.2 ×<br />

10 −8 cm 2 s −1 . The oxidation and reduction response time<br />

Figure 6. (a) Plot <strong>of</strong> square <strong>of</strong> scan rate versus current for the<br />

5 bilayers, PDDA/SPANI LBL, films in (1) 0.1 M H 2 SO 4 ,<br />

(2) 0.1 M HCl and (3) 0.1 M CH 3 COOH media. (b) CVs <strong>of</strong><br />

15 bilayers <strong>of</strong> PDDA/SPANI LBL films in 0.1 M HCl acid at<br />

50 mV s −1 as a function <strong>of</strong> scanning cycle, namely: (1) 1st cycle,<br />

(2) 10 2 cycles, (3) 10 3 cycles, (4) 10 4 cycles, (5) 10 5 cycles and<br />

(6) 10 6 cycles.<br />

Figure 7. Redox current response <strong>of</strong> 15 bilayers <strong>of</strong> PDDA/SPANI<br />

LBL films in 0.1 M HCl acid medium. Inset shows the plot <strong>of</strong><br />

fitting for the oxidation and reduction current.<br />

was found to be 200 ms. Similar studies <strong>of</strong> oxidation<br />

and reduction were performed for each PANI system, and<br />

the response time is given in table 2. Interestingly, the<br />

response time <strong>of</strong> SPANI was found to be greater than the<br />

other substituted PANI [28].<br />

4. Conclusion<br />

LBL films <strong>of</strong> PDDA/SPANI and SPANI (pH 5)/SPANI<br />

(pH 10) were fabricated. The LBL <strong>multilayers</strong> <strong>of</strong> conducting<br />

34

Table 1. Electrochemical parameters <strong>of</strong> PDDA/SPANI films.<br />

Diffusion<br />

Oxidation Reduction coefficients D 0<br />

Acidic media potential (mV) potential (mV) Slope in cm 2 s −1<br />

HCl 664.2, 455.3, 179.3 664.2, 455.3, 179.3 5.53 1.2 × 10 −8<br />

H 2 SO 4 630, 228.1 563.6, 89.3 5.125 0.92 × 10 −8<br />

CH 3 COOH 381.9, 124 328.6, 15.45, 2.7 4.061 0.75 × 10 −9<br />

<strong>Nanoassemblies</strong> <strong>of</strong> <strong>sulfonated</strong> <strong>polyaniline</strong> <strong>multilayers</strong><br />

Table 2. CV <strong>of</strong> 15 bilayers <strong>of</strong> PDDA/SPANI films.<br />

After number <strong>of</strong> cycles Oxidation potential (mV) Reduction potential (mV)<br />

2nd 689.7, 161.3 588.3, 8.33<br />

2 × 10 2 677.9, 494.9, 186.9 565.1, 17.66<br />

10 3 438.5, 315 359.2, 162.5<br />

10 4 369.9, 28.09 334.5, 133.5<br />

10 5 414.0 87.8, −37.24<br />

10 6 246.4 −32.67<br />

polymer were monitored by UV–visible spectroscopy. The<br />

linear variation in the PDDA/SPANI revealed a uniform<br />

deposition process, whereas the SPANI used as polyanion and<br />

polycation did not give a uniform film because the dipping<br />

solution was found to change the structure <strong>of</strong> polyanion<br />

or polycation SPANI. The nucleation and growth <strong>of</strong> the<br />

deposited films were investigated by AFM, showing a surface<br />

topology <strong>of</strong> PDDA/SPANI bilayers films covering particle<br />

size varying from 30 to 62.5 nm in diameter. The distribution<br />

<strong>of</strong> the grain size decreases with increase in the number<br />

<strong>of</strong> bilayers which is contrary to the results <strong>of</strong> Langmuir–<br />

Blodgett or LBL films <strong>of</strong> PANI. The redox processes in<br />

CH 3 COOH medium are slower than in H 2 SO 4 or HCl media.<br />

The weak acid takes longer diffusion time in the SPANI<br />

films. The diffusion coefficient (D 0 ) was calculated to<br />

be 1.2 × 10 −8 cm 2 s −1 . Typical multilayer films reveal<br />

a conductivity range from 10 −3 to 0.75 × 10 −9 Scm −1 .<br />

This investigation allowed us to fabricate thin films <strong>of</strong><br />

SPANI in a controlled way and we look forward to use<br />

such a structure in photovoltaic and light-emitting diode<br />

devices. We are also investigating the structural properties <strong>of</strong><br />

bilayer PDDA/SPANI LBL films to address the technological<br />

application <strong>of</strong> conjugated polymers.<br />

Acknowledgments<br />

We are grateful to M Panza for his help in carrying out the experiments.<br />

Financial support from Fondazione Elba (Chapter<br />

2102 <strong>of</strong> Ministry <strong>of</strong> Universities and Research <strong>of</strong> Italy) and a<br />

Murst-PST contract on Neural Net Work with Polo Nazionale<br />

Bioelettronica is gratefully acknowledged. This paper was<br />

presented as a poster in the Elba Foresight Conference on<br />

Nanotechnology in Rome on April 14–17, 1999.<br />

References<br />

[1] Fou A C and Rubner M F 1995 Macromolecules 28 7115<br />

[2] Martin C R 1991 Adv. Mater. 111 4138<br />

[3] Ram M K, Sundaresan N S and Malhotra B D 1993 J. Phys.<br />

Chem. 97 11 580<br />

Ram M K, Joshi M, Mehrotra R, Dhawan SKand<br />

Malhotra B D 1997 Thin Solid Films 304 65<br />

Ram M K, Gowri R and Malhotra B D 1997 J. Appl. Polym.<br />

Sci. 63 141<br />

[4] Agbor N E, Petty M C, Monkman A P and Harris H 1993<br />

Synth. Met. 55–57 3789<br />

[5] Cheung J H, Punkka E, Rikukawa M, Rosner M B,<br />

Rorappa A J and Rubner M F 1992 Thin Solid Films<br />

210–211 246<br />

Dhanabalan A, Dabke R B, Prasant Kumar N, Talwar S S,<br />

Major S, Lal R and Contractor A Q 1997 Langmuir 13<br />

4395<br />

[6] Decher G, Hong J D and Schmitt J 1992 Thin Sold Films<br />

210–211 831<br />

[7] Decher G 1996 Templating, self assembly and<br />

self-organization Comprehensive Supramolecular<br />

Chemistry vol 9, ed J-P Sauvage and M W Hosseini<br />

(Oxford: Pergamon) p 507<br />

Decher G 1997 Fuzzy nanoassemblies: towards layered<br />

polymeric multicomposites Science 277 1232<br />

[8] Lvov Y, Decher G and Möhwald H 1993 Langmuir 9 481<br />

[9] Decher G, Eckle M, Schmitt J and Struth B 1998 Current<br />

opinion in colloid and interface Science 3 32<br />

[10] Decher G, Lvov Y and Schmitt J 1994 Thin Solid Films 244<br />

772<br />

[11] Fou A C and Rubner M F 1995 Macromolecules 28 7107<br />

[12] Cheung J H, Fou A C and Rubner M F 1994 Thin Solid Films<br />

244 895<br />

[13] Raposo M, Pontes R S, Mattoso LHCandOliveiraONJr<br />

1997 Macromolecules 30 6095<br />

[14] Cheung J H, Stockton W B and Rubner M F 1997<br />

Macromolecules 30 2712<br />

Stockton W B and Rubner M F 1997 Macromolecules 30<br />

2717<br />

[15] Onitsuka O, Fou A C, Ferreira M, Hsieh BRand<br />

Rubner M F 1996 J. Appl. Phys. 80 4067<br />

[16] Ram M K, Salerno M, Adami M, Faraci F and Nicolini C<br />

1999 Langmuir 15 1252<br />

[17] Lehr B, Seufert M and Decher G 1995 Supramolecular<br />

Science 2 199<br />

[18] Alva K S, Kumar J, Marx K A and Tripathy S K 1997<br />

Macromolecules 30 4024<br />

[19] Epstein A J and MacDiarmid A G 1989 Electronic<br />

Properties <strong>of</strong> Conjugated Polymer ed H Kuzmany,<br />

M Mehring and S Roth (Berlin: Springer)<br />

MacDiarmid A G, Chiang J C, Halpern M, Huang W S,<br />

Mu S L, Somasiri N L, Wu W and Yaniger S I 1985 Mol.<br />

Cryst. Liq. Cryst. 121 173<br />

[20] Rubner M F and Skotheim T A 1991 Conjugated Polymers<br />

ed J L Bredas and R Silbey (Amsterdam: Kluwer) p 363<br />

[21] Barbero C, Miras M C and Haas O 1993 Synth. Met. 55–57<br />

1539<br />

35

N Sarkar et al<br />

[22] Wei X L, Wang Y Z, Long S M, Bobeczko C and Epstein A J<br />

1996 J. Am. Chem. Soc. 118 2545<br />

[23] Yue J, Wang A H, Cromack K R, Epstein AJand<br />

MacDiarmid A G 1991 J. Am. Chem. Soc. 113 2665<br />

Wu Q, Qi Z and Wang F 1999 Synth. Met. 105 191<br />

[24] Yue J and Epstein A J 1992 J. Chem. Soc. Chem. Commun.<br />

21 1540<br />

Wu Q, Wu L, Qi Z and Wang F 1999 Synth. Met. 105 13<br />

[25] Onoda M and Yoshino K 1995 Japan. J. Appl. Phys. 34<br />

L260–3<br />

[26] Ram M K, Carrara S, Paddeu S, Maccioni E and Nicolini C<br />

1997 Langmuir 13 2760<br />

[27] Yue J, Wang Z H, Cromack K R, Epstein AJand<br />

MacDiarmid A G 1991 J. Am. Chem. Soc. 113 2665<br />

[28] Ram M K, Adami M, Sartore S, Salerno M, Paddeu S and<br />

Nicolini C 1999 Synth. Met. 100 249<br />

[29] Porter T L, Thompson D and Bradley M 1996 Thin Solid<br />

Films 288 268<br />

36