clear ahead - Dimension-Polyant GmbH

clear ahead - Dimension-Polyant GmbH

clear ahead - Dimension-Polyant GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Designing the Future<br />

<strong>clear</strong> <strong>ahead</strong>

Sailcloth Technology<br />

Technology now available from the aerospace and<br />

automotive industries is being used by yachts<br />

competing in some of the Worlds most prestigious<br />

regattas including Americas Cup, Vendee Globe,<br />

Sydney-Hobart and of course the Olympic Games.<br />

The interest is such that financial, IT and Telecommunication<br />

companies make use of the prestige<br />

associated with such events. The fascination with<br />

Sailing has become a synonym for our high-tech<br />

society. DIMENSION-POLYANT's developments and<br />

innovative technology are leading the way. The<br />

Groups HQ are in Kempen 'lower Rhine' Germany<br />

with the U.S. and Australia being the other manufacturing<br />

centres.Together with the worldwide sales<br />

and distribution outlets they supply the increasing<br />

demands of the sailmakers around the globe.<br />

DIMENSION-POLYANT has become the global<br />

market leader with its continued emphasis on<br />

'quality and service'. Sailcloth Technology from<br />

DIMENSION-POLYANT has been used on a vast<br />

range of marine craft including demanding<br />

racing yachts, traditional cruisers, dinghies<br />

and windsurfers. The best sailcloth in the<br />

world is available to all sailors in the world.<br />

CNB 117 – Hamilton II – photo: Nicolas Claris

One Design<br />

All Purpose Blade<br />

Heavy Fabrics<br />

Strong Fill/High aspect<br />

Square ®<br />

HP Square ® Line<br />

UV Stabilized<br />

Touring NF/Coastal<br />

Strong Warp<br />

Storm Orange<br />

Color<br />

Classic

Wovens<br />

“Reliability is the most important factor.”<br />

Quote from the famous German sailor Wilfried Erdmann<br />

5<br />

Wovens<br />

DIMENSION-POLYANT has developed<br />

their fabrics to assist sailmakers in producing<br />

even more durable sails. Together<br />

with advances in cruising technology, the<br />

100% duplication of individual quality<br />

standards is a key factor for sailmakers<br />

and sailors alike. By uniquely integrating<br />

its finishing plants into its production<br />

sites, DIMENSION-POLYANT can offer<br />

this technical edge over its competition.<br />

At the Athens Olympics, more than 50%<br />

of medal winners used woven Polyester<br />

Sailcloth from DIMENSION-POLYANT.<br />

DIMENSION-POLYANT designed a special<br />

fabric of 600g/sqm (14 oz) to meet the handling<br />

needs for the 2.000 sqm sails aboard the<br />

German Navy’s training ship 'Gorch Fock'.

Code Zero Laminates<br />

CX - Polyester Line<br />

CX - Pen Line<br />

CXG GraphX ® Cruising<br />

DC - Line<br />

Profile ® - Line<br />

Multi Directional Scrim<br />

Polyester X-PLY ® Line<br />

PEN X-PLY ® Line<br />

X-Tech Alumashield<br />

FLEX ® -Line<br />

GPL Graphite Performance<br />

GPL GraphX ® Performance<br />

GXLD Line<br />

DYS ® OFFSHORE<br />

TECHNOLOGY

Laminates<br />

Zero-compromise racing sails<br />

Laminates<br />

Regattas around the world see the world’s<br />

rich and famous sailors fight it out. The<br />

challenge faced by the sailmakers involved<br />

is huge. DIMENSION-POLYANT has developed<br />

lamination technology to meet sailmakers<br />

demanding requirements. Unique<br />

fiber treatment processes and the patented<br />

'insert' technology combine to form<br />

the basis for the production of modern<br />

laminated sailcloth. Both the Graph X ®<br />

and the 'new' Flex ® Line absorb multidirectional<br />

loads and ensure optimum<br />

control over shape. Code Zero laminates<br />

for asymmetric headsails and numerous<br />

cruising developments are on offer to the<br />

sailmaker to shape his individual design.<br />

© Jacques Vapillon<br />

and sophisticated cruising sails<br />

7

D4 ®<br />

Revolution in the sailing market<br />

D4®<br />

After 87 days, 10 hours, 47 minutes and 55<br />

seconds, the Frenchman Vincent Riou won<br />

the Vendee Globe Race (singlehanded<br />

non-stop around the world) in a new record<br />

time; using sails made from D4 ® membranes,<br />

supplied by DIMENSION-POLYANT.<br />

With D4 ® , the sections of the membranes<br />

are produced to the exact specifications<br />

It doesn’t get much faster than this!<br />

9<br />

CNB 117 – Hamilton II – photo: Nicolas Claris<br />

© Arnaud PILPRE/ZEDDA/UMA<br />

of the individual sailmaker, fibers are selected<br />

based on the sails requirements<br />

racing, cruising etc and laid in layers, which<br />

are bonded into a membrane using precisely<br />

controlled heat and ultra high pressure.<br />

The sailmaker then joins the sections together<br />

to produce the finished sail, allowing<br />

every sail loft to produce sails with maximum<br />

potential and minimum weight. In 2007, D4 ®<br />

will be 10 years 'new'. In its comparatively<br />

short life has already proved itself a success.<br />

D4® sails can be seen at most if not all<br />

worldwide events including the grand prix<br />

racing circuit and Superyacht regattas.<br />

D4 ® is currently being used to its full in<br />

the premier 'Americas Cup', in Valencia.

Hydra Net ®<br />

Hydra Net ® radial

Hydra Net®<br />

A true example of our technical edge!<br />

11<br />

Hydra Net®<br />

DIMENSION-POLYANT’s patented Hydra Net ®<br />

and Hydra Net ® radial fabrics have revolutionized<br />

handling and durability whilst<br />

offering extremely low stretch. Sailors<br />

specify the fabric time after time not only<br />

for its innovative 'ripstop' pattern, but also<br />

for the other benefits it offers. The closely<br />

woven base that absorbs little water and<br />

soft hand are the two most recognized.<br />

The patented process is a combination of<br />

the highest quality polyester with integral<br />

Spectra/Dyneema. In Hydra Net ® , this<br />

stabilizing 'ripstop' technology achieves<br />

increased tensile strength, shape retention<br />

and durability exceeding that achieved<br />

by laminated fabric.The exclusive finish<br />

of the Hydra Net ® gives the cloth a soft<br />

feel together with a superb bias stability<br />

needed for sail shape retention. Hydra Net ®<br />

sails can be easily handled making this<br />

the ultimate 'cruising' sailcloth. This technological<br />

weave can only be produced on high<br />

performance looms especially designed<br />

for DIMENSION-POLYANT, over 70% of the<br />

global demand for sailcloth benefits from<br />

this technology. Large yachts, like the 50'<br />

trimaran Trilogic cross the world’s oceans<br />

with this 'new' sailcloth technology.

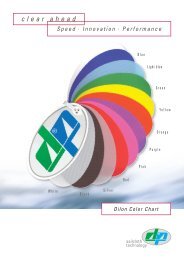

Code Zero Laminates<br />

Ripstop Spinnaker Nylon<br />

Ripstop Spinnaker Dilon<br />

Formulon Spinnaker Nylon<br />

Ripstop Spinnaker Polyester

Spinnakers, Code Zero<br />

Fabrics with high tensile strength<br />

Spinnakers<br />

More and more spinnakers are pushed<br />

beyond their limits, testing the high performance<br />

of DIMENSION-POLYANT fabric<br />

'downwind'. Maximum precision is therefore<br />

needed when developing and producing<br />

spinnaker qualities, and when<br />

sailors talk to their sailmakers they always<br />

stress the importance of tensile strength.<br />

DIMENSION-POLYANT's ripstop quality is<br />

what is needed in this ever-demanding<br />

combined with exclusive coatings<br />

area of the racecourse; it offers extremely<br />

tight woven cloth with a closely<br />

combined finish for excellent elongation<br />

resistance and the best tensile strength.<br />

Only at DIMENSION-POLYANT's extensive<br />

plants are these unique developments<br />

possible. DIMENSION-POLYANT can<br />

supply nylon, polyester or the modern<br />

Code Zero laminate, allowing sailmakers<br />

to get the right product for the right job.<br />

13

Surf Polyester<br />

Surf Laminates<br />

Mast Sleeve Material<br />

X-PLY ® Reinforced Monofilm

Windsurfing<br />

Windsurfing fabric technology<br />

Windsurfing<br />

Slalom, wave riding, freestyle or supercross,<br />

DIMENSION-POLYANT supplies the speed<br />

and wave 'freaks' with woven polyesters and<br />

high tech laminates. DIMENSION-POLYANT's<br />

patented X-PLY ® technology is perfectly<br />

suited to the demands of todays windsurfers.<br />

Sailboard sail designers situated in the worlds<br />

'hottest' surf spots are in close contact with<br />

the R&D department at DIMENSION-POLYANT,<br />

ensuring the World Champions, and Olympic<br />

medallists are kitted out year after year.<br />

DIMENSION-POLYANT has also developed<br />

its on exclusive fabrics for the kitesurf<br />

and paraglide markets around the globe.<br />

DIMENSION-POLYANT meeting the demands<br />

of nature!<br />

for new moves<br />

15

P r o d u c t i o n<br />

Something you can rely on,<br />

Production<br />

DIMENSION-POLYANT is the only supplier<br />

of sailcloth to develop and produce 'in<br />

house' with more than 400 different products.<br />

Weaving, finishing, laminating and<br />

quality control require a custom 14 stage<br />

program to allow production to progress<br />

smoothly. This linking of weaving and finishing<br />

ensures the consistent high quality<br />

of the sailcloth produced. Whether produced<br />

in Kempen Germany, Putnum USA or<br />

in this world of uncertainty<br />

Somersby Australia, DIMENSION-POLYANT<br />

guarantees the sailmaker that his chosen<br />

fabric will exhibit the same qualities to an<br />

exacting standard, as all sailcloth styles are<br />

checked over several processes. Sailcloth<br />

lies at the very heart of a sails performance<br />

and durability that is why sailmakers<br />

need a first-class product.It also explains<br />

why the most successful sailors and sailmakers<br />

demand DIMENSION-POLYANT.<br />

17

Worldwide

DIMENSION-POLYANT <strong>GmbH</strong>, Germany<br />

Headquarters<br />

Speefeld 7<br />

D-47906 Kempen<br />

Phone: +49 (2152) 891 0<br />

Fax: +49 (2152) 891 149<br />

info@dimension-polyant.com<br />

DIMENSION-POLYANT ApS, Denmark<br />

Redhavnsvej 9<br />

DK-2100 Kobenhavn<br />

Phone: +45 (39) 293 000<br />

Fax: +45 (39) 293 500<br />

copenhagen@dimension-polyant.com<br />

DIMENSION-POLYANT SAS, France<br />

Rue Newton<br />

Parc Technologique<br />

F-17000 La Rochelle<br />

Phone: +33 (0) 546 282 201<br />

Fax: +33 (0) 546 412 840<br />

larochelle@dimension-polyant.com<br />

DIMENSION-POLYANT SAS, France<br />

Port de la Pointe Rouge<br />

F-13008 Marseille<br />

Phone: +33 (0) 491 736 628<br />

Fax: +33 (0) 491 722 505<br />

marseille@dimension-polyant.com<br />

DIMENSION-POLYANT UK Ltd., United Kingdom<br />

Unit 11, Kingdom Close<br />

Kingdom Business Park<br />

Segensworth East<br />

GB-Fareham Hampshire PO15 5TJ<br />

Phone: +44 (1489) 570 551<br />

Fax: +44 (1489) 570 451<br />

uk@dimension-polyant.com<br />

DIMENSION-POLYANT Inc., USA<br />

78, Highland Drive<br />

USA-Putnam CT 06260<br />

Phone: +1 (860) 928 8300<br />

Fax: +1 (860) 928 8330<br />

info@us.dimension-polyant.com<br />

DIMENSION-POLYANT Sailcloth PTY Ltd., Australia<br />

P.O. Box 825<br />

Unit 7/9 Powells Rd.<br />

AUS-Brookvale N.S.W. 2100<br />

Phone: +61 (2) 9905 9565<br />

Fax: +61 (2) 9905 9569<br />

dp-aus@dimension-polyant.com<br />

WWW.SPRINZUNDSPRINZ.DE<br />

www.dimension-polyant.com