Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Heavy Duty Balanced Opposed Compressors - Ariel Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOR MODELS: JGZ AND JGU SECTION 5 - MAINTENANCE<br />

CAUTION!: DO NOT TOUCH HOT SURFACES WITHOUT PROPER INSULATION TO<br />

PREVENT INJURY.<br />

OIL SLINGER INSTALLATION:<br />

Put the crankshaft in the horizontal position. Put a rod of at least 1/2 inches (13 mm) in diameter<br />

through the slinger. (Special care should be exercised when handling the slinger, not<br />

only to keep its surfaces unmarred, but to avoid being cut by the outer sharp edge.) With the<br />

slinger suspended from the rod, heat it with a small torch. When it has attained a yellow<br />

glow, approximately 400°F (204°C), it can be slipped over the drive end of the crankshaft.<br />

Do not over heat the oil slinger. Hold the slinger in position with high temperature gloves or<br />

two pieces of clean wood, rotating it slightly to make sure it is square, until it has cooled<br />

enough to shrink onto the crankshaft.<br />

CAUTION!: DO NOT TOUCH HOT SURFACES WITHOUT PROPER INSULATION TO<br />

PREVENT INJURY.<br />

Crankshaft - Chain Sprockets<br />

CHAIN SPROCKETS REMOVAL:<br />

1. Examine the sprockets carefully for signs of wear and replace if necessary. If<br />

sprockets have been in operation for five years or more, it may be convenient to<br />

replace the sprockets when the crankshaft is removed from the frame. For<br />

6-throw crankshafts the sprockets are mounted on an adapter that may be<br />

unbolted to change sprockets without removing the crankshaft from the frame.<br />

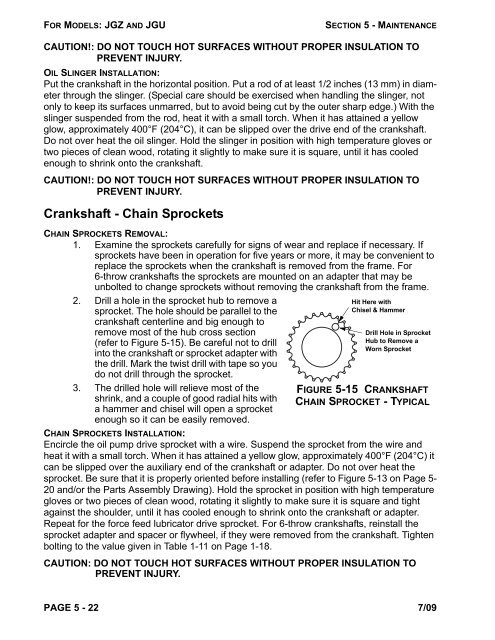

2. Drill a hole in the sprocket hub to remove a<br />

sprocket. The hole should be parallel to the<br />

crankshaft centerline and big enough to<br />

remove most of the hub cross section<br />

(refer to Figure 5-15). Be careful not to drill<br />

into the crankshaft or sprocket adapter with<br />

the drill. Mark the twist drill with tape so you<br />

do not drill through the sprocket.<br />

3. The drilled hole will relieve most of the<br />

shrink, and a couple of good radial hits with<br />

a hammer and chisel will open a sprocket<br />

enough so it can be easily removed.<br />

Hit Here with<br />

Chisel & Hammer<br />

Drill Hole in Sprocket<br />

Hub to Remove a<br />

Worn Sprocket<br />

FIGURE 5-15 CRANKSHAFT<br />

CHAIN SPROCKET - TYPICAL<br />

CHAIN SPROCKETS INSTALLATION:<br />

Encircle the oil pump drive sprocket with a wire. Suspend the sprocket from the wire and<br />

heat it with a small torch. When it has attained a yellow glow, approximately 400°F (204°C) it<br />

can be slipped over the auxiliary end of the crankshaft or adapter. Do not over heat the<br />

sprocket. Be sure that it is properly oriented before installing (refer to Figure 5-13 on Page 5-<br />

20 and/or the Parts Assembly Drawing). Hold the sprocket in position with high temperature<br />

gloves or two pieces of clean wood, rotating it slightly to make sure it is square and tight<br />

against the shoulder, until it has cooled enough to shrink onto the crankshaft or adapter.<br />

Repeat for the force feed lubricator drive sprocket. For 6-throw crankshafts, reinstall the<br />

sprocket adapter and spacer or flywheel, if they were removed from the crankshaft. Tighten<br />

bolting to the value given in Table 1-11 on Page 1-18.<br />

CAUTION: DO NOT TOUCH HOT SURFACES WITHOUT PROPER INSULATION TO<br />

PREVENT INJURY.<br />

PAGE 5 - 22 7/09