Effects of gamma and electron beam irradiation on the properties of ...

Effects of gamma and electron beam irradiation on the properties of ...

Effects of gamma and electron beam irradiation on the properties of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ARTICLE IN PRESS<br />

Radiati<strong>on</strong> Physics <str<strong>on</strong>g>and</str<strong>on</strong>g> Chemistry 79 (2010) 297–300<br />

C<strong>on</strong>tents lists available at ScienceDirect<br />

Radiati<strong>on</strong> Physics <str<strong>on</strong>g>and</str<strong>on</strong>g> Chemistry<br />

journal homepage: www.elsevier.com/locate/radphyschem<br />

<str<strong>on</strong>g>Effects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>electr<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

calendered cord fabrics<br />

Ays-e Aytac- a , Veli Deniz a, , Murat S-en b , El-Sayed Hegazy c , Olgun Güven b<br />

a Kocaeli University, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Chemical Engineering, 41040 Kocaeli, Turkey<br />

b Hacettepe University, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Chemistry, Beytepe, 06532 Ankara, Turkey<br />

c The Nati<strong>on</strong>al Centre for Radiati<strong>on</strong> Research <str<strong>on</strong>g>and</str<strong>on</strong>g> Technology (NCRRT), Cairo, Egypt<br />

article info<br />

Keywords:<br />

Gamma <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g><br />

E-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g><br />

Tyre cord<br />

Pre-vulcanizati<strong>on</strong><br />

abstract<br />

The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> mechanical <str<strong>on</strong>g>and</str<strong>on</strong>g> structural <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> nyl<strong>on</strong> 66 (Ny<br />

66), nyl<strong>on</strong> 6 (Ny 6) <str<strong>on</strong>g>and</str<strong>on</strong>g> poly(ethylene terephthalate) (PET) fabrics used in tyres were investigated. The<br />

untreated (greige), treated cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics were irradiated at different doses. It is found<br />

that <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> greige, treated cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics are similar. No<br />

protective effect <str<strong>on</strong>g>of</str<strong>on</strong>g> compounds used in calendering was observed against radiati<strong>on</strong>-induced oxidative<br />

degradati<strong>on</strong>. The deteriorati<strong>on</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> mechanical <strong>properties</strong> is much higher<br />

than that <str<strong>on</strong>g>of</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> for all types <str<strong>on</strong>g>of</str<strong>on</strong>g> samples. Limiting viscosity numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> both <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> irradiated nyl<strong>on</strong> 6 <str<strong>on</strong>g>and</str<strong>on</strong>g> nyl<strong>on</strong> 66 cords were found to decrease with increasing dose. It is<br />

c<strong>on</strong>cluded that PET calendered fabric has higher resistance to i<strong>on</strong>izing radiati<strong>on</strong>. Ny 6 <str<strong>on</strong>g>and</str<strong>on</strong>g> Ny 66<br />

calendered fabrics are more sensitive even at low doses. Therefore, <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g><br />

<strong>on</strong> tyre cords have to be taken into c<strong>on</strong>siderati<strong>on</strong> during tyre design reinforced with particularly Ny<br />

fabrics if pre-vulcanizati<strong>on</strong> with high energy radiati<strong>on</strong> is to be applied.<br />

& 2009 Elsevier Ltd. All rights reserved.<br />

1. Introducti<strong>on</strong><br />

Corresp<strong>on</strong>ding author. Tel.: +90 2623033531; fax: +90 2623033003<br />

E-mail address: vdeniz@kocaeli.edu.tr (V. Deniz).<br />

The curing process is <strong>the</strong> final step in tyre manufacturing,<br />

whereby a green tyre is built from plies made <str<strong>on</strong>g>of</str<strong>on</strong>g> rubber<br />

compounds <str<strong>on</strong>g>and</str<strong>on</strong>g> reinforcing fabrics. Curing <str<strong>on</strong>g>and</str<strong>on</strong>g> shaping <str<strong>on</strong>g>of</str<strong>on</strong>g> tyres<br />

are accomplished by internal <str<strong>on</strong>g>and</str<strong>on</strong>g> external heat treatment. In<br />

curing process, green tyre is placed into curing machine while a<br />

bladder permanently remains inside <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> green tyre <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

desired shape <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> tyre is formed during curing under press<br />

(Han et al., 1999). Curing process has a major effect <strong>on</strong> tyre<br />

uniformity. During bladder expansi<strong>on</strong> <strong>the</strong> materials should be<br />

distributed evenly for more uniform thickness, better balance <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

uniformity. One <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> soluti<strong>on</strong>s for tyre uniformity problem is<br />

radiati<strong>on</strong> processing <str<strong>on</strong>g>of</str<strong>on</strong>g> rubber plies for pre-vulcanizati<strong>on</strong>.<br />

Radiati<strong>on</strong> processing has been widely accepted for use in many<br />

areas <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> global industry. Sterilizati<strong>on</strong>, polymer cross-linking<br />

(tapes, tubes, cables), tyre comp<strong>on</strong>ent curing, <strong>the</strong> c<strong>on</strong>servati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

art objects, <strong>the</strong> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> selected food items are wellestablished<br />

technologies. One <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> successful industrial applicati<strong>on</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> radiati<strong>on</strong> processing has been <strong>the</strong> pre-vulcanizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

tyres imparting shape stability prior to final vulcanizati<strong>on</strong>. It is<br />

important to keep <strong>the</strong> dimensi<strong>on</strong>al c<strong>on</strong>sistency <str<strong>on</strong>g>of</str<strong>on</strong>g> each comp<strong>on</strong>ent<br />

in due course <str<strong>on</strong>g>of</str<strong>on</strong>g> tyre building <str<strong>on</strong>g>and</str<strong>on</strong>g> final vulcanizati<strong>on</strong>. The<br />

carcass, however, tends to deform <str<strong>on</strong>g>and</str<strong>on</strong>g> flow during assembly <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

vulcanizati<strong>on</strong> due to an extensive transformati<strong>on</strong> under high<br />

pressure, <str<strong>on</strong>g>and</str<strong>on</strong>g> results in <strong>the</strong> reducti<strong>on</strong> in thickness <str<strong>on</strong>g>and</str<strong>on</strong>g> uneven<br />

distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> compounds in <strong>the</strong> tyre. The c<strong>on</strong>venti<strong>on</strong>al tyre<br />

technology overcomes this problem by using more thick <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

expensive compound layers. The results <str<strong>on</strong>g>of</str<strong>on</strong>g> pre-vulcanizati<strong>on</strong> are<br />

<strong>the</strong> improved green strength <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> rubber compounds, especially<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> inner liner <str<strong>on</strong>g>and</str<strong>on</strong>g> stabilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> carcass plies <str<strong>on</strong>g>and</str<strong>on</strong>g> higher<br />

quality tyre with more uniform thickness <str<strong>on</strong>g>and</str<strong>on</strong>g> better balance<br />

(Drobny, 2005; Makuuchi, 2007). Dose requirements for prevulcanizati<strong>on</strong><br />

are in <strong>the</strong> range <str<strong>on</strong>g>of</str<strong>on</strong>g> 30–50 kGy (Sarma, 2005;<br />

Makuuchi, 2007). Electr<strong>on</strong> <str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> in tyre industry for<br />

pre-vulcanizati<strong>on</strong> is already being applied commercially worldwide,<br />

for example, 23 major Japanese tyre companies are using<br />

<str<strong>on</strong>g>electr<strong>on</strong></str<strong>on</strong>g> accelerators for <strong>the</strong> producti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> radial tyres (Makuuchi,<br />

2007; Minbiole, 2008). Since <str<strong>on</strong>g>electr<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> can be<br />

applied to different comp<strong>on</strong>ents <str<strong>on</strong>g>of</str<strong>on</strong>g> radial tyre, such as inner liner<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> carcass which is a composite <str<strong>on</strong>g>of</str<strong>on</strong>g> reinforcing materials <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

rubber compounds (Makuuchi, 2007), <strong>the</strong> influence <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy<br />

<str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> reinforcing materials, i.e. <strong>on</strong> <strong>the</strong> textile cord<br />

needs to be investigated.<br />

In our previous work, <strong>the</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

untreated <str<strong>on</strong>g>and</str<strong>on</strong>g> treated high tenacity Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET tyre cords was<br />

investigated (Aytac- et al., 2007). It has been found that <str<strong>on</strong>g>gamma</str<strong>on</strong>g><br />

<str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> tyre textile cords in air has slightly affected some<br />

0969-806X/$ - see fr<strong>on</strong>t matter & 2009 Elsevier Ltd. All rights reserved.<br />

doi:10.1016/j.radphyschem.2009.08.022

ARTICLE IN PRESS<br />

298<br />

A. Aytac- et al. / Radiati<strong>on</strong> Physics <str<strong>on</strong>g>and</str<strong>on</strong>g> Chemistry 79 (2010) 297–300<br />

mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny 66 at relatively high doses, but has<br />

not affected <strong>the</strong> mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> PET cords up to 200 kGy.<br />

Some <strong>properties</strong> such as hot shrinkage, was improved to some<br />

extent with dose.<br />

In this study, <strong>the</strong> investigati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> mechanical <str<strong>on</strong>g>and</str<strong>on</strong>g> structural <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny<br />

66, Ny 6 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET fabrics was aimed. The untreated (greige),<br />

treated cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics (also called as carcass plies)<br />

were irradiated at different doses with e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> rays.<br />

The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> types <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> cord types <strong>on</strong> <strong>the</strong><br />

mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> cords are discussed.<br />

2. Experimental<br />

Breaking Strength (N)<br />

160<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

Ny 6<br />

e-BEAM<br />

GAMMA<br />

0<br />

20 40 60 80<br />

Dose (kGy)<br />

2.1. Material<br />

The Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET greige yarns <str<strong>on</strong>g>and</str<strong>on</strong>g> treated fabrics were<br />

supplied from Kordsa Global (Turkey). The treated Ny 6 cord fabric<br />

was supplied from SRF Limited (India). Resorcinol–formaldehyde–<br />

latex (RFL) soluti<strong>on</strong> was used as dipping soluti<strong>on</strong>s where latex was<br />

styrene/butadiene/vinyl pyridine terpolymer. All types <str<strong>on</strong>g>of</str<strong>on</strong>g> fabrics,<br />

i.e. Ny 6 (940 dtex), Ny 66 (1400 dtex) <str<strong>on</strong>g>and</str<strong>on</strong>g> PET (1670 dtex) were<br />

calendered by Turk Pirelli Lastikleri A.S. in Izmit, Turkey. Natural<br />

rubber based compounds were used for calendering process.<br />

Thickness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> calendered fabrics was about 1.0–1.2 mm for all<br />

types.<br />

2.2. Method<br />

Breaking Strength (N)<br />

240<br />

220<br />

200<br />

180<br />

160<br />

Ny 66<br />

e-BEAM<br />

GAMMA<br />

0 20 40 60 80<br />

Dose (kGy)<br />

2.2.1. Irradiati<strong>on</strong> source<br />

Tyre cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics were irradiated with <str<strong>on</strong>g>gamma</str<strong>on</strong>g><br />

rays at ambient temperature by using a Gamma cell 220 type<br />

g-irradiator at a fixed dose rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.13 kGy/h. They were also<br />

irradiated by high-energy <str<strong>on</strong>g>electr<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>beam</str<strong>on</strong>g> with an accelerator <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

1.5 MeV–25 mA with 25 Gy/pass. All <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g>s were carried out<br />

in air.<br />

2.2.2. Tensile tests<br />

Tensile tests were performed by using Instr<strong>on</strong> tester 4502, with<br />

cross head speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 300 mm/min <str<strong>on</strong>g>and</str<strong>on</strong>g> gauge length <str<strong>on</strong>g>of</str<strong>on</strong>g> 254 mm<br />

according to ASTM D885. An average <str<strong>on</strong>g>of</str<strong>on</strong>g> 5 test results has been<br />

reported.<br />

2.2.3. Viscosimetric studies<br />

The viscosities <str<strong>on</strong>g>of</str<strong>on</strong>g> soluti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> unirradiated <str<strong>on</strong>g>and</str<strong>on</strong>g> irradiated<br />

samples were measured by an Ubbelohde type viscometer at<br />

30 1C, formic acid for nyl<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g> o-chlorophenol for polyester<br />

cords being <strong>the</strong> solvents used throughout <strong>the</strong> experiments.<br />

3. Results <str<strong>on</strong>g>and</str<strong>on</strong>g> discussi<strong>on</strong><br />

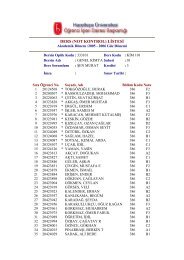

The breaking strength <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> el<strong>on</strong>gati<strong>on</strong> at break values are<br />

widely used for <strong>the</strong> measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> tyre<br />

cords. In this study, <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong>se mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny 6, Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET fabrics<br />

were evaluated. The breaking strength–dose curves for <strong>the</strong><br />

calendered fabrics made <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny 6, Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET are shown in<br />

Fig. 1(a) (b) <str<strong>on</strong>g>and</str<strong>on</strong>g> (c), respectively. As it can be seen in Fig. 1(a) <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

(b), <strong>the</strong> tensile strength decreased with increasing dose for Ny 6<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> Ny 66 cords, whereas slightly decreased for PET cords,<br />

Fig. 1(c). Both types <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny fabrics, i.e. Ny 6 <str<strong>on</strong>g>and</str<strong>on</strong>g> Ny 66 were much<br />

affected adversely from i<strong>on</strong>izing <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g>. In o<strong>the</strong>r words, PET<br />

fabrics have higher resistance to i<strong>on</strong>izing radiati<strong>on</strong> than <strong>the</strong> nyl<strong>on</strong><br />

fabrics. The ultimate effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> str<strong>on</strong>gly depends <strong>on</strong> <strong>the</strong><br />

Breaking Strength (N)<br />

240<br />

220<br />

200<br />

180<br />

160<br />

e-BEAM<br />

GAMMA<br />

PET<br />

0 20 40 60 80<br />

Dose (kGy)<br />

Fig. 1. Breaking strength–dose curves for calendered cords; (a) Ny 6, (b) Ny 66, (c)<br />

PET.<br />

Table 1<br />

Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> el<strong>on</strong>gati<strong>on</strong> at break values for calendared cords at<br />

50 kGy.<br />

Cord <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> type El<strong>on</strong>gati<strong>on</strong> at break (%)<br />

Un-irradiated Irradiated (50 kGy) Decrease (%)<br />

Ny 66 Gamma 21.6 20.2 6.4<br />

E-<str<strong>on</strong>g>beam</str<strong>on</strong>g> 20.8 3.7<br />

Ny 6 Gamma 24.9 23.0 7.6<br />

E-<str<strong>on</strong>g>beam</str<strong>on</strong>g> 24.4 2.0<br />

PET Gamma 14.0 13.9 0.7<br />

E-<str<strong>on</strong>g>beam</str<strong>on</strong>g> 13.9 0.7<br />

chemical structure <str<strong>on</strong>g>of</str<strong>on</strong>g> polymers. It is well known that PET shows<br />

good resistance to radiati<strong>on</strong> due to <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> aromatic<br />

rings <strong>on</strong> <strong>the</strong> main chain (Dole, 1973). The deteriorati<strong>on</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g>

ARTICLE IN PRESS<br />

A. Aytac- et al. / Radiati<strong>on</strong> Physics <str<strong>on</strong>g>and</str<strong>on</strong>g> Chemistry 79 (2010) 297–300 299<br />

<str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> mechanical <strong>properties</strong> is higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> for all types <str<strong>on</strong>g>of</str<strong>on</strong>g> samples for a given dose. This is<br />

a well-known fact due to dose rate difference between <str<strong>on</strong>g>gamma</str<strong>on</strong>g><br />

rays <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g>. It has been found that <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy<br />

<str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> untreated, treated cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics are<br />

almost similar c<strong>on</strong>forming to our previous findings for untreated<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> treated Ny 66 cords. This was also c<strong>on</strong>firmed by FTIR spectra<br />

(Aytac- et al., 2007). No protective effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> compounds used in<br />

<strong>the</strong> coating <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> cord in calendering against oxidative<br />

degradati<strong>on</strong> was observed. This dem<strong>on</strong>strates that <strong>the</strong>re has<br />

been still remaining oxygen interlayer phase <str<strong>on</strong>g>and</str<strong>on</strong>g>/or oxygen can<br />

easily diffuse into rubber compound during calendering.<br />

When we compare <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g>s <strong>on</strong> <strong>the</strong> calendered<br />

fabrics, <strong>the</strong> breaking strength values were found to decrease down<br />

to 90–80% <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>ir original values with increasing dose up to<br />

50 kGy for nyl<strong>on</strong> 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> nyl<strong>on</strong> 6 fabrics, whereas almost<br />

unchanged for PET fabric up to 75 kGy. The el<strong>on</strong>gati<strong>on</strong>s at break<br />

values for calendered fabrics irradiated at 50 kGy were given in<br />

Table 1. Generally, el<strong>on</strong>gati<strong>on</strong> at break values slightly decreased<br />

for nyl<strong>on</strong>s but unchanged for PET cords. The highest decrease in<br />

0.12<br />

Ny 6<br />

Limiting viscosity number (dL/g)<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

e-BEAM<br />

GAMMA<br />

0.00<br />

0<br />

15 30 45 60 75 90<br />

Dose (kGy)<br />

1.4<br />

Ny 66<br />

Limiting viscosity number (dL/g)<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

e-BEAM<br />

GAMMA<br />

0 20 40 60 80<br />

Dose (kGy)<br />

Limiting viscosity number (dL/g)<br />

1.6<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

e-BEAM<br />

GAMMA<br />

PET<br />

0<br />

0<br />

20 40 60 80<br />

Dose (kGy)<br />

Fig. 2. Limiting viscosity number–dose curves (a) Ny 6 (b) Ny 66, (c) PET tyre cords.

ARTICLE IN PRESS<br />

300<br />

A. Aytac- et al. / Radiati<strong>on</strong> Physics <str<strong>on</strong>g>and</str<strong>on</strong>g> Chemistry 79 (2010) 297–300<br />

el<strong>on</strong>gati<strong>on</strong> at break values was observed for <str<strong>on</strong>g>gamma</str<strong>on</strong>g> irradiated<br />

nyl<strong>on</strong> 6 cords.<br />

In order to see <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g>s<br />

<strong>on</strong> <strong>the</strong> structural <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fabric materials, <strong>the</strong> limiting<br />

viscosity numbers were determined. Fig. 2(a)–(c), show <strong>the</strong> effects<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> limiting viscosity<br />

numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny 6, Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET tyre cords. As shown in Fig. 2,<br />

limiting viscosity numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> nyl<strong>on</strong> cords decreased up to 75 kGy<br />

<str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> dose, whereas remained almost unchanged for PET<br />

cords. The behaviour <str<strong>on</strong>g>of</str<strong>on</strong>g> PET under <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> is ra<strong>the</strong>r different<br />

from that <str<strong>on</strong>g>of</str<strong>on</strong>g> nyl<strong>on</strong>s, because <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> aromatic rings that<br />

increase <strong>the</strong> resistance to i<strong>on</strong>izing radiati<strong>on</strong>. These behaviours can<br />

be ascribed to different mechanisms acting in <strong>the</strong> polymer during<br />

<str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g>: mainly chain scissi<strong>on</strong>s, resp<strong>on</strong>sible for <strong>the</strong> decrease <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> molecular weight, <str<strong>on</strong>g>and</str<strong>on</strong>g> cross-linking working in <strong>the</strong> opposite<br />

way. They both are present at any dose <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> overall trend <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

molecular weight depends <strong>on</strong> <strong>the</strong> prevailing mechanism.<br />

Fur<strong>the</strong>rmore, oxidative degradati<strong>on</strong> reacti<strong>on</strong>s must also be taken<br />

into account due to <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> air during <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g><br />

(Buttafava et al., 2005). The decrease in limiting viscosity<br />

number <str<strong>on</strong>g>of</str<strong>on</strong>g> nyl<strong>on</strong> cords is attributed to <strong>the</strong> radiati<strong>on</strong>-induced<br />

oxidative degradati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> main chain which causes<br />

deteriorati<strong>on</strong> in <strong>the</strong> mechanical <strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> nyl<strong>on</strong> cords.<br />

4. C<strong>on</strong>clusi<strong>on</strong><br />

The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> mechanical<br />

<strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny 6, Ny 66 <str<strong>on</strong>g>and</str<strong>on</strong>g> PET fabrics that are widely used<br />

as reinforcing textile materials in radial tyres were investigated.<br />

The deteriorati<strong>on</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> mechanical<br />

<strong>properties</strong> is higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g> e-<str<strong>on</strong>g>beam</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> for all types <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

samples. The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> untreated,<br />

treated cords <str<strong>on</strong>g>and</str<strong>on</strong>g> calendered fabrics are almost similar. No<br />

protective effects <str<strong>on</strong>g>of</str<strong>on</strong>g> both <strong>the</strong> compound used in <strong>the</strong> coating <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

cords in calendering <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> treatment process against oxidative<br />

degradati<strong>on</strong> are observed. The decrease in limiting viscosity<br />

numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> Ny cords with increasing dose is attributed to<br />

oxidative degradati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> main chain that causes deteriorati<strong>on</strong><br />

in <strong>the</strong> mechanical <strong>properties</strong>. PET calendered fabric has higher<br />

resistance to i<strong>on</strong>izing radiati<strong>on</strong>, <str<strong>on</strong>g>and</str<strong>on</strong>g> Ny 6 <str<strong>on</strong>g>and</str<strong>on</strong>g> Ny 66 calendered<br />

fabrics are more sensitive even at low doses. Advantages <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

use <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> in tyre industry, such as improving <str<strong>on</strong>g>of</str<strong>on</strong>g> tyre<br />

uniformity, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> possibility <str<strong>on</strong>g>of</str<strong>on</strong>g> saving materials <str<strong>on</strong>g>and</str<strong>on</strong>g> energy<br />

have l<strong>on</strong>g been acknowledged (Makuuchi, 2007). However, <strong>the</strong><br />

effect <str<strong>on</strong>g>of</str<strong>on</strong>g> high energy <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> cords in calendered fabrics has<br />

to be taken into c<strong>on</strong>siderati<strong>on</strong> design <str<strong>on</strong>g>of</str<strong>on</strong>g> reinforced tyres<br />

particularly with Ny fabrics if pre-vulcanizati<strong>on</strong> with high energy<br />

radiati<strong>on</strong> is to be applied.<br />

Acknowledgements<br />

The authors are grateful to KORDSA Global Industrial Yarn <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Tyre Cord Fabric Manufacturing <str<strong>on</strong>g>and</str<strong>on</strong>g> Trading Inc. <str<strong>on</strong>g>and</str<strong>on</strong>g> Turk Pirelli<br />

Lastikleri A.S. in Izmit (Turkey) for <strong>the</strong>ir valuable supports in<br />

realizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> this study.<br />

References<br />

Aytac-, A., Sen, M., Deniz, V., Güven, O., 2007. Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>the</strong><br />

<strong>properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> tyre cords. Nucl. Instr. Meth. B. 265, 271–275.<br />

Buttafava, A., C<strong>on</strong>solati, G., Mariani, M., Quasso, F., Ravasio, U., 2005. <str<strong>on</strong>g>Effects</str<strong>on</strong>g><br />

induced by <str<strong>on</strong>g>gamma</str<strong>on</strong>g> <str<strong>on</strong>g>irradiati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> different polyester studied by viscosimetry,<br />

<strong>the</strong>rmal analysis <str<strong>on</strong>g>and</str<strong>on</strong>g> positr<strong>on</strong> annihilati<strong>on</strong> spectroscopy. Polym. Degrad. Stabil.<br />

89, 133–139.<br />

Dole, M., 1973. The Radiati<strong>on</strong> Chemistry <str<strong>on</strong>g>of</str<strong>on</strong>g> Macromolecules, Vol. 2. Academic<br />

Press, New York, pp. 137–166.<br />

Drobny, J.G., 2005. Electr<strong>on</strong> <str<strong>on</strong>g>beam</str<strong>on</strong>g> processing <str<strong>on</strong>g>of</str<strong>on</strong>g> elastomers. Rubber World (pp. 27–<br />

30), 27–30 (July1).<br />

Han, I.S., Chung, C.B., Je<strong>on</strong>g, H.G., Kang, S.J., Kim, H.C.J., 1999. Optimal cure steps for<br />

product quality in a tire curing process. J. Appl. Polym. Sci. 74, 2063–2071.<br />

Makuuchi, K., 2007. Radiati<strong>on</strong> applicati<strong>on</strong> in tire ındustry. Tire Ind. 10, 623–625.<br />

Minbiole, PR., 2008. Industrial Applicati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> Radiati<strong>on</strong> Processing: Present Status<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> a Look to <strong>the</strong> Future. In: Invited lecture presented in <strong>the</strong> Eighth<br />

Symposium <strong>on</strong> I<strong>on</strong>izing Irradiati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> Polymers (IRaP 2008), 12–17 October,<br />

Rio de Janerio (Brasil).<br />

Sarma, K.S.S., 2005. Electr<strong>on</strong> <str<strong>on</strong>g>beam</str<strong>on</strong>g> technology in ındustrial radiati<strong>on</strong> processing.<br />

IANCAS Bull. 4, 128–134.