Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

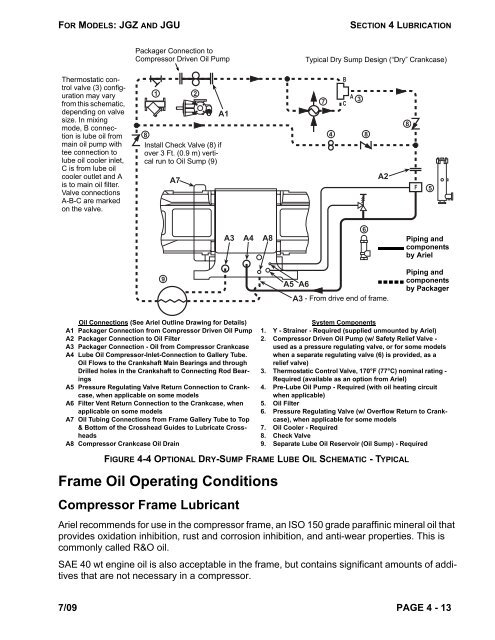

FOR MODELS: JGZ AND JGU SECTION 4 LUBRICATION<br />

Thermostatic control<br />

valve (3) configuration<br />

may vary<br />

from this schematic,<br />

depending on valve<br />

size. In mixing<br />

mode, B connection<br />

is lube oil from<br />

main oil pump with<br />

tee connection to<br />

lube oil cooler inlet,<br />

C is from lube oil<br />

cooler outlet and A<br />

is to main oil filter.<br />

Valve connections<br />

A-B-C are marked<br />

on the valve.<br />

Packager Connection to<br />

Compressor Driven Oil Pump<br />

1 2<br />

8<br />

Install Check Valve (8) if<br />

over 3 Ft. (0.9 m) vertical<br />

run to Oil Sump (9)<br />

Frame Oil Operating Conditions<br />

Compressor Frame Lubricant<br />

9<br />

A7<br />

A1<br />

A3 A4 A8<br />

Oil Connections (See <strong>Ariel</strong> Outline Drawing for Details)<br />

A1 Packager Connection from Compressor Driven Oil Pump<br />

A2 Packager Connection to Oil Filter<br />

A3 Packager Connection - Oil from Compressor Crankcase<br />

A4 Lube Oil Compressor-Inlet-Connection to Gallery Tube.<br />

Oil Flows to the Crankshaft Main Bearings and through<br />

Drilled holes in the Crankshaft to Connecting Rod Bearings<br />

A5 Pressure Regulating Valve Return Connection to Crankcase,<br />

when applicable on some models<br />

A6 Filter Vent Return Connection to the Crankcase, when<br />

applicable on some models<br />

A7 Oil Tubing Connections from Frame Gallery Tube to Top<br />

& Bottom of the Crosshead Guides to Lubricate Crossheads<br />

A8 Compressor Crankcase Oil Drain<br />

A5 A6<br />

Typical Dry Sump Design (“Dry” Crankcase)<br />

4 8<br />

<strong>Ariel</strong> recommends for use in the compressor frame, an ISO 150 grade paraffinic mineral oil that<br />

provides oxidation inhibition, rust and corrosion inhibition, and anti-wear properties. This is<br />

commonly called R&O oil.<br />

SAE 40 wt engine oil is also acceptable in the frame, but contains significant amounts of additives<br />

that are not necessary in a compressor.<br />

7/09 PAGE 4 - 13<br />

7<br />

B<br />

A<br />

C<br />

3<br />

6<br />

A2<br />

A3 - From drive end of frame.<br />

8<br />

F<br />

5<br />

Piping and<br />

components<br />

by <strong>Ariel</strong><br />

Piping and<br />

components<br />

by Packager<br />

System Components<br />

1. Y - Strainer - Required (supplied unmounted by <strong>Ariel</strong>)<br />

2. Compressor Driven Oil Pump (w/ Safety Relief Valve -<br />

used as a pressure regulating valve, or for some models<br />

when a separate regulating valve (6) is provided, as a<br />

relief valve)<br />

3. Thermostatic Control Valve, 170°F (77°C) nominal rating -<br />

Required (available as an option from <strong>Ariel</strong>)<br />

4. Pre-Lube Oil Pump - Required (with oil heating circuit<br />

when applicable)<br />

5. Oil Filter<br />

6. Pressure Regulating Valve (w/ Overflow Return to Crankcase),<br />

when applicable for some models<br />

7. Oil Cooler - Required<br />

8. Check Valve<br />

9. Separate Lube Oil Reservoir (Oil Sump) - Required<br />

FIGURE 4-4 OPTIONAL DRY-SUMP FRAME LUBE OIL SCHEMATIC - TYPICAL