Annual Report,2009 - Directorate General of Mines Safety

Annual Report,2009 - Directorate General of Mines Safety Annual Report,2009 - Directorate General of Mines Safety

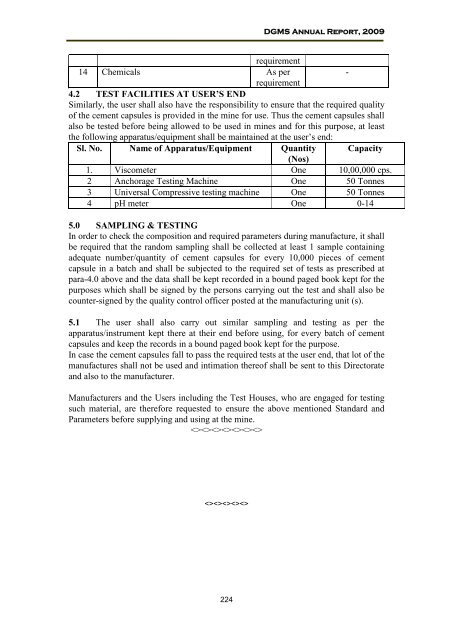

DGMS Annual Report, 2009 requirement 14 Chemicals As per requirement 4.2 TEST FACILITIES AT USER’S END Similarly, the user shall also have the responsibility to ensure that the required quality of the cement capsules is provided in the mine for use. Thus the cement capsules shall also be tested before being allowed to be used in mines and for this purpose, at least the following apparatus/equipment shall be maintained at the user‟s end: Sl. No. Name of Apparatus/Equipment Quantity (Nos) - Capacity 1. Viscometer One 10,00,000 cps. 2 Anchorage Testing Machine One 50 Tonnes 3 Universal Compressive testing machine One 50 Tonnes 4 pH meter One 0-14 5.0 SAMPLING & TESTING In order to check the composition and required parameters during manufacture, it shall be required that the random sampling shall be collected at least 1 sample containing adequate number/quantity of cement capsules for every 10,000 pieces of cement capsule in a batch and shall be subjected to the required set of tests as prescribed at para-4.0 above and the data shall be kept recorded in a bound paged book kept for the purposes which shall be signed by the persons carrying out the test and shall also be counter-signed by the quality control officer posted at the manufacturing unit (s). 5.1 The user shall also carry out similar sampling and testing as per the apparatus/instrument kept there at their end before using, for every batch of cement capsules and keep the records in a bound paged book kept for the purpose. In case the cement capsules fall to pass the required tests at the user end, that lot of the manufactures shall not be used and intimation thereof shall be sent to this Directorate and also to the manufacturer. Manufacturers and the Users including the Test Houses, who are engaged for testing such material, are therefore requested to ensure the above mentioned Standard and Parameters before supplying and using at the mine. 224

- Page 173 and 174: DGMS Annual Report, 2009 also cemen

- Page 175 and 176: DGMS Annual Report, 2009 immersion)

- Page 177 and 178: DGMS Annual Report, 2009 No. DGMS (

- Page 179 and 180: DGMS Annual Report, 2009 constituen

- Page 181 and 182: DGMS Annual Report, 2009 work perso

- Page 183 and 184: DGMS Annual Report, 2009 (i) (ii) (

- Page 185 and 186: DGMS Annual Report, 2009 4.0 The ty

- Page 187 and 188: DGMS Annual Report, 2009 DIRECTOR G

- Page 189 and 190: DGMS Annual Report, 2009 strength o

- Page 191 and 192: DGMS Annual Report, 2009 transmissi

- Page 193 and 194: DGMS Annual Report, 2009 Safety in

- Page 195 and 196: DGMS Annual Report, 2009 Flame safe

- Page 197 and 198: DGMS Annual Report, 2009 Correlatio

- Page 199 and 200: DGMS Annual Report, 2009 Photogramm

- Page 201 and 202: DGMS Annual Report, 2009 Haulage an

- Page 203 and 204: DGMS Annual Report, 2009 Rules, 195

- Page 205 and 206: DGMS Annual Report, 2009 rock mass

- Page 207 and 208: DGMS Annual Report, 2009 loaders; b

- Page 209 and 210: DGMS Annual Report, 2009 Notified a

- Page 211 and 212: DGMS Annual Report, 2009 Mine explo

- Page 213 and 214: DGMS Annual Report, 2009 Types of p

- Page 215 and 216: DGMS Annual Report, 2009 extraction

- Page 217 and 218: DGMS Annual Report, 2009 as substit

- Page 219 and 220: DGMS Annual Report, 2009 5 Anchorag

- Page 221 and 222: DGMS Annual Report, 2009 parameters

- Page 223: DGMS Annual Report, 2009 water redu

DGMS <strong>Annual</strong> <strong>Report</strong>, <strong>2009</strong><br />

requirement<br />

14 Chemicals As per<br />

requirement<br />

4.2 TEST FACILITIES AT USER’S END<br />

Similarly, the user shall also have the responsibility to ensure that the required quality<br />

<strong>of</strong> the cement capsules is provided in the mine for use. Thus the cement capsules shall<br />

also be tested before being allowed to be used in mines and for this purpose, at least<br />

the following apparatus/equipment shall be maintained at the user‟s end:<br />

Sl. No. Name <strong>of</strong> Apparatus/Equipment Quantity<br />

(Nos)<br />

-<br />

Capacity<br />

1. Viscometer One 10,00,000 cps.<br />

2 Anchorage Testing Machine One 50 Tonnes<br />

3 Universal Compressive testing machine One 50 Tonnes<br />

4 pH meter One 0-14<br />

5.0 SAMPLING & TESTING<br />

In order to check the composition and required parameters during manufacture, it shall<br />

be required that the random sampling shall be collected at least 1 sample containing<br />

adequate number/quantity <strong>of</strong> cement capsules for every 10,000 pieces <strong>of</strong> cement<br />

capsule in a batch and shall be subjected to the required set <strong>of</strong> tests as prescribed at<br />

para-4.0 above and the data shall be kept recorded in a bound paged book kept for the<br />

purposes which shall be signed by the persons carrying out the test and shall also be<br />

counter-signed by the quality control <strong>of</strong>ficer posted at the manufacturing unit (s).<br />

5.1 The user shall also carry out similar sampling and testing as per the<br />

apparatus/instrument kept there at their end before using, for every batch <strong>of</strong> cement<br />

capsules and keep the records in a bound paged book kept for the purpose.<br />

In case the cement capsules fall to pass the required tests at the user end, that lot <strong>of</strong> the<br />

manufactures shall not be used and intimation there<strong>of</strong> shall be sent to this <strong>Directorate</strong><br />

and also to the manufacturer.<br />

Manufacturers and the Users including the Test Houses, who are engaged for testing<br />

such material, are therefore requested to ensure the above mentioned Standard and<br />

Parameters before supplying and using at the mine.<br />

<br />

<br />

224