Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOR MODELS: JGZ AND JGU SECTION 1 - DESIGN SPECIFICATIONS & DATA<br />

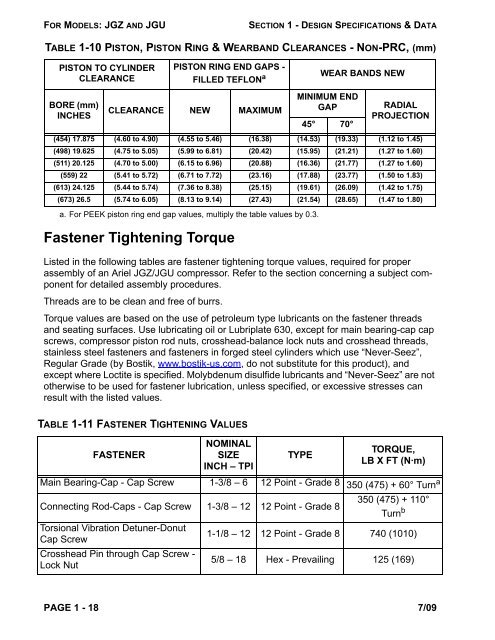

TABLE 1-10 PISTON, PISTON RING & WEARBAND CLEARANCES - NON-PRC, (mm)<br />

PISTON TO CYLINDER<br />

CLEARANCE<br />

BORE (mm)<br />

INCHES<br />

(454) 17.875 (4.60 to 4.90) (4.55 to 5.46) (16.38) (14.53) (19.33) (1.12 to 1.45)<br />

(498) 19.625 (4.75 to 5.05) (5.99 to 6.81) (20.42) (15.95) (21.21) (1.27 to 1.60)<br />

(511) 20.125 (4.70 to 5.00) (6.15 to 6.96) (20.88) (16.36) (21.77) (1.27 to 1.60)<br />

(559) 22 (5.41 to 5.72) (6.71 to 7.72) (23.16) (17.88) (23.77) (1.50 to 1.83)<br />

(613) 24.125 (5.44 to 5.74) (7.36 to 8.38) (25.15) (19.61) (26.09) (1.42 to 1.75)<br />

(673) 26.5 (5.74 to 6.05) (8.13 to 9.14) (27.43) (21.54) (28.65) (1.47 to 1.80)<br />

a. For PEEK piston ring end gap values, multiply the table values by 0.3.<br />

Fastener Tightening Torque<br />

Listed in the following tables are fastener tightening torque values, required for proper<br />

assembly of an <strong>Ariel</strong> JGZ/JGU compressor. Refer to the section concerning a subject component<br />

for detailed assembly procedures.<br />

Threads are to be clean and free of burrs.<br />

Torque values are based on the use of petroleum type lubricants on the fastener threads<br />

and seating surfaces. Use lubricating oil or Lubriplate 630, except for main bearing-cap cap<br />

screws, compressor piston rod nuts, crosshead-balance lock nuts and crosshead threads,<br />

stainless steel fasteners and fasteners in forged steel cylinders which use “Never-Seez”,<br />

Regular Grade (by Bostik, www.bostik-us.com, do not substitute for this product), and<br />

except where Loctite is specified. Molybdenum disulfide lubricants and “Never-Seez” are not<br />

otherwise to be used for fastener lubrication, unless specified, or excessive stresses can<br />

result with the listed values.<br />

TABLE 1-11 FASTENER TIGHTENING VALUES<br />

FASTENER<br />

NOMINAL<br />

SIZE<br />

INCH – TPI<br />

TYPE<br />

TORQUE,<br />

LB X FT (N·m)<br />

Main Bearing-Cap - Cap Screw 1-3/8 – 6 12 Point - Grade 8 350 (475) + 60° Turn a<br />

Connecting Rod-Caps - Cap Screw 1-3/8 – 12 12 Point - Grade 8<br />

Torsional Vibration Detuner-Donut<br />

Cap Screw<br />

Crosshead Pin through Cap Screw -<br />

Lock Nut<br />

PISTON RING END GAPS -<br />

FILLED TEFLON a<br />

CLEARANCE NEW MAXIMUM<br />

WEAR BANDS NEW<br />

MINIMUM END<br />

GAP<br />

45° 70°<br />

RADIAL<br />

PROJECTION<br />

350 (475) + 110°<br />

Turn b<br />

1-1/8 – 12 12 Point - Grade 8 740 (1010)<br />

5/8 – 18 Hex - Prevailing 125 (169)<br />

PAGE 1 - 18 7/09