NAKAMURA TOME LIVE TOOLING - Lyndex-Nikken

NAKAMURA TOME LIVE TOOLING - Lyndex-Nikken

NAKAMURA TOME LIVE TOOLING - Lyndex-Nikken

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

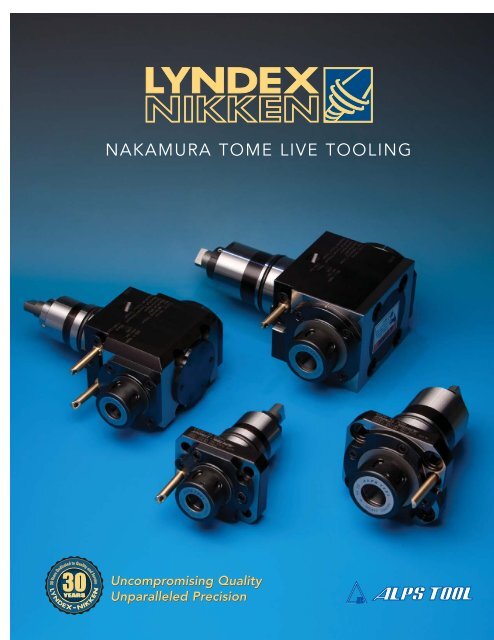

<strong>NAKAMURA</strong> <strong>TOME</strong> <strong>LIVE</strong> <strong>TOOLING</strong><br />

YEARS<br />

Uncompromising Quality<br />

Unparalleled Precision

N A K A M U R A T O M E<br />

Part No./Description<br />

<strong>Lyndex</strong>-<strong>Nikken</strong><br />

Nakamura<br />

Coolant-<br />

Thru<br />

High-<br />

Nakamura Tome Models<br />

Speed NTJ NTM3 NTY3 SC-150II SC-200L SC-250<br />

NK103-11000<br />

X-AXIS, 3600rpm<br />

NK103-10000<br />

Z-AXIS, 3600rpm<br />

NK103-13000<br />

X-AXIS, 6000rpm<br />

NK103-12000<br />

Z-AXIS, 6000rpm<br />

NK103-15000<br />

Z-AXIS, 3600rpm<br />

NK103-16000<br />

Z-AXIS, 6000rpm<br />

AR1390<br />

AR1393<br />

AC1310<br />

AC1313<br />

AG1313<br />

AG1393<br />

NK103-5K000 -<br />

X-AXIS, 6000rpm<br />

NK103-6H000 -<br />

Z-AXIS, 6000rpm<br />

NK103-6J000 -<br />

Z-AXIS, 6000rpm<br />

NKA01-20000<br />

Z-AXIS, 6000rpm<br />

NKA01-13000<br />

X-AXIS, 6000rpm<br />

NKA01-12000<br />

Z-AXIS, 6000rpm<br />

NKA00-11000<br />

X-AXIS, 4000rpm<br />

NKA00-10000<br />

Z-AXIS, 4000rpm<br />

NK105-37000<br />

X-AXIS, 3600rpm<br />

NK105-36000<br />

Z-AXIS, 3600rpm<br />

F26333<br />

C26330<br />

C26333<br />

D22310<br />

D22313<br />

R2390<br />

R2393<br />

NK105-49000 -<br />

X-AXIS, 6000rpm<br />

NK105-33000 -<br />

Z-AXIS, 6000rpm<br />

All Nakamura live tools can be used in all positions on all turrets (for main or sub) for each given machine model.

N A K A M U R A T O M E<br />

Nakamura Tome Models<br />

SC-300 TW-10 TW-20 WT-100 WT-150 WT-250II WT-300 WTS-150 WTW-150 WY-250<br />

Page<br />

6<br />

6<br />

7<br />

7<br />

8<br />

8<br />

9<br />

9<br />

10<br />

10<br />

11<br />

11<br />

12<br />

12<br />

13<br />

13<br />

14<br />

14<br />

1

SPECIAL <strong>LIVE</strong> TOOL INQUIRY FORM<br />

Fax: (847) 367-4815<br />

Email: inquiries@lyndexnikken.com<br />

Fill in the form below and fax it to (847) 367-4815, or visit www.lyndexnikken.com and complete the form online.<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> engineers will help you to determine the best live tool for your application.<br />

Company ___________________________________________ Name _______________________________________________<br />

Address ___________________________________________________________________________________________________<br />

Zip _________________________________________________ City _________________________________________________<br />

Phone ______________________________________________ E-mail _______________________________________________<br />

Please specify machine model, turret and direction (main or sub): circle selection<br />

SC-150II<br />

SC-200L<br />

SC-250<br />

SC-300<br />

TW-10<br />

TW-20<br />

WT-100<br />

WT-150<br />

WT-250II<br />

WT-300<br />

WY-250<br />

T1 Upper T1 Upper T2 Upper T1 Upper<br />

Main Sub Main Sub Main Sub<br />

T2 Lower<br />

WTS-150<br />

NTM3<br />

NTY3<br />

T1 Upper T2 Upper T1 Upper T2 Upper T1 Upper<br />

WTW-150<br />

NTJ<br />

Main Sub Main Sub Main Sub<br />

T3 Lower T3 Lower T4 Lower T2 Lower<br />

Please specify design configuration:<br />

Standard: 1) straight<br />

2) 90º (reducer/speeder)<br />

Offset: 1) straight<br />

2) 90º<br />

Saw Blade Holder: 1) straight<br />

2) 90º<br />

Multi Output: 1) straight<br />

2) 90º<br />

Offset Multi Output: 1) straight Adjustable Y straight Adjustable Angle Fixed Angle<br />

2) 90º<br />

Please specify holding system and cutting tool specifications:<br />

Holding System<br />

Preferred type of holding system (ER, Shrink Fit, Shell Mill Arbor, etc.): ___________________________________________<br />

Application and Cutting Tool Specifications<br />

Type of material: ___________________________________________________________________________________________<br />

Type and nature of application (milling, drilling, reaming, slitting, etc.): ____________________________________________<br />

Size of cutter (diameter): ___________________________________________ Overall length of cutter: ___________________<br />

Flute length: ___________________ Requested RPM: ______________________ Requested torque: ___________________<br />

Coolant Requirements<br />

External/Internal: ___________________ Requested pressure capabilities: __________________________________________<br />

Number of nozzle ports: ________________ Coolant pipe design or configuration specifications: _____________________<br />

2

TABLE OF CONTENTS<br />

<strong>NAKAMURA</strong> <strong>TOME</strong> <strong>LIVE</strong> <strong>TOOLING</strong><br />

General Matrix<br />

Inside cover-1<br />

Special Live Tool Inquiry Form 2<br />

Table of Contents 3<br />

Introduction 4<br />

Features and Technology 5<br />

Live Tooling Product Specifications 6-14<br />

Standard Live Tools<br />

for WY-250, WT-150, WT-250II, WTW-150, WTS-150, TW-10, NTM3, NTJ, SC-250, SC-200L<br />

NK103-11000 and NK103-10000 6<br />

NK103-13000 and NK103-12000 7<br />

NK103-15000 and NK103-16000 8<br />

Coolant-Through type Live Tools<br />

for WY-250, WT-150, WT-250II, WTW-150, WTS-150, TW-10, NTM3, NTJ, SC-250, SC-200L<br />

NK103-5K000 and NK103-6H000 9<br />

NK103-6J000 10<br />

Standard Live Tools<br />

for WT-100, WT-300, TW-20, SC-150II, SC-300, NTY3<br />

NKA01-20000 10<br />

NKA01-13000 and NKA01-12000 11<br />

NKA00-11000 and NKA00-10000 12<br />

NK105-37000 and NK105-36000 13<br />

Coolant-Through type Live Tools<br />

for WT-300, TW-20, SC-300<br />

NK105-49000 and NK105-33000 14<br />

Wrench Instructions, Warranty and Repair Services 15<br />

ER Series Collets 16-17<br />

ER Tap Collets 18-19<br />

Accessories 20<br />

Specials<br />

Custom-made live tools can be<br />

engineered for your specific<br />

application. Please direct your<br />

request to our office (see<br />

special live tool inquiry form).<br />

Our engineering staff is ready to<br />

assist you with your specific<br />

tooling needs.<br />

3

N A K A M U R A T O M E<br />

Turn Your Nakamura Tome<br />

into an Ultimate<br />

Performance Center.<br />

Alps live tooling for <strong>Lyndex</strong>-<strong>Nikken</strong> offers the latest<br />

technology for turning operations. Designed and<br />

manufactured directly with Nakamura engineers in Japan,<br />

our live tools have features and benefits unmatched by the<br />

competition. Gears, bearings, seals - every part is built to<br />

provide the highest accuracy, rigidity and stability.<br />

Parts inventory, maintenance and repair,<br />

and rebuild services are available through<br />

<strong>Lyndex</strong>-<strong>Nikken</strong>.<br />

(See page 15 for more details.)<br />

With more than 30 years of live tooling engineering and<br />

manufacturing experience, <strong>Lyndex</strong>-<strong>Nikken</strong> live tooling will<br />

maximize the capabilities of your machine, and keep you<br />

far ahead of the global competition. We understand that<br />

exceptional quality is key to your business. Let the<br />

manufacturers who share your philosophy in producing live<br />

tools join you in doing what you do best - machining the<br />

highest quality parts.<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> is a<br />

Nakamura Tome Authorized<br />

Live Tool Supplier.<br />

Enhanced with Alps/<strong>Lyndex</strong>-<strong>Nikken</strong> live tooling, your<br />

Nakamura machine will allow you to reduce cycle times,<br />

eliminate extra operations and achieve maximum<br />

efficiency.<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> live tools are<br />

manufactured by Alps Tool Co. Ltd.<br />

4

N A K A M U R A T O M E<br />

FEATURES AND TECHNOLOGY<br />

As an authorized OEM supplier to Nakamura, <strong>Lyndex</strong>-<strong>Nikken</strong> live tools are<br />

designed and manufactured in conjunction with Nakamura engineers at<br />

the factory in Japan.<br />

Protective Seals<br />

• Labyrinth Seals - provide a<br />

high pressure multi barrier<br />

construction that prevents<br />

contaminants and coolant<br />

from entering the main<br />

chamber.<br />

Gears for Stability<br />

• Gear Pairing - hand matched for<br />

each pair to minimize backlash.<br />

• Gear Design - custom ground<br />

spiral bevel gear tooth design<br />

maximizes drive torque output<br />

and reduces tooth root stress<br />

allowing for more tool longevity.<br />

• Gear Equilibrium - placement<br />

of bearings balance torque<br />

stress evenly through<br />

input/output shafts.<br />

Eccentric Bearing Nut<br />

• Ground Eccentric Nut - allows for<br />

fine accuracy and strong tool shank<br />

gripping capacity by preventing<br />

collet twisting or rocking.<br />

• Runout - guarantee of under 5-<br />

micron repeatability at collet nose.<br />

Tool Design and Engineering<br />

• Tool Body - manufactured from the highest tensile and<br />

compression Nickel Chrome Molybdenum alloys.<br />

• Drive Shafts - all features are ground on both the input<br />

and output Chrome Molybdenum drive shafts to assure<br />

proper torque transmission and precision concentricity.<br />

• Bearing Quality - only the highest precision ABEC 7<br />

angular contact bearings are used for smooth and high<br />

speed rotation.<br />

• Quality Control - all live tools go through a vigorous 60-<br />

point final inspection to satisfy the highest expectations of<br />

live tool performance.<br />

5

N A K A M U R A T O M E<br />

NTJ NTM3 SC-250 TW-10 WT-150 WT-250II WTS-150 WTW-150<br />

WY-250<br />

NK103-11000<br />

Nakamura Part Number<br />

AR1390<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 3600 17.5 (24) 100<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

NK103-10000<br />

Nakamura Part Number<br />

AR1393<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 3600 17.5 (24) 100 55mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-11050<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

6

N A K A M U R A T O M E<br />

NTJ NTM3 SC-200L WT-150 WT-250II WTS-150 WTW-150 WY-250<br />

NK103-13000<br />

Nakamura Part Number<br />

AC1310<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 6000 17.5 (24) 100<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-11050<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

NK103-12000<br />

Nakamura Part Number<br />

AC1313<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

Spanner Wrench<br />

for Spindle for Nut<br />

Z-Axis / 90° Angle 6000 17.5 (24) 100 55mm<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

SP-27<br />

FK-6<br />

7

N A K A M U R A T O M E<br />

NTJ WTS-150 WTW-150<br />

NK103-15000<br />

Nakamura Part Number<br />

AG1313<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 3600 17.5 (24) 100 70mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

NK103-16000<br />

Nakamura Part Number<br />

AG1393<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

8<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 17.5 (24) 100 70mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6

N A K A M U R A T O M E<br />

NTJ NTM3 SC-200L SC-250 TW-10 WT-150 WT-250II WTS-150<br />

WTW-150<br />

WY-250<br />

NK103-5K000<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 6000 17.5 (24) 1000<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-11050<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

Internal Coolant tools are capable up to 1000PSI. They require a minimum 20 micron filter and cannot be run dry.<br />

NK103-6H000<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 17.5 (24) 1000 55mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

Internal Coolant tools are capable up to 1000PSI. They require a minimum 20 micron filter and cannot be run dry.<br />

9

N A K A M U R A T O M E<br />

NTJ WTS-150 WTW-150<br />

NK103-6J000<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 17.5 (24) 1000 70mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

Internal Coolant tools are capable up to 1000PSI. They require a minimum 20 micron filter and cannot be run dry.<br />

NTY3<br />

NKA01-20000<br />

Nakamura Part Number<br />

F26333<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

10<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 11.8 (16) 100 60mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER20<br />

1/16” to 1/2”<br />

NA20<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-21<br />

FK-5

L IN VA KE A MT UOR OA LT IO NM GE<br />

NTY3<br />

WT-100<br />

NKA01-13000<br />

Nakamura Part Number<br />

C26330<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 6000 11.8 (16) 100<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER20<br />

1/16” to 1/2”<br />

NA20<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-21<br />

FK-5<br />

WT-100<br />

NKA01-12000<br />

Nakamura Part Number<br />

C26333<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 11.8 (16) 100 60mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER20<br />

1/16” to 1/2”<br />

NA20<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-21<br />

FK-5<br />

11

N A K A M U R A T O M E<br />

SC-150II<br />

NKA00-11000<br />

Nakamura Part Number<br />

D22310<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 4000 7.4 (10.1) 100<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-11050<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

NKA00-10000<br />

Nakamura Part Number<br />

D22313<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 4000 7.4 (10.1) 100 55mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER25<br />

1/16” to 5/8”<br />

NA25<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-27<br />

FK-6<br />

12

N A K A M U R A T O M E<br />

SC-300 TW-20 WT-300<br />

NK105-37000<br />

Nakamura Part Number<br />

R2390<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 3600 30 (39.3) 100<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER32<br />

1/8” to 25/32”<br />

NA32<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-36<br />

FK-8<br />

NK105-36000<br />

Nakamura Part Number<br />

R2393<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 3600 30 (39.3) 100 65mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER32<br />

1/8” to 25/32”<br />

NA32<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

SP-36<br />

FK-8<br />

13

N A K A M U R A T O M E<br />

SC-300 TW-20 WT-300<br />

NK105-49000<br />

Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

X-Axis / Straight 6000 30 (39.3) 1000<br />

Max. Pressure (PSI) Collet Size Replacement Nut Coolant Nozzle<br />

ER32<br />

1/8” to 25/32”<br />

NA32<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

FK-9<br />

FK-8<br />

Internal Coolant tools are capable up to 1000PSI. They require a minimum 20 micron filter and cannot be run dry.<br />

NK105-33000<br />

Counter Clockwise Input<br />

Clockwise Output<br />

Unit: mm [inch]<br />

14<br />

Description<br />

Max. RPM<br />

Max. Torque<br />

Output ft-lbs (N-m)<br />

Z-Axis / 90° Angle 6000 30 (39.3) 1000 65mm<br />

Max. Pressure (PSI) Center Height Collet Size Replacement Nut Coolant Nozzle<br />

ER32<br />

1/8” to 25/32”<br />

Internal Coolant tools are capable up to 1000PSI. They require a minimum 20 micron filter and cannot be run dry.<br />

NA32<br />

NK103-10140<br />

Spanner Wrench<br />

for Spindle for Nut<br />

FK-9<br />

FK-8

N A K A M U R A T O M E<br />

WRENCH INSTRUCTIONS, WARRANTY AND REPAIR SERVICES<br />

Wrench Instructions<br />

1<br />

Insert spindle wrench behind collet<br />

nut. Align spindle wrench with the<br />

wrench flats on the spindle.<br />

Service and Support<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> is dedicated to providing not only the highest<br />

quality of equipment, but also the highest quality of service and<br />

customer care. With over 60 years of experience, our certified<br />

service engineers are looking forward to supporting your needs<br />

beyond your expectations.<br />

We fully stock all internal components to provide an expedited<br />

and cost-effective maintenance program and rebuild package for<br />

your live tooling. Managing a maintenance schedule for all your<br />

machine tool accessory components can be challenging, so we’ll<br />

be glad to remind you when the time comes.<br />

Furthermore, to prevent an interruption in your production<br />

schedule, for certain models we can offer a “loaner” live tool<br />

while your live tool is under repair.<br />

Warranty:<br />

1 year warranty for internal components<br />

2 year manufacturer warranty on external body<br />

For any service request or inquiry, please contact our service<br />

department: (847) 367-4800<br />

2<br />

After securing spindle wrench in<br />

position, apply collet nut wrench<br />

onto collet nut.<br />

3<br />

While holding the spindle wrench<br />

firmly, turn the collet nut wrench<br />

clockwise to tighten.<br />

All Nakamura live tools can be used in all<br />

positions on all turrets (for main or sub) for<br />

each given machine model.<br />

Internal Coolant tools are capable of up<br />

to 1000PSI. They require a minimum 20<br />

micron filter and cannot be run dry.<br />

15

N A K A M U R A T O M E<br />

ER SERIES COLLETS (INCH)<br />

STANDARD<br />

SIZE INCH ER20 ER25 ER32<br />

1/16" E20-004 E25-004 -<br />

3/32" E20-006 E25-006 -<br />

1/8" E20-008 E25-008 E32-008<br />

5/32" E20-010 E25-010 E32-010<br />

3/16" E20-012 E25-012 E32-012<br />

7/32" E20-014 E25-014 E32-014<br />

1/4" E20-016 E25-016 E32-016<br />

9/32" E20-018 E25-018 E32-018<br />

5/16" E20-020 E25-020 E32-020<br />

11/32" E20-022 E25-022 E32-022<br />

3/8" E20-024 E25-024 E32-024<br />

13/32" E20-026 E25-026 E32-026<br />

7/16" E20-028 E25-028 E32-028<br />

15/32" E20-030 E25-030 E32-030<br />

1/2" E20-032 E25-032 E32-032<br />

17/32" - E25-034 E32-034<br />

9/16" - E25-036 E32-036<br />

19/32" - E25-038 E32-038<br />

5/8" - E25-040 E32-040<br />

21/32" - - E32-042<br />

11/16" - - E32-044<br />

23/32" - - E32-046<br />

3/4" - - E32-048<br />

25/32" - - E32-050<br />

COOLANT<br />

SIZE INCH ER20 ER25 ER32<br />

5/32" E20-010(C) - -<br />

11/64" E20-011(C) - -<br />

3/16" E20-012(C) - -<br />

13/64" E20-013(C) - -<br />

7/32" E20-014(C) E25-014(C) -<br />

15/64" E20-015(C) E25-015(C) -<br />

1/4" E20-016(C) E25-016(C) E32-016(C)<br />

17/64" E20-017(C) E25-017(C) E32-017(C)<br />

9/32" E20-018(C) E25-018(C) E32-018(C)<br />

19/64" E20-019(C) E25-019(C) E32-019(C)<br />

5/16" E20-020(C) E25-020(C) E32-020(C)<br />

21/64" E20-021(C) E25-021(C) E32-021(C)<br />

11/32" E20-022(C) E25-022(C) E32-022(C)<br />

23/64" E20-023(C) E25-023(C) E32-023(C)<br />

3/8" E20-024(C) E25-024(C) E32-024(C)<br />

25/64" E20-025(C) E25-025(C) E32-025(C)<br />

13/32" E20-026(C) E25-026(C) E32-026(C)<br />

27/64" E20-027(C) E25-027(C) E32-027(C)<br />

7/16" E20-028(C) E25-028(C) E32-028(C)<br />

29/64" E20-029(C) E25-029(C) E32-029(C)<br />

15/32" E20-030(C) E25-030(C) E32-030(C)<br />

31/64" E20-031(C) E25-031(C) E32-031(C)<br />

1/2" E20-032(C) E25-032(C) E32-032(C)<br />

33/64" - E25-033(C) E32-033(C)<br />

17/32" - E25-034(C) E32-034(C)<br />

35/64" - E25-035(C) E32-035(C)<br />

9/16" - E25-036(C) E32-036(C)<br />

37/64" - E25-037(C) E32-037(C)<br />

19/32" - E25-038(C) E32-038(C)<br />

39/64" - E25-039(C) E32-039(C)<br />

5/8" - E25-040(C) E32-040(C)<br />

41/64" - - E32-041(C)<br />

21/32" - - E32-042(C)<br />

43/64" - - E32-043(C)<br />

11/16" - - E32-044(C)<br />

45/64" - - E32-045(C)<br />

23/32" - - E32-046(C)<br />

47/64" - - E32-047(C)<br />

3/4" - - E32-048(C)<br />

49/64" - - E32-049(C)<br />

25/32" - - E32-050(C)<br />

16

N A K A M U R A T O M E<br />

ER SERIES COLLETS (METRIC)<br />

STANDARD<br />

SIZE mm ER20 ER25 ER32<br />

2.0mm E20-078 E25-078 -<br />

3.0mm E20-118 E25-118 E32-118<br />

3.5mm E20-137 E25-137 E32-137<br />

4.0mm E20-157 E25-157 E32-157<br />

5.0mm E20-196 E25-196 E32-196<br />

6.0mm E20-236 E25-236 E32-236<br />

7.0mm E20-275 E25-275 E32-275<br />

8.0mm E20-314 E25-314 E32-314<br />

9.0mm E20-354 E25-354 E32-354<br />

10.0mm E20-393 E25-393 E32-393<br />

11.0mm E20-433 E25-433 E32-433<br />

11.5mm E20-452 E25-452 E32-452<br />

12.0mm E20-472 E25-472 E32-472<br />

13.0mm E20-511 E25-511 E32-511<br />

14.0mm - E25-551 E32-551<br />

15.0mm - E25-590 E32-590<br />

16.0mm - E25-629 E32-629<br />

17.0mm - - E32-669<br />

18.0mm - - E32-708<br />

19.0mm - - E32-748<br />

19.5mm - - E32-767<br />

20.0mm - - E32-787<br />

COOLANT<br />

SIZE mm ER20 ER25 ER32<br />

5.0mm E20-196(C) - -<br />

5.5mm E20-216(C) - -<br />

6.0mm E20-236(C) E25-236(C) -<br />

6.5mm E20-255(C) E25-255(C) -<br />

7.0mm E20-275(C) E25-275(C) -<br />

7.5mm E20-295(C) E25-295(C) -<br />

8.0mm E20-314(C) E25-314(C) -<br />

8.5mm E20-334(C) E25-334(C) -<br />

9.0mm E20-354(C) E25-354(C) -<br />

9.5mm E20-374(C) E25-374(C) -<br />

10.0mm E20-393(C) E25-393(C) E32-393(C)<br />

10.5mm E20-413(C) E25-413(C) E32-413(C)<br />

11.0mm E20-433(C) E25-433(C) E32-433(C)<br />

11.5mm E20-452(C) E25-452(C) E32-452(C)<br />

12.0mm E20-472(C) E25-472(C) E32-472(C)<br />

12.5mm E20-492(C) E25-492(C) E32-492(C)<br />

13.0mm E20-511(C) E25-511(C) E32-511(C)<br />

13.5mm - E25-531(C) E32-531(C)<br />

14.0mm - E25-551(C) E32-551(C)<br />

14.5mm - E25-570(C) E32-570(C)<br />

15.0mm - E25-590(C) E32-590(C)<br />

15.5mm - E25-610(C) E32-610(C)<br />

16.0mm - E25-629(C) E32-629(C)<br />

16.5mm - E32-649(C)<br />

17.0mm - E32-669(C)<br />

17.5mm - E32-688(C)<br />

18.0mm - E32-708(C)<br />

18.5mm - E32-728(C)<br />

19.0mm - E32-748(C)<br />

19.5mm - E32-767(C)<br />

20.0mm - E32-787(C)<br />

ER Standard<br />

type collet<br />

ER Counter-Bored<br />

type collet<br />

Coolant Collet<br />

Nut Tightening Torque<br />

Style D D1 L Collet Range<br />

Size Range standard collet counter-bored collet<br />

ER20 21.2mm 14.5mm 31.0mm 1.0-13.0mm 5.0-13.0mm (5/32”-1/2”) 60-74 ft-lbs 42-52 ft-lbs<br />

ER25 26.2mm 18.5mm 35.0mm 1.0-16.0mm 6.0-16.0mm (7/32”-5/8”) 77-96 ft-lbs 54-67 ft-lbs<br />

ER32 33.2mm 24.4mm 40.0mm 2.0-20.0mm 10.0-20.0mm (1/4”-25/32”) 100-125 ft-lbs 77-96 ft-lbs<br />

17

N A K A M U R A T O M E<br />

ER TAP COLLETS<br />

L1<br />

ER Tap Collets feature a unique<br />

design that incorporates an internal<br />

square drive with our popular ER<br />

Series collets. The square drive<br />

matches the tap square, providing a<br />

tight fit for all rigid tapping<br />

applications.<br />

18<br />

PART NUMBER TAP INCH SIZE TAP METRIC SIZE L1<br />

ET20-168 #8, 5/32” M4 18.0mm 0.168 0.131<br />

ET20-194 #10, 3/16” M4.5, M5 18.0mm 0.194 0.152<br />

ET20-220 #12, 7/32” - 18.0mm 0.22 0.165<br />

ET20-255 #14, 1/4” M6, M6.5 18.0mm 0.255 0.191<br />

ET20-318 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET20-323 7/16” - 18.0mm 0.323 0.242<br />

ET20-367 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET20-381 3/8” M10 18.0mm 0.381 0.286<br />

ET25-168 #8, 5/32” M4 18.0mm 0.168 0.131<br />

ET25-194 #10, 3/16” M4.5, M5 18.0mm 0.194 0.152<br />

ET25-220 #12, 7/32” - 18.0mm 0.22 0.165<br />

ET25-255 #14, 1/4” M6, M6.5 18.0mm 0.255 0.191<br />

ET25-318 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET25-323 7/16” - 18.0mm 0.323 0.242<br />

ET25-367 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET25-381 3/8” M10 18.0mm 0.381 0.286<br />

ET25-429 9/16” M14 22.0mm 0.429 0.322<br />

ET25-437 1/8” NPT(L) - 22.0mm 0.437 0.328<br />

ET25-480 5/8” M16 25.0mm 0.48 0.36<br />

ET32-168 #8, 5/32” M4 18.0mm 0.168 0.131<br />

ET32-194 #10, 3/16” M4.5, M5 18.0mm 0.194 0.152<br />

ET32-220 #12, 7/32” - 18.0mm 0.22 0.165<br />

ET32-255 #14, 1/4” M6, M6.5 18.0mm 0.255 0.191<br />

ET32-318 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET32-323 7/16” - 18.0mm 0.323 0.242<br />

ET32-367 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET32-381 3/8” M10 18.0mm 0.381 0.286<br />

ET32-429 9/16” M14 22.0mm 0.429 0.322<br />

ET32-437 1/8” NPT - 22.0mm 0.437 0.328<br />

ET32-480 5/8” M16 25.0mm 0.48 0.36<br />

ET32-542 11/16” M18 25.0mm 0.542 0.406<br />

ET32-562 1/4” NPT - 25.0mm 0.562 0.421<br />

ET32-590 3/4” - 25.0mm 0.59 0.422<br />

ET32-652 13/16” M20 25.0mm 0.652 0.489<br />

Ø

N A K A M U R A T O M E<br />

ER TAP COOLANT COLLETS<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> has now combined<br />

the versatility of our ER tapping<br />

collets with the popularity of our<br />

coolant collets to create our<br />

patented ER Coolant Tap Collets.<br />

L1<br />

PART NUMBER TAP INCH SIZE TAP METRIC SIZE L1<br />

ET20-255(C) #14, 1/4” M6, M6.5 18.0mm 0.255 0.191<br />

ET20-318(C) 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET20-323(C) 7/16” - 18.0mm 0.323 0.242<br />

ET20-367(C) 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET20-381(C) 3/8” M10 18.0mm 0.381 0.286<br />

ET25-318(C) 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET25-323(C) 7/16” - 18.0mm 0.323 0.242<br />

ET25-367(C) 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET25-381(C) 3/8” M10 18.0mm 0.381 0.286<br />

ET25-429(C) 9/16” M14 22.0mm 0.429 0.322<br />

ET25-480(C) 5/8” M16 25.0mm 0.48 0.36<br />

ET32-255(C) #14, 1/4” M6, M6.5 18.0mm 0.255 0.191<br />

ET32-318(C) 5/16” M7, M6.5 18.0mm 0.318 0.238<br />

ET32-323(C) 7/16” - 18.0mm 0.323 0.242<br />

ET32-367(C) 1/2” M12, M12.5 18.0mm 0.367 0.275<br />

ET32-381(C) 3/8” M10 18.0mm 0.381 0.286<br />

ET32-429(C) 9/16” M14 22.0mm 0.429 0.322<br />

ET32-480(C) 5/8” M16 25.0mm 0.48 0.36<br />

ET32-542(C) 11/16” M18 25.0mm 0.542 0.406<br />

ET32-590(C) 3/4” - 25.0mm 0.59 0.422<br />

ET32-652(C) 13/16” M20 25.0mm 0.652 0.489<br />

Note: Seals up to maximum coolant pressure of 1000 PSI.<br />

Ø<br />

19

N A K A M U R A T O M E<br />

ACCESSORIES<br />

CNC Rotary Tables<br />

We offer a complete line of extremely accurate<br />

<strong>Nikken</strong> Rotary Tables. Featuring patented hardened<br />

assemblies, they retain their precision for years.<br />

Please call <strong>Lyndex</strong>-<strong>Nikken</strong> for more information:<br />

(800) 543-6237.<br />

U.S. Patent 5385424 (Brake System)<br />

5AX-201<br />

Worm Wheel System<br />

Installation Service<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> regional managers will assist you<br />

with product selection, integration and<br />

installation, guaranteeing complete customer<br />

satisfaction. Installation service includes drive,<br />

cable, table installation, parameter changes and<br />

documentation. Call <strong>Lyndex</strong>-<strong>Nikken</strong> for more<br />

information: (800) 543-6237.<br />

All-Precision Toolholders<br />

<strong>Lyndex</strong>-<strong>Nikken</strong> advanced<br />

products are innovatively<br />

designed to tackle the most<br />

complex and demanding<br />

applications. They guarantee<br />

a runout within 3 micron at 4<br />

times the diameter beyond<br />

collet nut.<br />

20<br />

AngleHeads<br />

Our large range of AngleHeads is designed to easily<br />

and effectively upgrade your machine tool capabilities<br />

by eliminating additional set ups.<br />

Units are equipped with 4340 ground gear and ground<br />

shaft components, high precision spindle bearings (P4<br />

quality) and cast iron bodies for vibration dampening.<br />

Each tool also features high torque capabilities for<br />

aggressive milling and drilling.<br />

Visit www.lyndexnikken.com to learn more about our<br />

complete line of AngleHeads, or call (800) 543-6237.

<strong>Lyndex</strong>-<strong>Nikken</strong>, Inc.<br />

www.lyndexnikken.com<br />

1468 Armour Blvd., Mundelein, IL 60060<br />

Phone: (800) 543-6237 • Fax: (847) 367-4815 • Email: inquiries@lyndexnikken.com

www.lyndexnikken.com<br />

(800) 543-6237<br />

CAT2009-NT