Blacksmith Metalsmith Knifemaker Farrier Blacksmith ... - Pieh Tool

Blacksmith Metalsmith Knifemaker Farrier Blacksmith ... - Pieh Tool

Blacksmith Metalsmith Knifemaker Farrier Blacksmith ... - Pieh Tool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

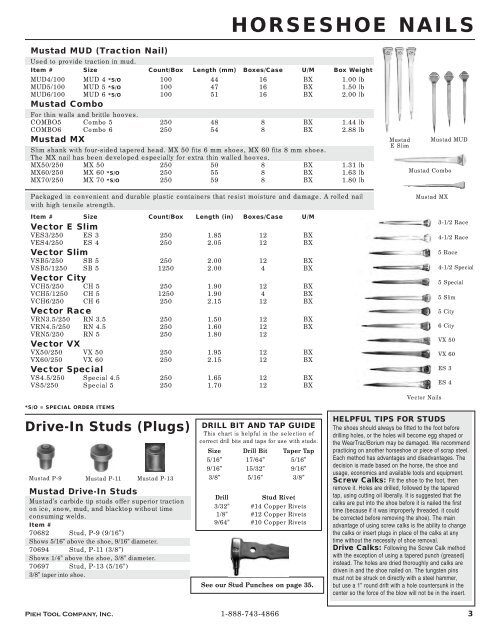

Mustad MUD (Traction Nail)<br />

Used to provide traction in mud.<br />

Item # Size Count/Box Length (mm) Boxes/Case U/M Box Weight<br />

MUD4/100 MUD 4 *S/O 100 44 16 BX 1.00 lb<br />

MUD5/100 MUD 5 *S/O 100 47 16 BX 1.50 lb<br />

MUD6/100 MUD 6 *S/O 100 51 16 BX 2.00 lb<br />

Mustad Combo<br />

For thin walls and brittle hooves.<br />

COMBO5 Combo 5 250 48 8 BX 1.44 lb<br />

COMBO6 Combo 6 250 54 8 BX 2.88 lb<br />

Mustad MX<br />

Slim shank with four-sided tapered head. MX 50 fits 6 mm shoes, MX 60 fits 8 mm shoes.<br />

The MX nail has been developed especially for extra thin walled hooves.<br />

MX50/250 MX 50 250 50 8 BX 1.31 lb<br />

MX60/250 MX 60 *S/O 250 55 8 BX 1.63 lb<br />

MX70/250 MX 70 *S/O 250 59 8 BX 1.80 lb<br />

Packaged in convenient and durable plastic containers that resist moisture and damage. A rolled nail<br />

with high tensile strength.<br />

Item # Size Count/Box Length (in) Boxes/Case U/M<br />

Vector E Slim<br />

VES3/250 ES 3 250 1.85 12 BX<br />

VES4/250 ES 4 250 2.05 12 BX<br />

Vector Slim<br />

VSB5/250 SB 5 250 2.00 12 BX<br />

VSB5/1250 SB 5 1250 2.00 4 BX<br />

Vector City<br />

VCH5/250 CH 5 250 1.90 12 BX<br />

VCH5/1250 CH 5 1250 1.90 4 BX<br />

VCH6/250 CH 6 250 2.15 12 BX<br />

Vector Race<br />

VRN3.5/250 RN 3.5 250 1.50 12 BX<br />

VRN4.5/250 RN 4.5 250 1.60 12 BX<br />

VRN5/250 RN 5 250 1.80 12<br />

Vector VX<br />

VX50/250 VX 50 250 1.95 12 BX<br />

VX60/250 VX 60 250 2.15 12 BX<br />

Vector Special<br />

VS4.5/250 Special 4.5 250 1.65 12 BX<br />

VS5/250 Special 5 250 1.70 12 BX<br />

*S/O = SPECIAL ORDER ITEMS<br />

Drive-In Studs (Plugs) DRILL BIT AND TAP GUIDE<br />

This chart is helpful in the selection of<br />

correct drill bits and taps for use with studs.<br />

Size Drill Bit Taper Tap<br />

5/16” 17/64” 5/16”<br />

9/16” 15/32” 9/16”<br />

Mustad P-9 Mustad P-11 Mustad P-13<br />

3/8” 5/16” 3/8”<br />

Mustad Drive-In Studs<br />

Mustad’s carbide tip studs offer superior traction<br />

on ice, snow, mud, and blacktop without time<br />

consuming welds.<br />

Item #<br />

70682 Stud, P-9 (9/16”)<br />

Shows 5/16” above the shoe, 9/16” diameter.<br />

70694 Stud, P-11 (3/8”)<br />

Shows 1/4” above the shoe, 3/8” diameter.<br />

70697 Stud, P-13 (5/16”)<br />

3/8” taper into shoe.<br />

HORSESHOE NAILS<br />

Drill Stud Rivet<br />

3/32” #14 Copper Rivets<br />

1/8” #12 Copper Rivets<br />

9/64” #10 Copper Rivets<br />

See our Stud Punches on page 35.<br />

Mustad MUD<br />

Mustad Combo<br />

Mustad MX<br />

<strong>Pieh</strong> <strong>Tool</strong> Company, Inc. 1-888-743-4866 3<br />

Mustad<br />

E Slim<br />

Vector Nails<br />

3-1/2 Race<br />

4-1/2 Race<br />

5 Race<br />

4-1/2 Special<br />

5 Special<br />

5 Slim<br />

5 City<br />

6 City<br />

VX 50<br />

VX 60<br />

ES 3<br />

ES 4<br />

HELPFUL TIPS FOR STUDS<br />

The shoes should always be fitted to the foot before<br />

drilling holes, or the holes will become egg shaped or<br />

the WearTrac/Borium may be damaged. We recommend<br />

practicing on another horseshoe or piece of scrap steel.<br />

Each method has advantages and disadvantages. The<br />

decision is made based on the horse, the shoe and<br />

usage, economics and available tools and equipment.<br />

Screw Calks: Fit the shoe to the foot, then<br />

remove it. Holes are drilled, followed by the tapered<br />

tap, using cutting oil liberally. It is suggested that the<br />

calks are put into the shoe before it is nailed the first<br />

time (because if it was improperly threaded. it could<br />

be corrected before removing the shoe). The main<br />

advantage of using screw calks is the ability to change<br />

the calks or insert plugs in place of the calks at any<br />

time without the necessity of shoe removal.<br />

Drive Calks: Following the Screw Calk method<br />

with the exception of using a tapered punch (greased)<br />

instead. The holes are dried thoroughly and calks are<br />

driven in and the shoe nailed on. The tungsten pins<br />

must not be struck on directly with a steel hammer,<br />

but use a 1” round drift with a hole countersunk in the<br />

center so the force of the blow will not be in the insert.