The American Society of Mechanical Engineers

The American Society of Mechanical Engineers

The American Society of Mechanical Engineers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

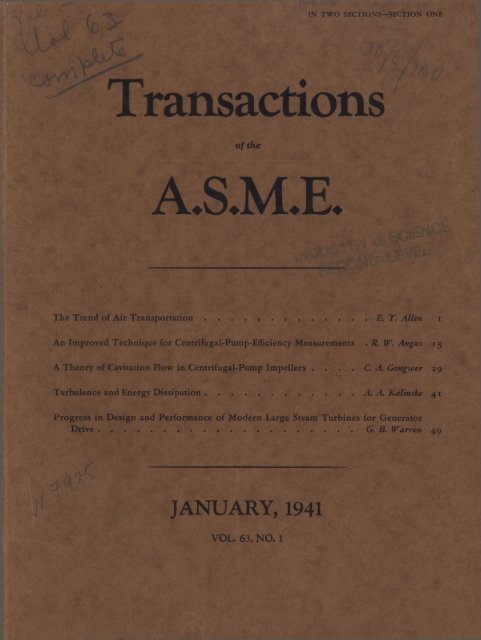

Transactions<br />

<strong>of</strong> <strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong> M echanical <strong>Engineers</strong><br />

Published on the tenth <strong>of</strong> every month, except March, June, September, and December<br />

OFFICERS OI THE SOCIBTY :<br />

W i l l i a m A. H a n l b y , President<br />

W. D. E n n i s , Treasurer C. E . D a v i e s , Secretary<br />

COMMITTBB ON PUBLICATIONS:<br />

C. B. P e c k , Chairman<br />

F. L. B r a d l e y A. R. S t e v e n s o n , Jr.<br />

C. R. SoDERBERG E. J. K a TES<br />

G e o r g e A. S t e t s o n , Editor<br />

ADVISORY MEMBERS OF THE COMMITTEE ON PUBLICATIONS:<br />

W. L. D u d l e y , S e a t t l e , W a s h . N. C. E b a d g h , G a i n e s v i l l b , F l a . O. B. S c h i b r , 2 n d , New Y o r k , N. Y .<br />

Junior Members<br />

C . C . K i r b y , N e w Y o r k , N . Y . F r a n k l i n H . F o w l e r , J r . , C a l d w e l l , N . J .<br />

P u blished m onthly by T h e A m erican <strong>Society</strong> <strong>of</strong> M echanical <strong>Engineers</strong>. Publication <strong>of</strong>fice at 20th and N ortham pton Streets, Easton, Pa. T h e editorial<br />

dep artm en t located at th e headquarters o f the <strong>Society</strong>, 29 W est T hirty-N inth Street, N ew Y ork, N . Y. Cable address, "D ynam ic,” N ew Y ork. Price $1.50<br />

a copy, $12.00 a year; to m em bers and affiliates, $1.00 a copy, $7.50 a year. C hanges o f address m ust be received at <strong>Society</strong> headquarters tw o w eeks before<br />

they are to be effective on the m ailing list. Please send o ld as w ell as new address___By-Law: T h e <strong>Society</strong> shall not be responsible for statem ents o r opinions<br />

advanced in papers o r . . . . printed in its publications (B 13, Par. 4) .... Entered as second-class m atter M arch 2, 1928, at th e Post Office at Easton, Pa.,<br />

under the Act o f A ugust 24, 1912. . . . C opyrighted, 1941, by <strong>The</strong> A m erican <strong>Society</strong> <strong>of</strong> M echanical <strong>Engineers</strong>.

IN TWO SECTIONS—SECTION TW ^<br />

Transactions<br />

<strong>of</strong> the<br />

A.S.M.E.<br />

SOCIETY RECORDS—PART 1<br />

William A. Hanley, President <strong>of</strong> <strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong><br />

<strong>Mechanical</strong> <strong>Engineers</strong>, 1940-1941<br />

Portrait and Biography<br />

Council and Committee Personnel<br />

RI-5—RI-38<br />

Officers and Council.................................. 5 Local Sections..................................... .... 15<br />

Standing Committees................................ 6 Student Branches................................. ___ 23<br />

Special Committees.................................... 7 Research Committees........................ .... 25<br />

Special Council Committees.................... 8 Standardization Committees........... .... 27<br />

A.S.M.E. Representatives on<br />

Other Activities.................................... 9<br />

Power Test Codes Committees.. . . .... 33<br />

Safety Committees............................... .... 35<br />

Pr<strong>of</strong>essional Divisions.............................. 10 Boiler Code Committees.................. .... 37<br />

W om an ’s Auxiliary to the A .S.M .E...........<br />

H onorary M em bers and P a st-P resid en ts.<br />

Index to <strong>Society</strong> Records.........................<br />

... RI-42<br />

... RI-43<br />

FEBRUARY, 1941<br />

VOL. 63, NO. 2

Transactions<br />

<strong>of</strong> <strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong> M echanical <strong>Engineers</strong><br />

Published on the tenth <strong>of</strong> every month, except March, June, September, and December<br />

OFFICERS OF THE SOCIETY:<br />

W i l l i a m A. H a n l e y , President<br />

W. D. E n n i s , Treasurer C. E. D a v i e s , Secretary<br />

C O M M IT T E E ON P U B L IC A T IO N S :<br />

C. B . P e c k , Chairman<br />

F. L. B r a d l e y . A. R. S t e v e n s o n , J r 4<br />

C. R. SoDERBERG E. J. K a TES<br />

G e o r g e A. S t e t s o n , Editor<br />

ADV ISORY M EM BERS OF THE C O M M IT T E E ON P U B L IC A T IO N S :<br />

W. L. D u d l e y , S e a t t l e , W a s h . N . C. E b a u g h , G a i n e s v i l l e , F l a . O. B. S c h i e r , 2 n d , N e w Y o r k , N. Y.<br />

Junior Members<br />

C . C . K i r b y , N e w Y o r k , N. Y . F . H. F o w l e r , J r . , C a l d w e l l , N. J.<br />

Published m onthly by T h e A m erican <strong>Society</strong> o f M echanical <strong>Engineers</strong>. P ublication <strong>of</strong>fice at 20th and N ortham pton Streets, Easton, Pa. T he editorial<br />

departm ent located at the headquarters o f the <strong>Society</strong>, 29 W est T hirty-N inth Street, N ew Y ork, N. Y. Cable address, “Dynam ic,” New Y ork. Price $ 1.50<br />

a copy, $12.00 a year; to m em bers and affiliates, $1.00 a copy, $7.50 a year. Changes o f address m ust be received at <strong>Society</strong> headquarters tw o weeks before<br />

they are to be effective on the m ailing list. Please send old as w ell as new address___ By-Law: T h e <strong>Society</strong> shall not be responsible for statem ents o r o p in <br />

io n s advanced in papers o r . . . . p rinted in its publications (B13, Par. 4 ) . . . . E ntered as second-class m atter M arch 2, 1928, at the Post Office at Easton, Pa.,<br />

u n d er the Act <strong>of</strong> August 24, 1912. . . . C opyrighted, 1941, by T h e A m erican <strong>Society</strong> o f M echanical <strong>Engineers</strong>.

Foreword<br />

THE Transactions <strong>of</strong> <strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong> <strong>Mechanical</strong> <strong>Engineers</strong> include<br />

selected technical papers and reports delivered at meetings <strong>of</strong> the <strong>Society</strong>, its<br />

Pr<strong>of</strong>essional Divisions, and its Local Sections, the Journal <strong>of</strong> Applied Mechanics<br />

(contributions <strong>of</strong> the Applied Mechanics Division), certain records <strong>of</strong> the <strong>Society</strong> <strong>of</strong><br />

permanent value, and indexes to its publications.<br />

In order to secure the advantages <strong>of</strong> timeliness and greater usefulness in issuing<br />

these <strong>Society</strong> Records, the material comprising them is divided into a number <strong>of</strong><br />

parts, each one <strong>of</strong> which is mailed as a supplement to one <strong>of</strong> the regular monthly<br />

issues <strong>of</strong> the Transactions. For 1941, the first <strong>of</strong> these, the present issue, contains<br />

the personnel <strong>of</strong> the Council and committees for the year. Another, to be issued<br />

sometime later in the year, will contain memorial notices <strong>of</strong> deceased members.<br />

<strong>The</strong> indexes to miscellaneous publications, <strong>Mechanical</strong> Engineering, and to the<br />

Transactions themselves, must, necessarily, be issued in 1942, and will probably be<br />

mailed as a supplement to the January issue <strong>of</strong> that year.<br />

In binding the 1941 Transactions, all <strong>of</strong> these parts <strong>of</strong> the <strong>Society</strong> Records will be<br />

assembled at the back <strong>of</strong> the volume as has been customary for several years. To aid<br />

in locating references in the bound volumes, the page numbers <strong>of</strong> the sections containing<br />

the Journal <strong>of</strong> Applied Mechanics and the <strong>Society</strong> Records are preceded by<br />

the letters A and RI, respectively.<br />

THE COMMITTEE ON PUBLICATIONS

W ILLIAM A. H ANLEY<br />

P r e s id e n t o f T h e A m e r ic a n S o c ie t y o f M e c h a n ic a l E n g i n e e r s<br />

1 9 4 0 - 1 9 4 1

W illiam A . H anley<br />

William Andrew Hanley, mechanical engineer and business executive, <strong>of</strong> Indianapolis,<br />

Ind., President <strong>of</strong> <strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong> <strong>Mechanical</strong> <strong>Engineers</strong> for the<br />

year 1940-1941, was born in Greencastle, Ind., in 1886. He attended St. Joseph's<br />

College, Rensselaer, Ind., for two years and then matriculated at Purdue University,<br />

where he received the degree <strong>of</strong> Bachelor <strong>of</strong> Science in mechanical engineering in 1911.<br />

Twenty-six years later, his alma mater bestowed upon him the honorary degree <strong>of</strong><br />

Doctor <strong>of</strong> Engineering.<br />

Prior to attending Purdue University, Mr. Hanley worked five years for the Republic<br />

Steel Corporation and the Broderick Boiler Company, both in Muncie, Ind.<br />

Immediately after graduation, he entered the employ <strong>of</strong> Eli Lilly and Company, <strong>of</strong><br />

Indianapolis, manufacturers <strong>of</strong> medicinal products. Today he is a director <strong>of</strong> that<br />

company and head <strong>of</strong> the engineering division. This division designs and supervises<br />

all engineering projects, construction, power, maintenance, etc., for the corporation,<br />

its branches and subsidiaries, and, in addition, operates certain highly mechanized<br />

production departments. In 1938-1939, Mr. Hanley spent much time in Basingstoke,<br />

England, building a new manufacturing plant for the British subsidiary <strong>of</strong> the Lilly<br />

company.<br />

Mr. Hanley was elected an Associate-Member <strong>of</strong> the A.S.M.E. in 1913, promoted<br />

to full membership in 1920, and made a Fellow in 1936. In 1916, he was one <strong>of</strong> the<br />

organizers and the first secretary <strong>of</strong> the Central Indiana Section. In 1919, the local<br />

members elected him chairman <strong>of</strong> the Section. <strong>The</strong> following year saw the beginning<br />

<strong>of</strong> many years <strong>of</strong> service by him in the activities and affairs <strong>of</strong> the parent body with<br />

his acceptance <strong>of</strong> an appointment as one <strong>of</strong> the A.S.M.E. representatives on the<br />

<strong>American</strong> Engineering Council. During the period from 1922 to 1927, he served on<br />

the Committee on Local Sections and, from 1933 to 1938, on the Committee on<br />

Relations With Colleges. In 1927, he was elected to a three-year term as a Manager<br />

<strong>of</strong> the <strong>Society</strong> and, in 1930, to a two-year term as Vice-President. Other A.S.M.E.<br />

activities in which he has taken a part include the Special Committee on Junior<br />

Participation, Special Committee on Relationship <strong>of</strong> <strong>Society</strong> to Accrediting Program,<br />

and Committee on Medals.<br />

Over a long period <strong>of</strong> years Mr. Hanley has contributed to the technical press a<br />

number <strong>of</strong> articles on both engineering and economic subjects. He is a past-president<br />

<strong>of</strong> the Indiana Engineering Council, an honorary member <strong>of</strong> Tau Beta Pi, a member<br />

<strong>of</strong> the Newcomen <strong>Society</strong> <strong>of</strong> England, and a fellow <strong>of</strong> the <strong>American</strong> Association for<br />

the Advancement <strong>of</strong> Science. He is also a trustee <strong>of</strong> Purdue University, <strong>of</strong> Park<br />

School <strong>of</strong> Indianapolis, <strong>of</strong> the Sigma Phi Epsilon Fraternity (national), and <strong>of</strong> the<br />

Associated Catholic Charities <strong>of</strong> Indianapolis.

<strong>The</strong> <strong>American</strong> <strong>Society</strong> <strong>of</strong> M echanical <strong>Engineers</strong><br />

HEADQUARTERS: 29 W e s t 39t h S t ., N e w Y o b k , N . Y .<br />

■MID-WEST OFEICE-. "Ro o m 1617, “205 W e s t W a c k e r Dkiye, C h ic a g o , II I.<br />

<strong>The</strong> members <strong>of</strong> the Council and <strong>of</strong> its standing and special committees given on the<br />

following pages are those in <strong>of</strong>fice on January 1, 1941, serving for the <strong>of</strong>ficial year 1940-1 9 4 1 .<br />

<strong>The</strong> terms <strong>of</strong> <strong>of</strong>fice <strong>of</strong> members <strong>of</strong> other committees are not fixed by the <strong>of</strong>ficial calendar.<br />

OFFICERS AND<br />

P R E S I D E N T<br />

W i l l ia m A . H a n l e y<br />

PAST-PRESIDENTS<br />

Terms expire December<br />

W i l l ia m L. B a t t (1941)<br />

J a m e s H . H e r r o n (1942)<br />

H a rv ey N. D a v is (1943)<br />

A l e x a n d e r G. C h r i s t i e (1944)<br />

W a r r e n H . M cB ry d e (1945)<br />

V ICE-PRESIDENTS<br />

Terms expire December, 19Jtl<br />

K e n n e t h H . C o n d it<br />

F r a n c is H o d g k in s o n<br />

J e r o m e C. H u n s a k e r<br />

K il s h a w M . I r w in<br />

Terms empire December, 1942<br />

S a m u e l B. E a r l e<br />

F r a n k H . P r o u ty<br />

E d w in B. R ic k e t t s<br />

COUNCIL<br />

MANAGERS<br />

Terms expire December, 191/1<br />

C l a r k e F r e e m a n<br />

W i l l ia m H . W i n t e k r o w d<br />

W i l l i s R. W o o l r i c h<br />

Terms expire December, 19tt2<br />

J o s e p h W . E s h e l m a n<br />

L i n n H e l a n d e r<br />

G u y T . S h o e m a k e r<br />

Terms expire December, 19JtS<br />

TREASURER<br />

W . D . E n n i s<br />

H u b e r 0 . C r<strong>of</strong>t<br />

P a u l B . E a t o n<br />

G eorge E . H u l s e<br />

SECRETARY<br />

C. E. D a v ie s<br />

Finance, J . L. K o pf<br />

Meetings and Program, W . J . W o h l e n b e r g<br />

Publications, C. B . P e c k<br />

Admissions, H. E . MouS<br />

Pr<strong>of</strong>essional Divisions, V ic t o r W i c h u m<br />

Local Sections, H. L. E g g lesto n<br />

Constitution and By-Laws, S. R . B e it l e r<br />

Honors and Awards, J . W . R oe<br />

CHAIRM EN OF STANDING COMMITTEES<br />

Representatives on Council w ithout vote<br />

Relations with Colleges, E. W . O ’B r ie n<br />

Education and Training for the Industries,<br />

A . R. S t e v e n s o n , J r .<br />

Library, J o h n B l iz a r d<br />

Research, E. G. B a il e y<br />

Standardization, A . L. B a k e r<br />

Power Test Codes, F r a n c is H o d g k in s o n<br />

S a f e t y , T. F . H a t c h<br />

Pr<strong>of</strong>essional Conduct, E . H. T e n n e y<br />

EXECUTIVE COMMITTEE OF THE COUNCIL<br />

W il l ia m A . H a n l e y , Chairman<br />

K e n n e t h H . C o n d it , Vice-Chairman<br />

C l a r k e F r e e m a n<br />

K il s h a w M. I r w in<br />

W i l l ia m H . W in t e r r o w d<br />

Advisory Members: Chairmen <strong>of</strong> the<br />

Finance, Local Sections, and Pr<strong>of</strong>essional<br />

Divisions Committees<br />

SECRETARIAL STAFF<br />

E r n e s t H artford, Assistant Secretary (Sections, Divisions, Student Branches, Membership,<br />

Meetings, etc.)<br />

C. B. L eP age, Assistant Secretary (Technical Committees)<br />

G eorge A. S t e t s o n , Editor<br />

F r e d e r ic k L a s k , Advertising Manager<br />

D. C. A. B o s w o r t h , Comptroller<br />

RI-5

RI-6 A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

STANDING COMMITTEES<br />

FINANCE<br />

J. L. K o p f, Chairman* (1941)<br />

K. W. J a p p e , Vice-Chairman (1942)<br />

G. L. K n ig h t (1943)<br />

W. I. S l i c h t e b (1944)<br />

J. J . S w a n (1945)<br />

Council Representatives<br />

E . B . R ic k e t t s (1941)<br />

G. E . I I u l s e (1942)<br />

A. M . M il l e r (1941)<br />

Junior Adviser<br />

M EETINGS AND PROGRAM<br />

W. J. W o h l en b eim j, Chairman* (1941)<br />

A. L. K im b a l l (1942)<br />

N. E. F u n k (1943)<br />

L . K . S il l c o x (1944)<br />

F. G. S w it z e r (1945)<br />

Junior Advisers<br />

F. M. G ib s o n , J r. (1941;<br />

R. F. W a r n e r, J r. (1942)<br />

PUBLICATIONS<br />

C. B . P e o k , Chairman* (1941)<br />

F. L. B r a d ley (1942)<br />

C. R . SoDERBERG (1943)<br />

A. R. S t e v e n s o n , J r. (1944)<br />

E . J . K a t e s (1945)<br />

W. L. D u d l ey<br />

N. C. E b a u g h<br />

0. B. S c h ie r , II<br />

Advisory Members (1941)<br />

Junior Advisers<br />

C. C. K ir b y (1941)<br />

F. H. F o w l e r, J r . (1942)<br />

(Personnel <strong>of</strong> Special Committee, p . R I-7 )<br />

ADMISSIONS<br />

H. E. Moli! Chairman* (1941)<br />

T. M. K n o o p (1942)<br />

S. H. L ib b y (1943)<br />

L. R. F ord (1944)<br />

J . P. J a c k s o n (1945)<br />

Advisory Member<br />

R. L. S a c k e t t (1941)<br />

(Personnel <strong>of</strong> Advisory Committee, p. RI-8)<br />

PROFESSIONAL DIVISIONS<br />

V ic t o r W i c h u m , Chairman* (1941)<br />

G. B. K a r e l it z (1942)<br />

W . A. C arter (1943)<br />

L. H. F ry (1944)<br />

J. H. S e n g s t a k e n (1945)<br />

Junior Advisers<br />

A. E. B l ir e r (1941)<br />

H. B. F e r n a l d, Jr. (1942)<br />

(Personnel <strong>of</strong> Pr<strong>of</strong>essional Divisions’ Executive<br />

Committees, p. RI-10)<br />

* Representative on the Council.<br />

LOCAL SECTIONS<br />

H. L. E g g l e s t o n, Chairman* (1941)<br />

J. N. L a n d is (1942)<br />

F. L . W i l k i n s o n , Jb. (1943)<br />

F. W . M a r q u is (1944)<br />

J. A. K e e t h (1945)<br />

Junior Advisers<br />

S id n e y D a v id s o n (1941)<br />

C. C. K ie b y (1942)<br />

(Personnel <strong>of</strong> Local Sections’ Executive<br />

Committees, p. RI-15)<br />

CONSTITUTION AND BY-LAWS<br />

S. R. B e it l e r , Chairman* (1941)<br />

A. T. D u p o n t (1942)<br />

L. H. K e n n e y (1943)<br />

F. B. O rr (1944)<br />

R. L. P a r s e l l (1945)<br />

Junior Adviser<br />

H. M. B l a c k (1941)<br />

HONORS AND AWARDS<br />

J . W. R oe, Chairman* (1941)<br />

R oy V. W r ig h t (1942)<br />

D. C. J a c k s o n (1943)<br />

C. L. B a u s c h (1944)<br />

L. W . W a l l a c e (1945)<br />

(Personnel <strong>of</strong> Special Committee, p. RI-7)<br />

RELATIONS W ITH COLLEGES<br />

E. W. O ’B r i e n , Chairman* (1941)<br />

A. C. C h i o k (1942)<br />

J. 1. Y e l l o t t (1943)<br />

H . E. D e g ler (1944)<br />

G. L. S u l l iv a n (1945)<br />

J. W. H a n e y<br />

B. T. M cM i n n<br />

R. H . P orter<br />

J. L. H a l l<br />

Advisory Members (1941)<br />

Junior Adviser (1941)<br />

(Student Branches and Officers, p. RI-23)<br />

EDUCATION AND TRAINING FOR<br />

THE INDUSTRIES<br />

A . R. S t e v e n s o n , J r ., Chairman* (1942)<br />

A . B . W i l l i (1941)<br />

M. R. B o w e r m a n (1943)<br />

A. C. H a r p e r (1944)<br />

R. L . G o e tzen b er g er (1945)<br />

Advisory Members (1941)<br />

V . C. A r m s p ig e r<br />

R. B u r d e t t e D ale<br />

A . B . G a t e s<br />

H. A . W r ig h t<br />

PROFESSIONAL CONDUCT<br />

E. H. T e n n e y , Chairman* (1941)<br />

W . H. K e n e r s o n (1942)<br />

C. E. W addell (1943)<br />

V. E. A l d e n (1944)<br />

G. S. A r m s t r o n g (1945)<br />

RESEARCH t<br />

E . G. B a il e y , Chairman* (1941)<br />

W . T h i n k s (1942)<br />

M. D . H e r s e y (1943)<br />

J . H . W a l k e r (1944)<br />

W . R. E l s e y (1945)<br />

STANDARDIZATION f<br />

A. L . B a k e r , Chairman* (1941)<br />

J . E. L ovely (1942)<br />

L . T. K n o c k e (1943)<br />

T. E. F r e n c h (1944)<br />

W . H . H il l (1945)<br />

POW ER TEST CODES f<br />

F r a n c is H o d g k in s o n , Chairman* (1944)<br />

A. G. C h r i s t i e , Vice-Chairman (1941)<br />

W . W . L a w r e n c e , Junior Observer (1941)<br />

H . H . M ic h e l s e n , Junior Observer (1942)<br />

A. G . C h r i s t i e<br />

P a u l D is e r e n s<br />

G e o. A. O rrok<br />

L . A. Q u a y l e<br />

W . M . W h i t e<br />

W . A. C arter<br />

H arte C o oke<br />

E . R . F i s h<br />

H . B. O a t l e y<br />

W . J . W o h l e n b e r g<br />

L o u i s E l l io t t<br />

G. A. H o r n e<br />

H . B . R ey n o ld s<br />

P . W . S w a in<br />

E . N . T r u m p<br />

Term expires 1941<br />

Term expires 1942<br />

Term expires 1948<br />

Term expires 194k<br />

C. H . B erry<br />

F r a n c is H o d g k in s o n<br />

I). S. J aco bu s<br />

L . F . M oody<br />

E . B. R ic k e t t s<br />

Term expires 1945<br />

T h eo dore B a u m e is t e r , J r .<br />

P . H . H a rd ie<br />

B. V . E. N ordberg<br />

R . J . S. P ig o tt<br />

M . C. S t u a r t<br />

SAFETY t<br />

T. F. H a t c h , Chairman* (1941)<br />

A. W . L u c e (1942)<br />

A. E. W in d l e (1943)<br />

H . C. H o u g h t o n (1944)<br />

E. R . G r a n n is s (1945)<br />

LIBRARY<br />

J o h n B l iz a r d , Chairman* (1941)<br />

E. F . C h u r c h , J r . (1943)<br />

A . R. M u m fo r d (1944)<br />

<strong>The</strong> Secretary, C. E . D a v ie s, Ex-Officio<br />

t Personnel <strong>of</strong> all Technical Committees,<br />

pp. RI-25-38.

A.S.M.E. SOCIETY RECO RD S, PA R T 1<br />

RI-7<br />

BIOGRAPHY ADVISORY<br />

(Spccial Committee <strong>of</strong> Publications<br />

Committee)<br />

R oy V . W r ig h t , Chairman<br />

L . P . A lford<br />

R . E . F l a n d er s<br />

G eo. A . O rrok<br />

J . W . R oe<br />

W . H . W in t e r r o w d<br />

BOILER CODE<br />

D. S. J a co bu s, Chairman<br />

E . R . F i s h , Vice-Chairman<br />

C. W . O b e r t, Honorary Secretary<br />

M . J u r is t , Acting Secretary<br />

C. A . A d a m s<br />

H . E . A l d r ic h<br />

H . C. B o a r d m a n<br />

P e rry C a ssid y<br />

R . E . C e c il<br />

F . S. C l a r k<br />

A . J . E ly<br />

V . M . F rost<br />

C. E . G orton<br />

A . M . G r e e n e , J r.<br />

W . ;G. H u m p t o n<br />

J. O. L e e c h<br />

I . E . M oultr o p<br />

C. O. M y ers<br />

H. B. O a t le y<br />

J a m e s P a r t in g t o n<br />

W a l t e r S a m a n s<br />

S. K . V a r n e s<br />

A . C. W e ig e l<br />

W. II. B o e h m<br />

W. F. D u ra nd<br />

T. E . D u r b a n<br />

C. L. H u s t o n<br />

W . F. K ie s b l . J r.<br />

M . F . M oore<br />

H. H. V a u g h a n<br />

II. L e R oy W h i t n e y<br />

Honorary Members<br />

(Personnel <strong>of</strong> Boiler Code Committees, pp.<br />

RI-37-38)<br />

MEDALS<br />

(Special Committee <strong>of</strong> Board <strong>of</strong> Honors<br />

and Atcards)<br />

J . W . R oe, Chairman<br />

H . A. E v erett<br />

H . A. S. I I o w a r t h<br />

G eo. A. O rrok<br />

A l e x a n d e r K l e m in<br />

E. W . O ’B r ie n<br />

E. S. P earce<br />

R oy V . W r ig h t<br />

Term expires 1941<br />

Term expires 1942<br />

C. M. A l l e n<br />

R . L. D a u g h e r t y<br />

D. C. J a c k so n<br />

R. C. M a r s h a l l , J r .<br />

C. L . B a u s c ii<br />

F r a n c is H o d g k in s o n<br />

L . C. M orrow<br />

J . M . T odd<br />

Term expires 1943<br />

Term expires 1944<br />

SPECIAL COMMITTEES<br />

A. D. B a il e y<br />

J . W . B a r k e r<br />

C l a r k e F r e e m a n<br />

L. W . W a l la c e<br />

MEDALS<br />

(Continued)<br />

Term expires 1045<br />

REGULAR NOMINATING COMMITTEE<br />

FOR 1941<br />

I<br />

II<br />

I I I<br />

IV<br />

V<br />

A. L . K im b a l l , Chairman<br />

N . C. E b a u g h , Secretary<br />

W . F. T h o m p s o n , New Haven, Conn.<br />

E. S. D e n n is o n , Groton, Conn., 1st<br />

Alternate<br />

R. A . N o r t h , Ansonia, Conn., 2nd<br />

Alternate<br />

E. J . B i l l in g s , New York, N.Y.<br />

W . McC. M cK e e, New York, N.Y.,<br />

Alternate<br />

A. L. K im b a l l , Schenectady, N.Y.,<br />

Ch airman<br />

C. M . M e r r ic k , Easton, Pa., 1st Al-<br />

S. T . H a r t, Syracuse, N.Y., 2nd A l<br />

ternate<br />

N. C. E b a u g h , Gainesville, Fla., Secretary<br />

C. E. K e r c h n e r , Greensboro, N.C.,<br />

1st Alternate<br />

II. S. K e n t , Homewood, Md., 2nd<br />

Alternate<br />

H. B. J oyce, Erie, Pa.<br />

C. J . F r e u n d , D etroit, Mich., A lternate<br />

V I Pi. E. T u r n e r , Chicago, 111.<br />

C. C. W il c o x , Notre Dame, Ind., 1st<br />

Alternate<br />

C. A. J a c o b so n, Beloit, W is ., 2nd<br />

Alternate<br />

V II E a r l M e n d e n h a l l , L o s Angeles,<br />

Calif.<br />

H. L . D o o l it t l e, L os A n g e le s , C a lif.,<br />

1st Alternate<br />

W . H. C l a p p , Pasadena, Calif., 2nd<br />

Alternate<br />

V III L . J . L a s s a l l e , University, L a .<br />

W . H . C a r s o n , Norman, Okla., 1st<br />

Alternate<br />

A. L. H il l , Denver, C olo., 2nd A l<br />

ternate<br />

LOCAL SECTIONS IN NOMINATING<br />

COMMITTEE GROUPS<br />

GROUP I<br />

B o sto n<br />

B r idgeport<br />

G r e e n M o u n t a in<br />

H artford<br />

N e w H a v e n<br />

N o r w ic h<br />

P ro v id e n c e<br />

W a t e r b u r y<br />

W e s t e r n M a s s a c h u s e t t s<br />

W orcester<br />

NOMINATING COMMITTEE GROUPS<br />

(Continued)<br />

GROUP II<br />

M e t r o po l it a n (N .Y .) a n d M e m b e r s<br />

O u t s id e t h e U n it e d S t a t e s<br />

( E x c e p t O n t a r io S e c t io n M e m b e r s )<br />

GROUP III<br />

A n t h r a c it e -L e h ig h V a l le y<br />

B u f f a l o<br />

C e n t r a l P e n n s y l v a n ia<br />

P h il a d e l p h ia<br />

P l a in f ie l d<br />

R o c h e s t e r<br />

S y r a c u s e<br />

S u s q u e h a n n a<br />

W a s h in g t o n<br />

I t h a c a<br />

B a l t im o r e<br />

S c h e n e c t a d y<br />

gro u p iv<br />

A t l a n t a<br />

P ie d m o n t -N o r t h C a r o l in a<br />

E a s t T e n n e s s e e<br />

B i r m i n g h a m<br />

F lo rid a<br />

G r e e n v il l e<br />

M e m p h i s<br />

R a l e ig h<br />

S a v a n n a h<br />

V i r g in ia<br />

A k r o n -C a n t o n<br />

C i n c i n n a t i<br />

C l ev e la n d<br />

C o l u m b u s<br />

D a y t o n<br />

D e t r o it<br />

E r ie<br />

O n t a r io<br />

P it t s b u r g h<br />

P e n in s u l a<br />

T oledo<br />

W e s t V i r g in ia<br />

Y o u n g s t o w n<br />

C e n t r a l I l l in o is<br />

C e n t r a l I n d ia n a<br />

C h ic a g o<br />

F ort W a y n e<br />

L o u is v il l e<br />

M il w a u k e e<br />

N e b r a s k a<br />

M in n e s o t a<br />

R o c k R iv e r V a l l e y<br />

S t . J o s e p h V a l l e y<br />

S t . L o u is<br />

T r j-C i t i e s<br />

gro u p v<br />

g ro u p VI<br />

g r o u p v ii<br />

I n l a n d E m p ir e<br />

Los A n q e l e s<br />

O regon<br />

S a n F r a n c isc o<br />

U t a h<br />

W e s t e r n W a s h in g t o n<br />

C olorado<br />

K a n s a s C it y<br />

M id -C o n t in e n t<br />

N e w O r l e a n s<br />

N o r t h T e x a s<br />

S otrTH T e x a s<br />

GROUP VIII

RI-8 A.S.M.E. SO CIETY R EC O RD S, PA R T 1<br />

ADVISORY COMMITTEE TO COM<br />

M ITTEE ON ADMISSIONS<br />

H . A . L a r d n e r, Chairman<br />

R . E . F l a n d e r s<br />

E. C. H u t c h in s o n<br />

A lfred I ddles<br />

J. II. L a w r e n c e<br />

R oy Y . W r ig h t<br />

BOARD OF REV IEW<br />

G. L. K n i g h t , Chairman (1941)<br />

W . A. S h o u d y (1942)<br />

P . W . S w a in (1943)<br />

BOARD ON TECHNOLOGY<br />

K . II. C o n d it , Chairman<br />

R. F . G agu<br />

J. C. litlNSAKER<br />

W . J. W o h l e n b e r g (Meetings and Program)<br />

V ic t o r W i c h u m (Pr<strong>of</strong>essional Divisions)<br />

F . L . B radley (P u b lic a tio n s )<br />

E. G. B a il e y (Research)<br />

CONSULTING PRACTICE<br />

S. L ogan K er r, Chairman<br />

P . L . B a t te y<br />

M . X. W il b e k d in g<br />

H. V. Coep<br />

P . T . N o r t o n, J r.<br />

DEPRECIATION<br />

DUES-EXEMPT MEMBERS’<br />

CONTRIBUTIONS<br />

H a r t e C o o k e , Chairman<br />

G. W. F a r n y<br />

F. D. H e r b e r t<br />

S. H . L ib b y<br />

J. W . R o e<br />

W . R . W ebster<br />

W. D. E n n i s , Treasurer<br />

ECONOMIC STATUS OF THE<br />

ENGINEER<br />

C. J. F r e u n d , Chairman<br />

D. S. K i m b a l l<br />

C. N. L a u e e<br />

H. B. O a t l e y<br />

H. L. W h i t t e m o r e<br />

W. E. W i c k e n d e n<br />

SPECIAL COUNCIL COMMITTEES<br />

(Dates in parentheses denote expiration <strong>of</strong> terms)<br />

ECONOMIC STATUS OF THE<br />

ENGIN EER<br />

(Continued)<br />

W . F . C a r h a r t<br />

W. S. M a g a l h a e s<br />

W . B . O a k l e y , J r.<br />

Junior Representatives<br />

Chairmen <strong>of</strong> Committees on Local Sections<br />

and Relations W ith Colleges, Ex-Officio<br />

EN G IN EERS’ CIVIC RESPO N SI<br />

B IL IT IE S<br />

A. R . C u l l im o r e , Chairman<br />

L i l l ia n M . G il b r e t ii<br />

W a l t e r K idde<br />

H . B. O a t l e y<br />

J . W . R oe<br />

W . H . W in t e r r o w d<br />

R o y V. W r ig h t<br />

D. R obert Y a r n a l l<br />

Chairmen <strong>of</strong> Committees on Local Sections<br />

and Relations W ith Colleges, Ex-Officio<br />

FREEM AN FUND<br />

C l a r k e F r e e m a n , Chairman<br />

E. C. H u t c h in s o n<br />

G e o. A. O rrok<br />

LEA D ER SH IP IN PROFESSIONAL<br />

DIVISIONS<br />

A lfr ed I d d l es. Chairman<br />

K . H . C o n d it<br />

L i n n H e l a n d e r<br />

F r a n c is H o d g k in s o n<br />

W . R. W o o l r ic h<br />

NATIONAL D EFENSE<br />

J . L . W a l s h , Chairman<br />

C. E . D a v ie s, Secretary<br />

W . L . B att<br />

G a n o D u n n<br />

E. A. M u l l e r<br />

Advisory Members<br />

Arm y and Navy Members<br />

A . B . A n d e r s o n (Navy)<br />

H . K . R u t h e r f o r d (Army)<br />

C. E . B r in l e y<br />

H. V. C oes<br />

K . II. C o n d it<br />

J . D . C u n n in g h a m<br />

H. N. D avis<br />

W . C. D ic k e r m a n<br />

W . F . D u r a n d<br />

R . E. F la n d er s<br />

K . T. K e l l e r<br />

D avid L a r k in<br />

F . T L e t c h f ie l d<br />

T. A. M organ<br />

R . C. M u ir<br />

T 15. M u r r a y<br />

W . I. W e st er v elt<br />

A. C. W illa r d<br />

NATIONAL DEFENSE<br />

(Continued)<br />

General Committee<br />

REGISTRATION<br />

V. M . P a l m e r , Chairman<br />

S. H. G ra f<br />

J. A. M cP h e r s o n<br />

F . H. P ro u ty<br />

W . K . S im p s o n<br />

SOCIETY OFFICE OPERATION<br />

A lfr ed I d d les, Chairman<br />

W a l la c e C l a r k<br />

W . H. W in t e r r o w d<br />

FR ED ERICK W. TAYLOR MEMORIAL<br />

L. P. A lford<br />

M. L. C ooke<br />

H . N. D a v is<br />

R. T. K e n t<br />

GEORGE W ESTINGHOUSE BUST<br />

D . S. K im b a l l , Chairman<br />

C. E. D a v ie s, Secretary<br />

K . T. C o m p t o n<br />

S. W . D u d l e y<br />

C. N. L a u e e<br />

W. G. M a r s h a l l<br />

J. H. M cG r a w<br />

L . A . O sborne<br />

C. F . S cott<br />

J. B. W r ig h t<br />

R oy V. W r ig h t

A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

RI-9<br />

A.S.M.E. REPRESENTATIVES ON OTHER ACTIVITIES<br />

See also A.S.M.E. Representatives on Other Research Committees, etc., pages RI-26, SI, SJi, 35, 38<br />

(Dates in parentheses denote expiration <strong>of</strong> terms)<br />

AMERICAN ASSOCIATION FOR THE<br />

ADVANCEMENT OF SCIENCE<br />

R. F. G agg<br />

R. L. S a c k e t t<br />

SECTION M , ENGINEERING<br />

AMERICAN STANDARDS<br />

ASSOCIATION<br />

A. L. B a k e r (1942)<br />

A lfred I ddles (1943)<br />

Alternates<br />

C. B . L f.P age (1941)<br />

W. C. M u e l l e r (1941)<br />

C. E. D a v ie s<br />

AMERICAN YEAR BOOK<br />

CORPORATION<br />

J . B . C h a l m e r s<br />

CENTER FOR SAFETY<br />

EDUCATION<br />

COAL TESTING CODE<br />

JO IN T COMMITTEE W IT H THE A .I.M .E .<br />

R . L . R o w a n , Chairman<br />

J . F . B a r k l e y<br />

R . A. F o r e s m a n<br />

R . M . H ardgrove<br />

T. A. M a r s h<br />

A . R . M u m fo r d *<br />

P ercy N ic h o l l s<br />

R. A. S h e r m a n<br />

L . A. S h i p m a n<br />

A. W . T h o r so n<br />

W a l ter K idde<br />

THOMAS ALVA EDISON<br />

FOUNDATION<br />

THE ENGINEERING FOUNDATION<br />

K. H. C o n d it (1943)<br />

A. A. P o tter (1943)<br />

W. II. F u l w e il e r (1944)<br />

r e s e a r c h pro c ed u r e c o m m it t e e<br />

W. H. F u l w e il e r (1941)<br />

G eo. A . O r r ok<br />

J . W . R oe<br />

ENGINEERING HISTORY<br />

ENGINEERING SOCIETIES LIBRARY<br />

BOARD<br />

J o h n B liz a r d<br />

E . F . C h u r c h<br />

A . R . M u m fo r d<br />

Secretary, A.S.M.E., Ex-Officio<br />

e n g in e e r in g s o c ie t ie s m o n o g r a p h s<br />

E. J . K a tes<br />

G. B . K a r e l it z<br />

c o m m it t e e<br />

* Also represents Power Test Codes Committee.<br />

ENGIN EERIN G SOCIETIES PERSON<br />

N EL SERVICE, INC.,<br />

E r n e s t H artford, N ational Board<br />

R. D. B r iz z o l a r a , Chicago Board<br />

C. J. F r e u n d , D etroit Board<br />

E r n e s t H artford, Chairman, M etropolitan<br />

Board<br />

S. R. Dows, San Francisco Board<br />

EN G IN EERS’ COUNCIL FOR PR O FES<br />

SIONAL DEVELOPMENT<br />

H . T. W oolson (1941)<br />

R. L. S a c k e t t (1942)<br />

A. R. S t e v e n s o n , J r . (1943)<br />

EN G IN EERS’ NATIONAL R E L IE F<br />

FUND<br />

E r n e s t H artford<br />

JO H N FR ITZ MEDAL BOARD OF<br />

AWARD<br />

J. H. H e r r o n (1941)<br />

H. N. D a v is (1942)<br />

A. G. C h r i s t i e (1943)<br />

W. H. M cB ryd e (1944)<br />

FU EL VALUES<br />

JO IN T COMMITTEE W IT H TH E A .I.M .E .<br />

A. D. B a il e y<br />

E. H . B a r r y<br />

F. M . G ib s o n<br />

H . D r a k e H a r k in s<br />

J . C. H obbs<br />

A. L. P e n n i m a n , J r .<br />

E. B . R ic k e t t s<br />

E. H . T e n n e y<br />

GANTT MEDAL BOARD OF AWARD<br />

L . C. M o rrow (1941)<br />

L i l l ia n M . G il b r e t h (1942)<br />

L . P. A lford (1943)<br />

D ANIEL GUGGENHEIM MEDAL<br />

FUND, INC.<br />

E. A. S p e r r y, J r . (1941)<br />

A l e x . K l e m in (1942)<br />

R. F. G agg (1943)<br />

JO SEPH A. HOLMES SAFETY<br />

ASSOCIATION<br />

J. F. B a r k l e y<br />

HOOVER MEDAL BOARD OF AWARD<br />

W. H. K e n e r s o n (1941)<br />

S. F. V o o r h e e s (1943)<br />

W. L. B a t t (1945)<br />

INTERNATIONAL ELECTROTECH<br />

NICAL COMMISSION<br />

U.S. NATIONAL COMMITTEE<br />

H . N. D a v is<br />

P a u l D is e r e n s<br />

F r a n c is H o d g k in s o n<br />

C. H arold B erry<br />

G e o. A. O rr ok<br />

Aternate<br />

MARSTON AWARD<br />

NATIONAL BUREAU OF EN G IN EER <br />

ING REGISTRATION<br />

V. M. P a l m e r<br />

NATIONAL CONFERENCE ON ENGI<br />

N EERIN G POSITIONS<br />

W. F. C a r h a r t<br />

W. L. ClSLER<br />

H. B. O a t l e y<br />

R. L. S a c k e t t<br />

NATIONAL F IR E WASTE COUNCIL<br />

J. A. N eale<br />

NATIONAL MANAGEMENT COUNCIL<br />

L . C. M orrow (1942)—J. R. B a n g s, A lternate<br />

L . P. A lford (1943)—C. W. L y t l e , A lternate<br />

J. M. T a lbot (1944)— H. B . B e r g e n , A l<br />

ternate<br />

NATIONAL RESEARCH COUNCIL<br />

DIVISION OF ENGINEERING AND INDUSTRIAL<br />

RESEARCH<br />

W . L. B a t t (1942)<br />

ALFRED NOBLE PR IZE<br />

A. M. G r e e n e , J r .<br />

UNITED EN G IN EERIN G TRUSTEES,<br />

INC.<br />

H. A. L a r d n e r (1942)<br />

W a l t e r K id d e (1943)<br />

K . H. C o n d it (1944)<br />

VERM ILYE MEDAL ADVISORY<br />

COMMITTEE<br />

R. A. W e n t w o b t h<br />

W ASHINGTON AWARD COMMISSION<br />

W. L. A bb o tt (1 9 4 1 )<br />

C. B . N o l te (1 9 4 2 )

RI-10 A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

PROFESSIONAL DIVISIONS<br />

A r t ic l e B6A, P a r. 16: <strong>The</strong> Standing; Committee on Pr<strong>of</strong>essional Divisions shall, under the<br />

direction <strong>of</strong> the Council, have supervision <strong>of</strong> the Pr<strong>of</strong>essional Divisions <strong>of</strong> the <strong>Society</strong>.<br />

STANDING- COMMITTEE<br />

V ic t o r W i c i i u m , Chairman (1941)<br />

G. E. K a r e l it z (1942)<br />

W . A. C a rter (1943)<br />

L. H . F ry (1944)<br />

J . H . S e n g s t a k e n (1945)<br />

Junior Advisers<br />

A. E. B l ir e r (1941)<br />

H. B. F e r n a l d , J r . (1942)<br />

Aeronautic<br />

Organized, 1920<br />

C. H . D o l a n , I I . Chairman<br />

EXECUTIVE COMMITTEE<br />

C. H. D o l a n , II, Chairman<br />

J. M. C l a r k , Secretary<br />

E. E. A l d r in<br />

R. F. G agg<br />

J. E. Y o u n g e r<br />

F . II. F o w l e r , J r.<br />

H e rbert K u n e in<br />

Junior Advisers<br />

ADVISORY COMMITTEE<br />

K a r l A r n s t e in<br />

C a r l B reer<br />

E. C. C l a r k e<br />

H . M . C r a n e<br />

L o u is D e F lorez<br />

W . F . D u r a n d<br />

A . J . G iffo r d<br />

M . B . G ordon<br />

W i l l ia m H ovgaard<br />

J . C. H u n s a k e r<br />

P. G . J o h n s o n<br />

C. F . K e t t e r in g<br />

A l e x . K l e m in<br />

R. K . L e B lond<br />

W . B . M ayo<br />

P. B. M organ<br />

T. A . M organ<br />

S. A . M o ss<br />

E . A . S per r y<br />

A. R. S t e v e n s o n , Jr.<br />

J. G. V in c e n t<br />

T h e o . von K a r m a n<br />

C. J. W ard<br />

E. P. W a r n er<br />

B. M. W oods<br />

O r v il le W r ig iit<br />

Ammunition<br />

(Pr<strong>of</strong>essional Group)<br />

Organized, 191/0<br />

Committee to be appointed<br />

Applied Mechanics<br />

Organized, 1927<br />

J . P . D e n H artog, Chairman,<br />

EXECUTIV E COMMITTEE<br />

J . P . D e n H artog, Chairman<br />

H . L . D r y d e n , Secretary<br />

J . H . K e e n a n<br />

J e s s e O rm o n d r o y d<br />

B . M. W oods<br />

R u p e n E k s e r q ia n<br />

J C. H u n s a k e r<br />

A. L. K im b a l l<br />

F. M. L e w is<br />

G. B . P eg ra m<br />

C. R. SODERBERG<br />

E. 0. W a ter s<br />

H . M. W estergaard<br />

Associates<br />

Representative on Aviation Liaison Group<br />

J . C. H u n s a k e r<br />

J e s s e O r m o n d r o y d<br />

Research Secretary<br />

JOURNAL OF A PPLIED MECHANICS<br />

J. M. L e s s e l l s, Editor<br />

SPONSORS<br />

Dynamics, E. L. T h e a r l e<br />

Elasticity, S t e p h e n T im o s h e n k o<br />

Fluid Mechanics, H. L. D ry d en<br />

Lubrication, G. B . K a r e l it z<br />

Plasticity, A. N a d a i<br />

Strength <strong>of</strong> Materials, R. E. P e terso n<br />

<strong>The</strong>rmodynamics, J. A. G o ff<br />

Fuels<br />

Organized, 1920<br />

W i l l ia m G. C h r is t y , Chairman<br />

EXECUTIVE COMMITTEE<br />

W il l ia m G. C h r is t y , Chairman<br />

D. C. W e e k s , Secretary<br />

0 . F . C a m p b e ll, Representative on A v i a <br />

tion Liaison Group<br />

H . F . H e b l e y<br />

A. R . M u m f o r d<br />

A. W . T iio r s o n<br />

J. F . B a r k l e y<br />

J'. S. B e n n e t t , 3 rd<br />

M . P . C l e g h o r n<br />

B . J. C ross<br />

M . D. E n g l e<br />

D. S. F r a n k<br />

E. R . K a is e r<br />

T . A. M a r s h<br />

M . A. M a y e r s<br />

R . L . R o w a n<br />

J. E. T obey<br />

D. C. W e e k s<br />

Associates<br />

COOPERATION W ITH A.I.M.E.<br />

J. E. T obey, Chairman<br />

MODEL SMOKE LAW<br />

J. F. B a r k l e y , Chairman<br />

O. F. C a m p b e l l<br />

A. G. C h r is t ie<br />

W il l ia m G. C h r is t y<br />

T. A. M a r s h<br />

T . E. P u r c e l l<br />

R. A. S h e r m a n<br />

R. R. T u c k e r<br />

PROGRAM<br />

A. W. T iio r s o n , Chairman<br />

D. S. F r a n k , Assistant Chairman<br />

E. R. K a is e r , Junior Member<br />

R EV IEW OF PAPERS<br />

W i l l ia m G. C h r is t y<br />

M. D. E n g l e<br />

A. W . T h o r so n<br />

D. C. W e e k s<br />

Graphic Arts<br />

Organized, 192:1<br />

EXECUTIVE COMMITTEE<br />

T. E. D a l t o n , Secretary<br />

A. E. G ie g e n g a c k<br />

F. W . H o o ii<br />

W . B. L a u g h t o n<br />

R. G. M a cD onald<br />

W . M . P a ssa n o<br />

B. L. S it e s<br />

B. D. S t e v e n s<br />

B. L. W e h m i io f f<br />

Heat Transfer<br />

(Pr<strong>of</strong>essional Group)<br />

Organized, 193 8<br />

E. D. G r im is o n , Chairman<br />

W. S. P a t t e r s o n , Group Secretary<br />

EXECUTIVE COMMITTEE<br />

E. D . G r i m i s o n , Chairman<br />

T. B . D r e w<br />

L. M. K. B o elter<br />

R . A. B o w m a n<br />

H . C. H o ttel<br />

C. E. L u o k e<br />

A. K . S cott<br />

J . H . S e n g s t a k e n<br />

J . L . M e n s o n<br />

R . H . W o l in<br />

Advisory Associates<br />

Junior Representatives

W. S. P a t terso n<br />

Heat Transfer<br />

(Continued)<br />

COORDINATION<br />

Liaison Officer for Local Sections<br />

A. K. S cott<br />

Representative on Aviation Liaison Group<br />

L. M. K. B o elter<br />

Representatives <strong>of</strong> Other Divisions<br />

Fuels, B . J. C ro ss<br />

Hydraulic, J. D. S cov ille<br />

Iron and Steel, W. T r in k s<br />

Oil and Gas Power, F. G. H e c h l e r<br />

Petroleum, J. D. P e terso n<br />

Power, 0. F . C a m p b e l l<br />

Process Industries, A rno ld W e is s e l b e r g<br />

Railroad, L. H. F ry<br />

T. B. D rew<br />

L. 51. K. B oelter<br />

R. II. H e il m a n<br />

G. L. T uve<br />

Research Secretary<br />

Members at Large<br />

DIRECT-FIRED FLUID HEATERS<br />

AND BOILERS<br />

E . D. G r im is o n , Chairman<br />

J o h n B liza rd<br />

D. S. F r a n k<br />

L. B . S c h u e l l e r<br />

W . J . W o iil e n b e r g<br />

INDUSTRIAL FURNACES AND KILNS<br />

W. T r i n k s , Chairman<br />

H . C. H ottel<br />

W. A. T ic k n o r<br />

PAPERS<br />

W . L . D e B a u f r e, Chairman<br />

R. A. B o w m a n<br />

C. F . K a y a n<br />

A. K . S cott<br />

R. A. S h e r m a n<br />

TESTING TECHNIQUE<br />

H . C. H o t t e l, Chairman<br />

B . J . C ross<br />

R . H . J a c k s o n<br />

J . H . R u s iit o n<br />

A. K . S cott<br />

THEORY AND FUNDAMENTAL<br />

RESEARCH<br />

L. M . K . B o elter, Chairman<br />

A. P . C o l b u r n<br />

T. B . D r e w<br />

M a x J akob<br />

D . D . S treid<br />

A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

THERMO-PHYSICAL PR O PER TIES<br />

OF MATERIALS<br />

R. H . N o r r is, Chairman<br />

O. K e n n e t h B a t e s<br />

T. H . C h il t o n<br />

R. C. H. H e c k<br />

M a x J a k o b<br />

R. J . S. P ig o tt<br />

J . F. D o w n ie S m i t h<br />

S u b c o m m it t e e o n S p e c if ic H e a t <strong>of</strong> G a s e s<br />

M a x J a k o b , Chairman<br />

W. L. D e B a u f r e<br />

J. A. G o f f<br />

A. C. G u l l ik s o n<br />

R. C. H . H e c k<br />

R. J . S. P ig o tt<br />

R. L. S w e ig e r t<br />

UNFIRED HEAT TRANSFER<br />

EQUIPM ENT<br />

R. A. B o w m a n , Chairman<br />

W. E. B e l in e<br />

A. C. M u e l l e r<br />

B . E. S h o r t<br />

T o w n s e n d T i n k e r<br />

Hydraulic<br />

Organized, 1926<br />

E. B. S t r o w g e r, Chairman<br />

EXECUTIVE COMMITTEE<br />

E. B . S tro w g e r, Chairman<br />

L . J . H ooper, Secretary<br />

M. P . O ’B r ie n<br />

J. D . S co v ille<br />

F. G. S w it z e r<br />

R . V . T erry<br />

CAVITATION<br />

“E. B . S t r o w g e r, Sponsor<br />

L . F. M oody, Chairman<br />

R . T. K n a p p<br />

J. M . M o u s s o n<br />

W . J . R h e in g a n s<br />

G. F. W is l ic e n u s<br />

Representatives <strong>of</strong> Other Societies<br />

<strong>American</strong> <strong>Society</strong> for Testing M aterials,<br />

F. N. S p e l l e r<br />

Engineering Institute <strong>of</strong> Canada, E r n e s t<br />

B r o w n<br />

Institution <strong>of</strong> <strong>Mechanical</strong> <strong>Engineers</strong>, G. S.<br />

B a k e r<br />

A . T e n o t<br />

Representative <strong>of</strong> France<br />

HYDRAULIC PR IM E MOVERS<br />

R . V . T e r r y , Sponsor<br />

J . F. R o berts, Chairman<br />

A . A b e r l i<br />

E. H . C o l l in s<br />

J . P. G r o w d en<br />

L. F. H a rz a<br />

P. L. H e sl o p<br />

G eorge J e s s u p<br />

F. S . R ogers<br />

F. S c h m id t<br />

S. 0 . S c h o m b e r g e b<br />

S. H . V a n P a t teb<br />

PU M PIN G MACHINERY<br />

F. G. S w it z e r , Sponsor<br />

R. L . D a u g h e r t y , Chairman<br />

W ATER HAMMER<br />

RI-11<br />

Honorary Chairman, L o ren zo A l l ie v i,<br />

Rome, Italy<br />

J . D . S co v il le, Sponsor<br />

S. L ogan K er r, Chairman<br />

N. R. G ib s o n<br />

E u g e n e H a l m o s<br />

L . F . M oody<br />

R. S. Q u i c k<br />

E . B . S tro w g er<br />

Affiliated Societies and <strong>The</strong>ir<br />

Representatives<br />

<strong>American</strong> <strong>Society</strong> <strong>of</strong> Civil <strong>Engineers</strong>, N. R.<br />

G ib s o n and F ord K u r t z<br />

<strong>American</strong> W ater W orks Association, F . M .<br />

D a w s o n and L . H . K e s s l e r<br />

Associate Members, Representing;<br />

Australia, G eorge H ig g in s<br />

B r a z il, A. W . K . B il l in g s and F. K n a p p<br />

Engineering Institute <strong>of</strong> Canada, R. W.<br />

A n g u s and F. M. W ood<br />

France, Louis B e r g ero n and C h a r l e s<br />

C a m ic h e l<br />

Germany and V erein deutscher Ingenieure,<br />

D . T h o m a<br />

G reat B ritain and Institution <strong>of</strong> <strong>Mechanical</strong><br />

<strong>Engineers</strong>, E. B r u c e B a l l and A. H .<br />

G ib s o n<br />

Italy, G a u d e n z io F a n t o l i and A l b in o<br />

P a s i n i<br />

Switzerland, C h a r l e s J aeger and 0.<br />

S c iin y d e r<br />

Machine Shop Practice<br />

Organized, 1921<br />

S ol E i n s t e i n , Chairman<br />

EXECUTIV E COMMITTEE<br />

S ol E i n s t e i n , Chairman<br />

W ar,n e e S e e l y , Secretary<br />

E . W . E r n e s t<br />

A. M. J o h n s o n<br />

E r i k O beeg<br />

CUTTING METALS<br />

H a n s E r n s t , Chairman<br />

FOUNDRY PRACTICE<br />

J a m e s T h o m s o n , C h a ir m a n<br />

R. E. K e n n e d y , S e c r e ta r y<br />

LUBRICATION ENGINEERING<br />

B. G. T a n g , Chairman<br />

C. M . L a rso n<br />

H . J . M a s s o n

RI-12 A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

Machine Shop Practice<br />

(Continued)<br />

MACHINE DESIGN<br />

E. 0 . W a t e r s, Chairman<br />

A. E. R . de J o nge<br />

J . H. M a r c h a n t<br />

J . M a r in<br />

GENERAL COMMITTEE<br />

Associates<br />

(Continued)<br />

A j . B o s to n<br />

D. B. P o eter S. M . M a r s h a l l<br />

F. E. R a y m o n d B. C. M cF a dden<br />

J . W . R oe<br />

J . H . R o m a n s<br />

E. H. S c h e l l M. D. S t o n e<br />

E. D . S m i t h R . J . W e a n<br />

L. W . W a l la c e S. M. W e c k s t e in<br />

J . E . Y o u n g e r<br />

T . H . W ic k e n d e n<br />

W ELDING<br />

C. W. O b e r t, Chairman<br />

Management<br />

Organized, 1920<br />

H . B . B e r g e n , Chairman<br />

EXECUTIVE COMMITTEE<br />

H . B . B e r g e n , Chairman<br />

J . R . B a n g s, J r ., Vice-Chairman<br />

G. M. V arga, Secretary<br />

L . A . A p p l e y<br />

J . M. T a lbot<br />

A r c h ie W i l l ia m s<br />

Representatives <strong>of</strong> Local Sections<br />

A tlanta, S. C. H a l e<br />

Kansas, A. H . S l u s s<br />

Louisville, C. D . E ldridge<br />

Metropolitan, W. P. C a e h a r t<br />

Milwaukee, B . V . E . N okdberg<br />

Philadelphia, C. S. G o t w a l s<br />

Seattle, H . J . M cI n t y r e<br />

P. R. K i e e n a n<br />

Junior Adviser<br />

Representative on Aviation Liaison Croup<br />

R . E . G il l m o r<br />

E . H . H e m p e l<br />

Research Secretary<br />

GENERAL COMMITTEE<br />

L . P . A lford<br />

R. M. B a r n e s<br />

W . L . B a i t<br />

C. W . B e e s e<br />

F . B . B e l l<br />

W a l la c e C l a r k<br />

H . V . C o es<br />

K . H . C o n d it<br />

H ow ard C o o n l e y<br />

N. E . E l sa s<br />

S. P . F is h e r<br />

R. E . F l a n d er s<br />

W . D . F u l l e r<br />

W . H . G e s e l l<br />

L il l ia n M . G il b r e t h<br />

R. E . G il l m o r<br />

C. H . H a t c h<br />

E . II. H e m p e l<br />

P . E . H o ld en<br />

W . F . H osford<br />

J . M . J u r a n<br />

D . S. K im b a l l<br />

W . H . K u s h n i c k<br />

T. S. M oE w a n<br />

L . C. M orrow<br />

A. I . P e t e r s o n<br />

COMMITTEE CHAIRMEN<br />

Administration Organization, L . A . A p p l e y<br />

Industrial M arketing, J . R. B a n g s, J r .<br />

M athematical Statistics, A. I. P e t e r s o n<br />

W orks Standardization, J . M. J u r a n<br />

DEPRECIATION STUDIES<br />

H . V . C oes<br />

P. T. N o r t o n, J e .<br />

Materials Handling<br />

Organized, 1920<br />

G. E . H a g e m a n n , Chairman<br />

EXECUTIVE COMMITTEE<br />

G. E. H a g e m a n n , Chairman<br />

R . B . R e n n e r , Vice-Chairman<br />

F. J . S h e p a r d , J e ., Secretary<br />

C. F. D ie t z<br />

J . A . J a c k s o n<br />

M . C. M a x w e l l<br />

N . W . E l m e e<br />

H. C. K e l l e e<br />

R. H. M cL a in<br />

F . E . M oore<br />

P . D. O e s t e e l e<br />

E . D. S m i t h<br />

J . B . W ebb<br />

A . J . B u r k e<br />

C o r n e l iu s C ro w ley<br />

!E. Z. G a b r ie l<br />

R. W . G r u n d m a n<br />

D. D. J o n e s<br />

P e t e r S h a w<br />

Associates<br />

Junior Associates<br />

Metals Engineering<br />

(Formerly Iron and Steel)<br />

Organized, 1927<br />

Reorganized, 19J/0<br />

W . R. W e b s t e r , Chairman<br />

EXECUTIV E COMMITTEE<br />

W . R . W e b s t e r, Chairman<br />

R . A . N o r t h , Secretary<br />

J. A . C l a u s s<br />

G. L. F i s k<br />

J. H . H it c h c o c k<br />

W . T r i n k s<br />

Oil and Gas Power<br />

Organised, 1921<br />

C. W . G ood, Chairman<br />

EXECUTIVE COMMITTEE<br />

C. W. G ood, Chairman<br />

L . N. R o w le y , J r . , S e c r e ta r y<br />

H . E. D egler<br />

E. S. D e n n is o n<br />

W. L . H . D oyle<br />

F . G . H e c h l e r<br />

R . D . C a m p b e l l<br />

G. J. D a s h e f s k y<br />

L . R . F ord<br />

W . K . G regory<br />

E . J. K ates<br />

L . H . M orriso n<br />

B . V . E . N ordberg<br />

M . J. R eed<br />

L e e S c h n e it t e r<br />

C. K . H o l la n d<br />

L e e S c h n e it t e r<br />

Associates<br />

Junior Adviser<br />

Research Secretary<br />

Liaison Representatives<br />

<strong>American</strong> <strong>Society</strong> <strong>of</strong> Naval Architects and<br />

Marine <strong>Engineers</strong>, L. R . F ord<br />

Aviation Liaison Group, H . E. D egler<br />

H eat Transfer Group, F . G. H e c h l e r<br />

E . J . K a t es<br />

E e n e s t N ib b s<br />

M . J . R eed<br />

EDITING<br />

METROPOLITAN SUBCOMMITTEE<br />

E . J . K a t e s<br />

L. H . M o r r iso n<br />

M . J . R eed<br />

OIL ENGINE POW ER COST<br />

H . C. M a jo r , Chairman<br />

H . C. L e n f e s t , Secretary<br />

B . B . B a c h m a n<br />

R. P. B olster<br />

L . T. B e o w n<br />

R. D . C a m p b e l l<br />

E. H a l e C odding<br />

W. J . C u m m i n g

A.S.M.E. SO CIETY RECO RD S, PA R T 1 R I-<br />

OIL ENGINE POW ER COST<br />

(Continued)<br />

E. J. K a t es<br />

A. B. M organ<br />

J. I. M oore<br />

G. D. N o il e s<br />

M. J . R eed<br />

R. T om S a w y e r<br />

L e e S c h n e it t e r<br />

P. H. S c h w e it z e r<br />

H. C. T h u e is k<br />

C. A. T r im m e r<br />

S t a n l e y W r ig h t<br />

OIL AND GAS POW ER CONFERENCES<br />

191/1 Arrangements Committee<br />

C. W. G ood, Chairman<br />

G . C. B o y e r, Chairman, Kansas City A r<br />

rangements Committee<br />

H. E. D egi.er<br />

191/2 Location and Selection Committee<br />

W. L. H. D o y l e, Chairman<br />

C. W. G ood<br />

W. K . G regory<br />

L. II. M o rrison<br />

PUBLICITY<br />

TECHNICAL PROGRAM<br />

E. S. D e n n is o n , Chairman<br />

G. C. B oyer<br />

W . L . II. D oyle<br />

L e e S c h n e it t e r<br />

Petroleum<br />

Organized, 1925<br />

Reorganized, 1987<br />

W . F . H erbert, Chairman<br />

EXECUTIVE COMMITTEE<br />

W . F . H e rbert, Chairman<br />

W . H . C a r s o n , Secretary<br />

H . R . A u e r s w a l d<br />

E . H . B arlow<br />

H . L. E ggleston<br />

O o st a v u s A u e r<br />

P . E. F r a n k<br />

T. H . H a m il t o n<br />

J . D . P ete r so n<br />

V W . S m i t h<br />

GENERAL COMMITTEE<br />

H . A . A u e r s w a l d<br />

C. J . C oberly<br />

W . F. H e rbert<br />

F. J. H olzbaur<br />

W . H . S t u ev e<br />

Atlantic Group<br />

Mid-Continent Group<br />

Power<br />

Organized, 1920<br />

G. C. E a t o n, Chairman<br />

EXECUTIVE COMMITTEE<br />

G . C, E a t o n , Chairman<br />

L. M. G o l d s m it h , Secretary<br />

T heo dore B a u m e is t e r , J r., Research Secretary<br />

O . F . C a m p b e l l<br />

E . L . H o p p in g<br />

F . R obert H a e t in<br />

Junior Adviser<br />

Process Industries<br />

Organized, 1931/<br />

J . W . H u n t e r , Chairman<br />

EXECUTIVE COMMITTEE<br />

J . W . H u n t e r , Chairman<br />

T . R . O l iv e , Secretary<br />

T h eo d o re B a u m e is t e r , J r .<br />

R ic h a r d O ’M ara<br />

W i l l ia m R a is c h<br />

A. F. S p it z g l a s s<br />

A rno ld W e is s e l b e r g<br />

W . R . W o o l r ic h<br />

J . I . Y ello tt<br />

F. L. Y e r z l e y<br />

Liaison Officer W ith Standing Committee on<br />

Pr<strong>of</strong>essional Divisions<br />

J . H . S e n g s t a k e n<br />

G. M. B e is c iie r<br />

A rno ld W e is s e l b e r g<br />

Junior Adviser<br />

Research Secretary<br />

Other Liaison Representatives<br />

Aviation Liaison Group<br />

Industrial Instrum ents and Regulators<br />

Committee, E. A . S p e r r y<br />

Subdivision on Rubber and Plastics<br />

W . F. B a rtoe, Plastics<br />

F. L. Y e r z l e y , Rubber<br />

H eat Transfer Group, A rn o ld W e is s e l b e r g<br />

<strong>Society</strong> <strong>of</strong> Automotive <strong>Engineers</strong>, F. L.<br />

Y e r z l e y<br />

COMMITTEE CHAIRMEN<br />

A ir Conditioning, C. F. K a y a n<br />

Drying, A rno ld W e is s e l b e r g<br />

Food Processing, G. L. M o n t g o m e r y<br />

Industrial Instrum ents and Regulators<br />

E. S. S m i t h , Chairman<br />

A . F. S p it z g l a s s , Secretary<br />

J. C. P e t e r s, Acting Secretary<br />

M anufactured G a s, G. M. B e is c h e r<br />

<strong>Mechanical</strong> Separation, R ic h a r d O ’M ara<br />

Papers, Awards, and Honors, C. E. LuC K E<br />

Program, J. W . H u n t e r<br />

Pulp and Paper, A . D. A s b u r y<br />

Sanitation, W i l l ia m R a is c h<br />

Sugar, F. M. G ib s o n<br />

Sulphur, B . E. S h o r t<br />

Vegetable Oils, R. W. M orton<br />

Subdivision on Rubber and<br />

Plastics<br />

EXECUTIV E COMMITTEE<br />

F. L. Y e r z l e y , Chairman<br />

J . F. D. S m i t h , Vice-Chairman<br />

G . M. K l i n e , Secretary<br />

W. F. B artoe<br />

S. H . H a h n<br />

L. E. J e b m y<br />

R . A . N o b t h<br />

W . A . Z in z o w<br />

Railroad<br />

Organized, 1920<br />

A . I. L ip e t z , Chairman<br />

EXECUTIV E COMMITTEE<br />

A . I . L i p e t z , Chairman<br />

C. L . C o m b e s, Secretary<br />

J . G . A d a ir<br />

D. S. E l l is<br />

J . R . J a c k so n<br />

W . M. S h e e h a n<br />

GENERAL COMMITTEE (RR2)<br />

A . I. L i p e t z , Chairman<br />

II. P. A l l s t r a n d<br />

B. S. Cain<br />

W. I. C a n t l e y<br />

J. E. D a v e n p o r t<br />

L . B. J o n e s<br />

F. G. L is t e r<br />

F. E. L y i’OBD<br />

K . F . N y s t r o m<br />

A. A. R a y m o n d<br />

J o h n R o berts<br />

R . W . S a l is b u r y<br />

W . C. S a n d e r s<br />

D e n n is t o u n W ood<br />

E. G. Y o u n g<br />

G. A. Y o u n g<br />

ADVISORY COMMITTEE (RR3)<br />

L . H. F ry<br />

G . W . R i n k<br />

C. T. R i p l e y<br />

E. C. S c h m id t<br />

W . H. W in t e r r o w d<br />

MF1ETINGS AND PA PER S (RR5)<br />

W. M. S h e e h a n , Chairman<br />

W . I . C a n t l e y<br />

J . R . J a c k s o n<br />

C. T. R ip l e y<br />

SURVEY (RR6)<br />

E. G. Y o u n g , Chairman<br />

B . S. C a in<br />

K . F . N y s t r o m<br />

M EM BERSH IP (RR8)<br />

A. A. R a y m o n d , Chairman<br />

D . S. E l l is<br />

W . C. S a n d e r s<br />

W . M. S h e e h a n<br />

L . K . S il l c o x

RI-14 A.S.M.E. SOCIETY RECO RD S, PA R T 1<br />

Textile<br />

Organized, 1SZ1<br />

A . D . A s b u r y, Chairman<br />

EXECUTIVE COMMITTEE<br />

A . D. A sbtjby, Chairman<br />

F . L . B r a d ley, Vice-Chairman<br />

W . B . H e i n z , Secretary<br />

R . D eV e r e H o pe<br />

I I . H . I ler<br />

J. D. R o bertso n<br />

E . R . S t a l l<br />

A. W a d s w o r t h S t o n e<br />

A. W . B e n o it<br />

W . S. B r o w n<br />

W i n n C h a s e<br />

M. A. G o l r io k , J r .<br />

A l ber t P a l m e r<br />

S. B . E a r l e<br />

Associates<br />

Southern Representative<br />

PROGRAM<br />

W . W . S t a r k e , Chairman and Metropolitan<br />

Representative<br />

Wood Industries<br />

Organized, 1921<br />

C. B . N o b b is, Chairm&n<br />

EXECUTIVE COMMITTEE<br />

C. B . N o r r is, Chairman<br />

M . J . M cD o n a ld<br />

D . R . G ray<br />

S e r n M a d s e n<br />

T. D . P e rry<br />

C. L . B a bc o c k J . S. M a t h e w s o n<br />

P . H. B il h u b e r<br />

E . D . M ay<br />

H. B . C a r p e n t e e R . H. M cC a r t h y<br />

F . P . C a b t w b ig h t A. D . S m i t h , Je.<br />

G. E . F r e n c h H. M . S u t t o n<br />

A. W . K e u f f e l C h a b l e s W h i t e<br />

A. S. K u r k j i a n<br />

A. C. F e g el, Metropolitan Representative<br />

COMMITTEE CHAIRMEN<br />

Dimensional Limits and Allowances, S e e n<br />

M a d s e n<br />

U s e o f P ly w o o d a s a n E n g in e e rin g M a te <br />

r i a l , T . D . P e rry<br />

W o o d F in is h in g , M . J . M a cD onald

A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

RI-15<br />

LOCAL SECTIONS<br />

A r t ic l e B6A, P a r. 17: <strong>The</strong> Standing Committee on Local Sections shall, under the<br />

direction <strong>of</strong> the Council, have supervision <strong>of</strong> the Local Sections <strong>of</strong> the <strong>Society</strong>.<br />

STANDING COMMITTEE ON LOCAL SECTIONS<br />

H. L. E g g l e st o n. Chairman (1941)<br />

J. N . L a n d is (1942) F . W . M a r q u is (1944)<br />

F . L. W i l k i n s o n , Jr. (1943) J. A. K e e t h (1945)<br />

Junior Advisers<br />

S id n e y D a v id so n (1941) C. C. K ir b y (1942)<br />

REGIONAL GROUP DELEGATES TO ANNUAL CONFERENCES<br />

Terms expire October, 191)1<br />

A . R. A c h e s o n , Speaker for 19lt0 Conference, Group II I<br />

L. H . V o n O h l s e n , Secretary, Group I<br />

O. li. S c i i ie r , IT, Group I I H. M. G a n o , Group V<br />

A. D. A s b u r y , Group IV B. V . E. N ordberg, Group VI<br />

W. D. T u r p i n , Group V II<br />

Terms expire October, 191/2<br />

A . R. M u m f o r d , Speaker for 191/1 Conference, Group II<br />

A . D. H u g h e s , Secretary, Group V II<br />

A. D. A n d r io l a , Group I C. T. O er g e l. Group V<br />

J. S. M o r e h o u s e , Group I I I R. A . C r o s s, Group VI<br />

E. (.!. S m i t h , Group IV C. W. C r a w fo r d , Group V III<br />

AKRON-CANTON<br />

Organized: 1920<br />

Territory: Counties <strong>of</strong> Richland, Ashland,<br />

Medina, Summit. Portage, Wayne,<br />

Stark, Holmes, Tuscarawas, Carroll,<br />

and Coshocton in Ohio<br />

Place <strong>of</strong> Meeting: As selected monthly<br />

Number <strong>of</strong> Members: 130<br />

E x e c u t iv e C o m m it t e e<br />

M. R. BowERMAN, Chairman<br />

A. G. W a l k e r , Vice-Chairman<br />

E . D. G eorge, Secretary-Treasurer<br />

V . R. C a m p<br />

J a m e s F orrest<br />

S. H. H a h n<br />

L. B. H o l m e s<br />

O. J. H orger<br />

E. H. K e n d a l l<br />

A. D. M a c l a c h l a n<br />

G. C. M cM u l l e n<br />

G. J. S c h o e s s o w<br />

A. W . S e e k i n s<br />

A. E. S u b t l e r<br />

J. H. V a n c e<br />

ANTHRACITE-LEHIGH v a l l e y<br />

Organized: 1920, as Lehigh Valley; reorganized,<br />

1928, as Anthracite-Lehigh<br />

Valley<br />

Territory: Counties <strong>of</strong> Bradford. Snsquehanna,<br />

Wayne, Sullivan, Wyoming,<br />

Lackawanna, Columbia, Luzerne, Monroe,<br />

Pike, Schuylkill, Carbon, Berks,<br />

Lehigh, Northampton in Pennsylvania,<br />

and W arren in New Jersey<br />

Place <strong>of</strong> Meeting: One meeting annually at<br />

Allentown, Bethlehem, Easton, Hazleton,<br />

Pottsville, Reading, Scranton, and<br />

Wilkes-Barre<br />

Local Organization: <strong>The</strong> <strong>Engineers</strong>’ Club<br />

<strong>of</strong> Lehigh Valley<br />

Number <strong>of</strong> Members: 200<br />

E x e c u t iv e C o m m it t e e<br />

R. H. P o rter, Chairman<br />

F . C. P e t e r s. Vice-Chairman<br />

J . W . S t e in m e y e r . Vice-Chairman<br />

D . G. W i l l ia m s , Vice-Chairman<br />

C. W . M e r r ic k . Secretary<br />

M . C. S t u a r t . Treasurer<br />

G. W . F a r n h a m<br />

J . W . G i s h . J r.<br />

C. C. H e r te l<br />

R. E. M oyer<br />

L . E. M y l t in g<br />

W . P. S a u n ie r<br />

W a l t e r T a l lg r en<br />

R. L . W il l is<br />

ATLANTA<br />

Organized: 1913<br />

Territory: Radius <strong>of</strong> sixty miles from A t<br />

lanta. Ga.<br />

Place <strong>of</strong> Meeting: A tlanta Athletic Club<br />

Luncheon meeting every Mondav at 12:30<br />

p.m. at A tlanta Athletic Club<br />

Number <strong>of</strong> Members: 85<br />

E x e c u t iv e C o m m it t e e<br />

F. C. S m i t h . Chai'-man<br />

A. H. K o c h , Vice-Chairman<br />

J . M. R it t l e m e y e r , Secretary<br />

R . N. B e n j a m i n<br />

R. S. H o w e l l<br />

W. C. K tr.by<br />

E. W. K l e i n . J r .<br />

R. L. SWEIGERT<br />

BALTIMORE<br />

Organized: 1916<br />

Territory: Radius <strong>of</strong> thirty miles from Baltimore.<br />

Md.<br />

Place <strong>of</strong> Meeting: <strong>Engineers</strong> Club <strong>of</strong> Baltimore<br />

Luncheon meeting every Wednesday at<br />

12:00 noon at <strong>Engineers</strong> Club<br />

Number <strong>of</strong> Members: 226<br />

E x e c u t iv e C o m m it t e e<br />

G . W . K e e n , Chairman<br />

S. B . S e x t o n , Secretary-Treasurer<br />

W . D . B o y n t o n<br />

L . F. C o f f in<br />

R . C. D a n n e t t e l<br />

S id n e y H a u s m a n<br />

J . W . M o u s s o n<br />

L . F. W e l a n e t z<br />

S. M . W h it e l e y<br />

J u n io r G ro u p<br />

W. A . H a z l e t t , Chairman<br />

G. I. C h i n n , Vice-Chairman<br />

W. B . E l it z , Secretary<br />

J . F. H a n n a<br />

D . F. L a n e<br />

BIRMINGHAM<br />

Organized: 1915<br />

Territory: Radius <strong>of</strong> sixty miles from Birmingham,<br />

Ala.<br />

Place <strong>of</strong> Meeting: Tutwiler Hotel<br />

Number <strong>of</strong> Members: 91<br />

E x e c u t iv e C o m m it t e e<br />

H . S. K e n t , Chairman<br />

J. M. G a l l a l e e, Vice-Chairman<br />

J. B . B e l l , Secretary-Treasurer<br />

R. A. P olglaze<br />

C. F. von H e r r m a n n , Jr.<br />

BOSTON<br />

Organized: 1909<br />

Territory: Radius <strong>of</strong> thirty miles from Boston,<br />

Mass.<br />

Place <strong>of</strong> Meeting: Mass. Inst, <strong>of</strong> Technology<br />

Local Organization: Engineering Societies<br />

<strong>of</strong> New England<br />

Number <strong>of</strong> Members: 547

RI-16 A.S.M.E. SO CIETY RECO RD S, PA R T 1<br />

BOSTON<br />

(Continued)<br />

E x e c u t iv e C o m m it t e e<br />

G . K . S a u r w e in , Chairman<br />

K err A t k in s o n , Vice-Chairman<br />

R . A . S p e n c e , Secretary-Treasurer<br />

H . J . B r o w n<br />

T. W. H o pper<br />

J . W. Z e l l e r<br />

J u n io r G r o u p<br />

R . N. G il b e r t, Chairman<br />

A n t o n S a l e c k e r, Vice-Chairman<br />

S a m u e l C r o w e l l, 3d, Secretary<br />

R . A . S p e n c e , Treasurer<br />

E . I . B o w e r<br />

F . M . M a g ee<br />

BRIDGEPORT<br />

Organized: 1917, as a Branch <strong>of</strong> Connecticut<br />

Section; reorganized as a Section,<br />

1923<br />

T erritory: Fairfield County, Conn.<br />

Place <strong>of</strong> Meeting: Stratfield Hotel<br />

Local Organization: <strong>Engineers</strong>’ Club <strong>of</strong><br />

Bridgeport<br />

Number <strong>of</strong> Members: 120<br />

E x e c u t iv e C o m m it t e e<br />

C. N. H o a g la n d, Chairman<br />

R u d o l f B e c k , Vice-Chairman<br />

W . H . S n i f f e n , Secretary<br />

A. W . H a g a n , Treasurer<br />

A. H . B e ed e<br />

C. A. Buss<br />

I . C. J e n n in g s<br />

R . C. M oody<br />

0 . J. R ic h m o n d<br />

J. W. R oe<br />

J. D. S k i n n e r<br />

J. II. V a n Yorx, Jr.<br />

BUFFALO<br />

Organized: 1915<br />

Territory: Radius <strong>of</strong> th irty miles from<br />

Buffalo, N.Y.<br />

Place <strong>of</strong> Meeting: University Club, Deleware<br />

Ave.<br />

Local Organization: Engineering <strong>Society</strong> <strong>of</strong><br />

Buffalo<br />

Humber <strong>of</strong> Members: 184<br />

E x e c u t iv e C o m m it t e e<br />

W . M . K a u f f m a n , Chairman<br />

C. B a r n a r d, Vice-Chairman<br />

M. C. C a s e , Secretary<br />

C. E . H a r r in g t o n , Treasurer<br />

J. G. B e n s o n<br />

P a u l D ubo sclard<br />

H . M . E varts<br />

H . F. K e r k e r<br />

J. L. Y a t e s, Adviser for Juniors<br />

CENTRAL ILLINOIS<br />

Organized: 1937<br />

Territory: All the territory in Central<br />

Illinois between the following counties<br />

on the northern boundary: Bureau,<br />

LaSalle, Knox, Stark, Putnam, M arshall,<br />

Livingston, Peoria; counties on<br />

the southern boundary: Pike, Scott,<br />

Morgan, Sangamon, Macon, P iatt,<br />

Douglas, and Edgar<br />

Place <strong>of</strong> Meeting: Hotel Pere M arquette or<br />

Caterpillar Show Room<br />

Number <strong>of</strong> Members: 104<br />

E x e c u t iv e C o m m it t e e<br />

F. L. M e y e r, Chairman<br />

R. T . M e e s, Vice-Chairman<br />

C. O. S m i t h , Vice-Chairman<br />

F. H . T h o m a s , Vice-Chairman<br />

L. E . J o h n s o n , Secretary-Treasurer<br />

R. E. M cC l a in , Assistant Secretary<br />

M . A. C l e m e n t s<br />

M . A . C l e m e n t s<br />

J u n io r G r o u p<br />

CENTRAL INDIANA<br />

Organized: 1916<br />

T erritory: Radius <strong>of</strong> eighty miles from In <br />

dianapolis, within Indiana<br />

Place <strong>of</strong> Meeting: Place varies<br />

Local Organization: Indiana Engineering<br />

<strong>Society</strong><br />

Number <strong>of</strong> Members: 140<br />

E x e c u t iv e C o m m it t e e<br />

J . A . D r o g u e, Chairman<br />

H . A . M cA n i n c h , Vice-Chairman<br />

W. J. C o p e , Secretary-Treasurer<br />

G . L . F o w l e r<br />

P. F . H e l m<br />

H . H . S k a b o<br />

R. W . W o rley<br />

CENTRAL PENNSYLVANIA<br />

Organized: 1921<br />

T erritory: Radius <strong>of</strong> approximately sixty<br />

miles from State College, Pa.<br />

Place <strong>of</strong> Meeting: State College and Altoona,<br />

Pa.<br />

Number <strong>of</strong> Members: 75.<br />

E x e c u t iv e C o m m it t e e<br />

F . C. S t e w a r t , Chairman<br />

J. O. P. H u m m e l , Secretary-Treasurer<br />

C. L . A l l e n<br />

J. S. D o o l it tl e<br />

W . D . G a r m a n<br />

G . L . G u il l e t<br />

A. H . Z e r b a n<br />

CHICAGO<br />

Organized: 1913<br />

T erritory: Radius <strong>of</strong> fifty miles from Chicago,<br />

111.<br />

H eadquarters: Mid-West A.S.M.E. Office,<br />

Room 1617, 205 W est W acker Drive,<br />

Chicago, 111.<br />

Place <strong>of</strong> Meeting: Civic Opera Bldg., 20 N.<br />

W acker Dr.<br />

Luncheon Meeting every Tuesday at 1 2 :1 5<br />

p.m. at Chicago <strong>Engineers</strong>’ Club<br />

Local Organization: W estern <strong>Society</strong> <strong>of</strong> <strong>Engineers</strong><br />

Number <strong>of</strong> Members: 805<br />

E x e c u t iv e C o m m it t e e<br />

L . M . E l l is o n , Chairman<br />

C. C. A u s t i n , Vice-Chairman<br />

H . M . B l a c k , Vice-Chairman<br />

J . R . M ic h e l , Vice-Chairman<br />

D a n ie l R o e s c h , Vice-Chairman<br />

F . B . O rr, Secretary-Treasurer<br />

R . H . B aco n<br />

J . A . F o l se<br />

W . P. H o l t z m a n<br />

A . H . J e n s<br />

J . S. K o z a c k a<br />

F . H . L a n e<br />

J . C. M a r s h a l l<br />